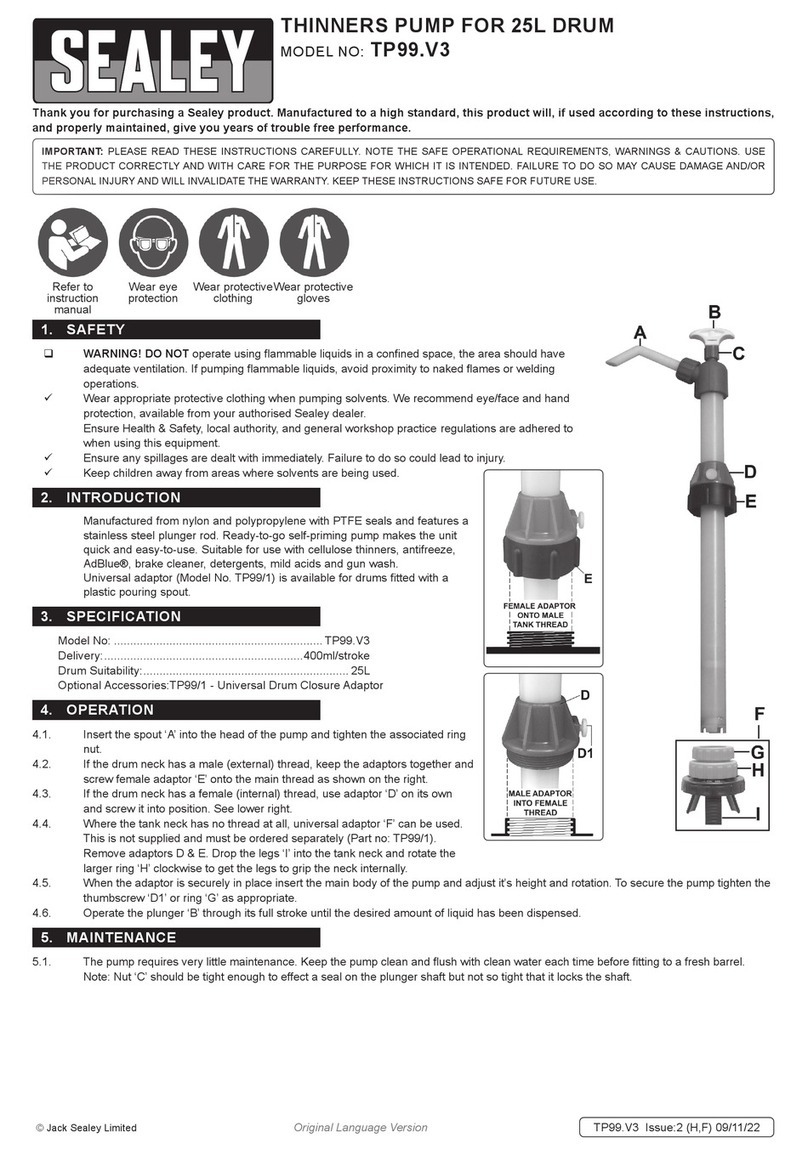

3. ASSEMBLY

3.1. ASSEMBLING THE CONTAINER FRAME.

Referringtog.1takethecontainerframeandattachthewheelstoitasfollows:

3.1.1. PassanM12x62mmbolt(5)througheachwheelandscrewthemintothethreadedbushesoneithersideoftheframe.

Backoffeachboltslightlytoallowthewheelstorotatefreely.LockeachboltbythreadinganM12nut(6)ontoeachprotrudingboltand

tighten.

3.1.2. Takethelowersupporttubeandxittotheframeasfollows.ThereisanM10boltweldedatthebaseofthetube,see(3)ing.1.

Placethetubeintotheindentinthecontainerframewiththeboltprotrudingthroughtheholeintheframe.Passawasheroverthebolt

followedbyanM10nut.See(4)ing.1.Tightenthenut.

3.1.3. Inserttheupperhandletubeintothelowersupporttubeandaligntheholesinthetwocomponents.PassanM6x30mmbolt

througheachhole(1)andscrewanM6nut(2)ontoeachprotrudingboltandtighten.

3.2. ASSEMBLING THE CONTAINER TO THE FRAME.

3.2.1. Standthecontainerontothecontainerstandsothattheupperhandletuberestsintothebracketonthecontainer.Passan

M8x44mmbolt(fig.1.7)throughthetubeandbracketandsecureitwithaflatwasher,splitwasherandM8nut.

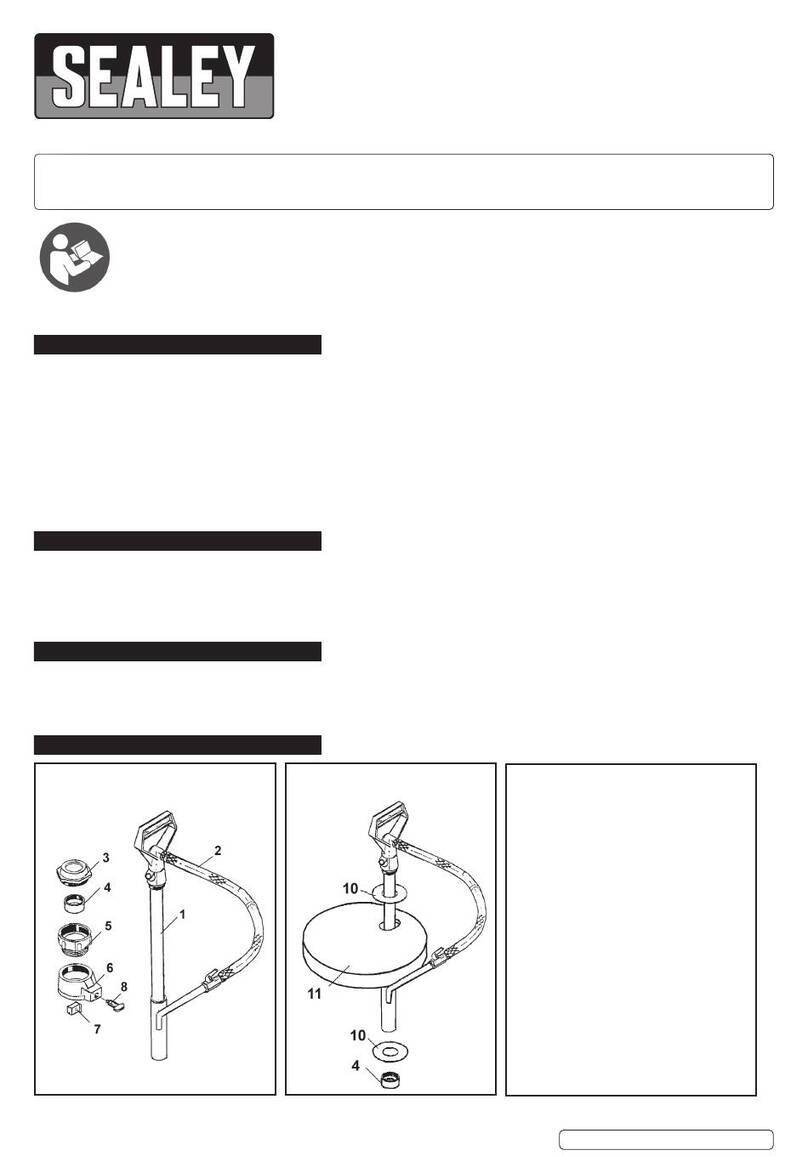

3.3. ASSEMBLING THE DISCHARGE HOSE.

3.3.1. Referringtog.2,slideawirehoseclipoveroneendofthedischargehose(9)andpushthehoseontotheoutletonthecastinginthe

centreofthelid.Slidethehoseclipontothettingandtightenittoretainthehose.See(5A)ing.2.

3.3.2. Slidetheotherhoseclipovertheotherendofthedischargehoseandpushitontothedispensingtube(6)adjacenttothevalve.

Retainthehosebytighteningthewireclip,see(5B)ing.2.Thedispensingtube(6)isshownpartiallyinsertedintothestowage

grommet(7).Thetubecanbefullyinsertedintothelidwhennotrequired.

3.4. ASSEMBLING THE PUMPING HANDLE.

3.4.1. Attachthehandle(1)andlink(4)tothelidandpumpasshowninfig.2using3pivotpins(2).Placeaflatwasherovereach

protrudingpinandretaineachpinwithan‘R’clip.See3infig.2.

4. OPERATION

4.1. FILLING

4.1.1. Releasethethreeclipswhichretainthelidandliftitoffcompletewiththepumpwhichisontheundersideofthelid.

4.1.2. Fillthecontainertwothirdsfullwithoil.Themaximumlevelshouldbeabout2cmbelowthemiddleridgewithinthecontainer.

Donotllabovethislevelastheoilmayspillduringtransportation.

Note: OnlyuseoilsuptoSAE80viscosity.

4.1.3. Replacethelidandrotateitsothatthepumpinghandleisconvenientlysituatedforoperation.Fastentheliddownwiththethreeclips.

Closethevalveonthedispensingtube.

4.2. DISPENSING

4.2.1. Insertthedispensingtubeintothegearboxtobelled.Openthevalveonthedispensingtube.

4.2.2. Pumphandletodispenseoil.

4.2.3. Whenthedesiredamounthasbeendispensed,closethevalveandstowthedispensingtubeintheholeinthelid.

Sealey Group, Kempson Way, Suffolk Business Park, Bury St Edmunds, Suffolk. IP32 7AR

01284 757500 01284 703534 sales@sealey.co.uk www.sealey.co.uk

Note: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior

notice.

Important:NoLiabilityisacceptedforincorrectuseofthisproduct.

Warranty:Guaranteeis12monthsfrompurchasedate,proofofwhichisrequiredforanyclaim.

ENVIRONMENT PROTECTION

Recycleunwantedmaterialsinsteadofdisposingofthemaswaste.Alltools,accessoriesandpackagingshouldbesorted,takento

arecyclingcentreanddisposedofinamannerwhichiscompatiblewiththeenvironment.Whentheproductbecomescompletely

unserviceable and requires disposal, drain any fluids (if applicable) into approved containers and dispose of the product and fluids

accordingtolocalregulations.

TP17 Issue:2 (HF SAE) - 08/10/18

Original Language Version

© Jack Sealey Limited