PipingRequirements.Standard fittings arefemaleNPT.

If the piping connected to the meter is metallic, care

should be taken not to overtighten. Straight pipe of at

least five diameters upstream of the meter is recom-

mended. Vertical, horizontal, or inverted (lens down)

installations are all acceptable.

Repair

Rotor Replacement. There is only one moving part to

thismeter. Thebearingsaremadeofruby,whichrarely

wears out, and will not need replacement unless they

have been physically damaged by severe shock. The

shaft is integrally molded into the rotor, and shaft and

rotor are replaced as one part. To replace the rotor,

remove all pressure from the meter. Then remove the

fourscrews which hold thelens (or cover) inplace. Lift

the lens, then remove the rotor. When putting in the

new rotor, be sure that the end of the shaft is started

into the bearing before the lens is put into place.

When putting on the lens, be sure that the shaft is

also started into the upper bearing before lower-

ing the lens into place. If any resistance is met

when the lens is replaced, the shaft is not started

into one of the bearings. Check that the lens o-

ring is also in place, then replace the four screws

and tighten.

Sensor Replacement. The sensor ordinarily doesnot

need replacement unless it is electrically damaged. If

replacement is necessary, unthread the sensor by

hand. Thread the replacement sensor in and tighten

by hand.

Installation

Field Replacement of Sensor

2 of 4

(BLACK) Power (-)

(WHITE) Signal

(RED) Power (+) 6-24 VDC

SPX sensor connection

Warning: This meter has low-

friction bearings. Do not at any

time test operation of the meter

with compressed air. Doing so

will subject it to rotational

speeds many times those for

which it was designed, and will certainly damage

the rotor, shaft, and/or bearings.

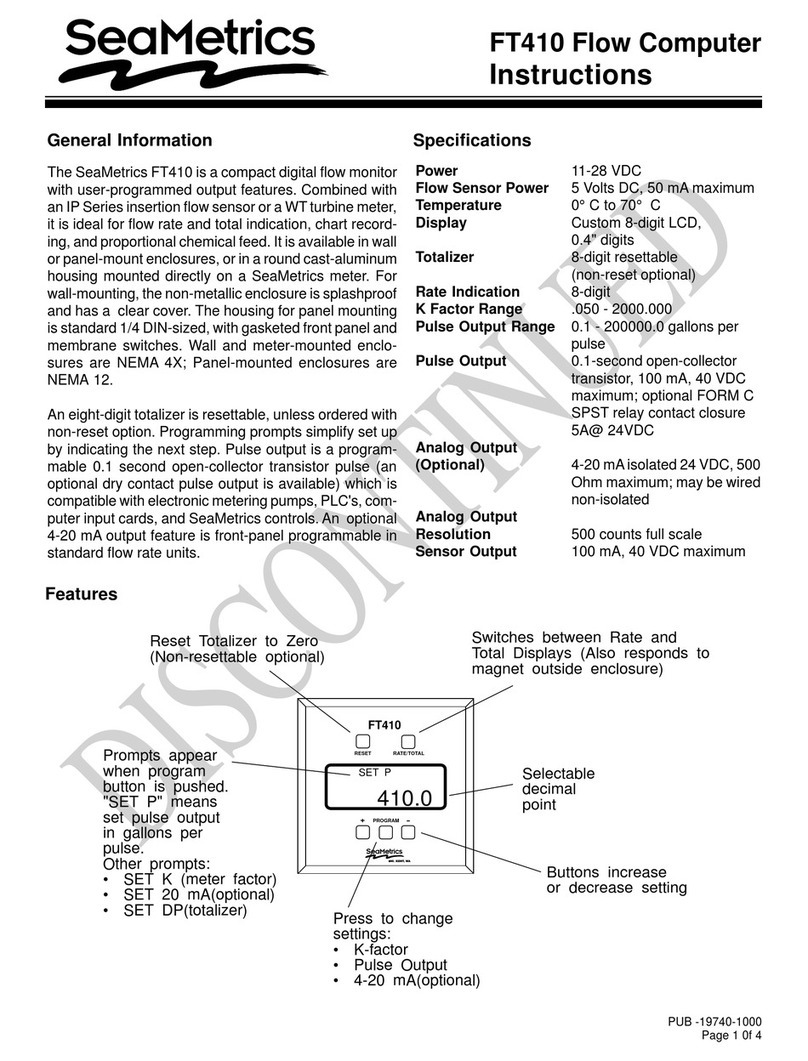

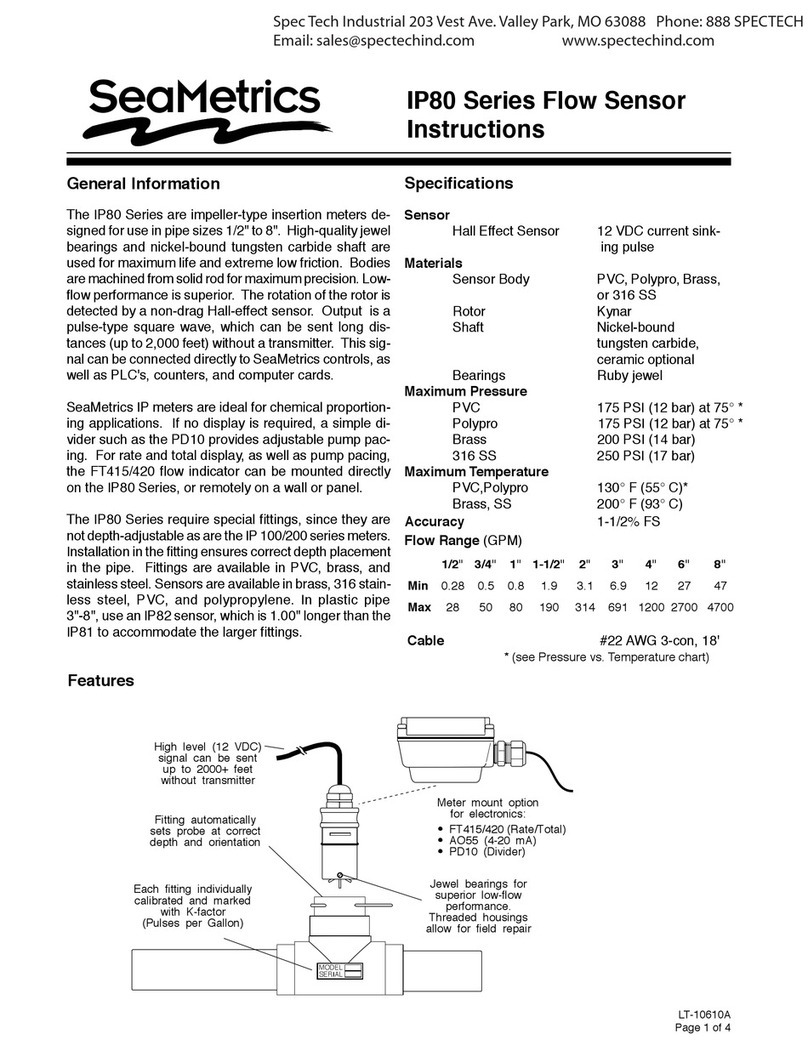

Electrical Connections. There are three conductors to

the sensor, two for positive and negative power and one

for the signal. See the diagram below for color coding.

K-factor on

model/serial

label on back

Nominal K-factor