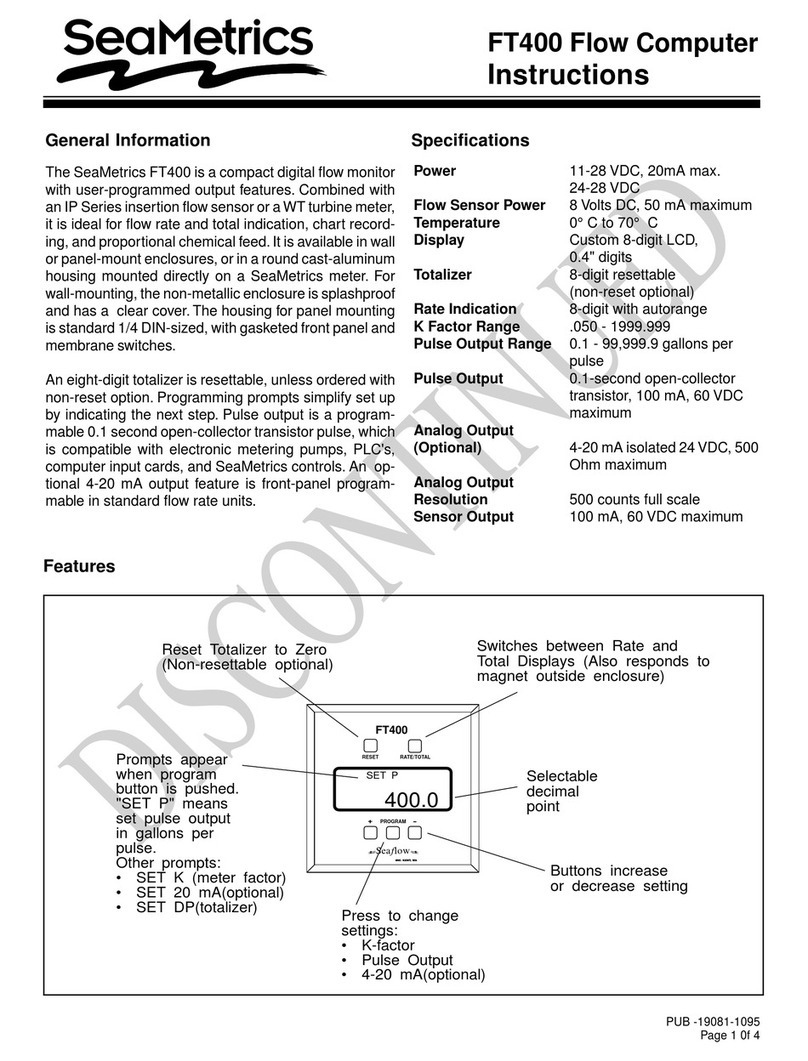

Installation

Fitting Installation. IP80 Series meters require spe-

cialfittings. Themeterfitting must first be installed in the

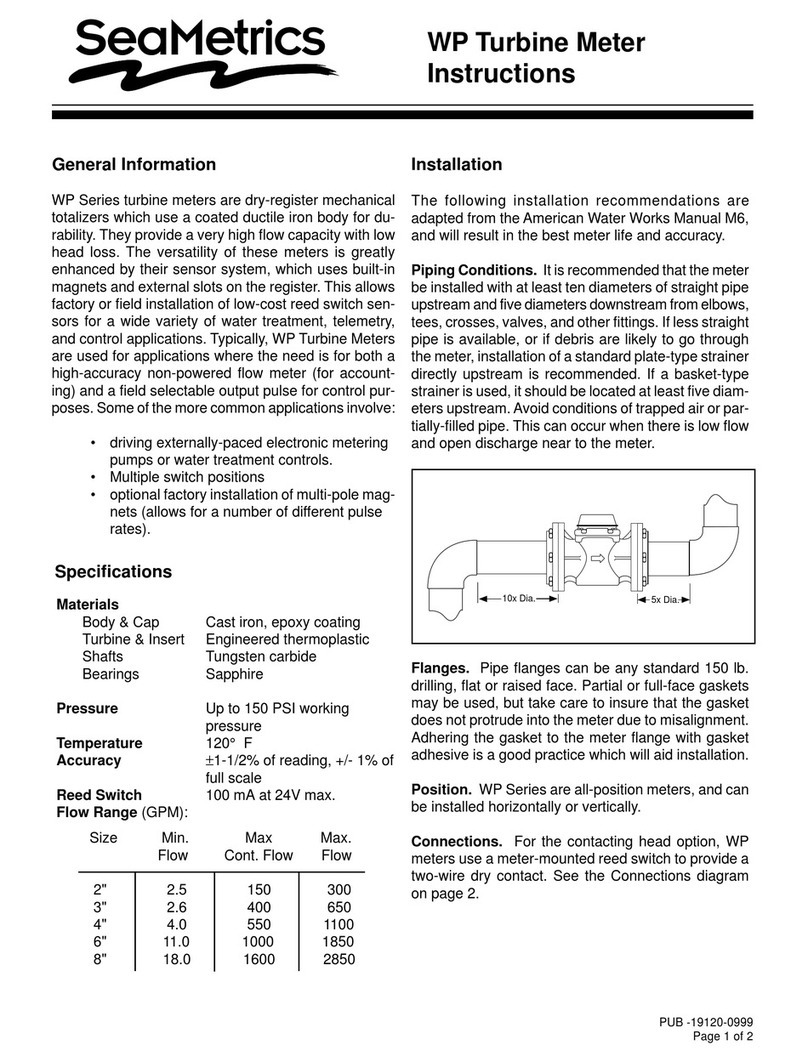

pipeline. Straight pipe of at least ten times the diameter

upstream of the meter and five diameters downstream

are strongly recommended. Inadequate straight pipe,

especially downstream of an elbow, change in pipe di-

ameter, or partially-opened valve, can result in signifi-

cant inaccuracy. Typically this inaccuracy is in the form

of the meter reading high. Some IP80 Series meter fit-

tings are supplied with upstream straight pipe.

Meter Installation. After the meter fitting is installed in

thepipeline,themetercan beinstalledin thefitting. Press

the meter into the fitting as far as it will go. Then retain

the meter in place by inserting the u-pin. This pin

canbe installed from eitherside. It is sometimes neces-

sary to rotate the probe back and forth slightly to start

the pin into the slots on the probe. Slide the pin in as far

as it will go.

Meter Connection. Seethe“IP80SeriesConnections”

diagramformeterconnections. Unlessthemeterissup-

pliedpre-connectedtoameter-mounted FT415/420 flow

indicator, three leads must be connected. These three

leads are color coded. The red wire is 6-24 VDC posi-

tive, the black is negative, and the white wire is the sig-

nal lead.

2 of 4

10 5

Diameters Diameters

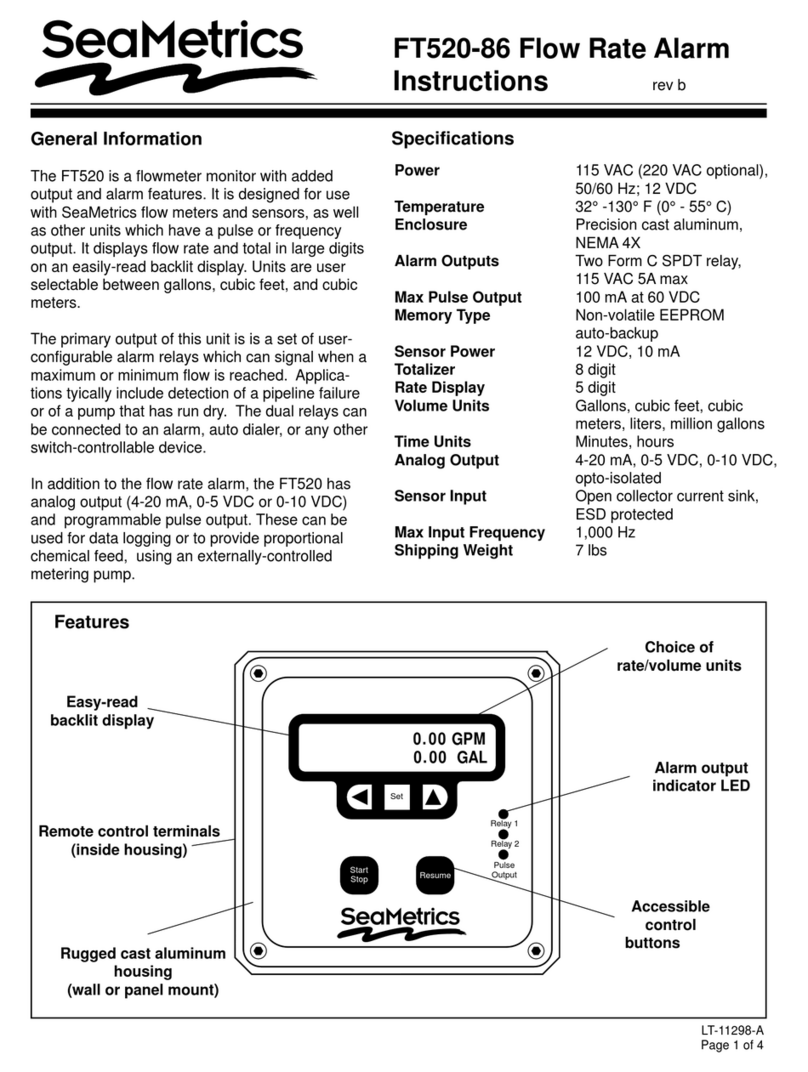

Red (+)

White (SIG)

Black (-)

These water meters are not recom-

mended for installation downstream of

theboilerfeedwater pump whereinstal-

lation fault may expose the meter to

boilerpressureandtemperature.Maxi-

mumrecommendedtemperatureis 130ºF (Plastic),

200ºF (Metal).

!

IP80 Series Connections

In the larger sizes, the length provided is less than ten

diameters upstream and five downstream. It is not ad-

visable to connect directly to the end of these fittings

withaflow-disturbingdevice such as a valve or elbow. If

possible, straight pipe should be added to these fittings.

A PVCfittingisusually installed by solvent welding. The

stainless steel and brass meter fittings have female pipe

threads,requiringtheappropriatemalethreadedfittings.

Saddle fittings (size 3" and above) require a hole to be

cut in the pipe. The recommended hole size is 1-3/4".

BEST

Okay, if no air in pipe

Okay, if no sediment

in pipe.

K-factor. If the IP80 Series meter is ordered with its

fitting, the meter is factory calibrated in the fitting. A K-

factor (meter factor) is indicated on the side of the fit-

ting. This represents the actual number of pulses per

gallon the meter produced during the factory flow test.

This number can entered into an FT415/420 or FT5210

flow indicator to make it read properly. If a pulse divider

is being used, the K-factor is the starting point for calcu-

lating the divider number.

!

Caution: Never remove the u-

clip retainer when the pipe is

underpressure. Alwaysremove

pressure from the pipe before

attempting to remove the meter.

Removal under pressure may result in damage

or serious injury.