5. OPERATION

5.1. Setting up (The dial ball gauge is a comparator not a measuring tool)

5.1.1. Measure the bore diameter or gap to be measured to the nearest millimetre with a rule or vernier callipers. The bore or gap

must range between 18mm and 34mm nominally with this tool. (Up to 36mm with spacers)

5.1.2. Select the range of parts required, anvils and spacers using the table on the last page.

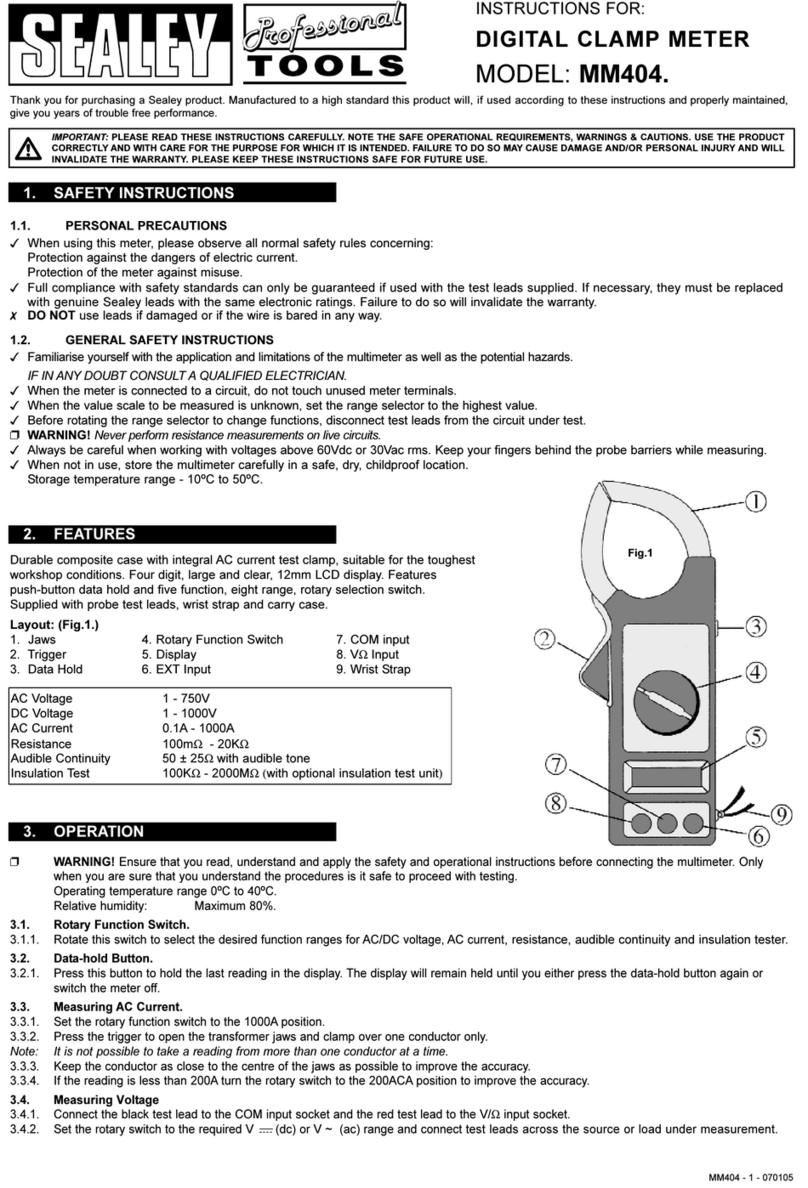

5.1.3. Assemble the dial bore gauge with selected parts as shown in fig.1 and fig.4. Ensure all components are clean before using the supplied

spanner to fit the required anvil/spacer requirement. DO NOT overtighten.

5.1.4. Insert the dial stylus into the probe body as shown in fig.4. The stylus will meet with resistance internally and the dial pointer will

begin to rotate clockwise. One complete cycle of the pointer is recommended for registration and will be indicated by the secondary dial

indicator annotated 1-5. The small pointer should now be indicating "1" [one].

5.1.5. Clamp the dial stem with the thumb screw. DO NOT overtighten.

5.2. Calibration

5.2.1. Depending upon accuracy requirement, calibration can be achieved with slip gauges, micrometer or vernier callipers. In our instructions

example the micrometer is suggested, which has similar accuracy to the dial gauge.

5.2.2. Set the micrometer (0mm-25mm) to the target size "x", for example Ø23.75 and lock. In our example the tolerance required is H9 from

BS 4500:1969 (+.052/-0).

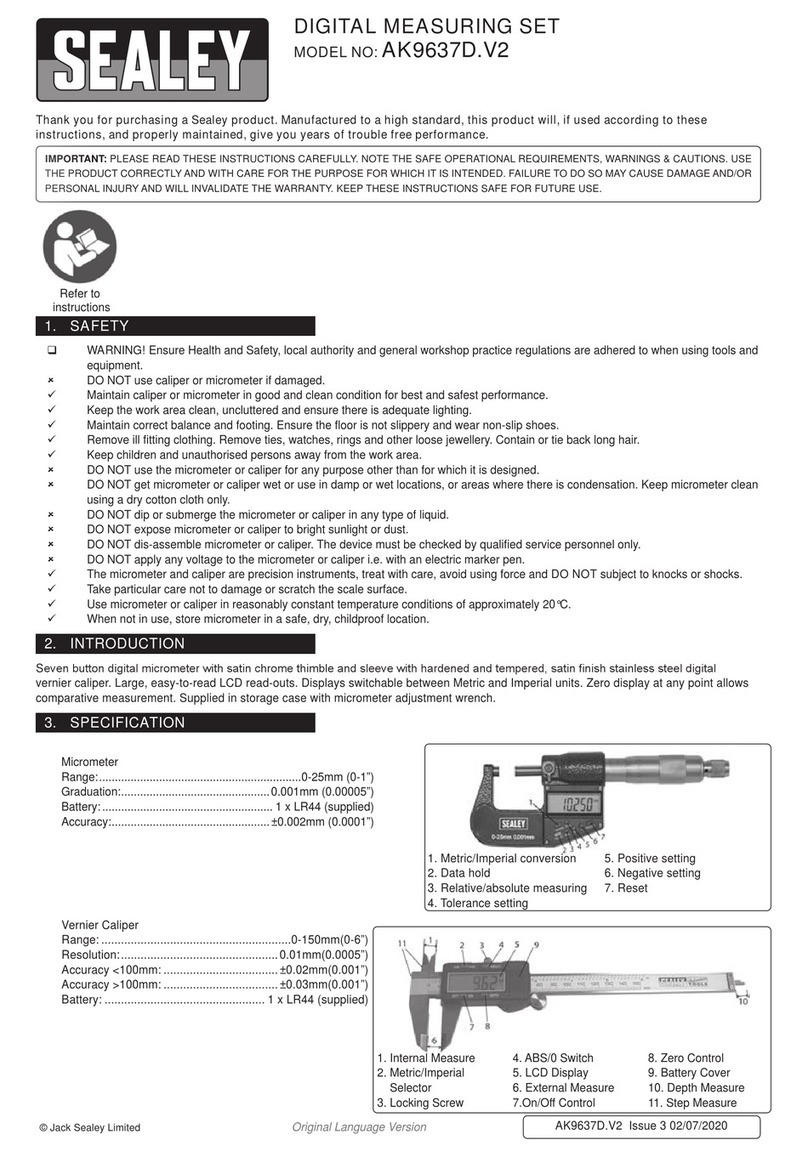

5.2.3. From instruction 5.1.2 and the tables on the back page; parts required are either the anvil 24 ("x"=23.60-24.40) or anvil 22 plus spacer

ring 1.3 and spacer ring 0.65 ("x"=23.55-24.55), from fig.5. Assemble as shown above in fig.1.

5.2.4. Maneouvre the gauge anvil and nib inside the measuring gap of the micrometer (fig.11). This activity could be eased by assistance or

carefully clamping the dial gauge in a retort stand or similar.

5.2.5. Observe the large dial pointer movement. It is essential that the axis of the gauge anvil and spring loaded nib are centralised in the

micrometer measuring faces. It is essential to observe the total sweep of the dial pointer using the small dial. Remember from the initial

setting the pointer had rotated one full cycle.

5.2.6. When satisfied with alignment, hold the position and rotate the dial bezel until the "0" [zero] aligns with the pointer. Lock the bezel with

the thumb screw. Your dial bore gauge has now been calibrated for use in a Ø23.25 to Ø24.25 bore ie +/-0.25mm of target.

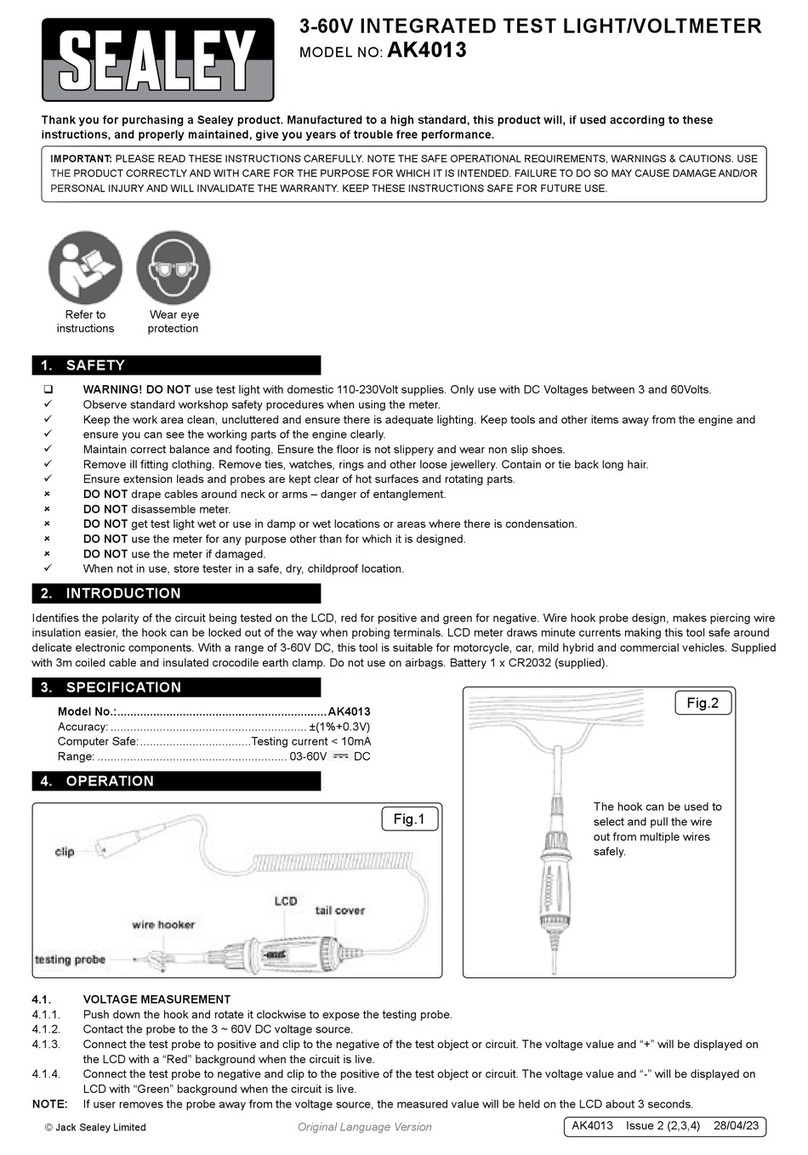

5.2.7. The tolerance band can now be set using the two "markers" on the bezel. Our example states the tolerance band to be +0.052 to -0. Set

one marker opposite and in line with "0" [zero] (fig.6) and the other +5.2 (fig.7) divisions apart. Note! the larger the deflection the smaller

the bore.

Nib

Anvil

see table on last page

Use the spacer rings to achieve "x" = 18.65, 19.30, 19.95:

20.65, 21.30, 21.95 etc..

Insert the stylus for 1 full large pointer revolution

g.4

g.1

Small pointer on "1"

Be aware, nib projection is 1.5 mm. Aim for

0.35mm to 1.15mm as the measurement zone.

DBG508 Issue: 1 - 19/06/15

Original Language Version

© Jack Sealey Limited

Nib

Nib total movement

Measurement zone = 0.8mm

Spacer

rings

Spring return self

centering guide.

(3 point location)

Anvil Bore

g.2

g.3

g.5

g.7

Pass Pass

Fail

Fail Fail

Fail

Lower Limit (+0.00mm) Upper Limit (+0.052mm)

Example only taken from

Calibration text 5.2.

g.5 g.6

Tolerance

markers