7.4.3. Rotate the work stop to contact the workpiece as close to the bottom as possible.

7.4.4. Tighten the knob.

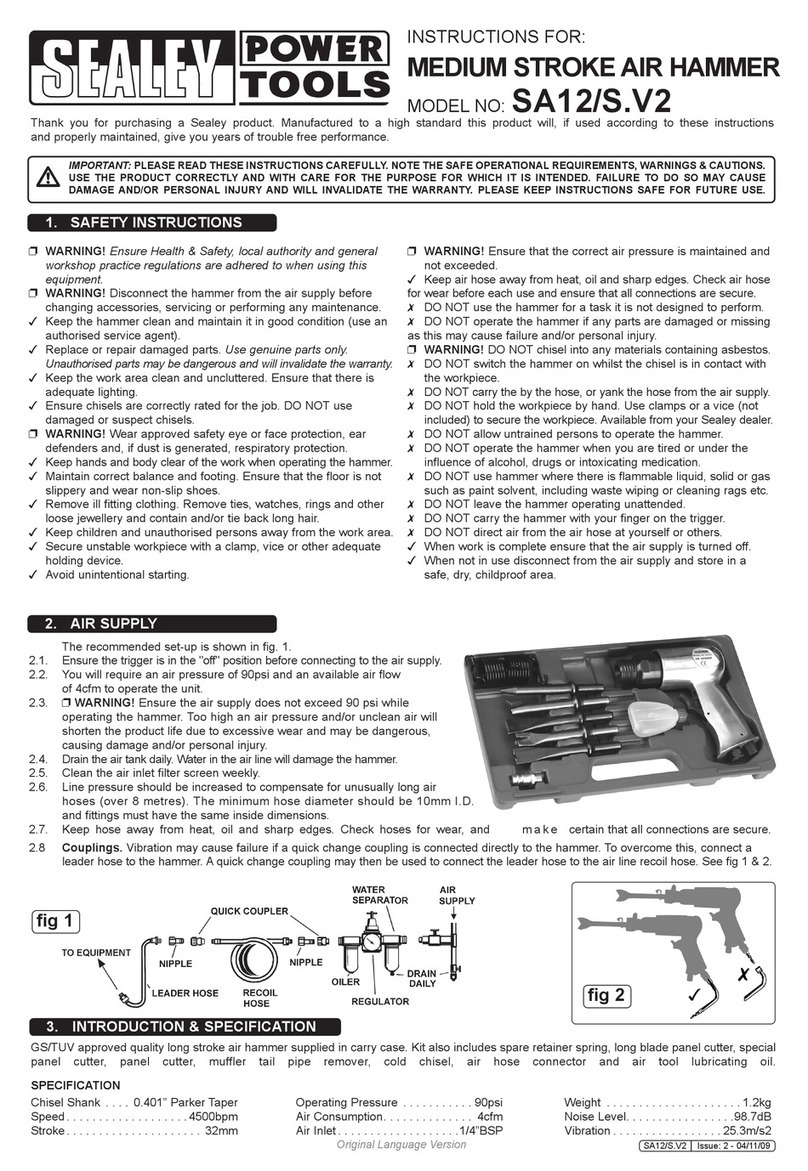

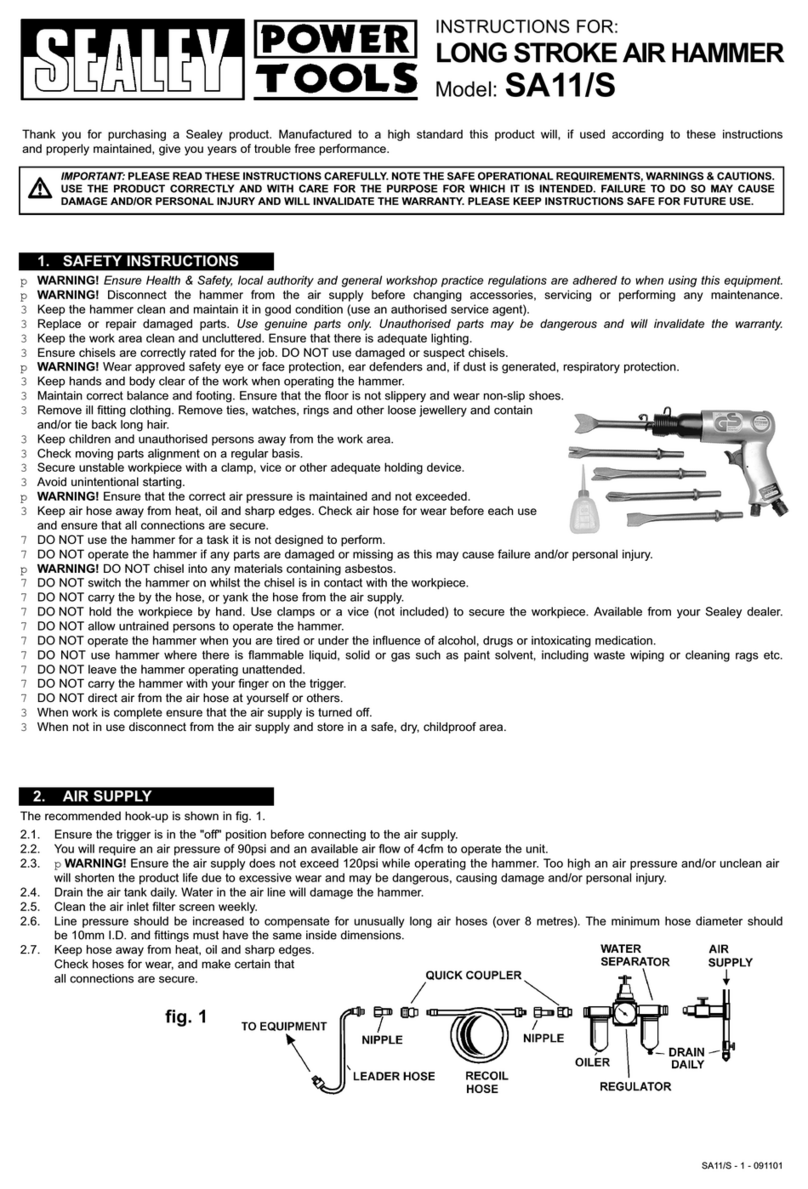

8DO NOT allow the blade to rest on the workpiece while the motor is shut o.

7.4.5. When cutting rectangular stock, position the workpiece vertically instead of at (g.15.W). This is to reduce the amount

of blade contact with the workpiece, which will result in more ecient sawing and a better-quality cut.

7.4.6. To provide blade support, position blade guide arms as close as possible to the workpiece. If the distance is too great,

the blade can “wander” in the cut. Be aware of how much downfeed pressure is acting on the cut as this contributes to

the blade wandering.

NOTE: See Blade Selection (6.10) for more information on thickness average calculation.

7.5. ADJUSTING GUIDE BRACKETS

7.5.1. If the bearings are positioned properly and the blade is not square, one or both blade guide brackets must be adjusted.

7.5.2. Loosen the socket head bolts.

7.5.3. Adjust the bracket to the correct position.

7.5.4. Tighten the socket head bolt.

7.5.5. Check the guide bearings. Repositioning the blade guide bracket can alter the previous adjustments. Readjust if

necessary.

7.6. REGULATING FEED

7.6.1. Feed pressure is controlled by the feed regulator. The regulator creates a force which counteracts the feed pressure.

The force from the feed regulator can be adjusted to create any feed pressure up to the set maximum.

7.6.2. Having the correct feed pressure will produce the optimum feed rate and the fastest cut. Incorrect pressure, whether

too great or too small, will put less power into the cut and reduce the feed rate.

NOTE: Wasted power damages the saw.

7.6.3. Determining the proper feed is largely a judgement based on experience. The feed is usually determined during the cutting operation.

Before the cutting begins, the blade should be o the work and the head should be held in position by placing the feed control knob in

the OFF position.

7.6.4. Once the blade is running, the head is slowly lowered onto the work by turning the feed control knob to the on position, and adjusting

the feed regulator knob to the desired feed rate.

7.6.5. After the blade begins the cut, optimum feed rate should be determined.

7.6.6. To determine if the feed is incorrect, examine the chips produced (g.16). When the blade is operating at the ideal feed for the speed,

the chips will be curled and continuous. If the chips are thick and not continuous, the feed pressure should be reduced. If the chips are

powdery, the feed pressure by leaning on head.

7.6.7. Curled shavings indicate correct feed pressure.

7.6.8. Thick discontinuous chips indicate too much pressure. Turn knob clockwise.

7.6.9. Powdery chips indicate too little pressure. Turn knob counter clockwise.

8. MAINTENANCE

8.1. Steps required to keep the saw in optimum operating condition have been described

under Operation. The Safety Precautions should be performed before operation.

8.2. For proper maintenance:

8.2.1. Keep saw clean and dry. Sweep o spots where chips have collected and wipe o

spots where coolant splashed.

8.2.2. Lubricate the unpainted surfaces with a light application of medium consistency

machine oil to prevent corrosion after cleaning.

8.2.3. Grease the vice lead screw if vice action becomes dicult.

8.2.4. Replace dull blades and blades from which teeth have been stripped. A clean saw

with a sharp blade will yield the best cut.

8.2.5. Internal parts of the band saw have been completely lubricated at the factory and DO

NOT need to be lubricated again.

8.2.6. After the rst fty hours of use, the gear box should be drained and relled.

WARNING Make certain unit is disconnected from power source before attempting to

service or remove any component. If power cable is worm, cut, or damaged in anyway,

have it replaced immediately by a qualied electrician.

8.3. OIL LEVEL

8.3.1. The gear box relies on an oil bath to lubricate the sliding surfaces and transfer heat.

The vent bolt is vented to release pressure created by the developed heat.

Insucient lubrication will cause the gears to heat up and wear at and If the gear box

is worked on, the oil should be replaced to avoid contamination. Always add fresh oil

and replace the oil seasonally, to guard against breakdown. The seals between the gearbox and the cover plates are gaskets. If a

cover plate is removed, the surface should be cleaned and new gasket should be applied. After the rst fty hours of use, the gear box

should be drained and relled with industrial gear oil.

8.4. CHECKING OIL LEVEL

8.4.1. Place the head in the horizontal position.

8.4.2. Let the oil settle. Allow a few minutes if the head was in motion.

8.4.3. Check the uid level. Look at the oil sight lens and follow the instructions (g.18).

Sight lens full of oil: Drain oil by removing drain plug.

Sight lens half-covered: The oil level is correct.

8.5. CHANGING THE BLADE

WARNING! Disconnect band blades. Wear leather gloves when handling band saw blades. DO NOT wear gloves

when operating saw.

8.5.1. Prop open the blade wheel covers.

8.5.2. Loosen the outer guide bearings on the left and right guide assemblies. No other guide bearings should be moved.

8.5.3. Remove knobs and blade guard.

8.5.4. With one hand, pinch the blade and the tracking wheel together to pro tect against the possibility of the blade popping

g.16

g.17

g.18

Original Language Version

© Jack Sealey Limited SM353CE.V3 Issue 1 23/01/20