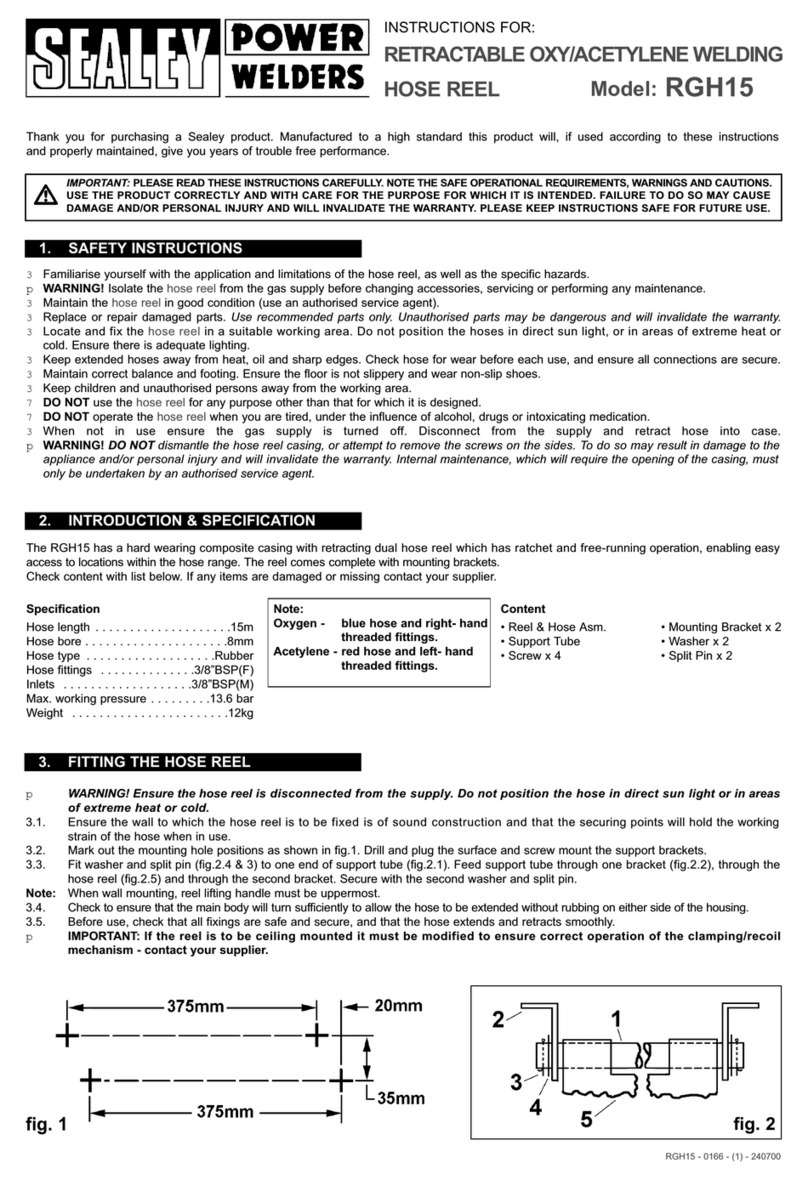

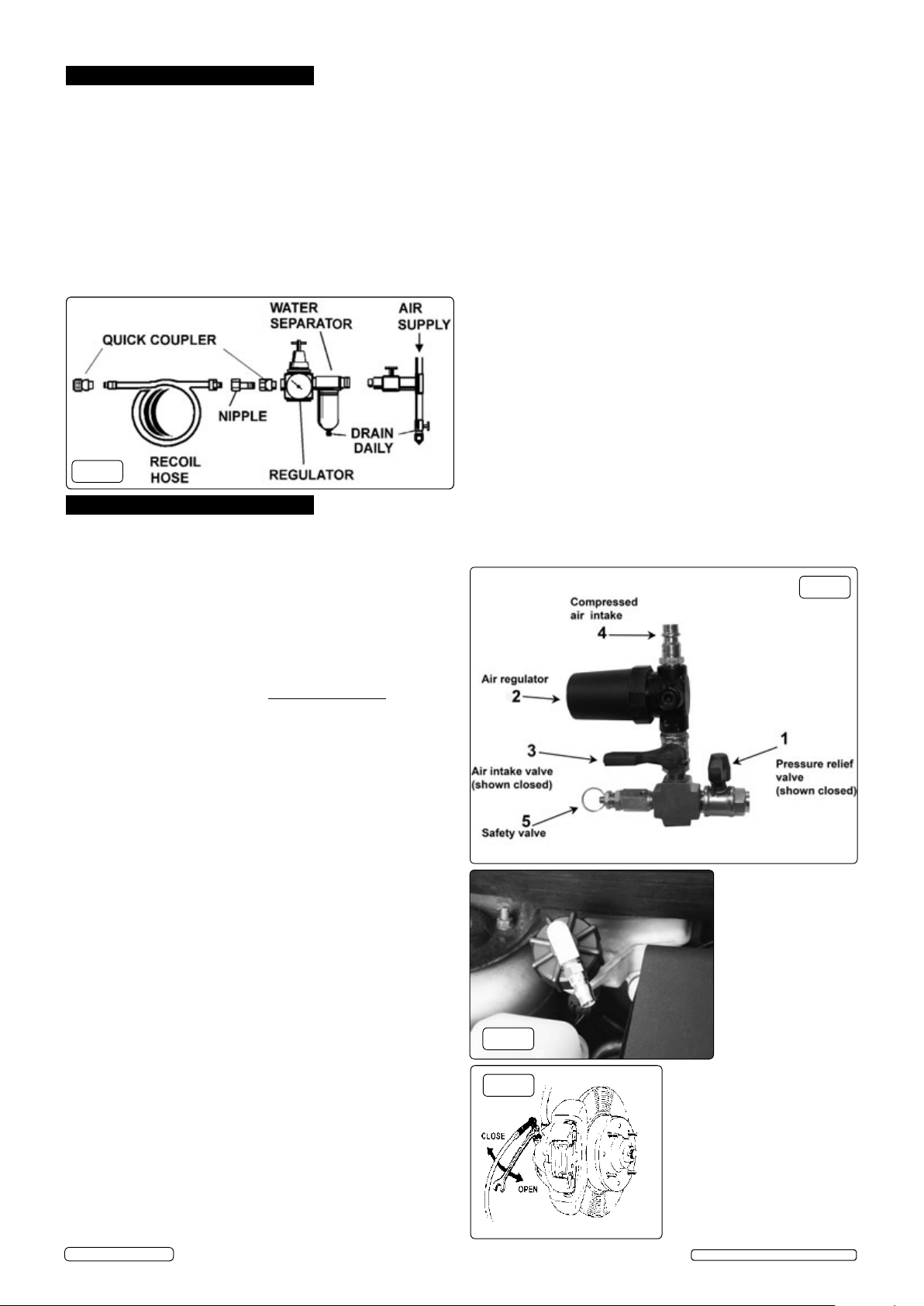

Recommendedhookupisshowning.2.

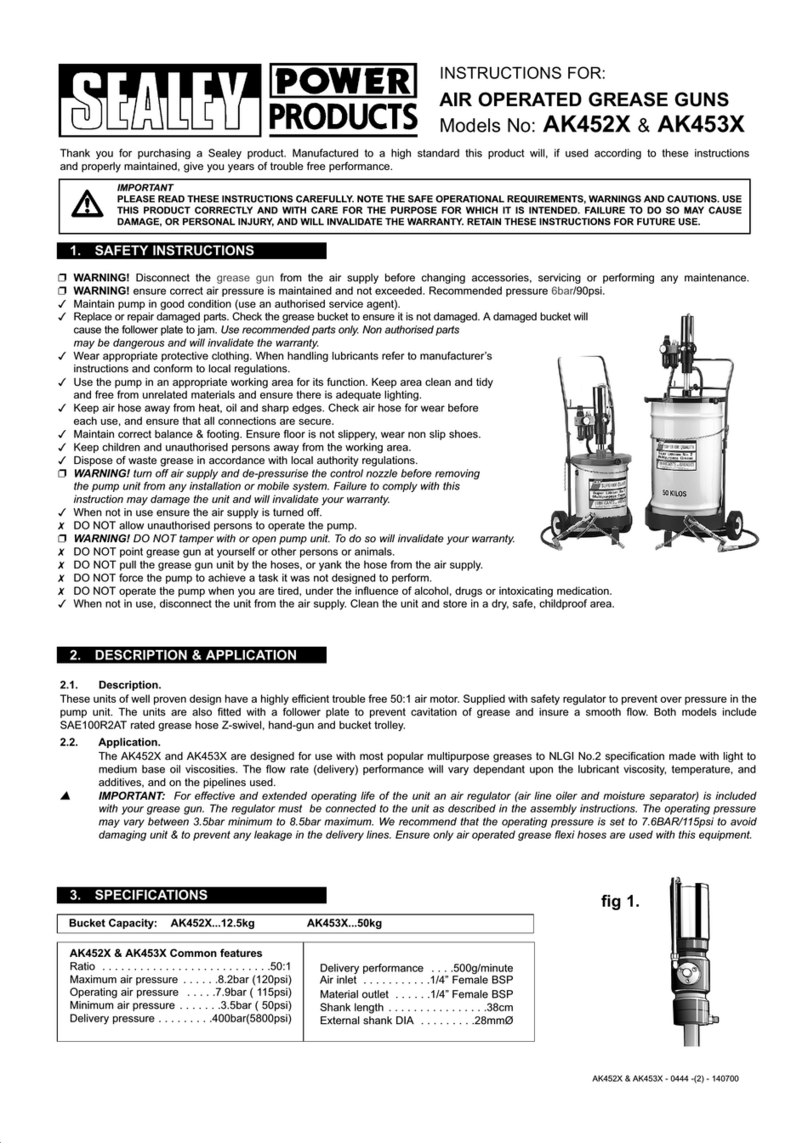

4.1. Y o u willrequireanairpressureof40psiandairowaccording

tospecication.

4.2. Ensure that the air supply is clean and does not exceed 40psi.

Too high a pressure and/or unclean air may damage the

diaphragm and will shorten the product life due to excessive

wear and may cause damage and/or personal injury.

4.3. Drain the air tank daily. Water in the air line will damage the

unit and invalidate your warranty.

4.4. Theminimumhosediametershouldbe¼"I.Dandttings

must have the same internal dimensions.

4.5. Keep hose away from heat, oil and sharp edges. Check

hoses for wear and make certain that all connections are secure.

5.1. Brake bleeding procedure.

Refer to the vehicle manufacturer’s instructions for brake

bleeding and wheel sequence before proceeding. If no

specific instructions from the vehicle manufacturer exist,

follow the instructions detailed below.

WARNING! Familiarise yourself with the hazards of brake

fluid - read manufacturer’s instructions on the container.

DO NOT touch the vehicle’s brake pedal whilst bleeding

the brakes.

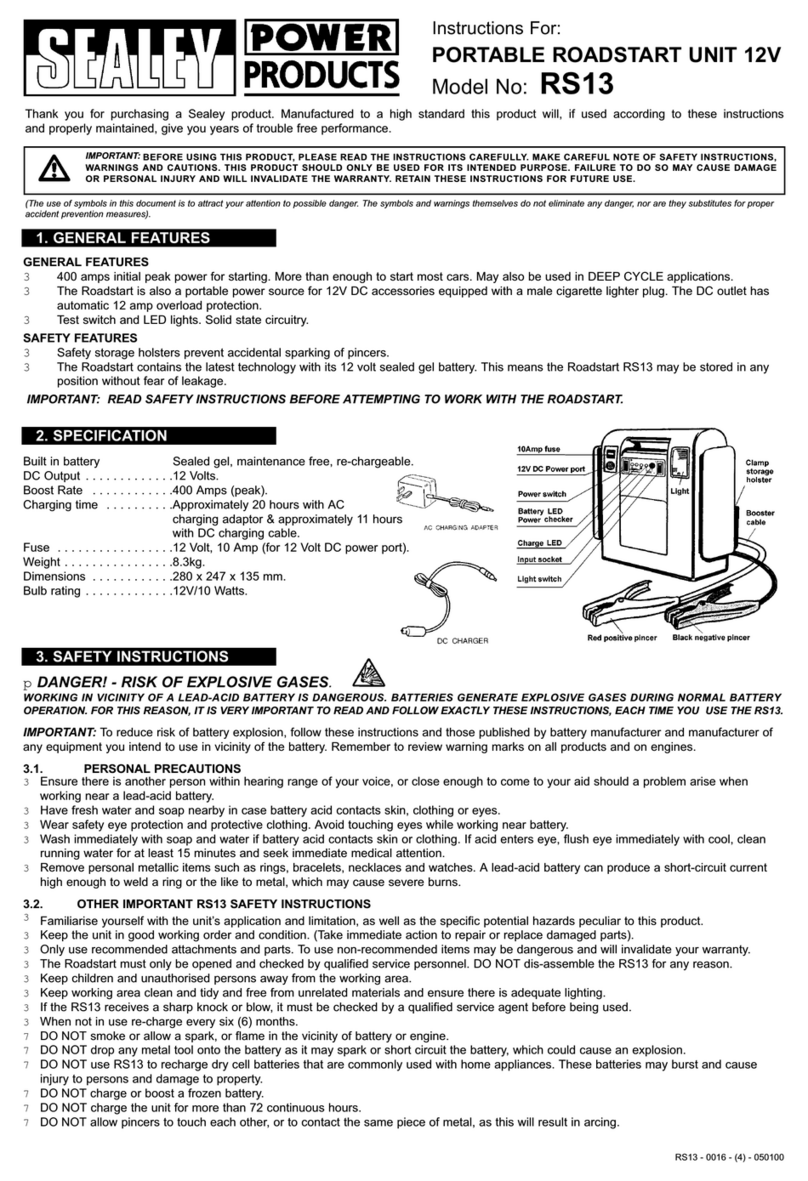

5.1.1. Check that the pressure release valve (fig.3.1) is open and

that there is no pressure within the unit. Unscrew the filler

cap (fig.1.1) on the unit and top up to full capacity with new

brake fluid. Replace filler cap and close the pressure release

valve.

WARNING! DO NOT allow the fluid capacity within the

unit to fall below ½ litre during the bleeding process

otherwise air may enter the system.

NOTE: The diaphragm may be visible from the neck of the

filler and will require deflating before filling, this can be done

by pushing down on the diaphragm with a clean blunt

instrument.

5.1.2. Check that the air regulator (fig.3.2) is turned fully counter

clockwise, the air intake valve (fig.3.3) and the fluid supply

pipe valve (fig.1.3) are in the closed positions.

5.1.3. Connect the brake bleeder (fig.3.4) to a suitable compressed

air supply.

5.1.4. Slowly open the air intake valve (fig.3.3) and turn the air

regulator clockwise until a pressure of 20psi is registered on

the pressure gauge (fig1.2).

NOTE: The brake bleeder can be used remotely by closing

the air supply valve once the unit has been charged with air

and then disconnect the air supply.

DO NOT exceed the maximum pressure of 40psi, if the unit

exceeds this pressure the safety valve (fig.3.5) will be

activated.

5.1.5. Connect one of the adaptors to the end of the fluid supply

pipe and hold over a waste oil container, slowly open the

valve (fig.1.3) to release air from the supply pipe. When

brake fluid is free flowing, close the valve.

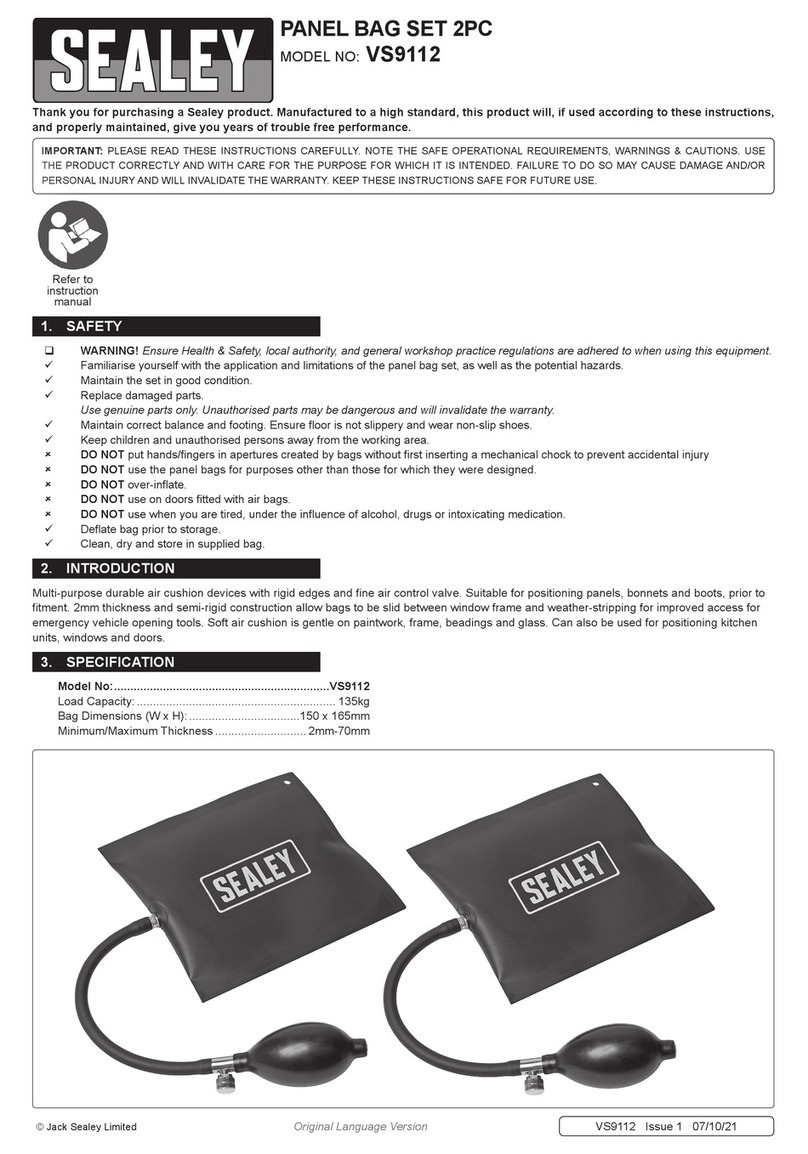

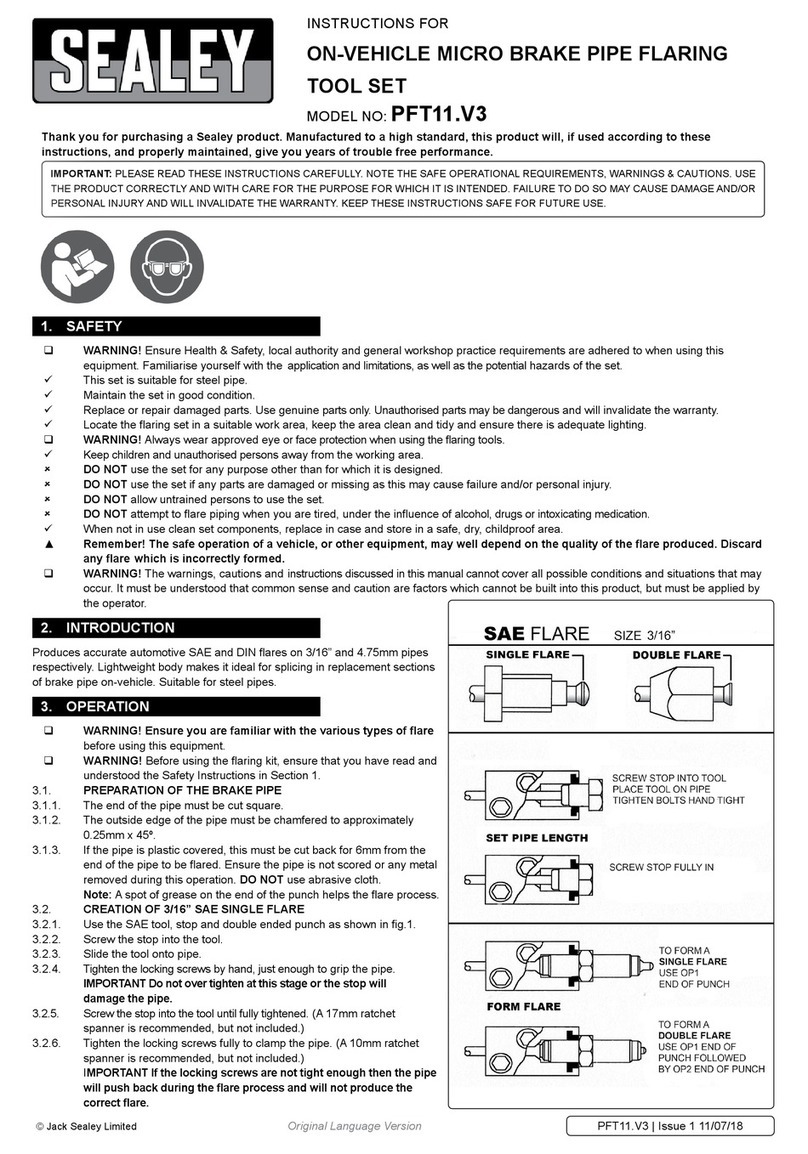

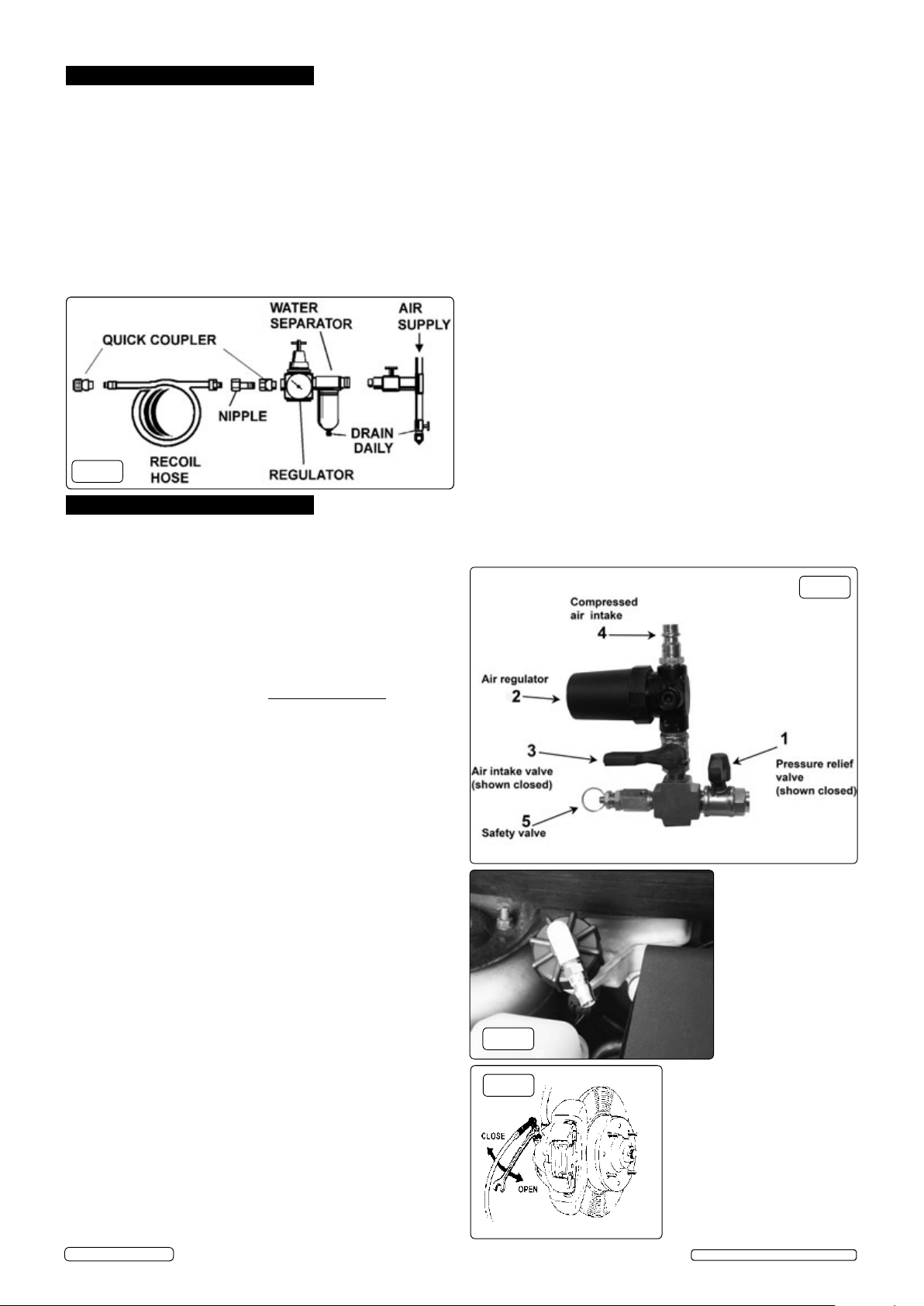

5.1.6. Remove the cap on the vehicle’s brake fluid reservoir. If the

brake fluid level is not at maximum, top it up and select a

suitable adaptor for the vehicle. In some cases a universal

adaptor will be required, see section 5.4. Tighten the adaptor

onto the master cylinder ensuring that a good seal is

achieved (fig.4).

5.1.7. Connect the fluid supply pipe quick connector to the adaptor

and slowly open the valve (fig.1.3) to pressurise the system.

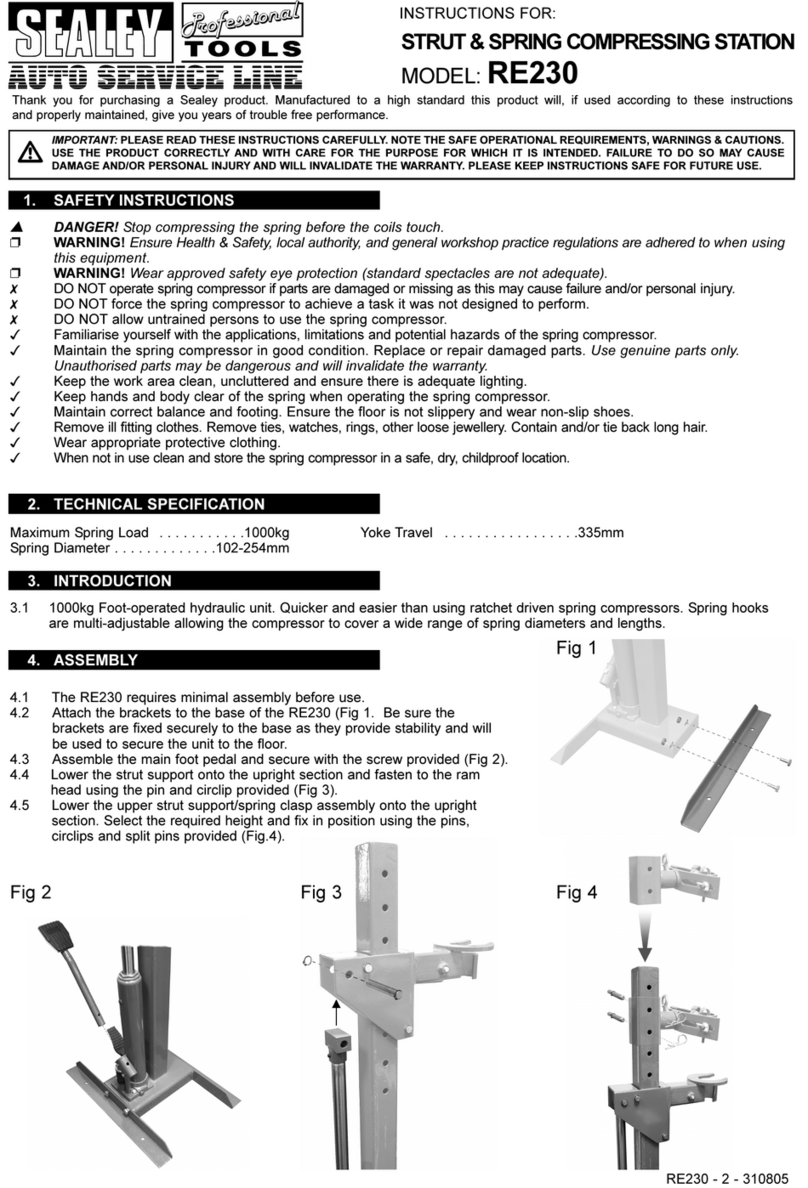

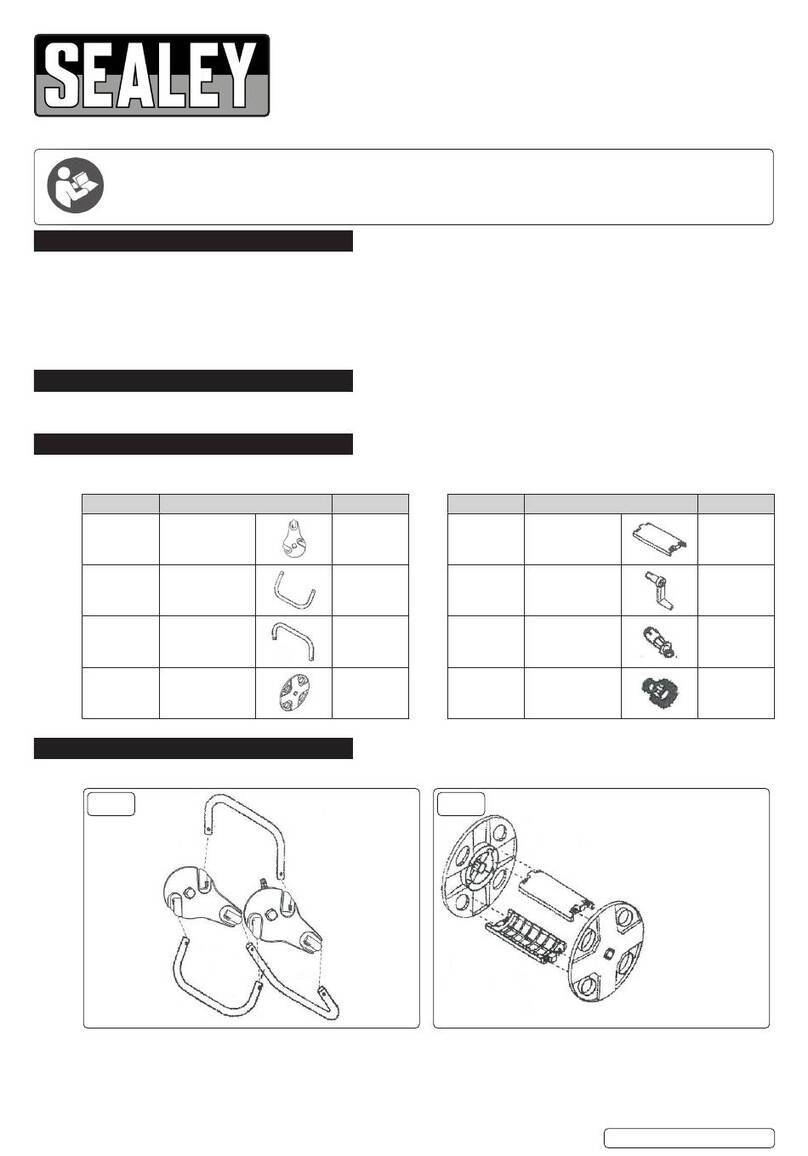

5.1.8. Starting with the brake furthest away from the master

cylinder connect the tube from the bleeding bottle to the

nipple and using a brake spanner open the nipple

approximately ¼ turn (fig.5), brake fluid will flow through the

clear pipe into the bottle, when there are no visible bubbles

tighten the bleed nipple.

5.1.9. Repeat the process at each wheel in turn as necessary.

5.1.10. To remove the brake bleeder, shut off the fluid supply pipe

valve (fig.1.3), close the air intake valve (fig.3.3) and open

the pressure release valve to depressurise the unit.

5.1.11. Disconnect the fluid supply pipe from the adaptor, taking care

not to spill any brake fluid and remove the adaptor from the

brake fluid reservoir. Any excess fluid in the reservoir should

be removed using the supplied rubber squeeze and disposed

of into a suitable waste oil container.

5.1.12. Refit the original brake fluid reservoir cap.

5.2. Changing the brake fluid.

5.2.1. Carry out the brake bleeding procedure as described above.

5.2.2. When new fluid can be seen in the clear tube tighten the

brake nipple.

5.2.3. Repeat this procedure at each wheel in turn.

5.2.4. Disconnect as above (4.1.10 & 4.1.11).

NOTE: When brake bleeding and/or fluid changing is

complete, test the action of the brake pedal to ensure that the

brakes are working and are not spongy before using the

vehicle on the road.

5.3. Clutch bleeding procedure.

Refer to the relevant vehicle manufacturer’s instructions for

clutch bleeding procedure. If no specific instructions from the

vehicle manufacturer exist, the same procedures as for brake

bleeding should be followed.

Fig.2

Fig.3

Fig.4

Fig.5

4. AIR SUPPLY

5. OPERATION

VS0204A Issue:2 (2) - 18/09/18

Original Language Version

© Jack Sealey Limited