SEC Signature DIR Manual

SEC Signature DIR Process Monitor

Instruction and Operation Manual

Sensor Electronics Corporation

12730 Creek View Avenue

Savage, Minnesota 55378 USA

(952) 938-9486 Fax (952) 938-9617

Part Number 71-3001 Version 011008

Sensor Electronics Corporation

Sensor Electronics Corporation (SEC) is an innovative manufacturer of fixed system gas detection equipment, for

combustible gases, oxygen and toxic gases.

Commitment

Our quality and service are uncompromising. We back each of our products with a two-year warranty on all materials and

workmanship. We offer technical support, user training and on-site service and maintenance of equipment to meet the

needs of our customers.

Gas Detection Service

Individually designed maintenance packages are available for specific customer needs. Service begins with verification of

the system installation that includes an initial system check and calibration. We then offer customer training programs (on-

site and at factory) to insure that technical personnel fully understand operation and maintenance procedures. When on-

the-spot assistance is required, service representatives are available to handle any questions or problems immediately.

WARRANTY

SENSOR ELECTRONICS CORPORATION (SEC) WARRANTS PRODUCTS MANUFACTURED BY SEC TO BE FREE

FROM DEFECTS IN WORKMANSHIP AND MATERIALS FOR A PERIOD OF TWO (2) YEARS FROM DATE OF

SHIPMENT FROM THE FACTORY. ANY PARTS RETURNED FREIGHT PRE-PAID TO THE FACTORY AND FOUND

DEFECTIVE WITHIN THE WARRANTY WOULD BE REPAIRED OR REPLACED, AT SEC'S OPTION. SEC WILL

RETURN REPAIRED OR REPLACED EQUIPMENT PRE-PAID LOWEST COST FREIGHT. THIS WARRANTY DOES

NOT APPLY TO ITEMS, WHICH BY THEIR NATURE ARE SUBJECT TO DETERIORATION OR CONSUMPTION IN

NORMAL SERVICE. SUCH ITEMS MAY INCLUDE:

CHEMICAL SENSOR ELEMENTS

FUSES AND BATTERIES.

WARRANTY IS VOIDED BY ABUSE INCLUDING ROUGH HANDLING, MECHANICAL DAMAGE, ALTERATION OR

REPAIR. THIS WARRANTY COVERS THE FULL EXTENT OF SEC LIABILITY AND SEC IS NOT RESPONSIBLE FOR

REMOVAL, REPLACEMENT COSTS, LOCAL REPAIR COSTS, TRANSPORTATION COSTS OR CONTINGENT

EXPENSES INCURRED WITHOUT PRIOR WRITTEN APPROVAL. SENSOR ELECTRONICS CORPORATION'S

OBLIGATION UNDER THIS WARRANTY SHALL BE LIMITED TO REPAIR OR REPLACEMENT OF ANY PRODUCT

THAT HAS BEEN RETURNED TO SENSOR ELECTRONICS CORPORATION FOR WARRANTY CONSIDERATION.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED,

AND ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF SENSOR ELECTRONICS CORPORATION

INCLUDING BUT NOT LIMITED TO, THE FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL SENSOR

ELECTRONICS CORPORATION BE LIABLE FOR DIRECT, INCIDENTAL, OR CONSEQUENTIAL LOSS OR

DAMAGE OF ANY KIND CONNECTED WITH THE USE OF IT'S PRODUCTS OR FAILURE TO FUNCTION OR

OPERATE PROPERLY.

Table of Contents

I. SPECIFICATIONS

II. GENERAL DESCRIPTION

Features

Theory of Operation

III. INSTALLATION

Mechanical

Electrical

IV. CALIBRATION / OPERATION

Zeroing

Warm Up

Normal

Spanning

Calibration Certification

V. PARTS LIST

VI. DRAWING SECTION

Figure 1 Dimensions/Wiring

Figure 2 Mounting

Figure 3 PC Link Wiring

Figure 4 Sensor Separation Kit

I. SPECIFICATIONS

Model: SEC Signature DIR Part Number: DIR011021000000

Measuring Range: EtO Channel:0-2000 milligrams/liter (maximum)

Factory calibrated to 0-1000 mg/l EtO

H2O Channel: 0-500 milligrams/liter (maximum)

Factory calibrated to 0-300mg/l H2O

Detection Method: Diffusion

Construction: Housing is anodized aluminum with sapphire optical windows.

Rating:CSA: Class 1, Division 1, Groups BCD

Accuracy: +/- 5% measured value or +/- 3% full scale (whichever greater)

Repeatability: +/- 3%

Operating Temperature Rating: +0C to +75C (maximum)

+32F to +167F (maximum)

Operating Voltage: 24 VDC. Operating range 18 to 32 VDC measured at the detector head.

Outputs (analog): 4-20 mA (Source type), max. 1000 Ohm load at 24 VDC supply voltage.

Output (digital): Interactive PC Link

Power Consumption at 24 VDC: 35 watts (Max)

Current Draw at 24 VDC: 1A (average)

Mechanical connection to sterilizer: ¾” NPT male

Electrical connection: ¾” NPT male

Weight: 30 ounces

Wire Connections: Red wire (+ 24 VDC)

Black wire (D.C. common)

Blue wire (4-20 output EtO)

Yellow Wire (4-20mA output H2O)

White wire (Calibration / digital interface)

Brown wire (Pressure Input 4-20mA)

II. GENERAL DESCRIPTION

The SEC Signature DIR Process monitor is a microprocessor based intelligent device that continuously and

simultaneously monitors levels of EtO and H2O in sterilization chambers.

The SEC Signature DIR Process monitor is a stand-alone device providing a dedicated 4-20 mA signal

corresponding to actual concentrations of ethylene oxide and a dedicated 4-20mA signal corresponding to the

actual concentration of H2O.

Features

Programmable Heater operates in Relative or Closed Loop Mode.

Continuous self-test automatically indicates a fault, with fail to safe operation.

A multi-layered filtering system protects optics from dirt and water ingress.

Straight optical path eliminates the need for mirrors, reflective surfaces or beam splitters thereby increasing

the stability and reducing the maintenance of the device.

Discourages condensation interference by internally heating optical chamber.

Standard 4 to 20 mA outputs (current sources).

Explosion proof housing designed for duty in harsh environments.

Smart Calibration AutoACcircuit.

Theory of Operation

The SEC Signature DIR Process monitor uses infrared absorption technology for detecting target gas

concentrations. Gases absorb infrared light only at certain wavelengths. The concentration of a gas can be

measured by the difference of two channels (wavelengths), a reference and a measurement channel. The SEC

Signature DIR Process monitor uses an infrared light source at one end and a dual channel receiver at the

opposite end. The dual channel receiver measures the intensity of two specific wavelengths, one at an

absorption wavelength and another outside of the absorption wavelength. The gas concentration is determined

by a comparison of these two values.

The multi channel receivers incorporate single wafer double filter technology with internal optical barriers. The

elements are perfectly matched resulting in overall stability and superior performance throughout the entire

temperature range. By using this multi channel receiver there is no need to use any special lenses or beam

splitters to achieve the dual measurement bands.

The SEC Signature DIR Process monitor utilizes a unique Automatic Analog Control circuit, the AutoACcircuit

(Patent Pending). The AutoACcontinuously makes adjustments to null out effects from temperature,

component drift, dirty optics, interferents and aging. These adjustments are made according to algorithms

derived from infrared gas absorption theory. The AutoACcircuit is continuously checking all unit operating

parameters. If any parameter goes out of tolerance, the AutoACcircuit sets a fault code appropriate to the

problem. The AutoACcircuit ensures that once the unit is spanned, it will remain accurate as long as the zero

is accurate. Simply calibrate (span one time) the unit with a specific amount of gas and the device will

repeatable track the gas concentrations in the chamber throughout the entire load cycle. The only ongoing

calibration that is necessary is an occasional zero.

The optical absorption efficiency of water vapor is a function of the chamber pressure. Higher chamber

pressures cause more absorption resulting in higher signal levels.

The H2O channel is designed to be accurate with pressure rise due to the vapor pressure of the H2O in the

chamber.

Pressure rise due to N2 EtO injections will cause higher H2O readings. Therefore, the H2O signal will be

accurate as long as the chamber contains only water vapor.

If accurate readings are required throughout the entire cycle, pressure compensation will be necessary.

Pressure compensation is achieved by adding the pressure compensation option and using a dedicated

absolute pressure sensor mounted close to the sensor. The 4-20mA output from the pressure sensor is

connected to the sensor’s pressure input wire.

III. INSTALLATION

Mechanical

The SEC Signature DIR Process monitor has a ¾” male NPT threaded connector for installing the device on the

sterilizer. Ideally the device can be installed on the recirculation line (see Figure 4). The device is vacuum

tested at the factory to 1 inches of mercury absolute and pressure tested to 40 psi.

Electrical

The SEC Signature DIR Process monitor has a ¾” male NPT threaded connector (with 4 wires) for mounting the

detector to a junction box. SEC can provide a junction box for this purpose with terminals (see Figure 5).

A user-supplied junction box can also be used, providing it has the appropriate sized NPT conduit entries. This

junction box must be suitable for use in the application and location in which it is being installed.

Wiring connections

Red wire: 18 to 32 VDC

Black wire: DC negative (common)

Blue wire: 4 to 20 mA output EtO

Yellow wire: 4 to 20 mA output H2O

White wire: Smart Calibration Wire (data wire)

Brown wire: Pressure Input (4-20mA)

Refer to Figures 2 and 3 for general wiring details.

Insulator

The SEC DIR Signature internal temperature should be at least 6º C warmer than the process temperature.

Temperature rise can be adjusted by adjusting heater level. The internal temperature of the Signature DIR can

be adjusted and monitored using the SEC IR PC LINK software package. If more temperature rise is needed

with heater at full power, it may be necessary to insulate sensor.

IV. OPERATION

Warm-up

When power is applied to the detector, it enters a one (1) minute warm-up mode in which time it performs

diagnostic checks and allows the sensor to stabilize before beginning normal operation. The current output

during this period is 0.8 milliamperes. At the end of the warm-up period with no faults present, the detector

automatically enters the normal operating mode. If a fault is present after warm-up, the detector current output

will indicate the fault (see chart above).

Normal

In the normal operating mode, the 4 to 20 mA signal levels correspond to the detected gas concentrations. The

device continuously performs self diagnostics, checks for calibration requests and displays operating status (see

table).

Calibration

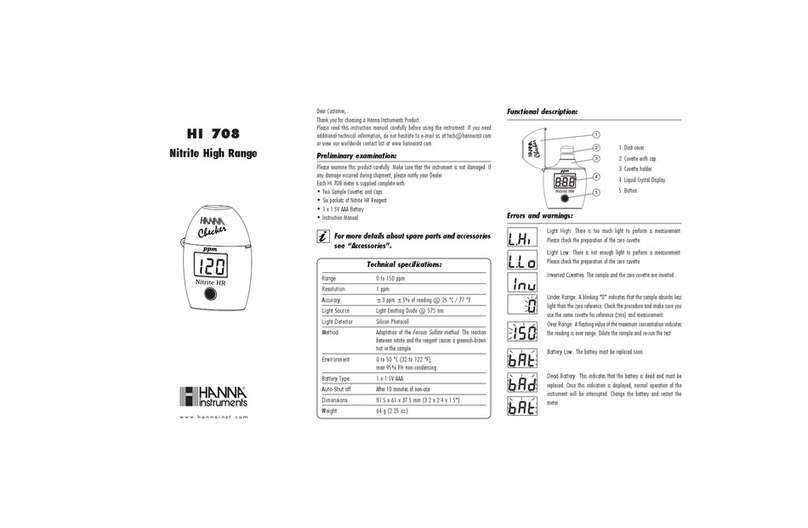

Calibration operations and Parameter download are accomplished via the Sensor’s white wire.

White wire is connected to Data Translator (SEC IR PC Link P/N 1420636)

Data Translator is connected to PC via serial port. Operating from USB port requires a USB to serial converter.

Commands are issued from PC (Software Package Supplied by SEC)

The software is compatible with most versions of MicrosoftWindows

Note: For best accuracy, the unit should be powered up for at least 1 hour before any calibration operation.

Zeroing

EtO (Channel 0)

Zeroing should be performed:

When unit is installed on chamber

If Sensor doesn’t return to zero between cycles

If Sensor shows abnormally high or low concentration readings during EtO exposure.

Annually (more often if the load material is dusty or oily)

Procedure:

After chamber evacuation, water injection and dwell:

Move cursor to “Zero EtO Channel” using “Up/Down” arrows

<enter>

Zero Channel 0 ? (Y/N)

<Y><enter> will initiate Zero Operation

The EtO output goes to 2.2mA while Zeroing.

A successful Zero will result in 4.0mA

An unsuccessful Zero will result in a 4-20mA fault level. (<4mA) See Status table.

H2O (Channel 1)

Zeroing should be performed:

When unit is installed on chamber.

If sensor shows abnormally high or low concentration readings during H2O exposure.

Annually (more often if the load material is dusty or oily)

Procedure:

It is very difficult to remove water from the chamber. Even after several N2 washes and evacuations, enough

water can remain in the chamber to skew the zero. The best way to ensure an accurate zero is to apply dry N2

directly to the sensor either in the chamber or removed from the chamber.

Procedure:

Move cursor to “Zero H2O Channel” using “Up/Down” arrows

<enter>

Zero Channel 1? (Y/N)

<Y><enter> will initiate Zero Operation

The H2O output goes to 2.2mA while Zeroing.

A successful Zero will result in 4.0mA

An unsuccessful Zero will result in a 4-20mA fault level. (<4mA) See Status table.

Note: For best accuracy, the unit should be powered up for at least 1 hour before any calibration operation.

Note: When calibrating with the sensor removed from chamber, best accuracy is obtained by calibrating with the

sensor in the same physical orientation as when installed on chamber.

Current Output and Corresponding Status Table

The 4 to 20 mA outputs are non-isolated current sources.

Current Output Status .

4-20 mA Normal measuring mode

0.0 mA Unit Fault

0.2 mA Reference channel fault

0.4 mA Analytical channel fault

0.8 mA Unit warm up

1.0 mA Optics fault

1.2 mA Zero drift fault

1.6 mA Calibration fault

2.0 mA Unit spanning

2.2 mA Unit zeroing

4.0 mA Zero gas level

20 mA Full scale

Spanning

Spanning is only required to establish measurement range. Spanning teaches the unit what 50% of full scale

looks like (25% for H2O).

The unit is designed to be spanned at the typical empty chamber operating concentration. The fact that the span

value becomes 50%(25%) of full scale gives the unit over-range capability. This is important since certain loads

will cause the EtO concentration (in the headspace) to spike much higher than the theoretical concentration right

after injection. Over-range capability allows the unit to track concentrations through the spikes.

The span will only be as accurate as the Zero point. Spanning should always be proceeded with Zeroing.

(Example) When the EtO channel is spanned at 520 mg/l, full scale range is 0 to 1040 mg/l.

When the H2O channel is spanned at 75 mg/l, full scale range is 0 to 300 mg/l.

EtO(Channel 0)

The EtO channel is factory coarse spanned with ethylene span gas to a range of 0-1000 mg/l EtO.

Spanning should be performed:

If abnormally high or low EtO readings are observed during EtO exposure and re-zeroing didn’t

resolve the problem.

If the unit needs to be ranged for a different full scale concentration.

Procedure:

Perform Zero Operation.

Introduce desired EtO concentration into chamber and let equilibrate.

Move cursor to “Span EtO Channel” using “Up/Down” arrows

<enter>

Span Channel 0 ? (Y/N)

<Y><enter> will initiate Span Operation

The EtO output goes to 2.0mA while Spanning.

A successful Span will result in 12mA

An unsuccessful Span will result in a 4-20mA fault level. (<4mA) See Status table.

H2O(Channel 1)

The H2O channel is factory spanned with 20.5 % volume CO2 (balance N2) span gas to a range of 0-300 mg/l

H2O.

Spanning should be performed:

If abnormally high or low H2O readings are observed during H2O exposure and re-zeroing didn’t

resolve the problem. (Be aware of pressure response that could be skewing your readings)

If the unit needs to be ranged for a different full scale concentration.

Procedure:

Perform Zero Operation.

Introduce desired H2O concentration into chamber and let equilibrate.

Move cursor to “Span H2O Channel” using “Up/Down” arrows

<enter>

Span Channel 0 ? (Y/N)

<Y><enter> will initiate Span Operation

The H2O output goes to 2.0mA while Spanning.

A successful Span will result in 8 mA

An unsuccessful Span will result in a 4-20mA fault level. (<4mA) See Status table.

Note: For best accuracy, the unit should be powered up for at least 1 hour before any calibration operation.

Heater Adjustment

Relative Mode (Recommended)

In the Relative Mode, a constant power level is applied to the heaters. This will give the best accuracy over

process temperature variations. There are 10 fixed power levels; 0=heaters off, 10=Full Power.

The sensor temperature is a function of process temperature, mounting surface temperature, and ambient

temperature. Therefore, an empirical method is the best way to set the heater level.

Procedure:

To adjust heater, select “Heater Level”

The heater mode will be displayed (Relative)

Followed by the current Heater Level

Followed by “Change Power Level? (Y/N)”

<Y><enter>

“New Heater Level: “

Enter Heater Level and <return>

Closed Loop Mode

In the Closed Loop Mode, a target temperature set by user and the heater level is automatically adjusted to

keep the sensor temperature at the target temperature.

Procedure:

To adjust target temperature, select “Heater Level”

The heater mode will be displayed (Closed Loop)

Followed by the current Target Temp

Followed by “Change Target Temp? (Y/N)”

<Y><enter>

“New Target Temp: “

Enter Target Temp and <return>

Calibration Certification

Document: 7305 Rev. 1.001

Customer:

Sales Order:

Ship Date:

SEC

Signature

DIR Serial #

Channel

Cal Date

Cal Gas Value

Span Hex Value

Check Sum

(Linearization)

Firmware Rev

Channel 0

EtO

70% Volume Ethylene

+/-2% NIST Traceable

Channel 1

H2O

20.5% Volume CO2

+/-2% NIST Traceable

Calibration Procedure: 7304

Test Procedure: 7302

TEST PERSON SIGNATURE PRINT NAME DATE

__________________________ _______________________ ____________

70%V/V Ethylene generates a unit response approximately equivalent to 500 mg/l ethylene oxide. This results in a

range of 0-1000mg/l.

20.5%V/V CO2 generates a unit response approximately equivalent to 75 mg/l water vapor. This results in a range of

0-300mg/l.

Best accuracy requires the unit to be zeroed and spanned in-chamber at operating temperature and humidity, using

typical concentrations of EtO and H2O for spanning.

Example of Calibration Certification

Each SEC Signature is shipped with a completed Calibration Certification.

V. PARTS LIST

Part Number Description

DIR011021000000 SEC Signature DIR Process monitor

142-1750 SEC DIR PC Link Kit

190-10001 SEC 2001 Explosion proof junction box

142-0852 Replacement Screen

142-0701 Replacement Filter

VI. DRAWING SECTION

Figure # Title

Figure 1 Dimensions/Wiring

Figure 2 Mounting

Figure 3 PC Link Wiring

Figure 4 Sensor Separation Kit

Figure 1

Figure 2

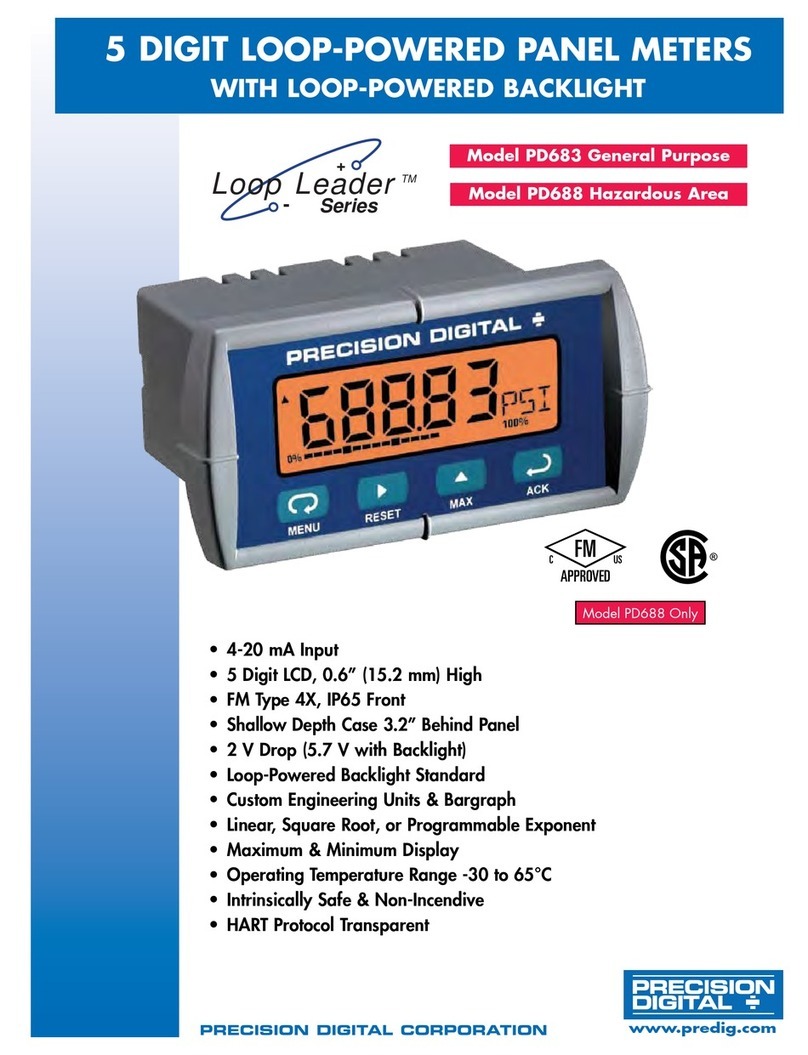

Chart Recorder

PLC, DAS, DCS, DVM

(Any control or monitoring system that accepts a 4-20 mA or 0-5 VDC signal)

Figure 3

SEC IR PC LINK

AC

Power

EtO/H20

MONITOR

Figure 4

Table of contents

Other SEC Measuring Instrument manuals