Seavo BioPack User manual

2

PRESENTATION OF MANUAL

INSTRUCTIONS FOR USE

CAUTION

Technical Name: Sealer

Trade Name: BioPack

Model: BioPack

Brand: Saevo

Manufacturer / Distribuitor:

Alliage S/A Indústrias Médico Odontológica

C.N.P.J. 55.979.736/0001-45 - Insc. Est. 582.002.897.114

Rod. Abrão Assed, Km 53+450m - Cx. Postal 782 CEP 14097-500

Ribeirão Preto - S.P. - Brasil

Phone +55 (16) 3512-1212

Technical Duties: Ricardo J. Ravaneli

CREA-SP: 5060714523

For improved safety:

Read and understand all the instructions contained in the Instructions for Use before installation

or operation of this equipment.

Note: The Instructions for Use must be read by all persons that operate this equipment.

3

INDEX

02 PRESENTATION OF MANUAL

04 IDENTIFICATION OF EQUIPMENT

06 MODULES, ACCESSORIES, OPTIONS AND MATERIALS OF CONSUMPTION

07 TECHNICAL SPECIFICATIONS

07 General features

08 Dimensions

09 Packing symbols

09 Product symbols

10 INSTALLATION OF EQUIPMENT

11 EQUIPMENT OPERATION

12 PRECAUTIONS, RESTRICTIONS AND WARNINGS

12 Transportation, storage and operation

12 Sensitivity to predictable environmental conditions in ordinary situations of use

12 Precaution and warnings “during the installation” of the equipment

13 Recommendations for preserving the equipment

13 Precautions and warnings “during the use” of equipment

13 Precautions and warnings “after” the use of equipment

13 Precautions and warnings during the “cleaning and disinfection” of equipment

14 Precautions in case of alteration in the functioning of equipment

14 Precautions to be adopted against foreseeable or uncommon risks, related to the deactivation

and abandoning of equipment

14 CORRECTIVE AND PREVENTIVE MAINTENANCE AND PRESERVATION

14 Additional procedures for reuse

14 Cleaning

14 Disinfection

15 Preventive Maintenance

15 Corrective Maintenance

16 UNFORESEEN EVENTS – SOLUTION OF PROBLEMS

16 EQUIPMENT’S WARRANTY

16 FINAL CONSIDERATIONS

4

IDENTIFICATION OF EQUIPMENT

Dear Customer

Congratulations. You have made a good choice when you decided to buy a SAEVO QUALITY product

comparable to the best products available in the World. This manual is a general presentation of

your product and it will give you important details to help you to solve possible problems.

Please, read it and keep this with you.

IDENTIFICATION OF PRODUCT

Technical Name: Sealer

Trade Name: BioPack

Model: BioPack

Brand: Saevo

5

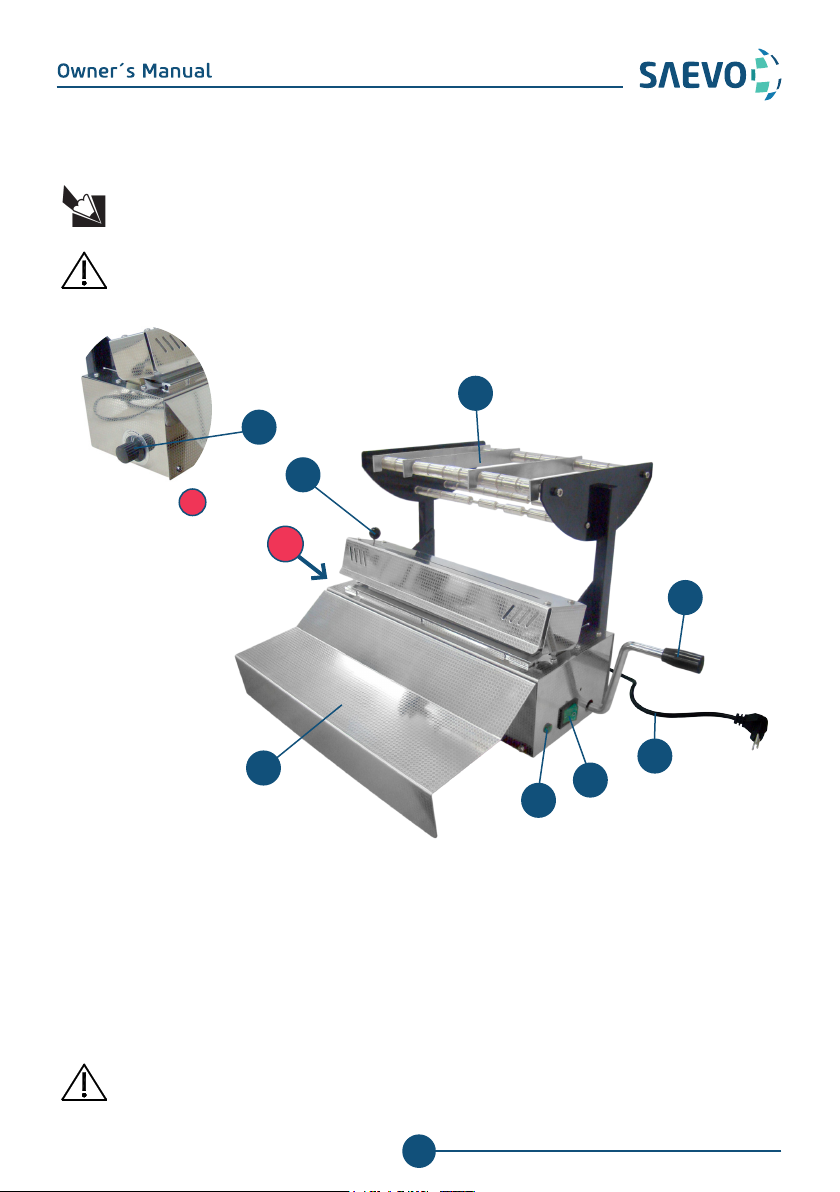

Descrição do Equipamento

BioPack Sealer is designed for a hermetic sealing of surgical grade papers of all sizes on the market,

ensuring the sterility of items since sterilization until the moment of use.

Simple and safe operation because:

It has isolated resistance, which inhibits the risk of burning the paper, even when the paper is not

removed from the sealing region and does not transmit heat to the surface of product.

It allows temperature adjustment for fast and safe sealing for each type of paper.

It is provided with a trail type paper cutter, which cuts both ways, allowing cutting the paper in the

desired size with no need to pass the knife twice.

The sealer’s closing is performed by hand lever with lock, which enables better control of sealing time

and allows sealing the surgical grade paper without using both hands of the operator.

Its body is made of stainless steel, which prevents corrosion, has high mechanical resistance and it its

easy to clean and disinfect, besides providing a pleasing appearance.

It has a removable front support plate that makes the product more compact and easy to transport.

Physical principle used by the sealing equipment

Equipment for sealing surgical grade paper through bars at high temperature that are pressed on it

with the help of a lever, which provides a hermetic sealing, it is also equipped with a double-edged

blade that allows an easy way to cut both ways, after sealing.

Indication of Equipment

It must be operated and utilized by specialized professional (certied professional, according to the

legislation of the country) and following the instructions of the manual. The operation of the equipment

required, for the professional, the utilization of correct instruments and it should to be in perfect

conditions of the use, and to protect the professional, the patients and others, in the eventual danger

situation.

Purpose of the equipment

Every article to be sterilized must be carefully packed and sealed for a safe process, the BioPack

Sealer has the purpose of sealing packaging in an ecient and hermetic way to a perfect packaging.

IDENTIFICATION OF EQUIPMENT

6

MODULES, ACCESSORIES, OPTIONS AND MATERIALS OF CON-

SUMPTION

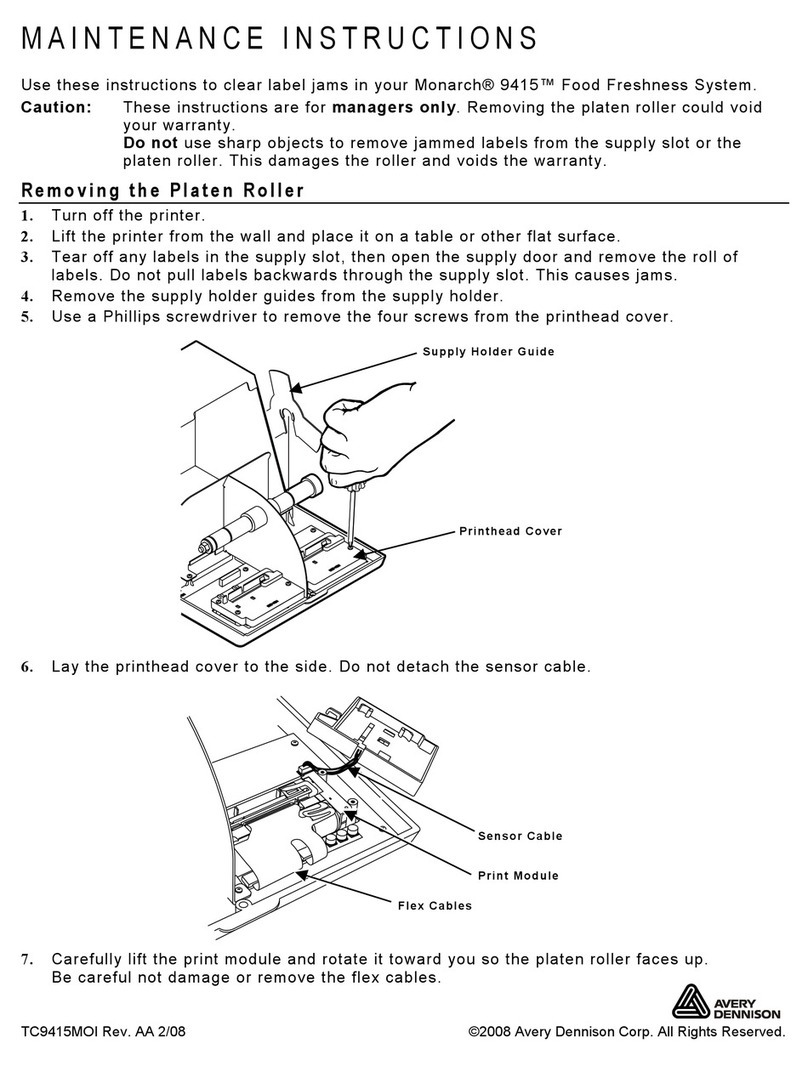

01 - Front Support plate;

02 - LED indicator;

03 - Power on/Power o switch;

04 - Power input cable;

05 - Operating lever;

06 - Lock;

07 - Knife handle;

08 - Temperature adjustment switch.

03

04

02

05

01

08

07

06

The materials used to produce the equipment are Biocompatible.

The use of any part, accessory or material not specied or provided in these instructions is of

entire responsibility of the user.

The contents of this page are of an informative nature, the equipment being able to dier

from that illustrated. So, upon acquiring the product check the technical compatibilty

between equipment, coupling and accessories.

a

a

side view

7

TECHNICAL SPECIFICATIONS

Operation mode

Continuous

Power supply voltage

127V~: 110V~ - 140V~ / 220V~: 198V~ - 240V~

Frequency

50/60 Hz

Potency for resistance

127V~ / 220V~ = 250W

Power

570 VA (127 V) / 460 VA (220 V)

Rated current

2,1 A (220 V)

4,5 A (127 V)

Fuses

2,5 A (220 V)

5 A (127 V)

Sealing area

260mm

Width sealing

10mm

Support rollers (maximum length)

275mm

External housing

Stainless steel

Temperature (heating system)

The heating system can reach to 300Deg C maximum.

But we have installed temp. protector to limit the heating temp. at max. 220Deg C.

Net weight

6,40 Kg

Gross weight

8,26 Kg

General features

8

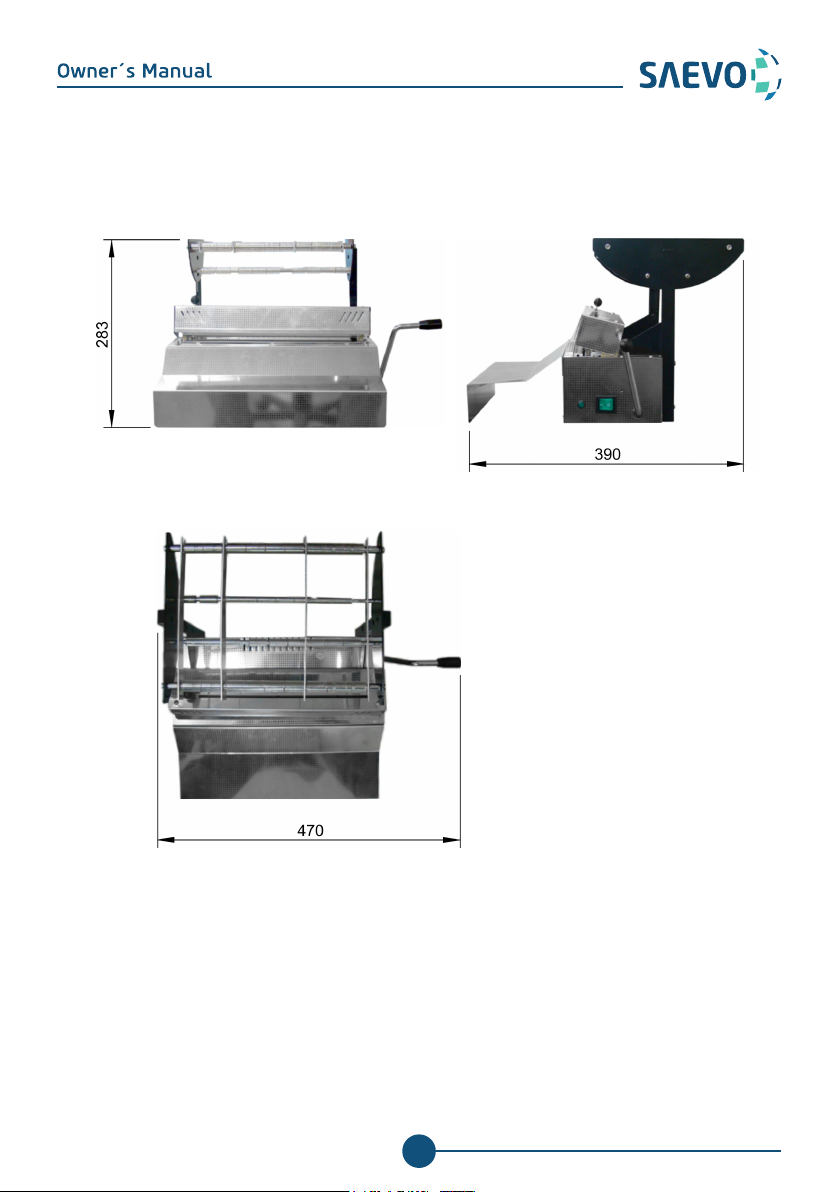

Dimensions (mm)

TECHNICAL SPECIFICATIONS

9

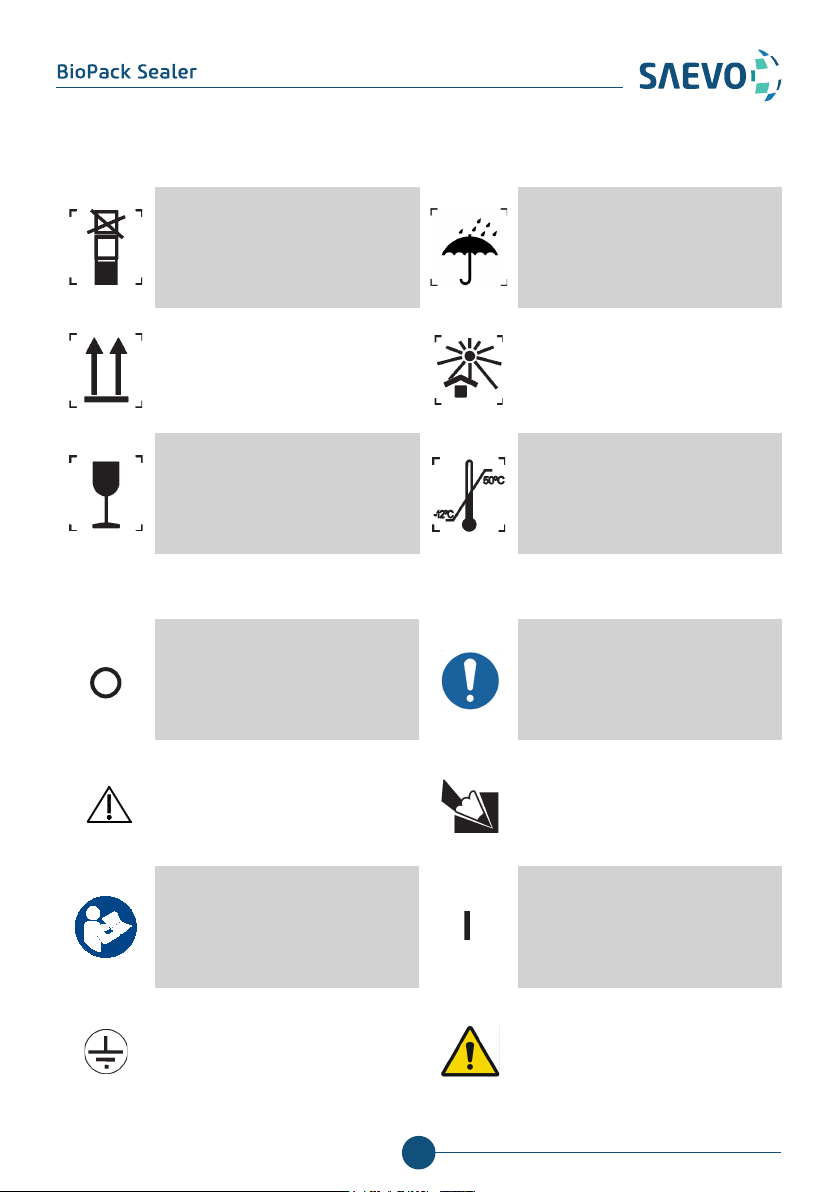

Packing symbols

Product symbols

It determines the maximum

quantity of boxes which can be

stacked during transportation and

storage “as per packaging”

Packing to be transported and /

or stored avoiding humidity, rains

and wet oor

Packing to be transported and / or

stored with the harrows up

The packing must be stored and

transported away from direct sun

light exposure

Packing to be transported and / or

stored with care (should not suer

drop and neither receive impact)

Temperature limit for the packing

to be stored or transported

Turned o General sign for mandatory action

Attention:

Check the working instructions

Note:

It indicates useful information for

operation of the product

Refer to the instruction manual Turned on

Grounding (at several points of the

equipment) indicates the condition

of being grounded

General warning:

If the instructions are not properly

followed, the use can lead to

damage to the product, user or

patient

TECHNICAL SPECIFICATIONS

10

INSTALLATION OF EQUIPMENT

- This equipment shall only be able to be unpacked and installed by a Saevo authorized technician,

under penalty of losing the warranty, as only (s)he has the information, suitable tools and training

required to execute this task.

- Saevo bears no responsibility for damages or accidents caused by poor installation executed by

a technician not authorized by Saevo.

- Only after the equipment has been installed and duly tested by the authorized technician

representing Saevo, will it be ready to start work operations.

The installation of this equipment requires the necessity of specialized technical assistance

(Saevo). Ask for the presence of a Saevo representative technician at the nearest seller,

or through the Saevo Service Center: + 55 (16) 3512-1212.

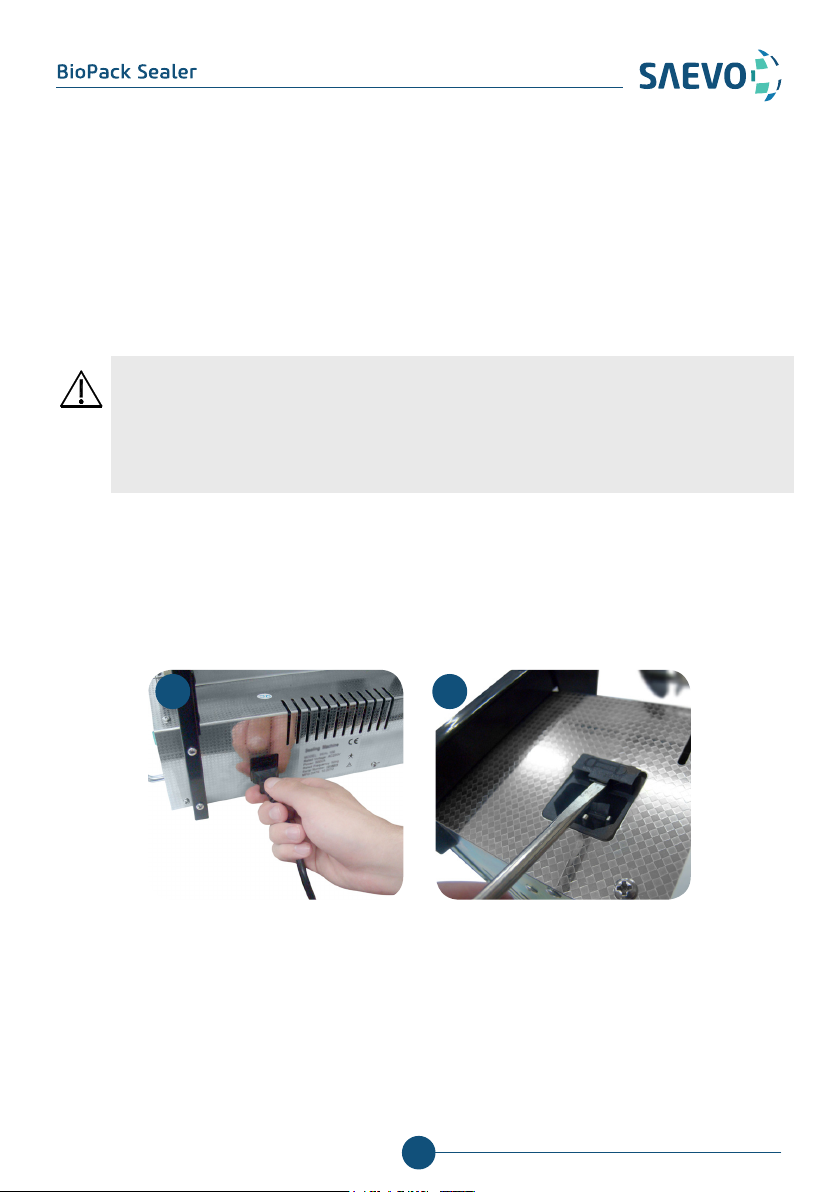

Moving parts installation

- Put the front support plate (01) into the Sealer, fitting the rip to thes upports (A).

- Fit the operating lever in the vertical position (05), on the sdie of the Sealer (B).

- Connect the Power input cable (04), to the connection behind the Sealer (C).

A B C

11

EQUIPMENT OPERATION

Press the key (03) to power the equipment on, the LED indicator will light up (02).

Set the temperature adjustment switch (08) between ranges 3 and 4.

Put the surgical grade paper on the scroll bars, by positioning the locks (06) so as to better accommodate

it according to its size.

Wait until the LED indicator turns o, indicating that the Sealer has reached the selected temperature.

Pass the surgical grade paper behind and between the pressure and sealing bars, so that the paper siding

is upside down and the plastic siding is upwards.

Pull the surgical grade paper forward suciently to encapsulate the instruments.

Operate the lever (05) until it locks and hold it for approximately 4 seconds. Using the handle (07) quickly

pass the knife in the direction of the paper (the knife cuts in both sides), deactivate the lever (05) and

remove the surgical grade paper cut and sealed.

Place the instruments to be autoclaved inside the paper, which is now with a sealed side.

Place the other end (open) of surgical grade paper between the sealing bars and operate the lever

again (08) until it locks and hold for approximately 4 seconds, deactivate the lever.

In the rst sealing, check the quality of it, if necessary, adjust the temperature by using

the adjustment switch. After the adjustment, the same material can be sealed without

new adjustments.

The sealing bar operation temperature bar is very high. Watch out not to touch it directly.

To start the operation it is necessary to wait for the LED indicator to turn o, the LED will

turn o and on again during the operation, these signs can be ignored.

12

PRECAUTIONS, RESTRICTIONS AND WARNINGS

Transportation, storage and operation

This equipment must be transported and stored observing the following directions:

- Avoid falls and impacts;

- Keep it dry, do not expose it to rain, water drops or wet oor;

- Keep it away from water and direct sunlight, and in it original wrapping;

- Don’t move it over irregular surfaces, protect it from rain and observe the maximum stack quantity

specied in the packaging;

Environmental condition for transportation or storage:

- Room temperature range for transportation or storage -29ºC to +60ºC.

- Relative humidity range for transportation or storage 20% to 90%.

- Atmospheric pressure range 500hPa to 1060 hPa (375 mmHg to 795 mmHg).

Environmental condition for storage (among the operations):

- Room temperature range for storage -10ºC a +55ºC.

- Recommended room temperature range +15ºC a +30ºC.

- Relative humidity range for storage 30% a 75%.

- Atmospheric pressure range 700 hPa to 1060 hPa (525 mmHg to 795 mmHg).

Environmental operation condition:

- Room temperature range for functioning +10ºC to +40ºC.

- Recommended room temperature range +21ºC to +26ºC.

- Relative humidity range for functioning 30% to 75%.

- Atmospheric pressure range 700 hPa to 1060 hPa (525 mmHg to 795 mmHg).

- Operation altitude: ≤2000m.

Attention

The Equipment maintains its condition of safety and ecacy, provided that it is maintained

(stored) as mentioned in this instruction of use. Thus, the equipment will not lose or alter

its physical and dimensional features.

Sensitivity to environmental conditions in normal situations of use

The equipment has been planned not to be sensitive to interference such as magnetic elds,

external electrical factors, electrostatic discharge, pressure or variance of pressure, provided that

the equipment is installed, maintained, clean, preserved, transported and operated as per this

instruction for use.

Precaution and warnings “during the installation” of the equipment

- The equipment should only be installed by Saevo authorized technical assistance or technicians.

- Check that the socket in which the device will be connected has a ground connection. According to

the ABNT standard, this is essential for the safe operation of the system;

- Position the equipment in a place where it will not get wet.

- Install the equipment in a place where it will not be damaged by the pressure, temperature, humidity,

direct sunlight, dust, salts.

- The equipment should not be submitted to inclination, excessive vibrations, or blows (including

during transportation and handling).

- This equipment was not planned for use in an environment where vapors, anesthetic mixtures

inammable with air, or oxygen and nitrous oxide can be detected.

13

Recommendations for preserving the equipment

Your Saevo equipment has been designed and developed according to the standards of modern

techology. Similarly to other kinds of equipment, it requires special care, which is many times

neglected due to several reasons and circunstances. Therefore, here are some important reminders

for your daily routine. Try to follow these simple rules, which will save you a lot of time and will

avoid unnecessary expenses once they start making part of your working procedure.

- The equipment should only be operated by duly enabled and trained technicians (Dental Surgeons,

Capacitated Professionals).

- If any maintenance should be required, only use services of the Saevo Authorized Technical

Assistance.

Precautions and warnings “during the use” of equipment

- This equipment must be installed so that it is level.

- Check the voltage of the equipment at the moment of executing the electrical installation.

- Before the rst use and/or after long interruptions from work such as vacations, clean and

disinfect the equipment.

Saevo shall not be responsible for:

- Use of the equipment diering from that for which it is intended.

- Damages caused to the equipment, the professional and/or the patient by the incorrect installation

and erroneous procedures of maintenance, diering from those described in these.

Instructions for use which come with the equipment or by the incorrect operation of it.

The sealing bar operation temperature bar is very high. Watch out not to touch it directly.

Precautions and warnings “after” the use of equipment

- Turn o the main switch of the dental set when it is not in use for an extended period of time.

- Always maintain the equipment clean for the next operation.

- Do not modify any part of the equipment. Do not disconnect the cable or other connections

without need.

Precautions and warnings during the “cleaning and disinfection” of equipment

- Before cleaning the equipment, turn o the main switch.

- Avoid spilling water or other liquids inside the equipment, which could cause short circuits.

- Do not use microabrasive material or steel wool when cleaning, or employ organic solvents or

detergents which contain solvents such as ether, stain remover, etc.

PRECAUTIONS, RESTRICTIONS AND WARNINGS

14

In order to avoid environmental contamination or undue use of the Equipment after it has become

useless, it should be discarded in the suitable place (as per the local legislation of the country).

Pay attention to the local legislation of the country for the conditions of installation and disposal of

residue.

Precautions to be adopted against foreseeable or uncommon risks, related to

the deactivation and abandoning of equipment

- If the equipment has any abnormality, check if the problem is related to any item listed in the

topic of unforeseen events (failures, causes and solutions). If it is not possible to resolve the

problem, turn o the equipment, remove the power supply cable from the socket and contact your

representative (Saevo).

Precautions in case of alteration in the functioning of equipment

CORRECTIVE AND PREVENTIVE MAINTENANCE AND PRESERVATION

Cleaning

Important: In order to execute cleaning or any type of maintenance, ensure that the equipment is

disconnected from the electrical network.

Additional procedures for reuse

The equipment can be reused in undetermined, i.e. unlimited, quantities, only needing to be cleaned

and disinfected.

Attention

- In order to prevent risks and damages to equipment, make sure that the liquid does not

enter into the equipment.

- To cleaning the equipment, using the damp cloth with a mild soap. The application of

other solvent-based cleaning products or sodium hypochloride isn’t recommended, because

they may damage the equipment.

PRECAUTIONS, RESTRICTIONS AND WARNINGS

Disinfection

- Use clean and soft cloth dampened in alcohol 70% to disinfection of the equipment.

- Never use corrosive disinfectants or solvents.

WARNING

For preventing contamination, use gloves and other protection systems during disinfection.

Even that, during the procedures, gloves are used, after removing gloves the hands must

be washed out.

15

CORRECTIVE AND PREVENTIVE MAINTENANCE AND PRESERVATION

Preventive Maintenance

The equipment must suer routinely measurements, following the current legislation of the country.

But, never with a period superior to 3 years.

For protecting your equipment, look for a Saevo’ technical assistance for periodic reviews as

preventive maintenances.

Attention

In case of the equipment presents any abnormality; check if the problem is related to some

of the listed items under the item Unpredictable (situation, cause and solution).

If it’s not possible to solve the problem, shutdown the equipment and demand the presence

of a Saevo’ technician from the nearest resale, or ask through the Attendance Service

Saevo: + 55 (16) 3512-1212.

Corrective Maintenance

Saevo states that the supplying of the circuits’ diagram, Part lists or any other information that

permits the technical assistance by the user, can be requested, since previously agreed between

the buyer and Saevo.

Replacement of fuses

Remove the power input cable (04) (D).

With the help of a screwdriver, release the fuseholder’s cover (E), afterwards replace the fuse.

WARNING: After replacing the fuses for the rst time, we recommend to reserve some fuses for

future replacements.

D E

16

Upon coming across any problem in operation, follow the instructions below to check and

repair the problem, and/or get in touch with your representative.

UNFORESEEN EVENTS – SOLUTION OF PROBLEMS

Imprevistos Provável Causa Soluções

Problem Probable cause Solution

- The equipment is not sealing. - Power input cable

disconnected;

- Switch turned o;

- Burned fuses;

-Bad adjustment of

temperature;

- Lack of pressure to the lever;

- Before the rst sealing, time

was not enough to reach the

adjusted temperature;

- Burned resistor.

- Connect the cable to the plug

- Check the voltage;

- Turn on the switch (03);

- Replace the fuses;

- Adjust the temperature on the

switch (08);

- When operating the lever, put

more pressure and hold it for

four seconds;

- When the Sealer is turned on,

before the rst sealing, wait

until the LED indicator turns o;

- Turn the equipment off

and contact the technical

assistance.

- Inappropriate cut. - Low speed while cutting;

- Knife does not cut anymore.

- Pull the knife’s handle quickly;

- Turn the equipment off

and contact the technical

assistance.

FINAL CONSIDERATIONS

Among the care you have to take with your equipment, the most important is regarding of the spare

parts replacement.

To ensure the lifetime of your device, only replace original spare parts from Saevo. They have the

assurance of the standards and technical specications required by the Saevo representative.

We call your attention to our authorized resellers’ chain. Only this chain will keep your equipment

constantly new, because it has trained technical assistant and specic tools for the correct

maintenance of your device.

Whenever you need, demand the presence of a Saevo’ technician from the nearest resale, or ask

through the Attendance Service Saevo: + 55 (16) 3512-1212.

EQUIPMENT’S WARRANTY

This equipment is covered by the warranty terms and norms contained in the Warranty Certicate

that accompany the product.

17

18

19

Table of contents

Popular Food Saver manuals by other brands

FoodSaver

FoodSaver V875 quick start

MUHLER

MUHLER MV-80N instruction manual

CASO DESIGN

CASO DESIGN 1344 Original operating manual

YUPACK Ausense

YUPACK Ausense FXJ-AT5050 Operating instruction

TREVIDEA

TREVIDEA G3 Ferrari EXPRESS VAC user manual

Super Sealer

Super Sealer REI-90F Operation & maintenance manual