3.1. Brake bleeding procedure.

Refer to the vehicle manufacturer’s instructions for brake bleeding and wheel sequence before proceeding. If no specific instructions from the vehicle

manufacturer exist, follow the instructions detailed below.

WARNING! Familiarise yourself with the hazards of brake fluid - read manufacturer’s instructions on the container. Do not touch the vehicle’s

brake pedal whilst bleeding the brakes.

3.1.1. Remove the cap of the vehicle’s brake fluid reservoir. If the brake fluid level is not at maximum, top it up.

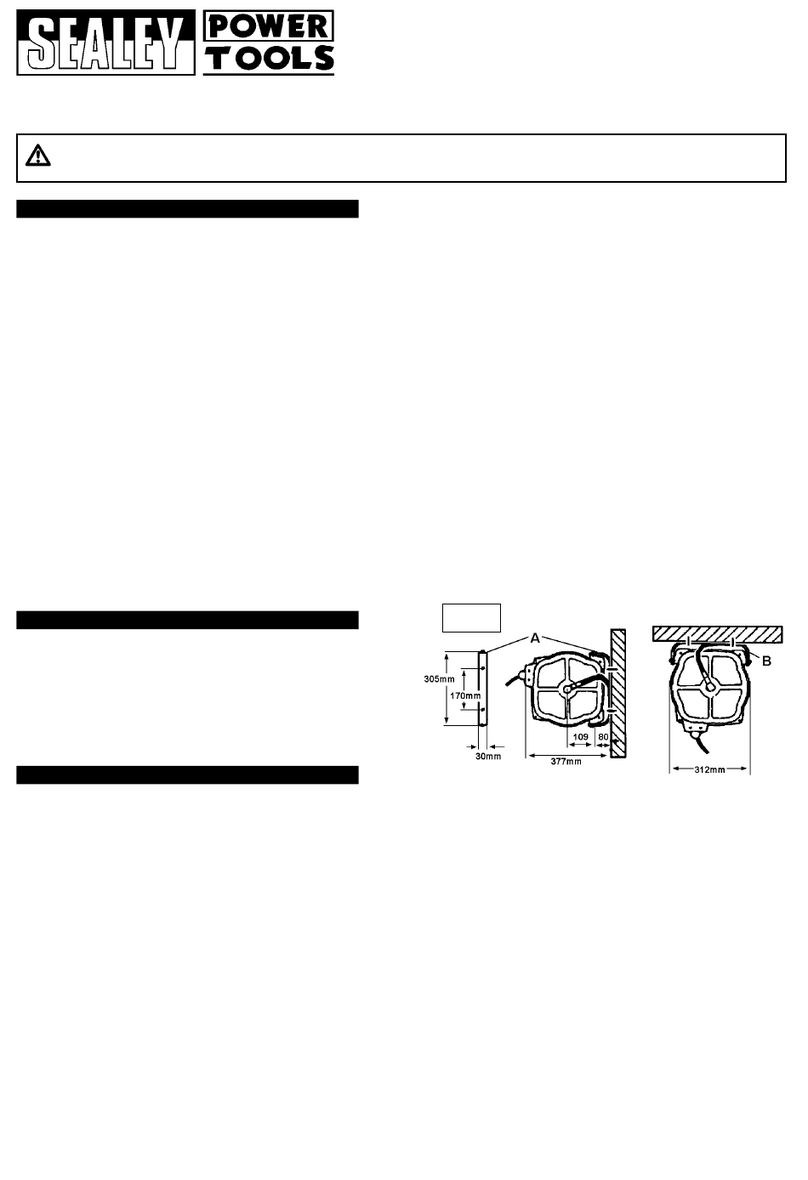

3.1.2. Fill the replenishment bottle to just under half full with new brake fluid, then screw the cap assembly onto the replenishment bottle. Invert the bottle over the

container of new brake fluid and open the valve ‘D’ so that the fluid level begins to drop towards the level marked on the bottle. As soon as the level mark

is reached, close the valve.

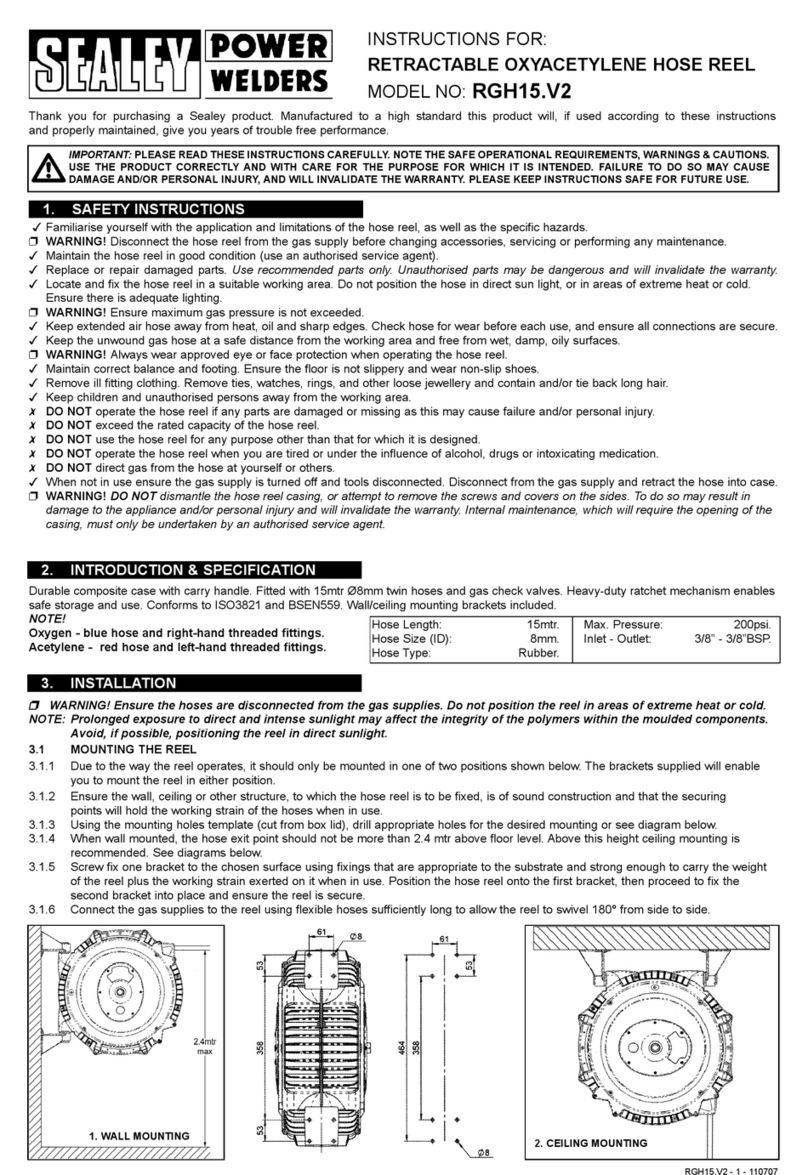

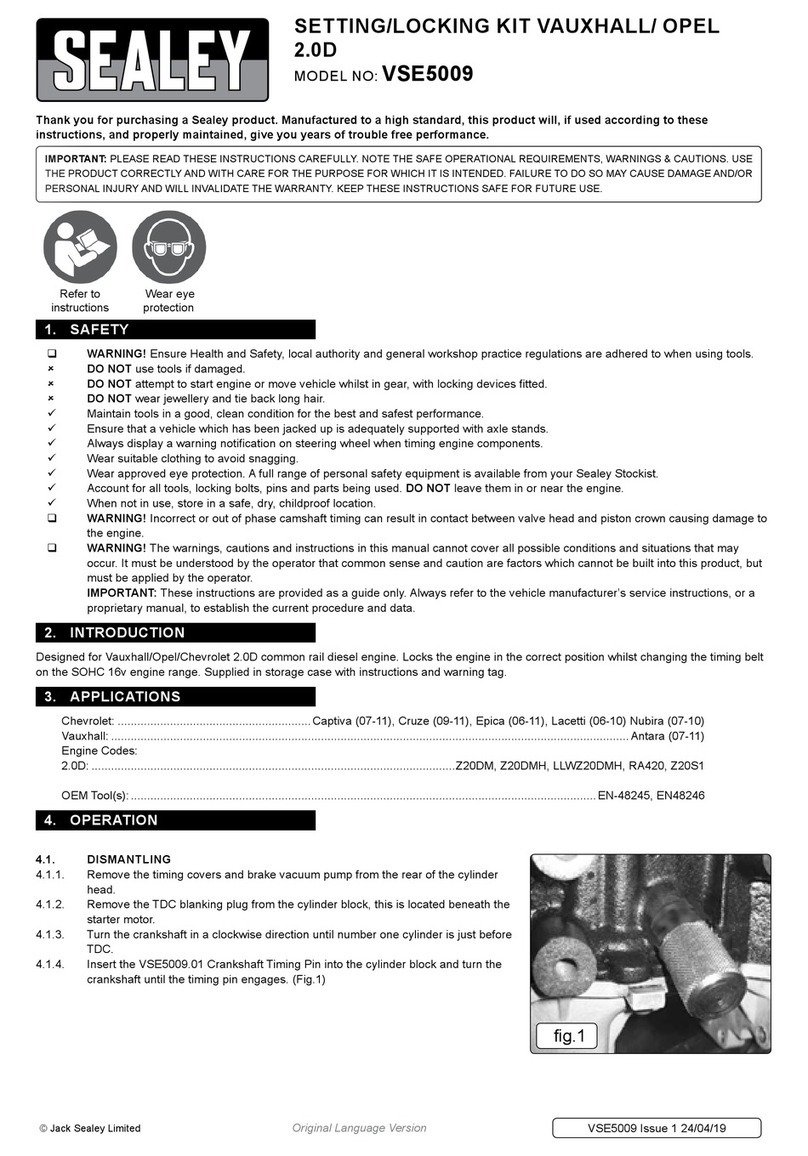

3.1.3. Screw on an appropriate size three legged adaptor that fits into the top of the brake fluid reservoir. Ensure valve ‘D’ is closed, and invert the replenishment

bottle within the neck of the brake fluid reservoir as shown in fig.1. The threaded outlet ‘B’ must be immersed in the brake fluid. If it is not, screw the three

legged adaptor ‘C’ clockwise towards the valve ‘D’ until sufficient thread is exposed to allow the outlet to be immersed in the brake fluid. Open the valve

‘D’ as in fig.2. As the brakes are bled, the fluid level in the reservoir will begin to drop and expose the bottle outlet. Brake fluid will begin to flow from the

replenishment bottle. Once the level in the reservoir has risen sufficiently to cover the outlet, the flow will automatically stop. Depending on the amount of

brake fluid bled from the system, the bottle may need to be filled again from time to time.

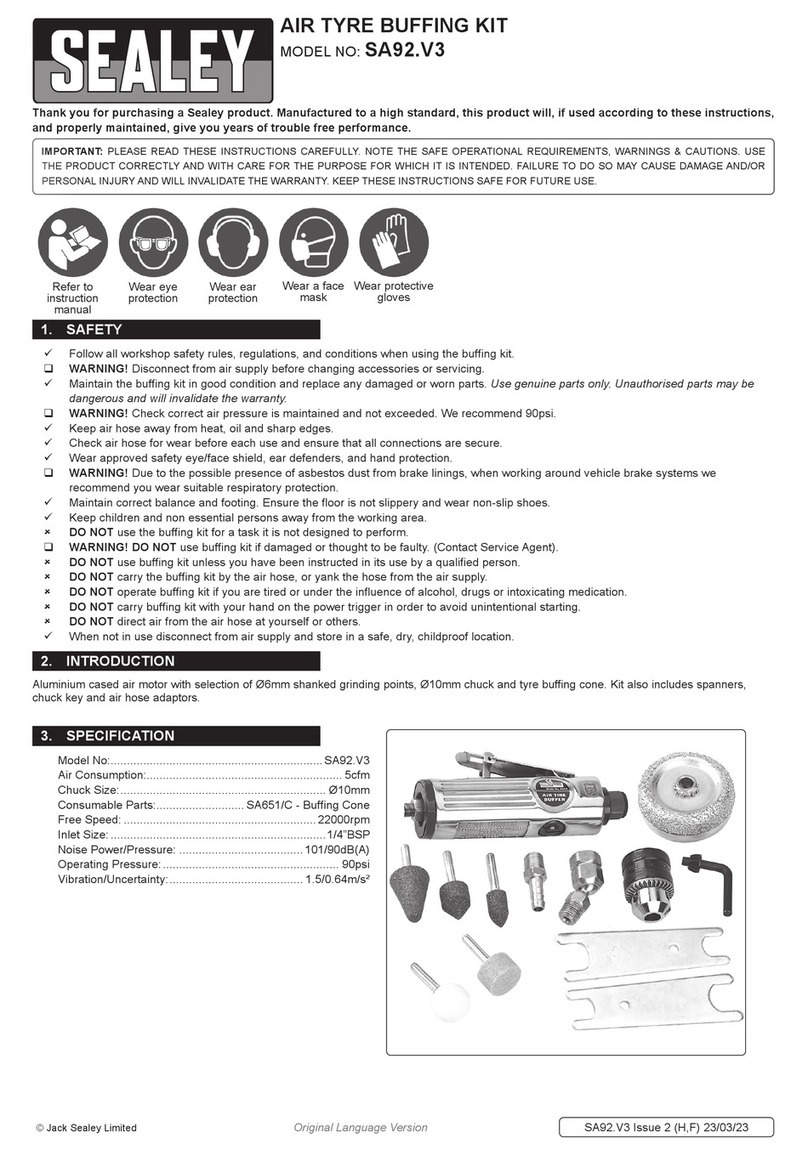

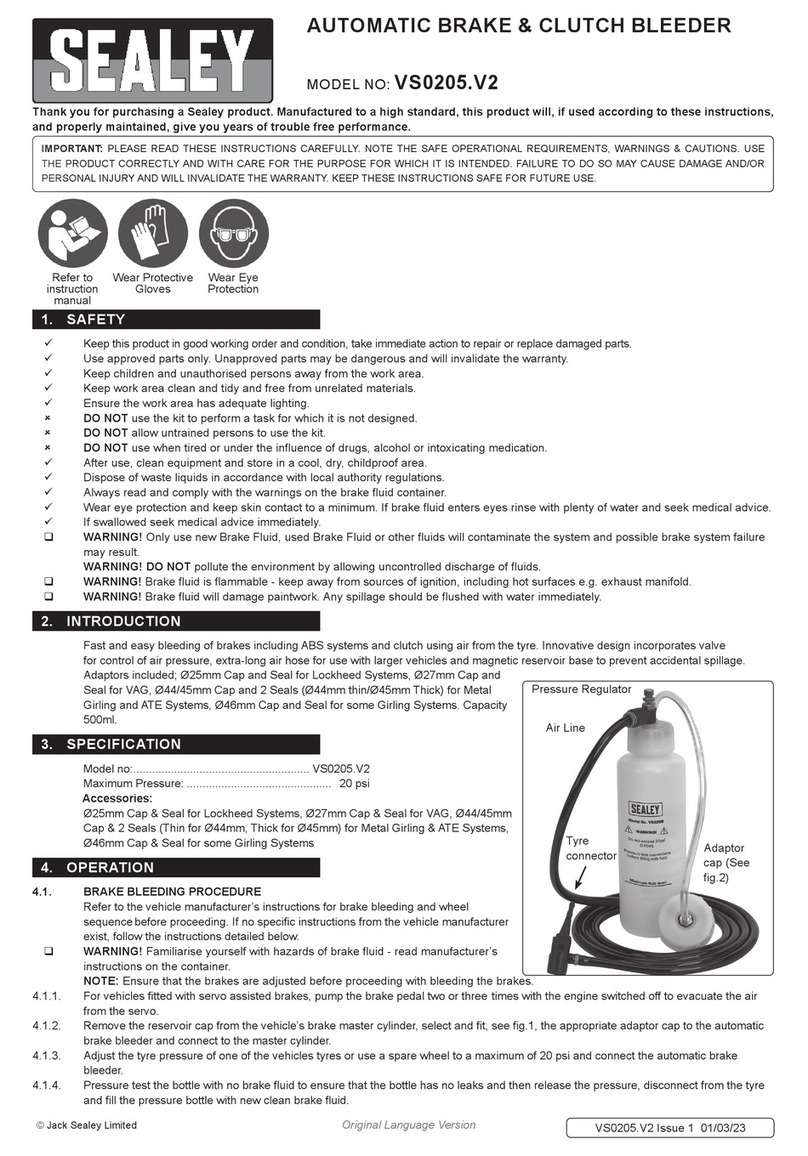

The VS0202.V2 workshop vacuum brake and clutch bleeder enables simple, one-man operation using standard workshop air supply (90 to 120psi).

Professional, quick, clean and efficient. Large capacity for the busy workshop. Draws fluid from the bleed nipple enabling either bleeding or full replacement of

fluid in system. Vacuum gauge for accurate vacuum application. Seperate cap for easy emptying. Long lasting silicon rubber hose for ultra flexibility. Includes

reservoir top-up kit and adaptors.

Inlet air pressure: . . . . . . . . . . . . . . . . . . . 90-120psi

Container capacity:....................5.0litres

Air consumption:....................180ltr/min

Vacuum: .............................. 60%

Thread connection:............1/4”BSP (female)

1. SAFETY INSTRUCTIONS

2. INTRODUCTION & SPECIFICATION

3. OPERATION

INSTRUCTIONS FOR:

WORKSHOP VACUUM BRAKE

AND CLUTCH BLEEDER - 5LTR

MODEL N

O: VS0202.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and properly maintained, give you years

of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS, AND

CAUTIONS. USE THIS PRODUCT CORRECTLY, AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY

CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY.

fig.1 fig.2 fig.3

Original Language Version VS0202.V2 Issue: 1 - 21/02/12

WARNING! Ensure that Health and Safety, local authority and general workshop practice regulations are adhered to when using tools.

DO NOT use tools if damaged.

DO NOT use the kit to perform a task for which it is not designed.

DO NOT allow untrained persons to use the kit.

DO NOT use when tired or under the influence of drugs, alcohol or intoxicating medication.

Maintain tools in a good and clean condition for the best and safest performance.

Ensure that the ignition key is removed, to prevent inadvertent engine cranking.

If the vehicle to be worked on is raised, ensure that it is adequately supported with axle stands or ramps and chocks.

Wear approved eye protection. A full range of personal safety equipment is available from your Sealey dealer.

Wear suitable clothing to avoid snagging. Do not wear jewellery and tie back long hair.

Keep children and unauthorised persons away from the work area.

Keep work area clean and tidy and free from unrelated materials.

Ensure the work area has adequate lighting.

Account for all tools being used and do not leave them on or in the vehicle.

Brake Fluid Precautions

Always read and comply with the warnings on the brake fluid container.

Wear eye protection and keep skin contact to a minimum. If brake fluid enters eyes, rinse with plenty of water and seek medical advice. If swallowed

seek medical advice immediately.

Brake fluid is flammable - keep away from sources of ignition, including hot surfaces e.g. exhaust manifold.

Brake fluid will damage paintwork. Any spillage should be flushed with water immediately.

Always read and comply with the warnings on the brake fluid container.

WARNING! DO NOT pollute the environment by allowing uncontrolled discharge of fluids. Dispose of waste liquids in accordance with local authority

regulations.

WARNING!Brake fluid is flammable - keep away from sources of ignition, including hot surfaces e.g. exhaust manifold.

WARNING!Brake fluid will damage paintwork. Any spillage should be flushed with water immediately.

After use, clean equipment and store in a cool, dry, childproof area.