Sedgwick TA315 Instruction Manual

TA315

TILT ARBOR SAWBENCH

OPERATION AND MAINTENANCE

INSTRUCTIONS

MACHINE SERIAL NO. TAH

TA Operation/Maintenance Instructions Page 2 of 36

EC Declaration of Conformity

The manufacturer:

M. Sedgwick & Co. Ltd

Stanningley Field Close, Leeds LS13 4QG

United Kingdom

Telephone +44 113 257 0637

www.sedgwick-machinery.co.uk

Email: admin@sedgwick-machinery.co.uk

declares that the Sedgwick TA315 Tilt Arbor Sawbench, when installed, maintained, and

used in applications for which it was designed, and in compliance with the

manufacturer’s instructions, complies with the provisions of the following European Union

legislation, wherever applicable:

2009/127/EC Machinery Directive

2014/30/EC Electromagnetic Compatibility Directive

BS EN ISO 19085-1:2017 Safety of Machinery. Basic Concepts, General Principles of

Design. Basic Terminology, Methodology.

BS EN 1870-19:2013 Safety of woodworking machines. Circular saw benches (with

and without sliding table)

EN 60204-1:2018 Safety of machinery. Electrical equipment of machines. General

requirements

Signed for and on behalf of the manufacturer:

Managing Director

M. Sedgwick & Co. Ltd, Jan 2022

TA Operation/Maintenance Instructions Page 3 of 36

List of Contents

1.0 Design and Purpose

1.1 Illustration

1.2 Machine Specification

1.3 Shipping Details

2.0 Handling Instructions

2.1 Positioning

2.2 Foundation Drawings

3.0 Connection to a Dust Extraction System

4.0 Electrical Installation

5.0 Switchgear

5.1 The Padlockable Isolator

5.2 Start/Stop Buttons

5.3Circuit Protection

5.4 Emergency Foot Operated Stop Switch

6.0 Machine Setting

6.1 The Spindle Rise & Fall

6.2 Tilting The Spindle

6.3 The Rip Fence

6.4 The Rip Fence Fine Adjuster

6.5 The Riving Knife or Splitter

6.7 Pushsticks

6.8 The Rear Extension Table

6.9 Blade Changing

7.0 Blade Selection

7.1 Blade Maintenance

8.0 Limitations of Use and Safe & Working Practices

8.1Noise Reduction

8.2 Warning Labels

9.0 Maintenance

9.1 Cleaning & Lubrication

9.2 620mm Cross Cut Table Setting & Installation

9.3 1220mm Panel Sizing Table Setting & Installation

9.4 Riving Knife Maintenance

9.5 Saw Spindle Maintenance

9.6 Belt Tensioning

9.7 Pulley Alignment

9.8 Rip Fence Alignment

9.9 Electro-magnetic Brake Installation & Maintenance

10.0 Electrical Information

10.1 Electric Motors: Trouble Shooting Checklist

10.2 Wiring Diagrams

11.0 Parts List

TA Operation/Maintenance Instructions Page 4 of 36

Introduction

This Instruction Manual is designed for you in accordance with The Supply of Machinery

(Safety) Regulations 1992, and the Supply of Machinery (Safety) (Amended) Regulations

1994, which implement the European Machinery Directive 89/392/EEC.

It describes how to operate the machine properly and safely. Be sure to follow the safety

instructions provided as well as any local accident prevention regulations and general

safety regulations. Before beginning any work on the machine, ensure that the manual, in

particular the chapter entitled "Safety" and the respective safety guidelines, has been

read in its entirety and fully understood. This manual is an integral part of the machine and

must therefore be always kept accessible. If the machine is sold, rented, lent, or otherwise

transferred to another party, a copy of the manual must accompany it.

All those appointed to work on or with the machine must have fully read and understood

the manual before commencing any work. This requirement must be met even if the

appointed person is familiar with the operation of such a machine or a similar one or has

been trained by the manufacturer.

1.0 Design and Purpose

The Sedgwick Tilting Arbor Sawbench is a hand fed circular ripsaw designed to re-saw

timber and other analogous materials. These operations include Deep Ripping, Angle

Ripping, Bevelling, Cross Cutting, Mitring, Compound Angling, and Panel Cutting.

Any use outside of the machine's intended purpose shall be considered

improper and is therefore not permitted. All claims regarding damage

resulting from improper use that are made against the manufacturer and its

authorised representatives shall be rejected. The operator shall be solely liable

for any damage that results from improper use of the machine.

It is expressly forbidden to make any unauthorised modifications to the machine.

TA Operation/Maintenance Instructions Page 5 of 36

1.1 Illustration

CROSS-CUT FENCE RIVING KNIFE

LENGTH STOP

SAWGUARD

FENCE CLAMP

HANDLES

RIP FENCE

TABLE INSERT

OPTIONAL ROLLING TABLE

FENCE LOCK

TILT LOCKING HANDLE

FENCE MICRO-SET

CONTROL

BLADE TILT

HANDWHEEL

RISE AND FALL HANDWHEEL FRONT GRADUATED GUIDE BAR

EMERGENCY FOOT STOP SWITCH

TA Operation/Maintenance Instructions Page 6 of 36

1.2 Technical Specification

TA315

SAW BLADE DIAMETER

315mm

SAW BLADE BORE

30mm

SAW BLADE PROJECTION @ 900

@ 450

105mm

76mm

SPINDLE SPEED

3700rpm

MOTOR RATING 3ph

1ph

3.0Kw IE2 (S1)

3.0Kw (S1)

SIZE OF TABLE LENGTH

WIDTH

800mm

750mm

HEIGHT OF TABLE

850mm

DISTANCE SAW TO FENCE

610mm

FENCE WITH MICRO ADJUSTMENT

600x75mm

DUST EXTRACTION OUTLET MACHINE

SAWGUARD

150mm

50mm

TOTAL AIR VOLUME REQUIRED

1445CMH

620mm CROSS CUT TABLE

OPTIONAL

TABLE SIZE LENGTH

WIDTH

600mm

350mm

DISTANCE SAW TO MITRE FENCE

620mm

1220mm PANEL SIZING TABLE

OPTIONAL

TABLE SIZE LENGTH

WIDTH

950mm

1000mm

DISTANCE SAW TO MITRE FENCE

1220mm

RIGHT HAND EXTENSION TABLE

OPTIONAL

TABLE SIZE LENGTH

WIDTH

800mm

700mm

DISTANCE SAW TO MITRE FENCE

1220mm

REAR TAKE OFF TABLE

OPTIONAL

TABLE SIZE LENGTH

WIDTH

800mm

700mm

1.3 Shipping Details

TA315

DIMS (machine only) L x W x H

GROSS WEIGHT

1500x1200x1200mm

345 kg

DIMS (c/w 1220mm Panel Table)

DIMENSIONS (Support Bar)

GROSS WEIGHT

1500x1200x1300mm

2720x250x200mm

466 kg

TA Operation/Maintenance Instructions Page 7 of 36

Personal Protective Equipment

When working on or with the machine, the following must be strictly observed:

Persons with long hair who are not wearing a hairnet are not permitted to work on or with

the machine.

It is prohibited to wear gloves while working on or with the machine.

When working on or with the machine, the following must always be worn by personnel:

Protective clothes - Sturdy, tight-fitting clothing (tear-resistant, no wide sleeves).

Protective footwear - that protect the feet from heavy falling objects and prevent sliding

on slippery floors

Hearing protection - To protect against loss of hearing.

Residual Hazards

The machine is considered operationally safe when used properly; nevertheless, there are

some remaining risks that must be considered:

•The machine runs with high electrical voltage.

Electrical energy can cause serious bodily injury. Damaged insulation

materials or defective individual components can cause a life-threatening

electrical shock.

Before carrying out any maintenance, cleaning, and repair work, switch off

the machine and ensure that it cannot be accidentally switched on again. When carrying

out any work on the electrical equipment, ensure that the voltage supply is completely

isolated. Do not remove any safety devices or alter them to prevent them from

functioning correctly.

• Risk of injury when changing the sawblade

• Risk of injury through accidental contact with the rotating sawblade

• Risk of injury due to ejected workpieces

• Risk of injury from workpiece kickback

• Hearing damage as a result of high noise levels

• Health impairments due to the inhalation of airborne particles, especially when working

with beech and oak wood.

The following section offers a guide to transporting, assembling, and installing the

machine. These are all skills that should not be attempted by those who have not received

relevant training.

2.0 Machine Handling

There is a risk of injury as a result of falling parts while transporting, loading or

unloading the machine.

The machine could be damaged or written-off if subjected to improper

handling during transport.

Always use a sling within the safe working load of the machine weight.

Machine weights are provided above. Sling underneath the machine’s cast table. Do not

walk or stand under the machine during lifting.

TA Operation/Maintenance Instructions Page 8 of 36

Storage

Keep the machine sealed in its original packaging until required for assembly/installation

and be sure to observe the machine handling advice on the outside of the packaging.

Store packed items only under the following conditions

• Do not store outdoors.

• Store in a dry and dust-free environment.

• Do not expose to aggressive substances.

• Protect from direct sunlight.

• Avoid subjecting the machine to shocks.

• Storage temperature: –10° to +50 °C

• Maximum humidity 60 %.

• Avoid extreme temperature fluctuations (condensation build-up).

• When storing for a period longer than 3 months, apply a coat of oil to all machine parts

that might be prone to rusting (corrosion protection). Regularly check the general

condition of all parts and the packaging. If necessary, refresh or re-apply a coat of anti-

corrosive agent.

• If the machine is to be stored in a damp environment, it must be sealed in airtight

packaging and protected against corrosion (desiccant).

Disposal

When disposing of the machine, separate all components into material groups in order to

facilitate recycling. The main structure is made of cast iron and steel and can therefore be

safely dismantled and disposed of without risk of pollution.

Unpacking

Dispose of the packaging materials in an environmentally friendly way and

always in accordance with local waste disposal regulations.

Remove the protective grease using turpentine or paraffin. Do not use any

solvent, petrol or gas oil, which might dull or oxidise the paintwork. Lightly oil

cleaned surfaces to prevent rusting.

2.1 Positioning

There should be provided around every woodworking machine sufficient clear and

unobstructed space to enable the work being done at the machine to be done without

risk of injury to persons employed. You must also ensure that there is an ample power

supply available, together with good lighting and ventilation.

Only operate the machine in ambient temperatures from +10° to +40° C. If the

instructions are not followed, damage may occur during storage.

The chosen floor space should be in good and level condition to enable the machine to

be anchored at four points. Holes for M10 foundation bolts (not supplied) are provided at

either corner of the inside of the fabricated body. Remove the machine’s side guard,

score marks through these holes, drag the machine out of the way, and drill the necessary

holes and insert fixing plugs. Finally, make sure that the saw is not rocking. Pack under the

feet of the base if it is. This will keep the saw from rocking and generating vibration during

the cut.

TA Operation/Maintenance Instructions Page 9 of 36

2.2 TA315 Foundation Drawing

1800mm + 620mm for RH Extension

Hole centres for bolting to floor

470mm

1210mm

850mm

685mm

TA Operation/Maintenance Instructions Page 10 of 36

3.0 Connection to a Dust Extraction System

This machine must be connected to a compatible dust extraction unit using a

suitable size and grade of vacuum hose.

Wood dust can be harmful to health by inhalation and skin contact, and concentrations

of small dust particles in the air can form an explosive mixture. Prevention or control of

wood dust exposure should as far as is reasonably practicable, be achieved by measure

other than the provision of personal protective equipment.

Employers have duties under the Provision of Use of Work Equipment Regulations 1998

(PUWER) and the Control Of Substances Hazardous To Health Regulations 1988 to carry out

an adequate assessment of the possible risks to health associated with wood dust

particularly when machining hardwoods, and if necessary seek expert advice as to the

method of dust extraction.

The minimum recommended air volume required to effectively exhaust this machine at

20m/sec is 1400 Cubic Metres per Hour.

A 150mm-dia outlet is located at the rear of the machine base. Provision is also made for

extraction from above the sawguard, simply remove bottom of the 50mm dia connection

point.

Always switch the dust extraction system on before switching on the machine.

4.0 Electrical Installation

All electrical wiring should be carried out by a fully qualified electrician and in

strict observance of the safety instructions.

Please follow these directions when connecting to the mains:

•The motor, starter, and isolator have been wired in at the factory and tested

before despatch. All that is required is to connect the power supply to the

isolator.

•Check that the supply details on the motor nameplate correspond with the site

supply.

•It is important that the correct cable size is used to avoid a voltage drop at the

motor terminals. If the motor is operated on a voltage outside, plus or minus 6%

of the spot voltage, then premature failure will occur.

•Do not wire single-phase machines into a 13 amp plug socket.

•It is important to check rotation of the sawblade which should be clockwise

when viewed from the left of the machine.

Should you encounter problems on start up please refer to the trouble shooting checklist

provided in the Maintenance Instructions.

TA Operation/Maintenance Instructions Page 11 of 36

5.0 Switch Gear

5.1 The Padlockable Isolator

With this switch in the OFF position the machine is effectively isolated from

the supply to allow personnel safe access for maintenance or repair work

and to prevent dangerous restarts. To prevent unauthorised use of the

machine the switch can also be secured in the OFF position using a

padlock.

To operate the machine first turn the isolator to the ON position.

5.2 Start / Stop Buttons

The motor is then started by pushing the green (power on) button on the starter panel and

stopped using the red (power off) button. The mushroom headed lock-off stop switch,

once pressed will remain locked in the off position. To restart the machine, it is necessary

to release the off button by twisting it in a clockwise direction.

5.3 Circuit Protection

In case of a mains failure the starter is fitted with no volt release protection and will not

restart without being switched on again. The starter is also fitted with an overload

protection device. An electrical overload occurs where an electric motor is subjected to a

greater load than it was designed for. This can be caused by short circuit, by incorrect

installation, or by misuse (including poor machine maintenance). The inbuilt breaker will

therefore help prevent damage to the motor should such a situation occur. The motor

cannot be restarted until the breaker has reset itself.

5.4 Emergency Foot Operated Latching Stop Switch

This switch is provided for use in emergency situations only. We do not

recommend that it is used in lieu of the stop switch on the front of the

starter panel. The foot switch once pressed will remain locked in the off

position. To restart the machine, it is necessary to release the switch by

pulling it towards you.

TA Operation/Maintenance Instructions Page 12 of 36

6.0 Machine Setting

Details on the correct setting of the guard, fence and riving knife, together with the use of

the necessary safety devices, are detailed in the following sections of this manual. Prior to

these operations however the following checks should be carried out:

1. The machine is isolated.

2. The saw is not cracked or distorted.

3. The saw collar is clean and in good condition.

4. The sawblade is mounted correctly for clockwise rotation when viewed from left-hand

side of machine.

5. The gap plate is correctly positioned.

6. The saw runs free (check by slowly turning it by hand).

7. The sawguard and riving knife are secure.

8. The timber is free of grit, nails or other foreign bodies.

9. The table is free of spanners, rules etc., and that all tools are returned to their rightful

place.

ENSURE THAT ALL STOCK IS CLEAR OF THE BLADE BEFORE START-UP

ENSURE THAT THE SAWBLADE HAS REACHED FULL SPEED BEFORE PRESENTING THE

WORKPIECE TO IT. IT IS ESSENTIAL THAT THE MACHINE IS SWITCHED OFF WHEN LEFT

UNATTENDED.

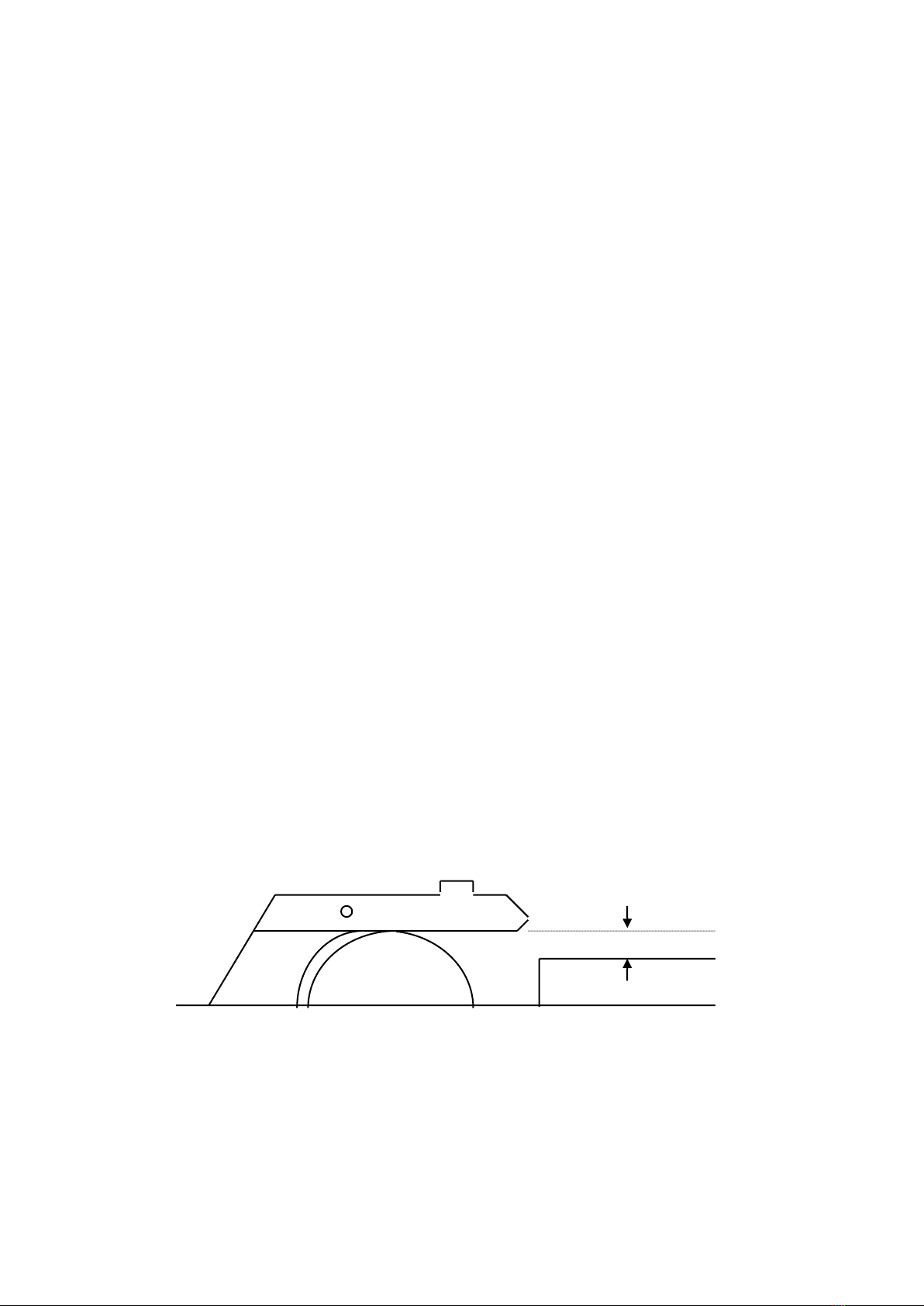

6.1 The Spindle Rise and Fall

The height of the saw spindle is adjusted using the rise and fall handwheel at the front of

the machine.

The blade should be set so that the distance between the bottom edge of the sawguard

and the top of the timber being cut does not exceed 10mm. In this position you should

aim to have 3-5 of the blade’s teeth in the wood during the cut. This will minimise the

amount of friction and enable you to maximise feed speed. Clearly, the thicker the stock

the more teeth there are in the wood. This increases friction, reduces feed speed, and

taxes the saw motor. The solution is to replace the blade with a coarser one. Avoid the

temptation to raise the blade to full height. While the number of teeth in the wood

decreases, the footprint of the blade in the wood is much greater. This increases the

chance of kick-back. There is also a much greater chance of injury with the blade at full

height.

10mm

6.2 Tilting the Spindle

The motor and motor bracket tilt on a quadrant of 450from the vertical, by means of the

handwheel positioned to the side of the machine. The graduated protractor scale at the

front of the saw indicates the angle at which it is set. A locking lever is positioned above

the rise and fall handwheel for locking / unlocking the tilt. Do not attempt to tilt the

sawblade with the lock engaged.

TA Operation/Maintenance Instructions Page 13 of 36

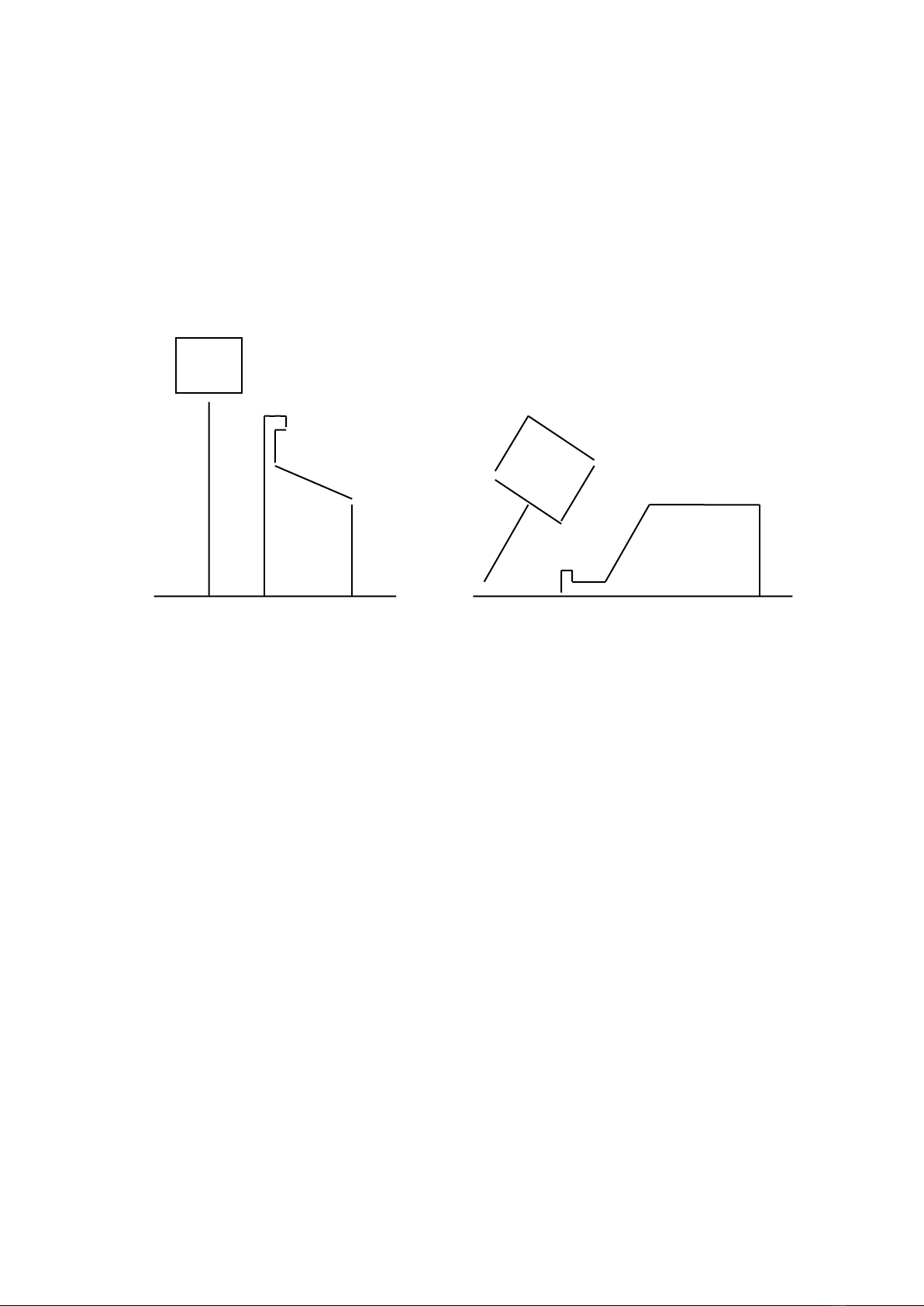

6.3 The Rip Fence

The function of the sawfence is to act as a guide and support to the timber. It can be

adjusted fore and aft to suit the operation being carried out. When ripping, the front edge

of the fence should be in line with the root of the teeth of the sawblade. When

crosscutting, the maximum possible length of fence should lie on the machine table. To

adjust, simply release the two clamping levers at the back of the fence. Note: the fence

casting is eased along its travel by means of a nylon roller. To ensure that the roller remains

in contact with the machine table in all fence positions, the fence extrusion should be set

slightly higher than the table itself. When sawing thin pieces of timber ensure that the two

positional fence is adjusted to suit:

High position for deep work Low position for shallow or angled cutting

6.4 The Rip Fence Fine Adjuster

For approximate setting of the width of cut the table rule can be used, located on the

fence support bar, although the accuracy of this will depend on the sawblade being

used. The most reliable method for setting the width of cut is to measure from the fence to

the inside edge of the tooth. This takes account of different amounts of set on the saw

teeth of other saws. To take account of any wobble on the saw, a trial cut should be

made and measured with a steel rule; then adjustments may need to be made using the

fine adjustment screw. The guards should be in place for the trial cut. Ensure that the

machine is switched off before making any adjustments.

6.5 The Riving Knife or Splitter

The riving knife should be adjusted so that at table level the distance between the front of

the knife and the saw teeth does not exceed 8mm and its arc follows that of the

sawblade.

Its height should be adjusted so that the bottom of the sawguard covers the teeth of the

sawblade. The sawguard must be adjusted so that it is parallel with the machine table

using the sawguard horizontal adjustment.

TA Operation/Maintenance Instructions Page 14 of 36

8mm Max.

6.7 Pushsticks

Pushsticks (provided as standard with this machine) should always be used when making

any cut less than 300mm in length or when feeding the last 300mm of a longer cut, to

avoid working with hands close to the sawblade. The leading hand should never be closer

than is necessary to the front of the saw and hands should never be in line with the saw

blade. When a pushstick is used, the left hand should be moved to a position along the

plate of the saw, so that in the event of an unexpected movement of the workpiece, the

fingers will not be thrown against the teeth.

A pushstick should always be used to remove the cut piece from between the saw and

fence, unless the width of the cut piece exceeds 150mm.

A pushblock should be used when cutting small workpieces or in circumstances where it is

necessary to push the workpiece against the fence.

6.8 The Optional Rear Extension Table

If an assistant is employed at the rear of the machine to remove cut pieces the table

should be extended so the distance between the saw blade spindle and the rear edge of

the table is at least 1200mm. The assistant should always remain at the outfeed end of the

extension table and should not lean forward and put his hands near to the saw teeth.

1200mm

TA Operation/Maintenance Instructions Page 15 of 36

6.9 Blade Changing

Saws should be regularly examined to check that the plate is free from cracks and is true,

that the tips are firmly held in position and damage free. The teeth should be sharpened

the moment they become dull. The Grinding of TCT Sawblades requires specialised

equipment. This creates a tendency to retain the blade in the saw long after initial dulling

takes place. This is a false economy.

To remove the sawblade first isolate the machine, then remove the gap plate. Loosen

screw ‘A’ on the sawguard and tilt the front of the guard upward to expose the blade.

Rotate the blade until one of the holes in the saw spindle (behind the fixed collar) is

exposed through the slot in the cradle plate. Slide the spindle lock bar down the slot and

into the exposed hole. This will prevent the spindle from rotating. Use the Saw Spanner

provided to loosen and remove the securing nut. Note the direction of the thread, left

hand. Finally remove the loose saw collar and blade. The use of a wire hook for

transferring the saw to the tool room reduces the risk of cut fingers and damaged saw

teeth (if the blade is dropped when carrying it by hand).

To replace the blade clean both saw collars, ensure that the sawblade being fitted is

clean and sharp, and place onto the spindle ensuring that the direction of rotation is

correct.

Replace the loose saw collar and saw nut and tighten.

Important: Remove the spindle lock bar prior to replacing the gap plate, levelling the

sawguard, and re-tightening screw ‘A’.

7.0 Blade Selection

The machine’s designation (e.g. TA315) indicates maximum sawblade diameter in mm.

Spindle speed is set accordingly, and we do not recommend the use of smaller diameter

sawblades, which require a much faster running speed. When using a smaller diameter

sawblade , be sure that its rpm rating is correct for the saw. The blade’s peripheral speed

will decrease. This means that feed speed (speed at which stock goes through the blade)

will also decrease. This could mean increased friction and burning. Smaller diameter

blades should have fewer teeth than the larger diameter blade that has been removed.

Do not attempt to use a blade that is less than 200mm dia on the TA315.

All blades will require a 30mm bore and a 14mm pinhole (25mm from centre to centre).

Selecting the correct blade for each operation is an essential link in the sawing process.

Your guarantee will be invalidated if you do not select the correct cutting tools.

The sawblade supplied with the machine is a 32-tooth tungsten carbide tipped anti-kick

back blade, with alternate top bevel and raker teeth to give a good finish for both ripping

and crosscutting applications. Its anti-kick back feature limits the size of bite any tooth can

take, and therefore the grip that the saw has on the wood, giving the operator better

control of the stock. It does however make the blade unsuitable for deep ripping. When

cutting material in excess of 76mm, use a blade which is expressly designed for this

purpose. Misuse will put undue load on the motor, which could cause long-term damage

to the motor windings.

Tungsten Carbide Tipped sawblades will stay sharp for much longer than conventional

saws and will produce a much higher quality of cut. The following table gives examples of

the type of TCT blades available, and their applications:

TA Operation/Maintenance Instructions Page 16 of 36

Type

Description

No.

Teeth

Softwood Rip

For rough ripping of softwoods and green hardwoods.

Large gullet space for chip clearance and rapid cutting

with grain

24

Universal Rip

Ripsawing of both hardwood and softwood and

occasional rough crosscutting. 200tooth angle, 100

alternate bevel.

32

Combination

Rip & Crosscut

General Purpose Blade providing a good finish for both

ripping and crosscutting applications. 100tooth angle, 100

alternate bevel.

48

Trimming

Accurate sizing and trimming of timber, plywoods and

particle boards, veneers, and soft plastics. 100tooth angle,

triple chip.

72

Finishing

Fine trimming and finishing applications for double sided

laminated boards, veneers, and hard plastics. 50 tooth

angle, triple chip.

96

Courtesy of Atkinson Walker

For maximum efficiency, always use the coarsest blade that produces adequate results.

7.1 Blade Maintenance

A dull, badly set or badly ground blade will cause slow, inefficient cutting. It will also

increase the effort required for feeding and possibly overload the saw motor. It is good

practice to have a second set of sharp blades available for when dull ones are away for

sharpening (for saw sharpening services look under ‘SAW SHARPENING & REPAIRS’ in the

Yellow Pages). Deposits of gum or resin near the saw teeth tend to cause a saw to stall or

the timber to stick. This gum can be best removed with trichlorethylene, kerosene or

turpentine. The most common method for cleaning off resin is to use a brush and scrape.

A wooden scraper will avoid unnecessary scratching of the sawblade surface. Never try to

clean a running blade.

TA Operation/Maintenance Instructions Page 17 of 36

8.0 Limitations of Use and Safe Working Practises

Training and instruction is a central requirement of the Provision of Use of Work Equipment

Regualtions 1998 (PUWER). No hand-fed circular saw can be operated by any person

under the age of 18 without them having first completed an approved course of training.

The regulation does realise that young persons may need to operate one of these

machines as part of a course, and such use is permitted provided that it is carried out

under the supervision of a person who has thorough knowledge and experience of the

machine and of its safeguarding requirements.

It is essential that all operators of circular saws are adequately trained in the use,

adjustment and operation of the machine, this covers in particular:

•The dangers associated with the operation of the machine.

•The principles of machine operation, correct use and adjustment of the fence, blade

and safeguards.

•The correct selection of sawblade for each operation.

•The safe handling of the workpiece when cutting.

•The position of the hands relative to the blade and the safe stacking of workpieces

before and after cutting.

Persons who install this machine for use at work have a duty under the Health and Safety

at Work Act 1974 to ensure, as far as is reasonably practicable, that nothing about the

way in which it is installed makes it unsafe or a risk to health at any time during setting, use,

cleaning, and maintenance. This includes such aspects as correct assembly, electrical

installation, construction of enclosures, and the fitting of guards and ventilation

equipment. When installing this machine consideration must be given to the provision of

adequate lighting and working space.

Repairs and maintenance must only be undertaken by competent technicians. Ensure

that all power supplies are isolated before maintenance work begins. Instructions for

routine maintenance work are included in this manual.

The machine is designed to be operated by only one person. If an assistant is employed

to remove cut pieces a table extension must be fitted to the rear of the machine as

detailed above.

No circular sawing machine is to be used for the crosscutting of logs and branches. These

operations relate mainly to the production of firewood and the practice of feeding the

wood by hand to a conventional sawbench is not permitted.

The use of a circular saw for the cutting of any rebate, tenon, or groove is prohibited,

unless the part of the blade above the table is effectively guarded. When it is not

practicable to carry out these operations with the riving knife and top guard in position,

suitable alternative guards and fixtures will be necessary.

TA Operation/Maintenance Instructions Page 18 of 36

8.1 Noise

Noise levels can vary widely from machine to machine depending on conditions of use.

Persons exposed to high noise levels, even for a short time, may experience temporary

partial hearing loss and continuous exposure to high levels can result in permanent

hearing damage. The Woodworking Machines Regulations require employers to take

reasonably practicable measures to reduce noise levels where any person is likely to be

exposed to a continuous equivalent noise level of 90 dB(A) or more over an 8 hour

working day. Additionally, suitable ear protectors must be provided, maintained and

worn.

Machines identified as generating unhealthy noise levels should be appropriately marked

with a warning of the need to wear hearing protection and it may be necessary to

designate particular areas of the workplace as ‘Ear Protection Zones’. Suitable warning

signs are specified in the Safety Signs Regulations Act 1995. It may be necessary to

construct a suitable enclosure, for which professional advice should be sought.

Further information and references to practical guidance are contained in free leaflets

available from The Health & Safety Executive.

Using correctly designed extraction hoods and a compatible system the compound

effect on this machine was to increase the readings by 1dB(A).

The following noise levels were recorded at a distance of one metre from the machine

(operator side) with a 24-tooth anti kick sawblade fitted, using varying feed rates and

depths of cut.

TIMBER

DEPTH OF CUT

NOISE LEVEL dB(A) @ 1M

None

No load

80

Softwood

20mm

85

Softwood

38mm

87

Softwood

75mm

88

Hardwood

20mm

86

Hardwood

38mm

88

Hardwood

75mm

89

The figures quoted for noise are emission levels and not necessarily safe working levels.

Whilst there is a correlation between emission levels and exposure levels, this cannot be

used reliably to determine whether or not further precautions are required. Factors that

influence the actual level of exposure to the work force include the duration of exposure,

the characteristics of the workroom, the other sources of dust and noise, etc., i.e. the

number of machines and other adjacent processes. Also the permissible exposure levels

can vary from country to country. This information, however, will enable the user of the

machine to make a better evaluation of the hazard and risk.

The list below outlines some of the variables which directly effect the noise level of the

machines:

VARIABLE

RELEVANT FACTOR

EFFECT

Timber

Species

Hard stiff timber can mean more noise

(approx. 2dB(A) difference when cutting

oak and pine) & more transmitted noise.

Width

Wide work pieces radiate noise over a

greater area increasing the noise level.

TA Operation/Maintenance Instructions Page 19 of 36

Thickness

Thin workpieces generally vibrate more

increasing the noise level.

Length

Long workpieces transmit noise away

from the cutting area towards the

operator.

Tooling

Width of Blade

This affects the windage noise and

increases roughly in proportion to the

width of cut.

Blade Sharpness

Dull and worn blades exert more force

on the timber thus creating more noise.

Balance

Out of balance blades mean vibration

and changes in cutting conditions,

resulting in increased noise levels.

Extraction

Air Velocity/ System Design

Resonant conditions can lead to high

noise levels, excessive turbulence and

chip impact can increase noise levels

substantially

8.2 Warning Labels

The warning label fixed to the machine gives the following advice. Please ensure that all

operators read it carefully.

Ensure that you fully understand the manufacturer’s

instruction manual and have received sufficient training in

the use of this machine and the particular safety

precautions to be observed.

BEFORE OPERATING THIS MACHINE ENSURE THAT:

1. All guards and fences are securely fitted and correctly

set in accordance with the current regulations.

2. Tooling is of the correct type, sharpness, and direction of

cut and is securely fastened.

3. Correct spindle speed and feed is selected (for the cutter

equipment) where appropriate.

4. Loose clothing is either removed or fastened and

jewellery removed.

5. Suitable jigs and push sticks are available for use where

appropriate.

6. The working area is well lit, clean and unobstructed.

7. Extraction equipment where appropriate is switched on,

properly adjusted and working efficiently.

DURING MACHINING:

1. Wear suitable protective equipment where necessary,

e.g. goggles, ear defenders and dust mask.

2. Ensure all moving parts of the machine are stationary

before setting, cleaning or making any adjustments.

3. Ensure all power sources are isolated before any

maintenance work commences.

TA Operation/Maintenance Instructions Page 20 of 36

General caution

Check guard

Refer to instruction manual

Use hearing protection

Use protective eyewear

Use protective footwear

Use protective apron

Wear a mask

All notices and labels which are affixed to the machine must be kept readable and may

not be removed. Any that have become damaged or unreadable must be replaced

promptly.

Table of contents

Popular Saw manuals by other brands

Target

Target PRO 35 III DIESEL operating instructions

ALDI

ALDI Workzone Titanium HM80MP user manual

Bauer

Bauer 21702CR-B user manual

Skil

Skil 5580 Operating and s Operating and safety instructions

Eurotops

Eurotops 20405 operating instructions

Record Power

Record Power SABRE-250 Original instruction manual