PUB -19120-0999

Page 1 of 2

General Information

Specifications

Materials

Body & Cap Cast iron, epoxy coating

Turbine & Insert Engineered thermoplastic

Shafts Tungsten carbide

Bearings Sapphire

Pressure Up to 150 PSI working

pressure

Temperature 120°F

Accuracy ±1-1/2% of reading, +/- 1% of

full scale

Reed Switch 100 mA at 24V max.

Flow Range (GPM):

WP Turbine Meter

Instructions

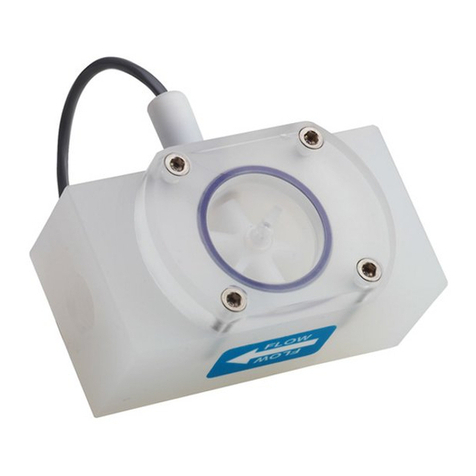

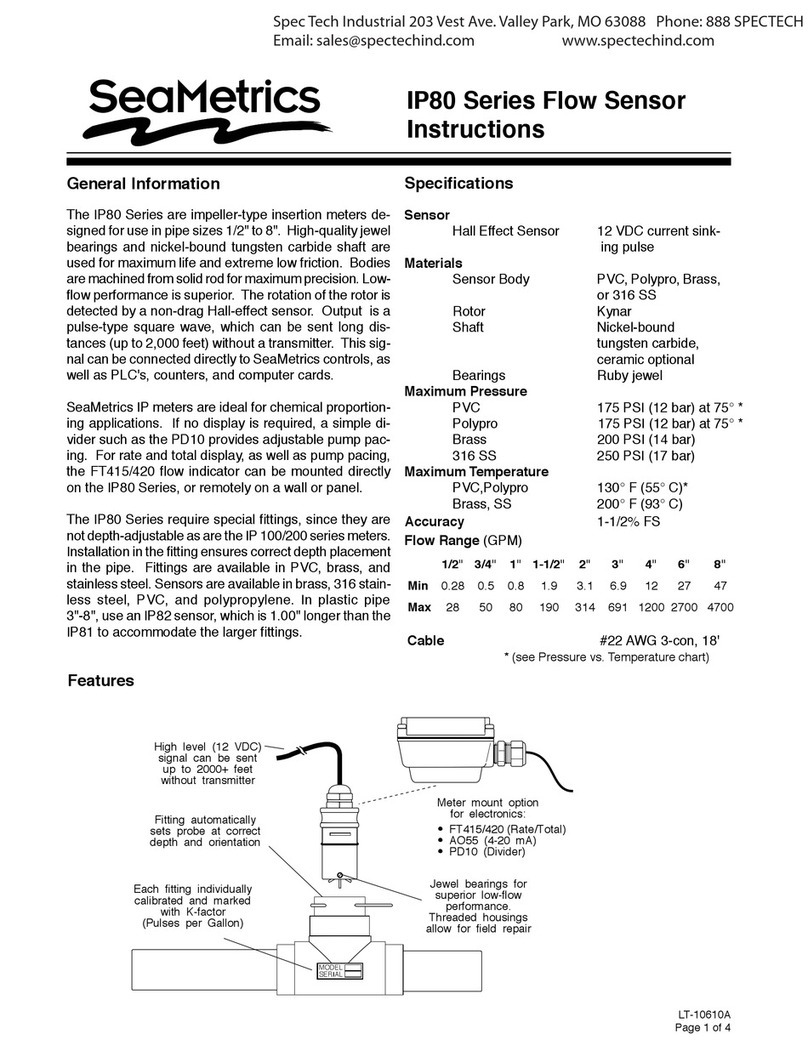

WP Series turbine meters are dry-register mechanical

totalizers which use a coated ductile iron body for du-

rability. They provide a very high flow capacity with low

head loss. The versatility of these meters is greatly

enhanced by their sensor system, which uses built-in

magnets and external slots on the register.This allows

factory or field installation of low-cost reed switch sen-

sors for a wide variety of water treatment, telemetry,

and control applications. Typically, WP Turbine Meters

are used for applications where the need is for both a

high-accuracy non-powered flow meter (for account-

ing) and a field selectable output pulse for control pur-

poses.Someofthemorecommonapplicationsinvolve:

• driving externally-paced electronic metering

pumps or water treatment controls.

• Multiple switch positions

• optional factory installation of multi-pole mag-

nets (allows for a number of different pulse

rates).

Size Min. Max Max.

Flow Cont. Flow Flow

2" 2.5 150 300

3" 2.6 400 650

4" 4.0 550 1100

6" 11.0 1000 1850

8" 18.0 1600 2850

Installation

The following installation recommendations are

adapted from theAmerican Water Works Manual M6,

and will result in the best meter life and accuracy.

Piping Conditions. Itisrecommended that the meter

be installed with at least ten diameters of straight pipe

upstreamandfivediametersdownstreamfromelbows,

tees,crosses, valves, and other fittings. Ifless straight

pipe is available, or if debris are likely to go through

the meter, installation of a standard plate-type strainer

directly upstream is recommended. If a basket-type

strainer is used, it should be located at least five diam-

eters upstream.Avoid conditions of trapped air or par-

tially-filled pipe. This can occur when there is low flow

and open discharge near to the meter.

Flanges. Pipe flanges can be any standard 150 lb.

drilling, flat or raised face. Partial or full-face gaskets

may be used, but take care to insure that the gasket

does not protrude into the meter due to misalignment.

Adhering the gasket to the meter flange with gasket

adhesive is a good practice which will aid installation.

Position. WP Series are all-position meters, and can

be installed horizontally or vertically.

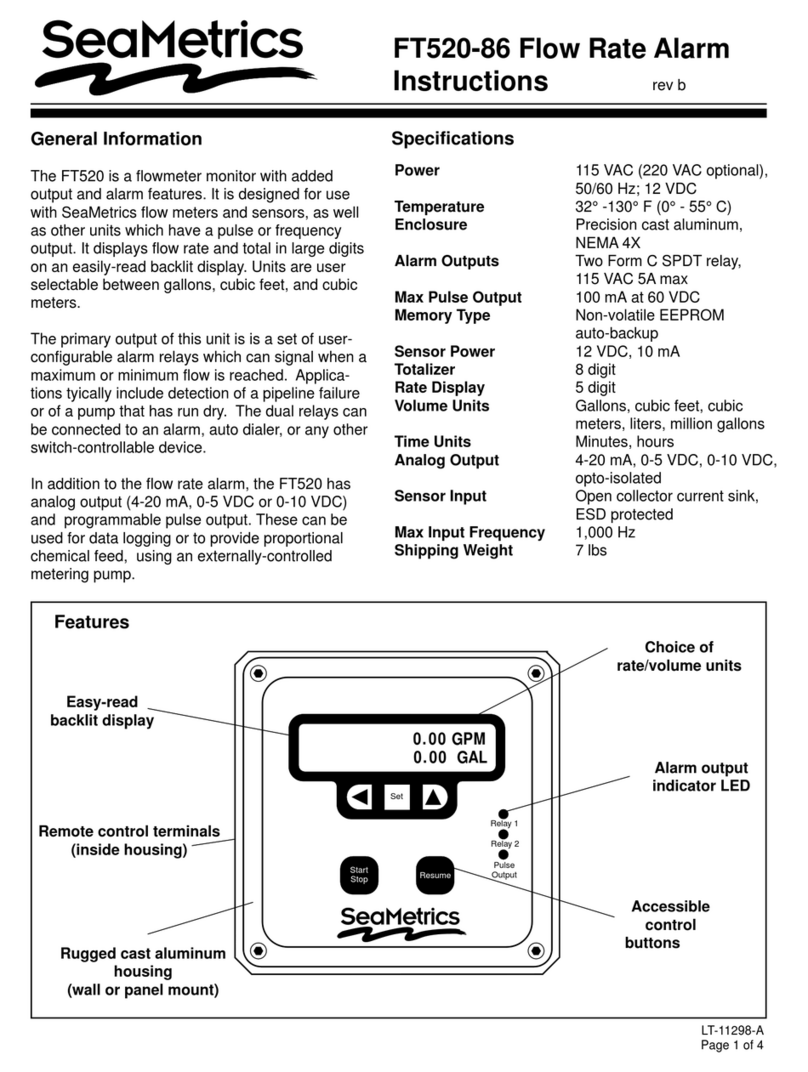

Connections. For the contacting head option, WP

meters use a meter-mounted reed switch to provide a

two-wire dry contact. See the Connections diagram

on page 2.

5x Dia.

10x Dia.