SECOLink P16 User manual

Wiring manual

Intruder alarm system SAFETY WARNINGS

The device must be installed in a place with limited access.

Pleaseactaccordingtoyourlocalrulesanddonotdisposeofyourunusablealarmsystemoritscomponents withotherhousehold

waste.Thisproduct utilizationinEUiscoveredbyEuropeanDirective 2002/96/EC.

ThedevicemustbeconnectedtoanACpowersupplywithProtectiveEarthing.Cablecoloursmean:PhaseorLiveline(L)- black

or brown cable, Neutral line (N) - blue cable, Protective Earth line (PE) - green cable with a vertical yellow dash. Double isolated

2

cableswithminimumcross-sectionalareaof 0,75mm for230Vpowersupplymustbeused.

Thedeviceusestwopowersupplies:mainandback-up.

2V,7Ah/20HRcapacity,rechargeablehermeticallysealedLead-Acidbattery.

Mainpowersupply:a power transformer with:

-primarywinding:~230V,50Hz;

-secondarywinding:~20V,1.5A,50Hz.

Back-uppowersupply:1

SECOLINKintruderalarmsystem iscompliantwith EN60950-1safetyrequirements.

PowersuppliesdescribedabovemustcomplywiththeEN60950-1safetyrequirements.

All devices being connected with the alarm system (sirens, detectors, computer for programming and etc.) must comply with

EN60950-1safetyrequirements.

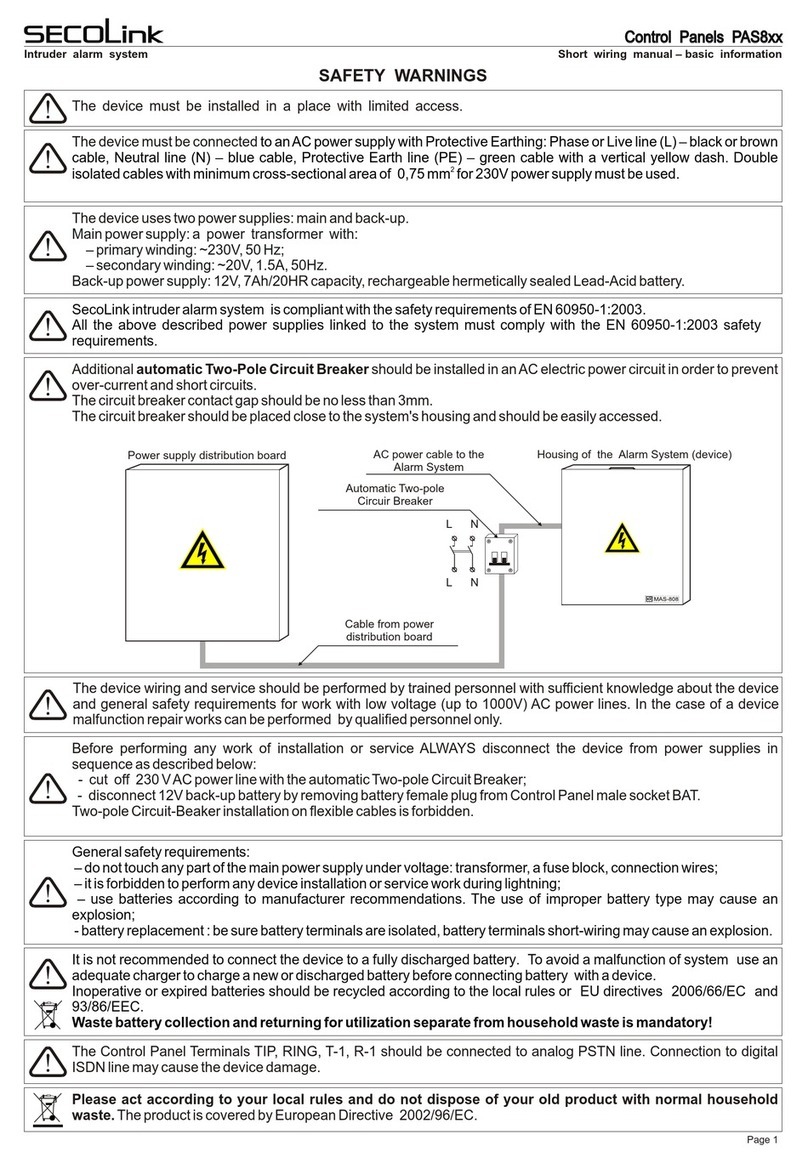

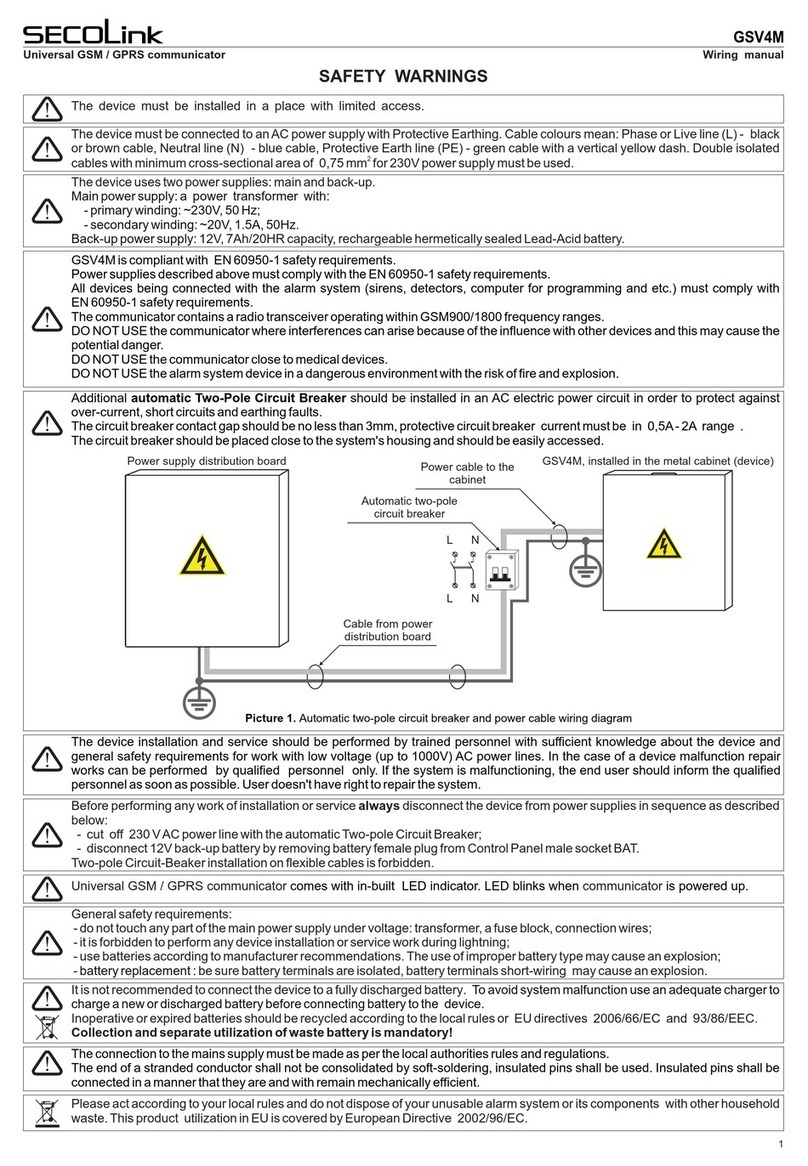

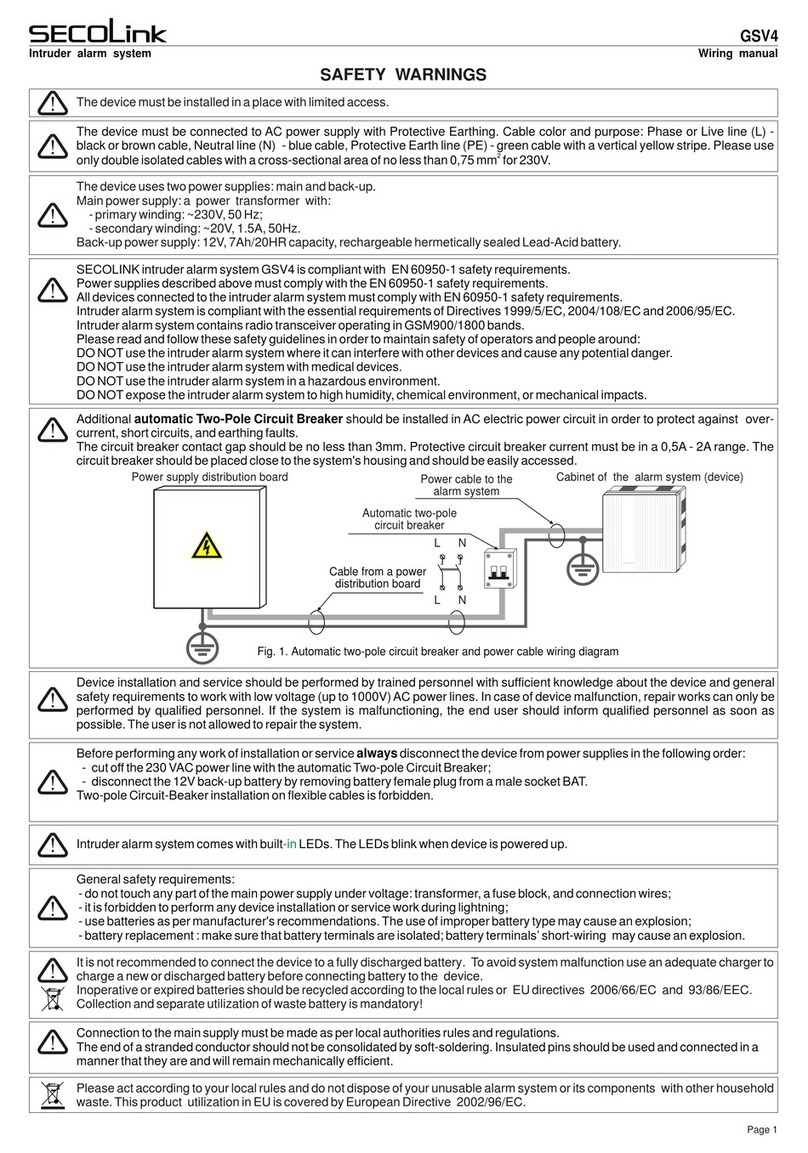

Additional automatic Two-Pole Circuit Breaker should be installed in an AC electric power circuit in order to protect against

over-current,shortcircuitsandearthingfaults.

Thecircuitbreakercontactgapshouldbenolessthan3mm,protectivecircuitbreaker currentmustbe in 0,5A-2A range .

Thecircuitbreakershouldbeplacedclosetothesystem'shousingandshouldbeeasilyaccessed.

Beforeperforminganyworkofinstallationorservice always disconnect thedevice frompowersuppliesinsequenceasdescribed

below:

- cut off 230VACpowerlinewiththeautomaticTwo-poleCircuitBreaker;

- disconnect12Vback-upbatterybyremovingbatteryfemaleplugfromControlPanelmalesocketBAT.

Two-poleCircuit-Beakerinstallationonflexiblecablesisforbidden.

Generalsafetyrequirements:

-donottouchanypartofthemainpowersupplyundervoltage:transformer,afuseblock,connectionwires;

-itisforbiddentoperformanydeviceinstallationorserviceworkduringlightning;

-usebatteriesaccordingtomanufacturerrecommendations.Theuseofimproperbatterytypemaycauseanexplosion;

- besurebatteryterminalsareisolated,batteryterminalsshort-wiring maycauseanexplosion.batteryreplacement:

Itisnotrecommendedtoconnectthedevicetoafullydischargedbattery.

Inoperativeorexpiredbatteriesshouldberecycledaccordingtothelocalrulesor EUdirectives 2006/66/EC and 93/86/EEC.

Collectionandseparateutilizationofwastebatteryismandatory!

Toavoidsystemmalfunctionuseanadequatechargerto

chargeanewordischargedbatterybeforeconnectingbatterytothe device.

Theconnectiontothemainssupplymustbemadeasperthelocalauthoritiesrulesandregulations.

The end of a stranded conductor shall not be consolidated by soft-soldering, insulated pins shall be used. Insulated pins shall be

connectedinamannerthattheyareandwithremainmechanicallyefficient.

Power supply distribution board

Automatic two-pole

circuit breaker

L N

NL

Cable from power

distribution board

Power cable to the

alarm system

The PSTN communicator PSTP terminals TIP, RING, T-1, R-1 should be connected to analog PSTN line. Connection to digital

ISDN line may cause device damage.

The device installation and service should be performed by trained personnel with sufficient knowledge about the device and

general safety requirements for work with low voltage (up to 1000V) AC power lines. In the case of a device malfunction repair

works can be performed by qualified personnel only. If the system is malfunctioning, the end user should inform the qualified

personnelassoonaspossible.Userdoesn'thaverighttorepairthesystem.

Page 1

Control Panels P16, P32, P64

Cabinet of the alarm system (device)

Picture 1. Automatic two-pole circuit breaker and power cable wiring diagram

Alarmsystemmodulescomeswithin-built LEDindicator.LEDblinkswhenmoduleispoweredup.Anoptiontocheckisthesystem

ispoweredupornotcanbeapressofanykeyonkeypad.Ifsystemwaspoweredupthekeypadbacklightwilllastfor30seconds.

LAN800and VIDNETare designedtobe usedincouple witharouter whichisplaced inthesame room orpremises.It’sprohibited

toconnectLAN800orVIDNETdirectlyto WideAreaNetwork(MAN,WAN)orbuildingITinfrastructurecables.

DAT

COM

+12V

CLK

3.15A

P16

P32

P64

COM

+BELL

DAT

+AUX

CLK

COM

-PGM

+PGM

COM

Z2

Z6 +AUX Z7 COM Z8

Z1

ANT

R-1

T-1

RING

TIP

PSTP

For correct operation P series control panels

P16, P32, P64 (abbreviation: Pxx) needs one

12V 7Ah rechargeable battery. The battery is

used as a back-up power supply in case of

temporal ACloss.Thisbatteryis also usedwhen

alarmsystemconsumesmorepowerthancontrol

panel can supply. Excessive consumption may

happen when system activates siren or radio

transmitter. Usually activation last only few

minutes,soitdoesnot dischargethebattery.

Power supply

distribution board

AC power transformer:

Primary winding: 230V AC 50Hz

Secondary winding: 20V AC 50Hz

~~

12V battery

7Ah/20HR Black

Red

Installation of control panel

Live

wire

L

Neutral

wire

N

Protective

Earth wire

PE Fuse

250mA

+BELL

COM

Intruder alarm system

Page 2

Picture 2. Wiring of power supply, PSTN line and siren without battery

Picture 4. Installation of 2 wire type siren. Siren uses back-up battery

Note: in case installation uses 2 wire siren with back-up

battery (picture 4) installer needs to make changes as

showedontheright.Thistypesirensusesback-upbattery

to sound alarm and makes alarm when power supply line

(+BELL) do not provide power from control panel. Use

Inversion of Status PGM attribute to program system for

thisoperation.Programming sequence on the right.

System Setup:

PGM Outputs

Service Mode:

System Setup

Definition

Fire/BurgAlarm

O01

Attributes

+InversionOfS

O01

S

power supply

positive control / power supply

Note: check siren wiring manual from manufacturer.

Switchesorjumperscanbeused tosetupthistypesiren.

Note: in most templates +BELL is set for sirens with no

battery (picture 2). To use the siren with back-up battery

(picture 3) you need to change +BELL(O01) definition to

Power supply. Definition changing sequence is showed

ontheright (exampleforKM20Bxkeypad).

System Setup:

PGM Outputs

Service Mode:

System Setup

Definition

Power Supply

O01

If adirect connection of the control panel PGM output -PGM to siren

triggering input S does not ensure astable siren activation, please

connect the pull up resistor (3 - 15 kOhm) between the +BELLand -

PGMasshowninthepicture.

+BELL

COM

-PGM

10kΩ

S

power supply

negative control

power supply

Picture 3. Installation of 3 wire type siren. Siren uses back-up battery

Wiring manual

SECOLINK security systems are supplied to customers with a pre-installed

template in the keypad memory. The template is a set of most frequently used

system settings. During First start procedure keypad sends these settings to

other modules. When First start is completed the system will be set to

1partitionand 8 zones:

Z1ispresettobeusedwithaentrydoormagneticcontact;

Z2- with PIRmotiondetectorinentry/exit path;

Z3,Z4- forPIRdetectorswiring;

Z5- withsmokedetector;

Z6-forcabinettamperswitchwiring;

PGMoutputs:

+BELL(O01)ispresetinthetemplatetocontrolasirenwithnobattery;

-PGM (O02) is preset to make activation (makes “minus”) of siren with back-

upbattery;

+PGM(O03) is preset tomake+12V power supply forsmokedetectors.

Template. Siren output programming

SECOLINK security systems may have different templates for different

countries. Check keypad sticker for a country prefix or pre-installed template

code. Example: KM20B_MY

Main Protective

Earthing terminal

Attention!

Do not cover ventilation

holes of cabinet!

Mounting modules in

cabinet

Service Mode:

System setup

System setup:

Modules:

Use Tamper

Settings

No

M00

Modules

Use a tamper switch to protect control panel

Securing power cable

to cabinet

Zones (see "Zone wiring")

+PGM

COM

+12V CLKDAT COM

CLK

DAT

+AUX

Module

-PGM

Main Protective

Earthing terminal

Protective Earth

wire PE

Analog PSTN

line

Control Panels P16, P32, P64

TIP RING T-1 R-1

Serial port SERIAL (see "Wiring of system modules”)

+AUX Z3 COM Z4 -Z5F +Z5F

COM

+BELL

-PGM

Z3

Z4

-Z5F

+Z5F

Z6

+AUX

Z7

COM

Z8

COM

+AUX

20VAC COM -PGM +PGM COM CLK DAT +AUX Z1 COM Z2+BELL

20 VAC

20 VAC

20VAC COM -PGM+BELL

+BELL

COM

COM

+BELL

-PGM

20VAC COM -PGM+BELL

20 VAC

Leave minimum 10 cm of free

space between the ventilation hole

and any other surface. Heating of

controlpanelcanreducemaximum

currenton+AUXandPGMoutputs:

+BELL,+PGM.

By default control panel zone Z6 is set for detection of alarm system

cabinet opening. Opening the cabinet when system is disarmed will

makeatroubleevent or willtriggeranalarm if system is armed. When

cabinet’stamperis unused, input Z6canbeset asnormalzone.

How to set by using

keypad KM20Bx:

Plastic box

Board

Pxx

Screw

Z6

AUX

Z7

COM

Z8

+Z5F

+Z5F Z6 +AUX Z7 COM Z8

SERIAL port

+13,8 V

COM

RX-DAT

TX-CLK

Use plastic component to

fastenpowercabletocabinet.

Boards of control panels and

modules have to be fastened in

plastic cabinet by using screws.

Module's mounting holes should

correspond to cabinet's rear wall

holes.

Attention!Consumed by radio

transmitter short time current

should not exceed 3A. Control

panel supply current to this

connector with not full electronic

short-circuit protection. In case

of long term high current PCB

damageispossible.

Maximum battery charging current: 0,35A

Module disconnect battery when it’s

voltage less than: 9,5V

Black

Red

12V battery

7Ah/20HR

3.15A

COM

+BELL

20VAC COM -PGM+BELL

System start-up with no 230V AC power

Connect 12V battery with P

seriescontrol panel by using

a BAT connector. Use the

jumper to close the shown

pins for 1 second.The

system will start operating;

howeverAC loss trouble will

beindicated.

Jumper

Keypad mounting

Keypad

Use only self-tapping screws with flat

(countersunk) head (3x30 PH) to mount keypad’s

plasticonthewall.Makesurethescrewisscrewed

completely and screw head hides in the plastic.

Other shape screws or not completely screwed

screws may touch keypad electronics and cause

damageof keypad.

Wiring manual

Intruder alarm system

Maximum current out of +AUX:

Maximum battery charging current:

1,5 A

2A

+1 A

+0,35 A

Maximum load ratings and electrical characteristics

of P series control panels

Maximum current out of +BELL:

Maximum current out of +PGM for P16:

Maximum current out of +PGM for P32, P64:

+2,0 A

+0,5 A

+0,9 A

Control panel disconnect battery when it’s voltage less than: 9,5 V

Minimum AC voltage on 20 VAC:

Note: with ~16 V on 20 VAC max DC current generated by

control panel power supply is 0,7A.

Maximum current of fast blowing fuse used in battery circuit:

~16 V

3,15 A

Maximum AC voltage on :

Note: higher than V voltage can damage control panel

20 VAC

~22 .

Maximum voltage on +AUX, +BELL, +PGM outputs:

Minimum voltage on +AUX, +BELL, +PGM outputs:

~22 V

+13,9 V

+12,0 V

Maximum current of slow blowing fuse used in primaryAC:

Maximum AC power consumption:250 mA

150 mA

Maximum long term output current of P16 control panel:

(I + I + I + I 1,5 A )

+AUX +BELL +PGM BAT. CHARGE

Maximum long term output current of P32, P64 control panel:

(I + I + I + I 2 A )

+AUX +BELL +PGM BAT. CHARGE NowservicePINisrestoredto0000valueandsystemwithenabledservice

mode.ToresetuserPINfollowthesteps:

donotblockservice bypressingENT;

pressarrowkeytonavigateinmenu;

go to: Main Menu/Settings/Users/Edit Users/ enter 0000 /Reset PIN to

default/YES

Restoring service PIN to default value

Electrical characteristics and additional information

Live

wire

L

Neutral

wire

N

Protective

Earth wire

PE Wire

Main Protective

Earthing terminal

COM

+BELL

DAT

+AUX

Z1

COM

Z2

CLK

COM

-PGM

+PGM

Maximum current into -PGM: -0,3A

Torestoredefaultvalue(0000)forservicePIN,followthesteps:

disconnectcontrolpanelfrom20VACpowersupply;

disconnectcontrolpanelfromback-upbattery;

makeshortcircuitof -PGM and zone Z1;

connectcontrolpanelto20VACpowersupply.

Calculated life expectancy for P series control panels at 40

ambient temperature: °C

-20°C to +55°COperating temperature range: 12 years

Note: ambient temperature over 40 may reduce life expectancy.°C

Note: poor ventilation of cabinet increase ambient temperature.

Page 3

Control Panels P16, P32, P64

20 VAC

20VAC COM -PGM +PGM COM CLK DAT +AUX Z1 COM Z2+BELL

Fuse

250mA

20 VAC

Maximum long term current out of PWR20:

Maximum current out of +AUX:

2,0A

+1A

Maximum load ratings and electrical

characteristics of PWR20

Maximum current out of +BELL:

Maximum current into -PGM1:+2A

-0,05A

Wiring of modules in large or high security level system

12V battery

7Ah/20HR

Black

Red

Safe wiring of outdoor siren

Use other (than control panel) transformer and

rechargeable 12V 7Ah battery to power up

PWR20.Incase alarmsystem includes PWR20 it

is recommended to wire an outdoor siren to the

PWR20terminals+BELL,-PGM1, (-PGM2), COM

same as shown on page 2. Failure of siren’s

internal battery or the siren itself will not affect

PWR20 – power supply module with bus

repeater

Repetition of system bus is a perfect solution

when some system modules (PROX8, EXTx16)

are placed outside premises or in area not

protected by detectors. It is recommended to wire

to repeated (by PWR20) bus all outside proximity

readers or keypads located near to entry door.

Attempt to make a short circuit on outside module

will make no affect to system performance as

PWR20will detect theshortcircuitonrepeatedbus

and will disconnect repeated bus from main bus.

Terminals CLK-I, DAT-I are inputs for main bus,

terminals CLK-O and DAT-O are outputs of

repeatedbus. For powersupply modules mustuse

PWR20output +AUX.

Live

wire

L

Neutral

wire

N

Protective

Earth wire

PE

Power supply

distribution board

Main Protective

Earthing terminal

Module address LED

Low battery indicator

Battery charging on

Overload of +BELL or + AUX.

X1

BAT

OVL

CHG

LOW

MOD

PWR20

3.15A

Fuse

250mA

AC power transformer:

Primary winding: 230V AC 50Hz

Secondary winding: 20V AC 50Hz

~~DAT-O

CLK-O

COM

+12V

+12VCLK COMDAT

COM

DAT

+12V

CLK

DAT from Pxx

CLK from Pxx

COM from Pxx

+BELL

COM

-PGM1

TMP

COM

+AUX

CLK-I

CLK-O

DAT-I

DAT-O

20 VAC

DAT-O

CLK-O

COM

+12V

+12VCLK COMDAT

COM

DAT

+12V

CLK

+BELL

~20VAC COM-PGM1TMP COM +AUXCLK-ICLK-O

DAT-IDAT-O

Module

(I + I + I 2 A )

+AUX +BELL BAT. CHARGE

3.15A

P16

P32

P64

COM

+BELL

DAT

CLK

COM

-PGM

+PGM

Wiring of system modules Wiring manual

Wiring of system modulesWiring of system modules

Page 4

KM24, KM24A, KM24G

KM20B, KM20BT

COM

+12V

+12V

COM

CLK

DAT

Z2

Z1

DAT

CLK

COM

+AUX

CLKDAT

+12VCOM

+12V Z1

Z2 COM

Z2/PGM

Z1

+12V

COM

CLK

DAT

COM

CLK

DAT

+12V

Z1

PGM

Z2

+AUX

COM

CLK

DAT

KRbus

EXM800

Z1 COM Z2K7 Z3K6 Z4K5 Z5K4

COM

Z1

COM

Z2/K7

Z3/K6

COM

Z4/K5

Z5/K4

DAT

COM

CLK

+12V

Z6K3 Z7K2 Z8K1

COM COM +AUX

COM

Z6/K3

Z7/K2

COM

Z8/K1

+AUX

3.15A

P16

P32

P64

COM

+BELL

DAT

CLK

COM

-PGM

+PGM

Wiring of system modules Wiring manual

Wiring of system modulesWiring of system modules

Page 4

KM24, KM24A, KM24G

KM20B, KM20BT

COM

+12V

+12V

COM

CLK

DAT

Z2

Z1

DAT

CLK

COM

+AUX

CLKDAT

+12VCOM

+12V Z1

Z2 COM

Z2/PGM

Z1

+12V

COM

CLK

DAT

COM

CLK

DAT

+12V

Z1

PGM

Z2

+AUX

COM

CLK

DAT

KRbus

EXM800

Z1 COM Z2K7 Z3K6 Z4K5 Z5K4

COM

Z1

COM

Z2/K7

Z3/K6

COM

Z4/K5

Z5/K4

DAT

COM

CLK

+12V

Z6K3 Z7K2 Z8K1

COM COM +AUX

COM

Z6/K3

Z7/K2

COM

Z8/K1

+AUX

Ethernet cable

COM CLK DAT+12V

LAN800

+12V

COM

CLK

DAT

+12VCOM CLK DAT

Intruder alarm system

Control Panels P16, P32, P64

20VAC COM -PGM +PGM COM CLK DAT +AUX Z1 COM Z2 +AUX Z3 COM Z4 -Z5F +Z5F Z6 +AUX Z7 COM Z8+BELL

ANT

OPENOPEN

LOCKLOCK

GSVU

+AUX

+AUX

Z4

-Z5F

+Z5F

Z6

+AUX

Z7

COM

Z8

COM

Z3

COM

Z2

Z1

20 VAC

RING TIP

Not used

PROX8

+12V

COM

CLK

DAT

Modules compatibility with control panels Pxx

KM20B, KM20BT

Module Compatible (firmw.: v.5.030 and +) Not compatible

KM24, KM24A Compatible (firmw.: v.2.051 and +) Not compatible

KM24G Compatible (firmw.: v.3.009 and +)

PROX8 Limited compatibility (firmw.: v.0.10)

Only first 31 users will be able to control the system. Only first

32 zones will be monitored by PROX8 LEDs.

EXM800 Compatible (firmw.: all versions)

Compatible (firmw.: all versions)

Compatible (firmw.: all versions)

Compatible (firmw.: all versions)

Compatible (firmw.: all versions)

Compatible (firmw.: all versions)

Compatible (firmw.: all versions)

EXM3F

RCM800WL

EXT016, EXT216

EXT116S

PWR20

GSVU

GSV6, GSV6T,

GSV6U Compatible (firmw.: from v.1.025)

It is recommended to use GSVUmodule with P series control

panels. GSV6x module is only useful

LAN800

VIDNET Compatible (firmw.: from v.1.42)

Compatible (firmw.: all versions)

P16 P32 P64

BAT

CLK DAT +AUX Z1 COM Z2 +AUX Z3 COM Z4 -Z5F +Z5F Z6 +AUX Z7 COM Z820VAC COM -PGM +PGM+BELL COM

OPENOPEN

LOCKLOCK

CAM2 CAM3CAM4 COM COM COMCAM1 COM

CAM1 CAM2 CAM3 CAM4

P16

P32

P64

VIDNET

Control panels Pxx are designed in the way, that all commonly used modules can be directly plugged-on on the panel board (GSM

moduleGSVU,videomoduleVIDNET).Allothermodules,thatdoesn'thavethedirectinterfacewithapanelmustbeconnectedtodatabus-

KRbus.

Wiring of zones

Normally closed

contact

(NC)

Normally closed

contact with one

resistor

(NC/EOL)

Normally closed

contact with two

resistors

(NC/DEOL)

Normally open contact

(NO)Normally open contact

with one resistor

(NO/EOL)

Normally open contact

with two resistors

(NO/DEOL)

Wiring of single zones

Wiring of double zones

Detector

Control panel or

module Control panel or

module Control panel or

module Control panel or

module Control panel or

module Control panel or

module

+AUX

COM

Z1

COM

Tamper

Z2

Control

panel

+AUX

COM Z2

Detector

Detector

Z1

Cable

Cable

+AUX

COM

Detector

+AUX

COM

Z1

Cable

EXM800

+AUX

COM

Z1

Z2

+AUX

COM Z2

Detector

Detector

Z1

Cable

Cable

+AUX

COM

Detector

EXM800

ATTENTION! Avoid power supply loops

1kΩ620Ω

Control panel

+AUX

COM

Z1

COM

Detector A

T1

T2

NC*

C

Tamper Detector B

T1

T2

NC*

C

Tamper

300Ω

Detector A

Detector B

* - Detector contact must be NC or NO.

Control panel

Correct wiring

Wrong wiring

1kΩ

+AUX

COM

Z1

COM

Tamper

Detector

1kΩ

+AUX

COM

Z1

COM

Tamper

Detector

+AUX

COM

Z1

COM

Tamper

Detector

+AUX

COM

Z1

COM

Tamper

Detector

+AUX

COM

Z1

COM

Tamper

Detector

Wiring samples

Wiring of 2-wire smoke detector

Detector

Control

panel

-Z5F

+Z5F

NO Note: smoke detectors, produced

by different manufacturers, may

have a different terminals layout.

For more information check

detector wiring manual from

manufacturer.

Terminals of smoke detector

To -Z5F

To +Z5F

It is recommended to use diode to

supressvoltage surgesonrelay.

Wiring of relays

Smoke detectors can be triggered by dust. Therefore, to prevent

false alarms, it is recommended to verify the fire alarm. For

verification,theusermustactivatesystemsettingslistedbellow.

Zonesettings:

Zoneaddress:00_5(controlpanelzoneterminals-Z5F,+Z5F);

Zonelooptype:NO/EOL;

Zonedefinition:24hsmoke;

Attributeassignedtoazone:Fireverification;

Resettimemustbeset;

Systemtimessettings:

Detectorsettlingtimemustbeset;

Fireverificationtimemustbeset;

Operation: In order to check the triggered fire detector, the

power supply of the detector has to be turned off and turned on

again. The system turns the -Z5F off for a Reset time. When the

resettimeexpires,thesystemturnsthe-Z5Fonagainandwaitsfor

the detector to settle down (Detector settling time). After that, the

system checks the detector again for a time period set in the menu

under the Fire verification time setting. If the fire detector is

triggeredagain,itmeansthealarmwasreal.

Wiring manual

Intruder alarm system

Control panel or

module

+AUX

-PGM

Control panel or

module

+PGM

COM

T1

T2

NC

C

NO

NO

NO

Control Panels P16, P32, P64

Control

panel

2,2kΩ

Page 5

T1

T2

NC

C

T1

T2

NC

C

T1

T2

C

T1

T2

C

T1

T2

C

+AUX COM Z1 COM+AUX COM Z1 COM

12V CT2 NCT1 12V CT2 NCT1

1kΩ1kΩ1kΩ1kΩ

12V CNCT2T1 12V CT2 NOT1 12V CNOT2T1 12V CNOT2T1

+AUX COM Z1 COM +AUX COM Z1 COM +AUX COM Z1 COM+AUX COM Z1 COM

+AUX COM Z1 COM

CNC*12V T2T1 CNC*T2T112V

D1

NCNC NONO

Relay

D1

NCNC NONO

Relay

+AUX -PGM+PGM COM

2,2kΩ2,2kΩ

-Z5F +Z5F

Wiring manual

Intruder alarm system

Control Panels P16, P32, P64

Page 6

Typical system installation example - SECOLINK P16, P32

Installation of GSVU module and PSTP

communicator

P16, P32, P64

GSVU

PSTP

3.15A

P16, P32, P64

20VAC COM -PGM +PGM COM CLK DAT +AUX Z1 COM Z2 +AUX Z3 COM Z4 -Z5F +Z5F Z6 +AUX Z7 COM Z8+BELL

ANT

3.15A

+AUX

COM

Z2

Z6 +AUX Z7 COM Z8

ANT PSTP

TIP RING T-1 R-1

20VAC COM -PGM +PGM COM CLK DAT +AUX Z1 COM Z2 +AUX Z3 COM Z4 -Z5F +Z5F+BELL

OPENOPEN

LOCKLOCK

GSVU

P16, P32, P64

If the system must be expanded with other modules, that doesn't have

direct connection with control panel (for example LAN800), it could be

installed next to the panel board. Crosses and dashed line present

commonly used locations of modules. Module's mounting holes should

correspondtocabinet'srearwallholes.

Installation of control panel and GSM/GPRS or LAN module

Installation of modules in CAS6 plactic cabinet

+12VCOM CLK DAT

RING TIP

BAT

CLK DAT +AUX Z1 COM Z2 +AUX Z3 COM Z4 -Z5F +Z5F Z6 +AUX Z7 COM Z820VAC COM -PGM +PGM+BELL COM

KM20B

LAN800

P16

KM24

PROX8 PROX8

BK1, BK3, BK4,

BV3, BT1 LT5

BP1

12V battery

7Ah/20HR

OPENOPEN

LOCKLOCK

GSVU

Wiring manual

Intruder alarm system

Control Panels P16, P32, P64

Page 6

Typical system installation example - SECOLINK P16, P32

Installation of GSVU module and PSTP

communicator

P16, P32, P64

GSVU

PSTP

3.15A

P16, P32, P64

20VAC COM -PGM +PGM COM CLK DAT +AUX Z1 COM Z2 +AUX Z3 COM Z4 -Z5F +Z5F Z6 +AUX Z7 COM Z8+BELL

ANT

3.15A

+AUX

COM

Z2

Z6 +AUX Z7 COM Z8

ANT PSTP

TIP RING T-1 R-1

20VAC COM -PGM +PGM COM CLK DAT +AUX Z1 COM Z2 +AUX Z3 COM Z4 -Z5F +Z5F+BELL

OPENOPEN

LOCKLOCK

GSVU

P16, P32, P64

If the system must be expanded with other modules, that doesn't have

direct connection with control panel (for example LAN800), it could be

installed next to the panel board. Crosses and dashed line present

commonly used locations of modules. Module's mounting holes should

correspondtocabinet'srearwallholes.

Installation of control panel and GSM/GPRS or LAN module

Installation of modules in CAS6 plactic cabinet

+12VCOM CLK DAT

RING TIP

BAT

CLK DAT +AUX Z1 COM Z2 +AUX Z3 COM Z4 -Z5F +Z5F Z6 +AUX Z7 COM Z820VAC COM -PGM +PGM+BELL COM

KM20B

LAN800

P16

KM24

PROX8 PROX8

BK1, BK3, BK4,

BV3, BT1 LT5

BP1

12V battery

7Ah/20HR

OPENOPEN

LOCKLOCK

GSVU

Wiring manual

Intruder alarm system

Control Panels P16, P32, P64

Page 6

Typical system installation example - SECOLINK P16, P32

Installation of GSVU module and PSTP

communicator

P16, P32, P64

GSVU

PSTP

3.15A

P16, P32, P64

20VAC COM -PGM +PGM COM CLK DAT +AUX Z1 COM Z2 +AUX Z3 COM Z4 -Z5F +Z5F Z6 +AUX Z7 COM Z8+BELL

ANT

3.15A

+AUX

COM

Z2

Z6 +AUX Z7 COM Z8

ANT PSTP

TIP RING T-1 R-1

20VAC COM -PGM +PGM COM CLK DAT +AUX Z1 COM Z2 +AUX Z3 COM Z4 -Z5F +Z5F+BELL

OPENOPEN

LOCKLOCK

GSVU

P16, P32, P64

If the system must be expanded with other modules, that doesn't have

direct connection with control panel (for example LAN800), it could be

installed next to the panel board. Crosses and dashed line present

commonly used locations of modules. Module's mounting holes should

correspondtocabinet'srearwallholes.

Installation of control panel and GSM/GPRS or LAN module

Installation of modules in CAS6 plactic cabinet

+12VCOM CLK DAT

RING TIP

BAT

CLK DAT +AUX Z1 COM Z2 +AUX Z3 COM Z4 -Z5F +Z5F Z6 +AUX Z7 COM Z820VAC COM -PGM +PGM+BELL COM

KM20B

LAN800

P16

KM24

PROX8 PROX8

BK1, BK3, BK4,

BV3, BT1 LT5

BP1

12V battery

7Ah/20HR

OPENOPEN

LOCKLOCK

GSVU

P16, P32, P64

LAN800

Wiring manual

Intruder alarm system

Control Panels P16, P32, P64

Typical system installation example - SECOLINK P64

Plastic cabinet CAS6 has few plastic components for power cable

fastening,videocablelockingandbottomcoversifvideomodule VIDNETis

notused.Locateplasticcomponentsin the bottom of plasticcabinet andcut

themwithacutter.

SafetywarningincasealarmsystemusesLAN800orVIDNETmodules!

LAN800 and VIDNET are designed to be used in couple with a router which is placed in the same room or premises.

It’s prohibited to connect LAN800 directly to Wide Area Network (MAN, WAN) or building IT infrastructure cables.

RouterRouter

Plastic components Assigning a remote control unit to the user

OPENOPEN

LOCKLOCK

CAM2 CAM3CAM4 COM COM COMCAM1 COM

CAM1 CAM2 CAM3 CAM4

+12V

COM

CLK

DAT

+12VCOM CLK DAT

RING TIP

LAN800

VIDNET

Receiver

Cover

Video cable

locking

component

Covers

CAM2 CAM3 CAM4

Wiring manual

Intruder alarm system

Control Panels P16, P32, P64

Typical system installation example - SECOLINK P64

Plastic cabinet CAS6 has few plastic components for power cable

fastening,videocablelockingandbottomcoversifvideomoduleVIDNETis

notused.Locateplasticcomponentsin the bottom of plastic cabinetand cut

themwithacutter.

SafetywarningincasealarmsystemusesLAN800orVIDNETmodules!

LAN800 and VIDNET are designed to be used in couple with a router which is placed in the same room or premises.

It’s prohibited to connect LAN800 directly to Wide Area Network (MAN, WAN) or building IT infrastructure cables.

RouterRouter

Plastic components Assigning a remote control unit to the user

OPENOPEN

LOCKLOCK

CAM2 CAM3CAM4 COM COM COMCAM1 COM

CAM1 CAM2 CAM3 CAM4

+12V

COM

CLK

DAT

+12VCOM CLK DAT

RING TIP

LAN800

VIDNET

Receiver

Cover

Video cable

locking

component

Covers

CAM2 CAM3 CAM4

COM

Wiring manual

Intruder alarm system

Control Panels P16, P32, P64

Typical system installation example - SECOLINK P64

Plastic cabinet CAS6 has few plastic components for power cable

fastening,videocablelockingandbottomcoversifvideomoduleVIDNETis

notused.Locateplasticcomponentsin the bottom of plastic cabinetand cut

themwithacutter.

SafetywarningincasealarmsystemusesLAN800orVIDNETmodules!

LAN800 and VIDNET are designed to be used in couple with a router which is placed in the same room or premises.

It’s prohibited to connect LAN800 directly to Wide Area Network (MAN, WAN) or building IT infrastructure cables.

RouterRouter

Plastic components Assigning a remote control unit to the user

OPENOPEN

LOCKLOCK

CAM2 CAM3CAM4 COM COM COMCAM1 COM

CAM1 CAM2 CAM3 CAM4

+12V

COM

CLK

DAT

+12VCOM CLK DAT

RING TIP

LAN800

VIDNET

Receiver

Cover

Video cable

locking

component

Covers

CAM2 CAM3 CAM4

COM

Locking

component

Page 7

BAT

CLK DAT +AUX Z1 COM Z2 +AUX Z3 COM Z4 -Z5F +Z5F Z6 +AUX Z7 COM Z820VAC COM -PGM +PGM+BELL COM

OPENOPEN

LOCKLOCK

CAM1 CAM2 CAM3 CAM4

P64

VIDNET

PROX8 PROX8

BK1, BK3, BK4,

BV3, BT1 LT5

BP1

KM24GKM24G

+12V

COM

CLK

DAT

+12V COM CLK DAT

Module LED

EXM800

CAM1CAM2 CAM3CAM4 COM COM COMCOM

Wiring manual

Intruder alarm system

Control Panels P16, P32, P64

Typical system installation example - SECOLINK P64

Plastic cabinet CAS6 has few plastic components for power cable

fastening,videocablelockingandbottomcoversifvideomodule VIDNETis

notused.Locateplasticcomponentsin the bottom of plasticcabinet andcut

themwithacutter.

SafetywarningincasealarmsystemusesLAN800orVIDNETmodules!

LAN800 and VIDNET are designed to be used in couple with a router which is placed in the same room or premises.

It’s prohibited to connect LAN800 directly to Wide Area Network (MAN, WAN) or building IT infrastructure cables.

RouterRouter

Plastic components Assigning a remote control unit to the user

OPENOPEN

LOCKLOCK

CAM2 CAM3CAM4 COM COM COMCAM1 COM

CAM1 CAM2 CAM3 CAM4

+12V

COM

CLK

DAT

+12VCOM CLK DAT

RING TIP

LAN800

VIDNET

Receiver

Cover

Video cable

locking

component

Covers

CAM2 CAM3 CAM4

COM

Locking

component

Page 7

BAT

CLK DAT +AUX Z1 COM Z2 +AUX Z3 COM Z4 -Z5F +Z5F Z6 +AUX Z7 COM Z820VAC COM -PGM +PGM+BELL COM

OPENOPEN

LOCKLOCK

CAM1 CAM2 CAM3 CAM4

P64

VIDNET

PROX8 PROX8

BK1, BK3, BK4,

BV3, BT1 LT5

BP1

KM24GKM24G

+12V

COM

CLK

DAT

+12V COM CLK DAT

Module LED

EXM800

CAM1CAM2 CAM3CAM4 COM COM COMCOM

Wiring manual

Intruder alarm system

Control Panels P16, P32, P64

Typical system installation example - SECOLINK P64

Plastic cabinet CAS6 has few plastic components for power cable

fastening,videocablelockingandbottomcoversifvideomodule VIDNETis

notused.Locateplasticcomponentsin the bottom of plasticcabinet andcut

themwithacutter.

SafetywarningincasealarmsystemusesLAN800orVIDNETmodules!

LAN800 and VIDNET are designed to be used in couple with a router which is placed in the same room or premises.

It’s prohibited to connect LAN800 directly to Wide Area Network (MAN, WAN) or building IT infrastructure cables.

RouterRouter

Plastic components Assigning a remote control unit to the user

OPENOPEN

LOCKLOCK

CAM2 CAM3CAM4 COM COM COMCAM1 COM

CAM1 CAM2 CAM3 CAM4

+12V

COM

CLK

DAT

+12VCOM CLK DAT

RING TIP

LAN800

VIDNET

Receiver

Cover

Video cable

locking

component

Covers

CAM2 CAM3 CAM4

COM

Locking

component

Page 7

BAT

CLK DAT +AUX Z1 COM Z2 +AUX Z3 COM Z4 -Z5F +Z5F Z6 +AUX Z7 COM Z820VAC COM -PGM +PGM+BELL COM

OPENOPEN

LOCKLOCK

CAM1 CAM2 CAM3 CAM4

P64

VIDNET

PROX8 PROX8

BK1, BK3, BK4,

BV3, BT1 LT5

BP1

KM24GKM24G

+12V

COM

CLK

DAT

+12V COM CLK DAT

Module LED

EXM800

CAM1CAM2 CAM3CAM4 COM COM COMCOM

Video jungties

fiksatoriai

12V battery

7Ah/20HR

Analog camera (resolution D1)

Power cable

fastening

component

Simultaneosly hold down the buttons and

.

Message Done should appear on keypad

LCD when remote control unit is enrolled

succesfully.Releasebuttons and .

Advance to the next user with a keypad keys

or .

7

PQRS

7

PQRS

7

PQRS

7

PQRS

7

PQRS

7

PQRS

7

PQRS

7

PQRS

7

PQRS

7

PQRS

7

PQRS

ChooseNewRCUandpress button.

ENTENTENTENTENTENTENTENTENTENTENT

11

MainMenu

Settings

22

22

Settings

Users

Users

Edit users

U01 User 01

Controls NewRCU

66

Waiting...

Done

U01 User 01

Name User 01

11

Wiring manual

Control Panels P16, P32, P64

Intruder alarm system

Page 8

SECOLINK wireless detectors

11

Service mode

System setup

Enable wireless zone by changing Not used loop

type to any other loop type. If system uses keypad

produced before 2014 installer obliged to change

thelooptypetotheNO/DEOLorVibration.

Advance to the next unlearned zone with a keypad

keys or .

7

PQRS

7

PQRS

7

PQRS

7

PQRS

7

PQRS

7

PQRS

7

PQRS

7

PQRS

7

PQRS

7

PQRS

7

PQRS

11

Z01 Door

Name Door

33

System setup

Zones

Z01 Door

Looptype NO/DEOL

33

Z01 DoorZ01 Door

WLdet.loop(zone)IDWLdet.loop(zone)ID 201

44

Z01 Door

Address 06_1

33

Enter zone address MA_Z, where MA is module

addressinsystemandZiszonenumberinmodule.

Note: for wireless zones MA_1 – MA_8 system

automatically will assign NO/DEOL loop type and

for wireless zones MA_9 – MA_16 the Vibration

looptype.Don'tchangethelooptypeofzone!

Moduleaddress:

EXT116S - address 06 (default) or given during

registrationprocedure;

Virtual module EXT116S address depends on

controlpaneltype:

P16-address12;

P32-address12and13;

P64-address12,13,14and15.

Enter wireless detector loop (zone) ID number and

press key to start enrolling.Use also this field for

deletingthesensorfromthemodule.

ENTENTENTENTENTENTENTENTENTENTENT

Whenenrollment is started, immediately,for a short

timepresstamperswitch:

BKx, BT1, BV3: press the detector battery as

showninpicturethanyouwillfeelaclick.Thisaction

activates the tamper switch on back side of the

detector.

BP1: press the tamper switch as shown in picture

thanyouwillfeelaclick.

Waitingfor

WLdetector

Done If the wireless detector is successfully enrolled, the

messageDonewill appearonscreen. No additional

transmissionsareneededforconfirmation.

BK1

BK4

Supports Wireless detector loop (zone) ID number

Built-in reed switch

(used in conjuction

with a magnet)

200

255

Normally closed

circuit contact loop

wired to ...

Roller detector

loop wired to ...

Vibration detector

loop wired to ...

BK3

BK4

210

211

111

Input 1

Input 1

220

221

121

Input 2

Input 2

230

231

131

Input 3

Input 3

212 222 232

213 223 233

215 225 235

217 227 237

219

...

119

229

...

129

239

...

139

Zone response (speed) time of 0,4 sec.

211-lastdigitdefinesthenumberofRollerpulses.

111-lastdigitx10definesthezoneresponse(speed)

time(example:1x10=10msec).

Built-in

temperature

sensor BT1

BK3

BV3

BK4

Input 1 Input 2 Input 3

BV3

Delete detector

in particular zone

Delete all

detectors

in particular

wireless module

All

All

201

254

BP1

Passive infrared

sensor

(PIR sensor)

180

Built-in

temperature

sensor

181

BP1

Enrolling the wireless detector to the system zone

Use

Wireless detector loop (zone) enrolling ID numbers

Rev.19/01/16

This manual suits for next models

2

Table of contents

Other SECOLink Control Panel manuals