12MM VARIABLE SPEED BELT SANDER 260W

MODEL NO: SBS260.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLYAND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURYAND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

1.1. ELECTRICAL SAFETY

WARNING! It is the user’s responsibility to check the following:

Check all electrical equipment and appliances to ensure that they are safe before using. Inspect power supply leads, plugs and

all electrical connections for wear and damage. Sealey recommend that an RCD (Residual Current Device) is used with all electrical

products. You may obtain an RCD by contacting your local Sealey Stockist.

If the product is used in the course of business duties, it must be maintained in a safe condition and routinely PAT (Portable

Appliance Test) tested.

Electrical safety information, it is important that the following information is read and understood.

1.1.1. Ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply.

1.1.2. Regularly inspect power supply cables and plugs for wear or damage and check all connections to ensure that they are secure.

1.1.3. Important: Ensure that the voltage rating on the appliance suits the power supply to be used and that the plug is tted with the

correct fuse - see fuse rating in these instructions.

8DO NOT pull or carry the appliance by the power cable.

8DO NOT pull the plug from the socket by the cable. Remove the plug from the socket by maintaining a rm grip on the plug.

8DO NOT use worn or damaged cables, plugs or connectors. Ensure that any faulty item is repaired or replaced immediately by a

qualied electrician.

1.1.4. This product is tted with a BS1363/A 13 Amp 3 pin plug.

If the cable or plug is damaged during use, switch the electricity supply and remove from use.

Replace a damaged plug with a BS1363/A 13 Amp 3 pin plug. If in doubt contact a qualied electrician.

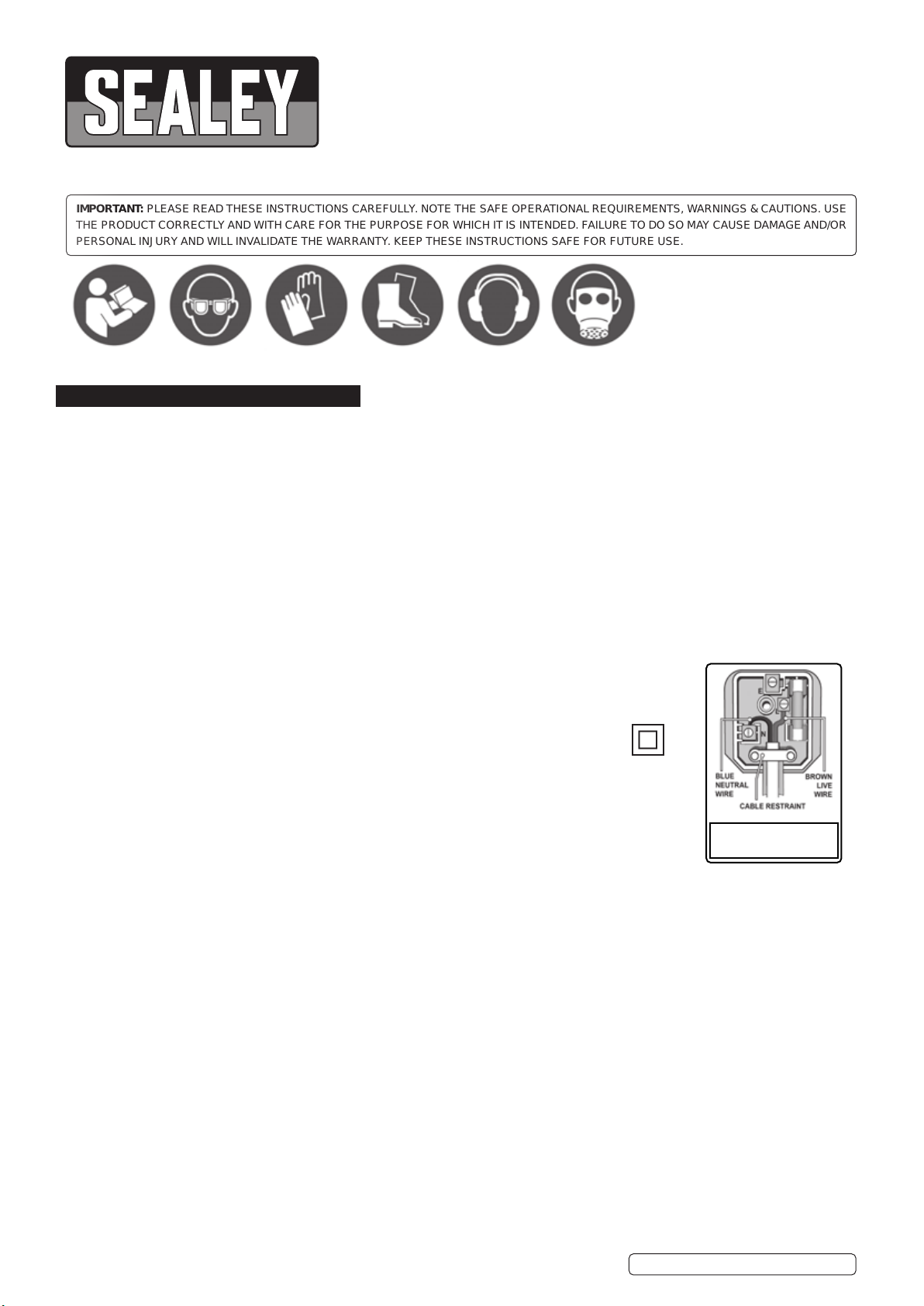

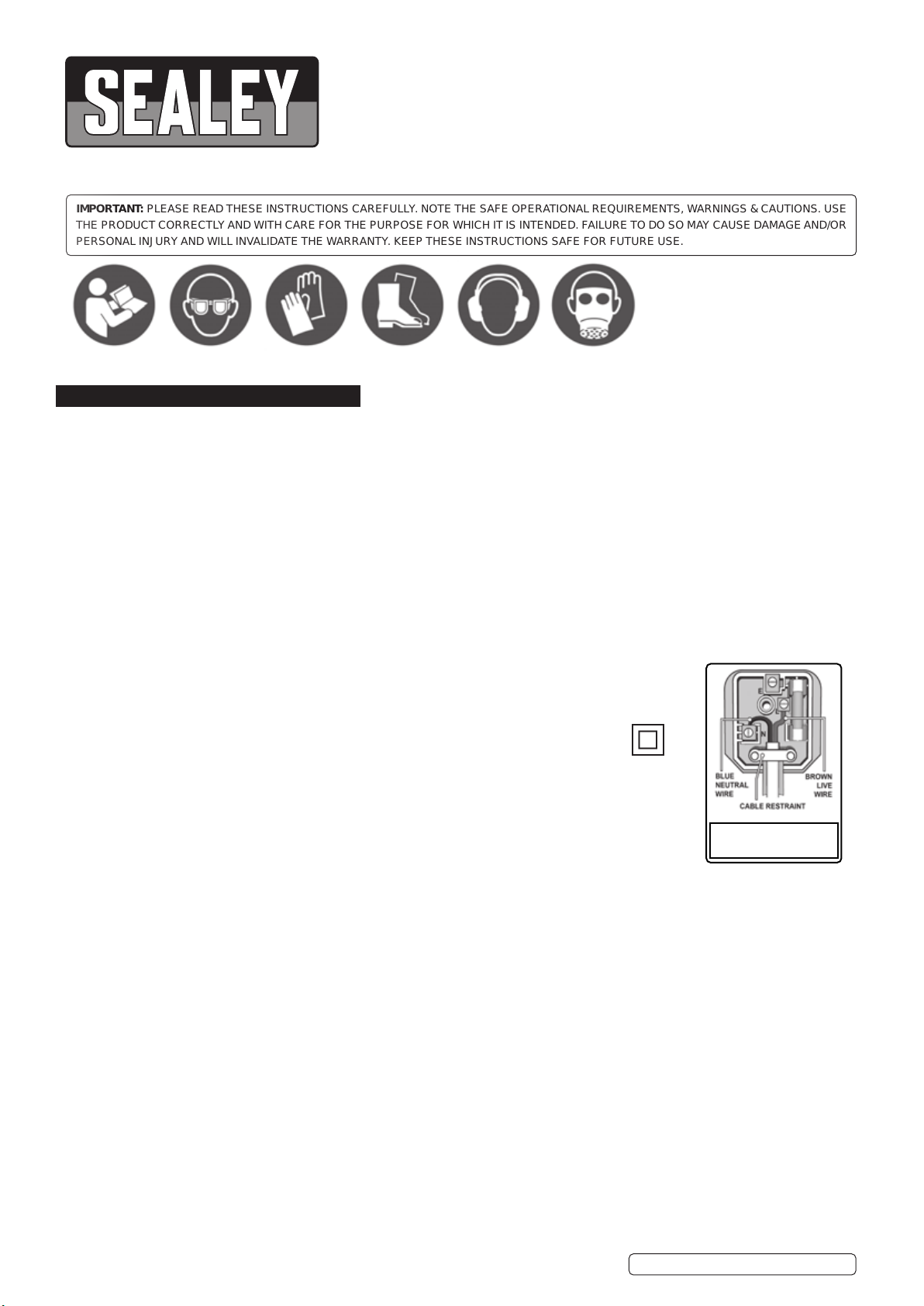

Class II products are wired with live (brown) and neutral (blue) only, and are marked with the

Class II symbol;

A) Connect the BROWN live wire to the live terminal ‘L’.

B) Connect the BLUE neutral wire to the neutral terminal ‘N’.

C) After wiring, check that there are no bare wires and ensure that all wires have been correctly

connected.

Ensure that the cable outer sheath extends inside the cable restraint and that the restraint is tight.

8DO NOT connect either wire to the earth terminal.

9 Sealey recommend that repairs are carried out by a qualied electrician.

1.2. GENERAL SAFETY

WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to when using this

equipment.

WARNING! Disconnect from power supply before changing accessories or servicing.

9Maintain the sander in good condition (use an authorised service agent).

9 Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

9Use in suitable clean and tidy working area, free from unrelated materials and ensure there is adequate lighting.

9 Before each use check abrasive belt for condition. If worn or damaged replace immediately.

9 Use only the correct size and type of sanding belt with this sander.

9Ensure there are no flammable or combustible materials near the work area.

WARNING! Always wear approved eye or face and hand protection when operating the sander. Use face, dust, or respiratory

protection in accordance with COSHH regulations.

9Remove ill fitting clothing. Remove ties, watches, rings, other loose jewellery and contain and/or tie back long hair.

9 Wear appropriate protective clothing and keep hands and body clear of working parts.

9Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

9Keep children and unauthorised persons away from the work area.

9Check moving parts alignment on a regular basis.

9Ensure workpiece is secure before operating the sander. Never hold a work piece by hand.

9Check the work piece to ensure there are no protruding screws, bolts, nuts, nails, rivets, etc.

9Avoid unintentional starting.

9Keep power lead away from heat, oil and sharp edges.

9Prolonged exposure to vibration from this sander poses a health risk. It is the owner’s responsibility to correctly assess the potential

hazard and issue guidelines for safe periods of use and offer suitable protective equipment.

Recommended fuse rating

3 Amp

SBS260.V2 Issue 1 23/06/2020

Original Language Version

© Jack Sealey Limited

Refer to

instructions Wear eye

protection Wear protective

gloves Wear ear

protection

Wear safety

footwear Wear a

respirator