Sectoriel SR 03 PCU Quick guide

SR 03 PCU ACTUATORS

ASSEMBLING AND MAINTENANCE INSTRUCTIONS

Information given as an indication only, and subject to possible modifications

SECTORIEL S.A.

45, rue du Ruisseau

38290 SAINT QUENTIN-FALLAVIER –FRANCE

Tél : +33 4 74 94 90 70 - Fax : +33 4 74 94 13 95

www.sectoriel.com / Email : secto[email protected]

Pages

1/14

Ref.

IME23070 ENG

Rev.

02

Date

10/2023

SR 03 PCU

SR 03 PCU ACTUATORS

ASSEMBLING AND MAINTENANCE INSTRUCTIONS

Information given as an indication only, and subject to possible modifications

SECTORIEL S.A.

45, rue du Ruisseau

38290 SAINT QUENTIN-FALLAVIER –FRANCE

Tél : +33 4 74 94 90 70 - Fax : +33 4 74 94 13 95

www.sectoriel.com / Email : secto[email protected]

Pages

2/14

Ref.

IME23070 ENG

Rev.

02

Date

10/2023

1. DESCRIPTION

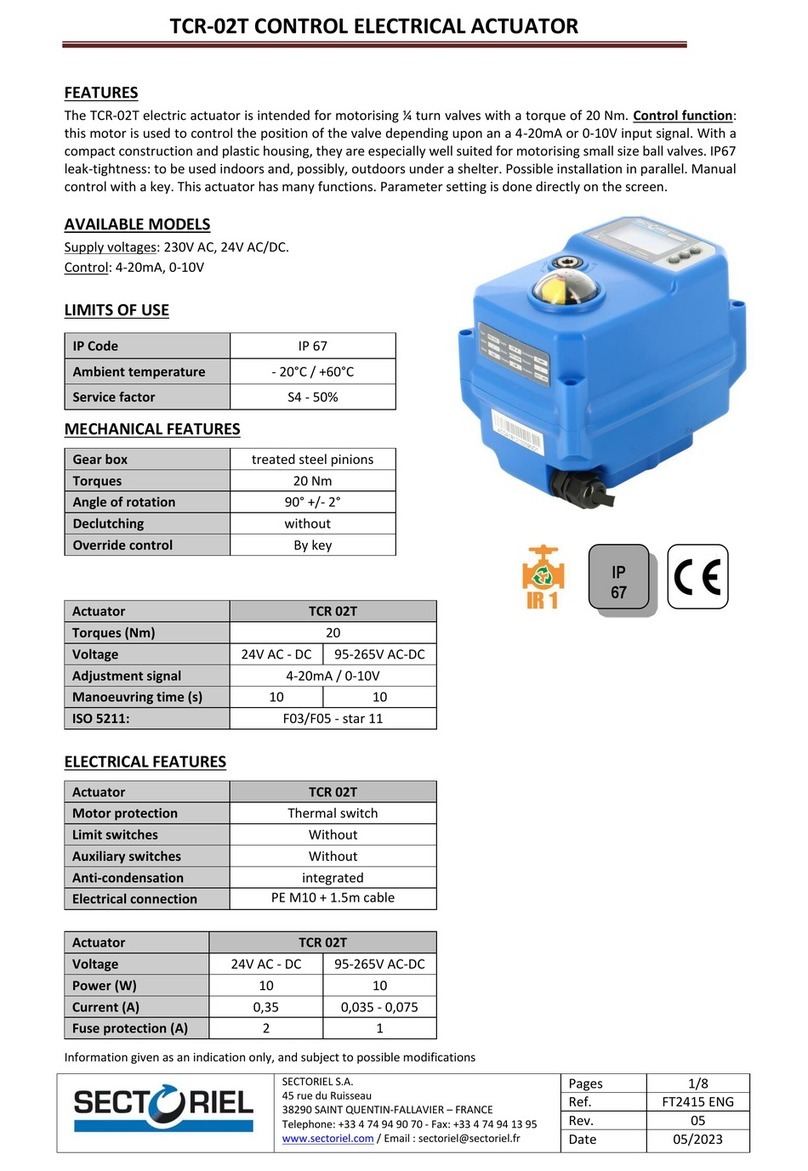

1.1 Electric actuator for motorising 90° turn valves.

1.2 The full features of this device are given in sheet FT23070.

1.3 Before operating this device, read the present instructions carefully.

2. GUARANTEE

2.1 Before any contact with our services, identify the type of actuator.

2.2 SECTORIEL actuators have a 12-month guarantee from the delivery date. Parts recognized

as defective by an assessment at our facility, will be replaced at our expense. Complaints

generated by incorrect use or a modification of the actuator cannot be taken into account.

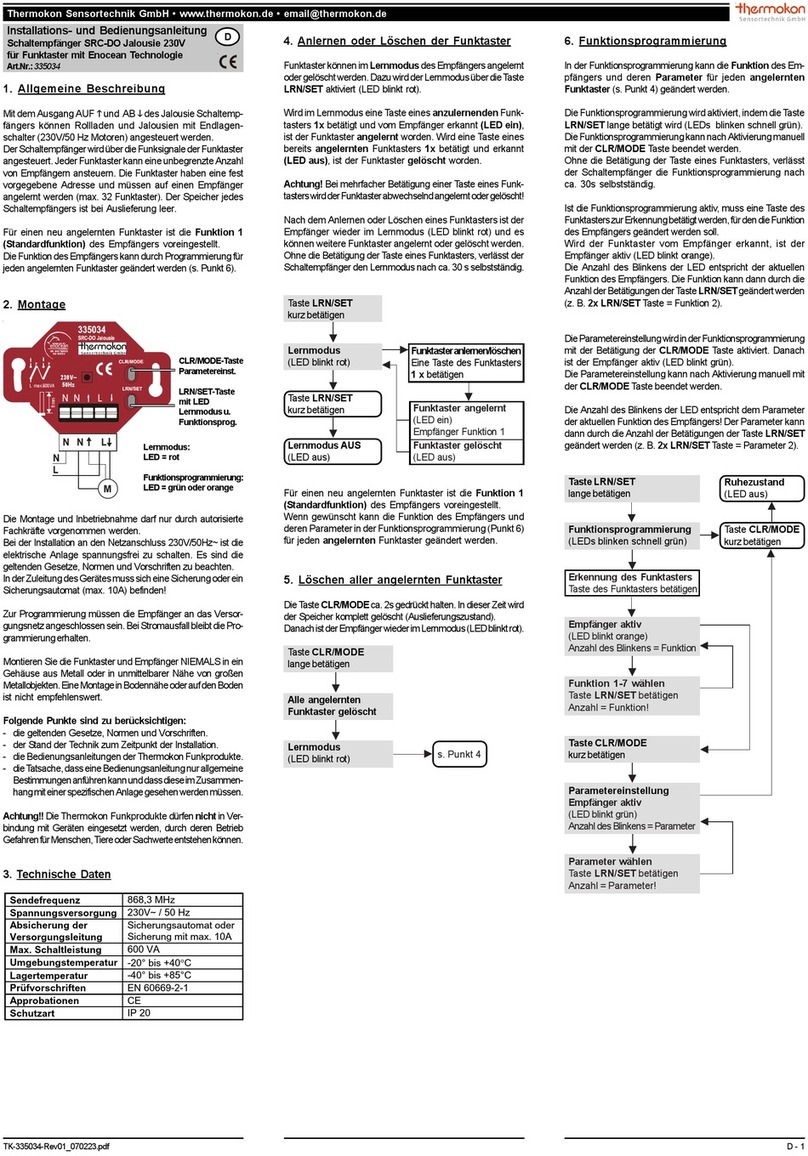

N°

Désignation

1

Heater

2

Power board

3

Potentiometer

4

Indicator

5

Limit switch

6

Terminal

7

Control board

8

BLDC motor

9

Declutch gear

SR 03 PCU ACTUATORS

ASSEMBLING AND MAINTENANCE INSTRUCTIONS

Information given as an indication only, and subject to possible modifications

SECTORIEL S.A.

45, rue du Ruisseau

38290 SAINT QUENTIN-FALLAVIER –FRANCE

Tél : +33 4 74 94 90 70 - Fax : +33 4 74 94 13 95

www.sectoriel.com / Email : secto[email protected]

Pages

3/14

Ref.

IME23070 ENG

Rev.

02

Date

10/2023

3. VERIFICATIONS AND ACCEPTANCE

3.1 At acceptance, check that:

- the packaging is in good condition.

- the actuator is as ordered.

- the equipment is not damaged.

3.2 It is recommended to install the actuator as soon as accepted and not to leave it unused. If the

equipment has to be stored, it has to be in a dry place protected from weather.

4. PRECAUTIONS FOR OPERATION

4.1 Before installing, make sure that the installation is completely depressurized and brought to

ambient temperature.

4.2 In a zone classified as explosive, install only model SA05X.

Do not install this actuator in a marine environment and do not immerse it.

4.3 The actuator must not be electrically powered during the installation and maintenance of

the valve on the pipework, and of the actuator on the valve.

4.4 Before proceeding to the electrical connection, check the supply voltage of the actuator.

4.5 Do not mount the actuator in series or in parallel with other electrical motors. If need be

use relays.

4.6Do not mount the actuator on valves with higher torque than the nominal torque of the actuator.

4.7 Under normal operation: These motors have to be electrically controlled for opening or closing.

Spring driven return only takes places in case of power supply cut-off.

5. INSTALLATION ET UTILISATION

5.1 Install the actuator on the valve (already done for units assembled in our workshops)

5.2 Perform the electrical wiring as shown in the diagram below.

5.3 Adjust the switch stops (already done for units assembled in our workshops).

5.4 View the valve’s movement using the indicator light on the cover.

5.5 Mounting

Model

A (mm)

SR03

130

SR 03 PCU ACTUATORS

ASSEMBLING AND MAINTENANCE INSTRUCTIONS

Information given as an indication only, and subject to possible modifications

SECTORIEL S.A.

45, rue du Ruisseau

38290 SAINT QUENTIN-FALLAVIER –FRANCE

Tél : +33 4 74 94 90 70 - Fax : +33 4 74 94 13 95

www.sectoriel.com / Email : secto[email protected]

Pages

4/14

Ref.

IME23070 ENG

Rev.

02

Date

10/2023

6. MANUAL INTERVENTION

CAUTION : Before any manual intervention, cut off the power supply, otherwise the SR actuator provided with

an electromagnetic clutch, can be damaged.

6.1 Put the hex wrench into the manual socket and turn to CW.

The lever shaft pops up and manual operation is available.

6.3 Put the lever shaft and turn the wrench to CCW it is switched to auto mode.

6.4 The declutch gear should go down to its original positon to restore the limit setting to factory set and pop

up using the hex wrench when resetting the limit positions.

SR 03 PCU ACTUATORS

ASSEMBLING AND MAINTENANCE INSTRUCTIONS

Information given as an indication only, and subject to possible modifications

SECTORIEL S.A.

45, rue du Ruisseau

38290 SAINT QUENTIN-FALLAVIER –FRANCE

Tél : +33 4 74 94 90 70 - Fax : +33 4 74 94 13 95

www.sectoriel.com / Email : secto[email protected]

Pages

5/14

Ref.

IME23070 ENG

Rev.

02

Date

10/2023

7. STOP ADJUSTMENT

The return spring of the actuator becomes active in case of emergency stop (a power cut, e.g.)

In this case, spring stops have to be adjusted, using stop screws.

The SR actuator is protected when the stops are properly adjusted.

(carry out the adjustment of stops (screws) before adjusting the limit switches).

7.1 Manually place the actuator in the closed position after attaching it on top of the valve.

7.2 If the stops are incorrectly adjusted, the valve will not be in the fully closed position. In this case,

Adjust the stops to reach the fully closed position. Tighten the stops screws once the adjustment performed.

NOTA : Do not touch the adjustment already performed at the facility.

7.3 Adjust the stops in the same way as the stops in the closed position.

CAUTION : When the limit switch reaches the stop, the actuator works normally. Return to the initial position

when the actuator goes into fault.

The actuator works properly if the cams switch the limit switches before the stop plate reaches the screw. If the

actuator does not work properly, adjust the stop screws again.

SR 03 PCU ACTUATORS

ASSEMBLING AND MAINTENANCE INSTRUCTIONS

Information given as an indication only, and subject to possible modifications

SECTORIEL S.A.

45, rue du Ruisseau

38290 SAINT QUENTIN-FALLAVIER –FRANCE

Tél : +33 4 74 94 90 70 - Fax : +33 4 74 94 13 95

www.sectoriel.com / Email : secto[email protected]

Pages

6/14

Ref.

IME23070 ENG

Rev.

02

Date

10/2023

8. SWITCH SETTING

Limit setting when electrical power isn’t supplied.

8.1 Put the hex wrench into the declutch gear and turn to CW. The declutch gear pops and manual operation

is available. The actuator remains the last position during the manual operation without holding the wrench.

Adjust limit cams with the hex wrench after mounting with the valve.

8.2 The declutch gear should go down to its original position to restore the limit setting to factory set and pop

Up using the hex wrench when resetting the limit positions.

Be sure to push the ASCN button to save the setting after limit setting.

Limit setting when electrical power is supplied

8.3 Position the declutch gear to the auto mode before limit setting.

8.4 Push the ZERO and SPAN buttons at the same time and check if the POWER and FAULT lamps turn on.

8.5 Limit setting by ZERO (closing) / SPAN (opening) buttons.

8.6 Push the ZERO and SPAN buttons to change into the auto / manual mode mentioned here is the setting

mode on the BLDC board. In the auto mode : Power lamp (lighting) / fault lamp (flickering)

8.7 Push the declutch gear and turn to CCW to position to the auto mode with the hex wrench after finishing

the setting.

Be sure to push the ASCN button to save the setting after limit setting.

SR 03 PCU ACTUATORS

ASSEMBLING AND MAINTENANCE INSTRUCTIONS

Information given as an indication only, and subject to possible modifications

SECTORIEL S.A.

45, rue du Ruisseau

38290 SAINT QUENTIN-FALLAVIER –FRANCE

Tél : +33 4 74 94 90 70 - Fax : +33 4 74 94 13 95

www.sectoriel.com / Email : secto[email protected]

Pages

7/14

Ref.

IME23070 ENG

Rev.

02

Date

10/2023

Closing/opening limit switch

8.1 The cams ate attached to the drive stem.

8.2 Clockwise rotation = valve closing. The micro-switch closes the actuator.

8.3 Anti-clockwise rotation = valve opening. The micro-switch stops the actuator.

9. CONNEXION

The two inlet cables of the SR actuator are connected using an M20 x 1.5 connection.

9.1 The unused cable inlets must be plugged.

9.2 Standard cable glands and version for shielded cable can be used.

It is recommended to fit a glued (resin) sealing gasket on the actuator’s connections once

the wiring is completed. This is to prevent humidity and water from penetrating inside.

AOLS :

Dry contact open limit switch

ACLS :

Dry contact close limit switch

OLS :

Open limit switch

CLS :

Close limit switch

SR 03 PCU ACTUATORS

ASSEMBLING AND MAINTENANCE INSTRUCTIONS

Information given as an indication only, and subject to possible modifications

SECTORIEL S.A.

45, rue du Ruisseau

38290 SAINT QUENTIN-FALLAVIER –FRANCE

Tél : +33 4 74 94 90 70 - Fax : +33 4 74 94 13 95

www.sectoriel.com / Email : secto[email protected]

Pages

8/14

Ref.

IME23070 ENG

Rev.

02

Date

10/2023

10. ELECTRICAL WIRING

10.1 Separate the cover from the actuator’s body. Unscrew the four bolts.

10.2 Before any electrical connection, check that the electrical diagram provided corresponds to the

rating plate.

10.3 Check that the mains voltage corresponds to the voltage mentioned on the rating plate.

10.4 The SR actuator series has a WAGO terminal box which is easy to wire and is protected against vibrations.

Use an AWG 28-4 standard cable.

10.5 Insert a screwdriver as shown above, press and insert the wire.

10.6 Check that the actuator’s earthing is compliant indoors (body) and outdoors (body).

Use a wire of identical cross-section 4.5 ~ 5 mm² for earthing the SR actuator.

10.7 Each actuator has to be actuated by their own individual relays to prevent the voltage from coming back

and possible damage to other actuators.

SR 03 PCU ACTUATORS

ASSEMBLING AND MAINTENANCE INSTRUCTIONS

Information given as an indication only, and subject to possible modifications

SECTORIEL S.A.

45, rue du Ruisseau

38290 SAINT QUENTIN-FALLAVIER –FRANCE

Tél : +33 4 74 94 90 70 - Fax : +33 4 74 94 13 95

www.sectoriel.com / Email : secto[email protected]

Pages

9/14

Ref.

IME23070 ENG

Rev.

02

Date

10/2023

11. SCHEMA DE CABLAGE

Wiring for 230Vac 50Hz voltage

1

Common

2

Phase

3-6

Manual opening command

4-6

Manual closing command

5-6

Fonctioning 4-20 mA

6

Manual and automatic command

7

Opening auxiliary common

8

Closing auxiliary command

9

Auxiliary common

SR 03 PCU ACTUATORS

ASSEMBLING AND MAINTENANCE INSTRUCTIONS

Information given as an indication only, and subject to possible modifications

SECTORIEL S.A.

45, rue du Ruisseau

38290 SAINT QUENTIN-FALLAVIER –FRANCE

Tél : +33 4 74 94 90 70 - Fax : +33 4 74 94 13 95

www.sectoriel.com / Email : secto[email protected]

Pages

10/14

Ref.

IME23070 ENG

Rev.

02

Date

10/2023

Wiring for 24Vcc voltage

1

Common

2

Phase

3-6

Manual opening command

4-6

Manual closing command

5-6

Fonctioning 4-20 mA

6

Manual and automatic common

7

Opening auxiliary command

8

Closing auxiliary command

9

Auxiliary common

SR 03 PCU ACTUATORS

ASSEMBLING AND MAINTENANCE INSTRUCTIONS

Information given as an indication only, and subject to possible modifications

SECTORIEL S.A.

45, rue du Ruisseau

38290 SAINT QUENTIN-FALLAVIER –FRANCE

Tél : +33 4 74 94 90 70 - Fax : +33 4 74 94 13 95

www.sectoriel.com / Email : secto[email protected]

Pages

11/14

Ref.

IME23070 ENG

Rev.

02

Date

10/2023

12. FAULT DIAGNOSTIC

If the actuator does not work properly, check all mechanisms, and look for alignment problems and electrical

problems. (See table below)

PROBLEM

CAUSE

SOLUTIONS

The manual control does not engage

Blocked worm drive

and stop mechanism

Turn the wheel again from left to right

In manual mode, the actuator does

complete its open or closed cycle

Gear box problem or

broken rings

Disassemble the actuator and replace

the gear boxes, damaged stop screw.

Normal

operation,

remote control

The actuator does

complete its open or

closed cycle

Fault on the limit

switch or on the stop

mechanism

Reset of the limit switch or on the stop

mechanism

The actuator does not

work under remote

control

Power cut

Power cut diagnostic

Disconnected wires

or cut-off circuit

Replace the faulty wires

Damaged motor or

condenser

Replace the motor or the condenser

Too high motor

temperature

Motor cycle stop

Wiring problem

Check the electrical diagram and the

cable connection

Blocked gear boxes

Unblock the gear boxes

When the actuator continues to turn

even after the cams engage

the limit switches

Fault on the limit

switch

Disconnection or cut-

off circuit.

Replace the limit switch. Reconnect

the cut circuit

Phase inversion

SR 03 PCU ACTUATORS

ASSEMBLING AND MAINTENANCE INSTRUCTIONS

Information given as an indication only, and subject to possible modifications

SECTORIEL S.A.

45, rue du Ruisseau

38290 SAINT QUENTIN-FALLAVIER –FRANCE

Tél : +33 4 74 94 90 70 - Fax : +33 4 74 94 13 95

www.sectoriel.com / Email : secto[email protected]

Pages

12/14

Ref.

IME23070 ENG

Rev.

02

Date

10/2023

13. CONTROL BOARD

N°

Désignation

N°

Désignation

1

Do not touch the factory setting

10

Time delay

2

Input setting switch

11

Limit switch connector

3

Auto scan / Span / Zero button

12

Input / Output

4

Speed volume

13

Do not touch the factory setting

5

Manual button

14

Motor connector

6

Dead band

15

Do not touch the factory setting

7

Potentionmeter connector

16

Fail speed setting switch

8

Load volume

17

Control DIP switch

9

Terminal

SR 03 PCU ACTUATORS

ASSEMBLING AND MAINTENANCE INSTRUCTIONS

Information given as an indication only, and subject to possible modifications

SECTORIEL S.A.

45, rue du Ruisseau

38290 SAINT QUENTIN-FALLAVIER –FRANCE

Tél : +33 4 74 94 90 70 - Fax : +33 4 74 94 13 95

www.sectoriel.com / Email : secto[email protected]

Pages

13/14

Ref.

IME23070 ENG

Rev.

02

Date

10/2023

CONTROL DIP SWITCH

1

F - C

Fail close

2

F - O

Fail open

3

AFULL

3.8 ~ 4.3 : Input fully Close

19.7 ~ 20.2 : Input fully open

4

CH1

Discretion setting

5

CH2

Manual setting

6

REV

Reverse action

1 - Fail close :

When there is no input signal, the actuator auto manically turns to a full close positon.

2 - Fail open :

When there is no input signal, the actuator auto manically turns to a full open positon.

3 - AFULL :

- If the input signal is at 3.8 ~ 4.3mA , the actuator turns to a full close position.

- If the input signal is at 19.7 ~ 20.2mA , the actuator turns to a full open position.

4 - CH1 : Optional modulation

- It is used when the user voluntarily changes the input signal.

Example : When setting to 6~18mA Input.

- CH1 ON →Input 6mA and press ZERO button.

- Input 18mA and press SPAN button. →CH1 OFF.

- Input and check if the device operates normally.

5 - CH2 : Optional modulation using manual lever

- If is used when the user controls the actuator using the manual lever.

Example : When controlling using the manual lever.

- CH2 ON →Put the actuator at Full Close.

→Press the ZERO button→Put the actuator at Full Open.

→Press the SPAN button→CH2 OFF.

→Input and check if the device operates normally.

6 - REV :

- It is used when the actuator operates in the inverse direction.

- When REV is on and at 4mA, the actuator turns to a full open position, and to a full close position when at 20mA.

SR 03 PCU ACTUATORS

ASSEMBLING AND MAINTENANCE INSTRUCTIONS

Information given as an indication only, and subject to possible modifications

SECTORIEL S.A.

45, rue du Ruisseau

38290 SAINT QUENTIN-FALLAVIER –FRANCE

Tél : +33 4 74 94 90 70 - Fax : +33 4 74 94 13 95

www.sectoriel.com / Email : secto[email protected]

Pages

14/14

Ref.

IME23070 ENG

Rev.

02

Date

10/2023

DIP SWITCH for INPUT Setting

S/W

Input

1

2

3

4 - 20 mA

ON

OFF

OFF

2 - 10 V

OFF

ON

OFF

0 - 5 V

OFF

OFF

ON

0 - 10 V

OFF

ON

ON

1 - 5 v

OFF

OFF

OFF

Fail Speed Setting

S/W

Fail Speed

1

2

4 sec

OFF

OFF

7 sec

ON

OFF

10 sec

ON

ON

ZERO / SPAN / ASCN Button

ZERO

Close manual control button / Input module button

SPAN

Open manual control button / Input module button

ACSN

AUTO SCAN BUTTON (ACTUATOR automatic control button)

delivered from the factory the resistance value of potentiometer may can be changed if the user

modifies its limit setting.

Please make sure to press the autoscan button for at least 2 seconds before operating proportional control.

Check the input and output are correct. (Standard : In/Ouptut 4 –20 mA)

Actuator SPEED Setting : (Between 10 to 35 secondes)

Table of contents

Other Sectoriel Controllers manuals

Popular Controllers manuals by other brands

Emerson

Emerson Powerdrive F300 Getting started guide

TECSYSTEM

TECSYSTEM NT935-4 instruction manual

MicroART

MicroART Kes DOMINATOR MPPT 200/60 user manual

Uponor

Uponor Smatrix Base PRO X-147 installation manual

GSL

GSL RBC-12 Installation & operating instructions

Johnson Controls

Johnson Controls Metasys NCE25 series installation instructions

Schako

Schako VAQS DS0 Series manual

Banner

Banner A-GAGE MINI-ARRAY MAC Series instruction manual

Ashly

Ashly VCM-88 operating manual

Thermokon

Thermokon SRC-DO jalousie Installation and operating instructions

ELCART

ELCART 42/12800-00 user manual

Warner Electric

Warner Electric CBC-802 Service & installation instructions