See Water Oil Smart OSSIM-30 Setup guide

Oil Smart® Simplex Panel (Model #OSSIM-30)

Oil Smart System:

The Oil Smart® System includes the Oil Smart®

Water Pump Control and Oil Smart® High Liquid

Alarm. The Oil Smart® Pump Controller, when

combined with a manual pump, automatically pumps

water from elevators, transformer containment barriers,

underground vaults, substations, and other applications

without the risk of pumping oil. While the Oil Smart®

Alarm provides information to building management or

maintenance personnel about leak or high liquid level

conditions at any given location. The alarm will

activate with the presence of any liquid/substance and

will identify if oil or water is present. Since 1995, the

Original and Patented Oil Smart System has been the

reliable choice for safely pumping water. Installation of

the Oil Smart System allows you to comply with State

and Federal regulations while reducing the risk of

adverse publicity, fines and expensive cleanup costs.

Features:

• No Moving Parts. Patented Electronic Oil Smart®

and Liquid Smart® Controls

• Indoor/Outdoor NEMA 4X Heavy Duty

Polycarbonate Enclosure: 10”x8”x4”, UL-50 Type

6P Listing

• Voltage: 120/240VAC Single Phase 50/60Hz, 30

Amp Motor Start Relay

• CSA International Certified No. 229594

• External Mounting Feet: Quick Installation.

• High Liquid Alarm with Test and Silence Features,

Red Beacon Alarm Light, White Light for Water

Present, Yellow Light for Oil Present, High 84

Decibel Audible Alarm. Complete Dry Contacts

for Each Alarm Condition.

• Oil Smart Pump Switch and Liquid Smart Alarm

Sensor with 20’ cord and mounting brackets.

• HOA Switch and Green Light for Pump Run

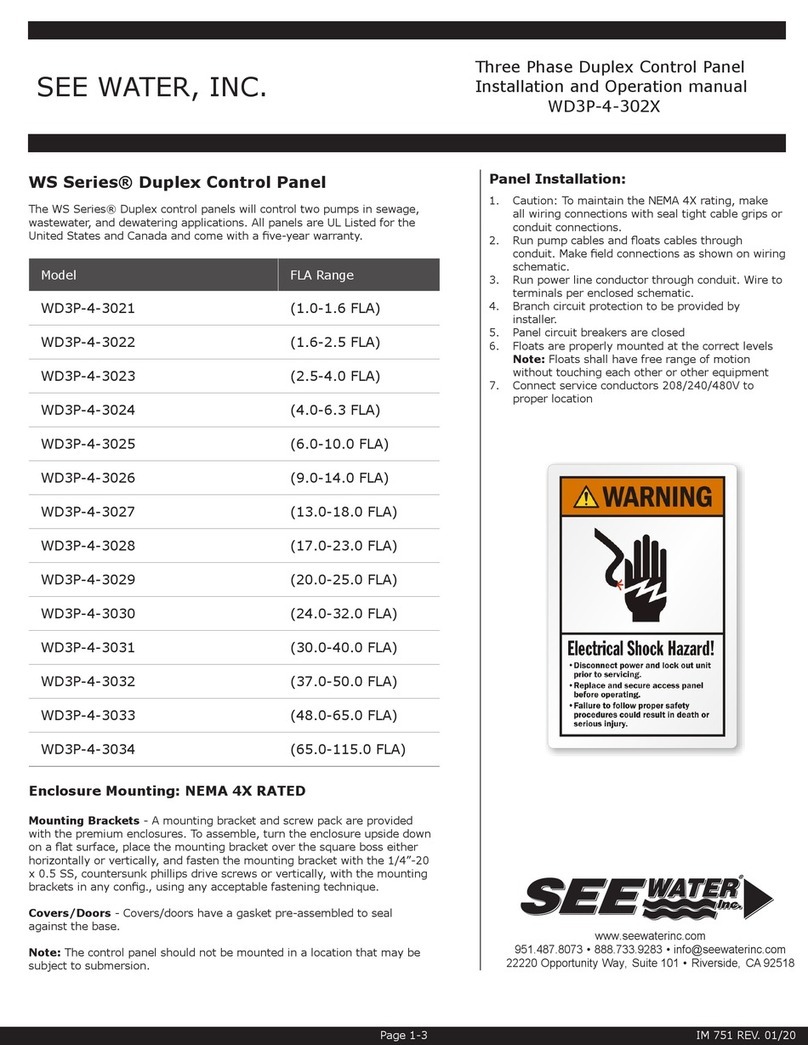

Panel Installation:

• Caution: To maintain the NEMA 4X rating, make

all wiring connections with seal tight cable grips or

conduit connections to be supplied by end user.

I. Determine hole location on panel for liquid-

tight or conduit connectors. Drill proper

sized holes for conduit connections.

II. Determine mounting location for control

panel. Mount panel using mounting feet

supplied.

III. Attach connectors and conduits.

IV. Run pump cable, Liquid Smart® cable, and

Oil Smart® cable through conduit. Make

field connections as shown on wiring

diagram (See Page 3).

V. Run two separate power line conductors

through conduit. (One 15 amp 120VAC for

alarm and one 20 Amp maximum for motor

load). Wire to terminals per enclosed

schematic. It is important that the alarm

circuit is independent of the pump to assure

that the alarm will activate if pump circuit

fails.

Components Installation:

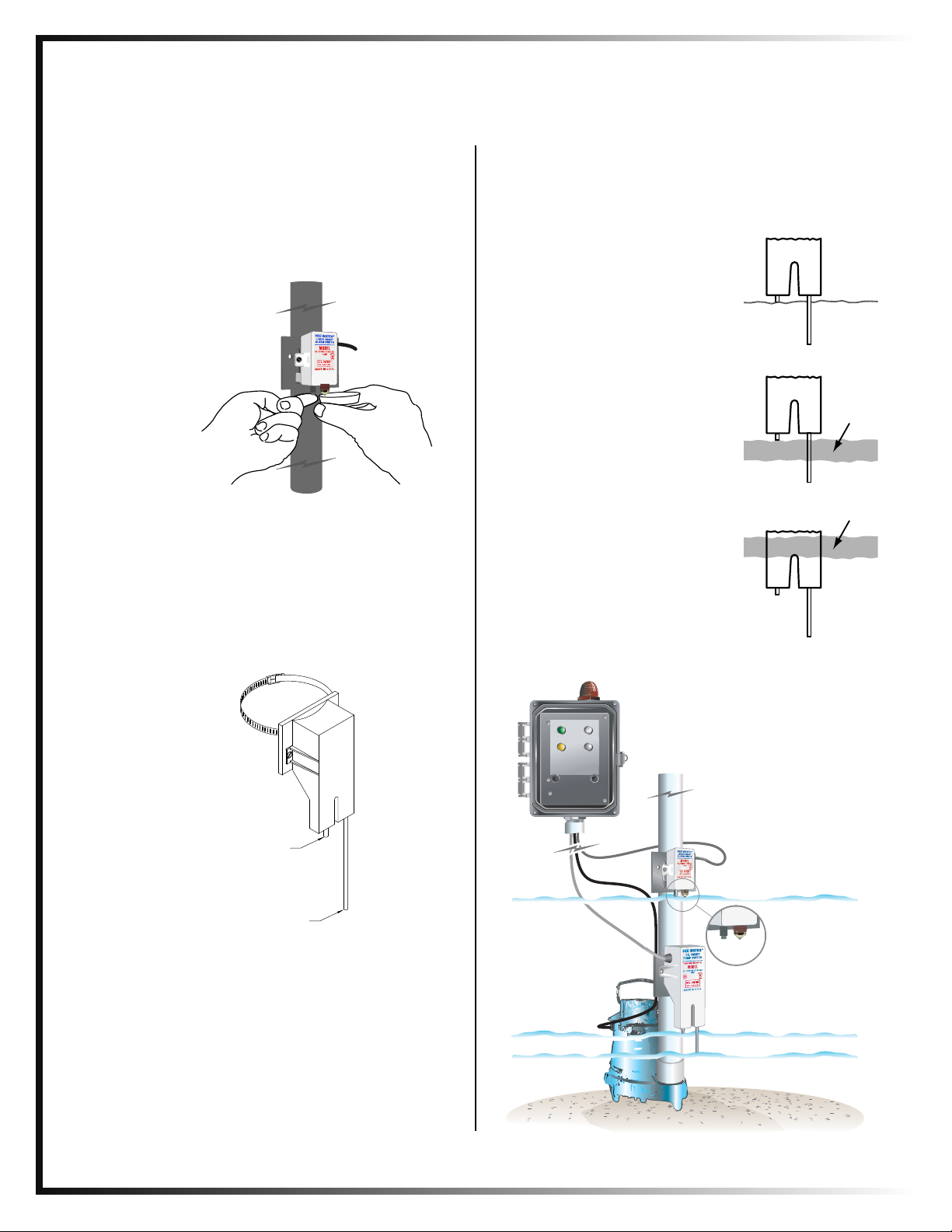

I. The Oil Smart Pump Switch and Liquid Smart

Alarm Sensor shall be mounted in a clean

environment, clear of mud and all metallic

debris.

II. The switches shall be installed where the water

intrusion will not directly contact or splash the

white plastic case.

III. Mud or other conductive materials left on the

body of the switches will hamper its operation;

clean the switch with rubbing alcohol prior to

initital installation.

IV. Mount with enclosed mounting brackets. Note:

Keep sensors at least 2” clear of any metallic

material.

1. All installations must be in accordance with the National Electrical

Code, and any other applicable state and local electrical

requirements.

Sing

#

www.seewaterinc.com

or www.oilsmart.org

951.487.8073 • 888.733.9283

Email: info@seewaterinc.com

121 North Dillon Street • San Jacinto, CA 92583

P.O. Box 1269 • San Jacinto, CA 92581

Fail-Safe Technology since 1995.

©Copyright 2009 See Water, Inc. All Rights Reserved.

Installation and Operator's Manual

Oil Smart® Simplex Panel (Model #OSSIM-30)

Testing:

• Liquid Smart® Alarm Sensor: Fill small cup

supplied with oil. Submerge only the plastic lens

(optic sensor) into oil, the alarm will activate

showing oil present (yellow light). Now touch

finger to the exposed stainless steel sensor, the

alarm will show water present (white light) will

turn on.

• Oil Smart® Switch: Place the HOA switch on

control panel in the automatic position. Place your

thumb on the short sensor of Oil Smart® Pump

Switch and the pump will turn on. While touching

the short sensor, touch the long sensor “off” with

your fingers. Remove your thumb from on sensor

and begin to move your fingers down the off

sensor. Remove your fingers from off sensor and

the pump will turn off.

Operation:

Normal Condition (Water Only)

The short sensor probe turns the pump

"on" and the long sensor probe turns

the pump "off". When the short sensor

is in contact with water, the pump will

continue to cycle "on and off" until the

short sensor detects oil.

Oil Present Condition

The pump will not cycle if oil is in

contact with the short sensor.

High Water (Oil Present Condition)

If additional water enters the basin, it

will cause the oil layer to rise above

the short sensor, resulting in the pump

cycling.

"OFF"

"ON"

WATER

WATER

OIL

LAYER

WATER

OIL

LAYER

PUMP ON MANUAL OFF AUTO

WATER OIL

SILENCE TEST

SSEEEE

WWAATTEERR,,IInncc..

Oil Smart

®

Alarm System

©Copyright 2009 See Water, Inc. All Rights Reserved.

Oil Smart and Liquid Smart Maintenance:

Plastic Switch case must be kept clean. Free of: rust,

mud, soap, etc. If switch is submerged in water

during initial installation, switch must be cleaned.

Clean with a rag and household Alcohol or

kerosene. Consistent inspection and preventive

maintenance ensures longevity and proper operation

of components. It is recommended to develop

a schedule to keep the white plastic case clean.

Liquid Smart Switch

Oil Smart Switch

High Liquid Level

On

Off

Note: Off sensor needs to be a minimum

of 2" above the impeller of the pump

See Water

Alarm

Circuit Board

Terminal 1 Terminal 2

Motor

Starter

Blue

Red

White

Green

X

(120V) L

N

Water

Common

Oil

High Liquid

Terminal 1 (Alarm) Terminal 2 (Pump Control)

Liquid Smart 120V Dry Contacts

For 120V Power Supply

For 240V Power Supply

Setup for 120V *

(For 240V,

Remove Jumper)

L1 N* T1 T2

P N

Brown

Black

White

Power Supply Pump Oil Smart Switch

120V

P P N T1 T2

P N

Power Supply Pump Oil Smart Switch

120V

Brown

Black

White

©Copyright 2009 See Water, Inc. All Rights Reserved.

Data:

• Pollution degree 2

• Installation category II

• Altitude 2000m

• Humidity up to 5% to 95%

Warranty:

See Water® Inc. warrants that the See Water Control Panel will be free from defects in material and

workmanship for a period beginning as of the date of purchase for two (2) years. Replacement of the panel

and/or components is only at the sole discretion of See Water Inc. This warranty is valid only when the

product is installed in strict compliance with the manufacturer's installation instructions. See Water, Inc.

will in no way be responsible for the reliability of any pump that is connected to or operates with See

Water, Inc. products. See Water, Inc. will replace the panel when it is returned to See Water's factory,

postage prepaid with proof of original purchase included. It is imperative that in no way, can any

components/parts be removed from the control panel during installation. Any alterations/additions/changes

to the panel will result in a void warranty. Failure to properly install and test this product can result in

personal injury or equipment malfunction.

©Copyright 2009 See Water, Inc. All Rights Reserved.

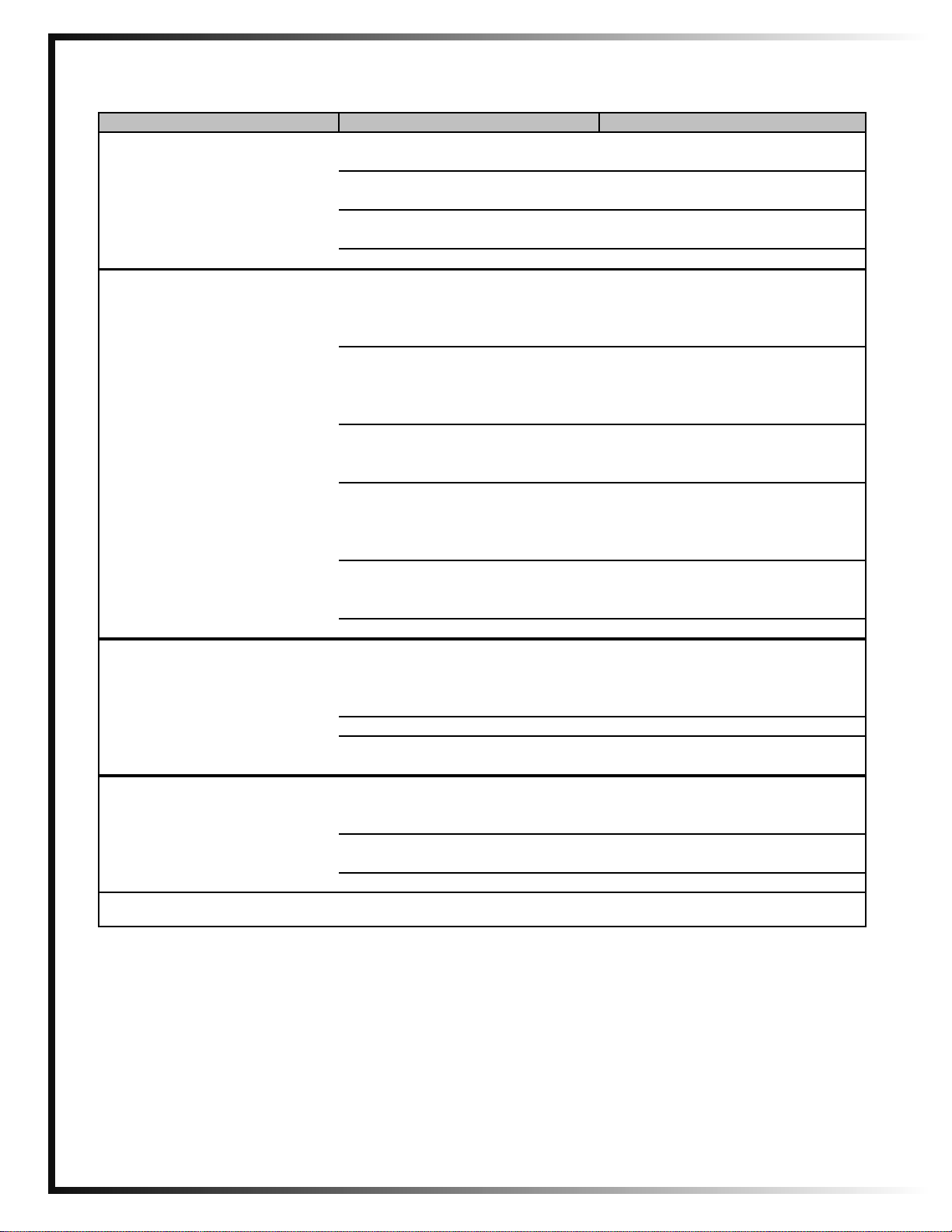

Problem Possible Cause Solution

Pump Control does not activate The Oil Smart Switch will not Make sure phase and neutral are

the pump. Pump does not run. function with incorrect polarity. not reversed.

Loose connection in control panel. Confirm all connections are tight

or electrical system. and secure.

Non-Conductive Water Test pump switch with fingers per

(Highly Filtered Water) the instructions (See Page 2)

Defective Control Replace Control

Pump Control is not operating Problem with electrical system Check electrical circuits for

properly; not consistant or common neutrals;

staying on. may cause switch to not function

correctly.

Control Panel Wiring Problems Do not run DC conductors

through same conduit as AC

conductors. Circulating current

can cause problems.

Control is not clean of conductive White plastic case must be kept clean.

material. Clean with alcohol or an oil base

product: kerosene, solvent.

Control is mounted to metallic pipe Keep control (1" to 2") clear of

any metallic material. Mount to pvc

pipe or wrap electrical tape

between pipe and switch.

Float switch attached to pump Float switch must be removed,

secured in manual operation, or

replaced with correct pump.

Defective Control and/or Pump(s) Replace Control and/or Pump(s)

Alarm will not activate Power supply failure Confirm separate 120V power to

circuit board. Can be jumpered

from incoming power on pump

terminal if 120v is available.

Defective Alarm Sensor Replace Alarm Sensor

Loose connection in control panel. Confirm all connections are tight

or electrical system. and secure.

Pump will not turn on or pump is Incorrect match on control panel Confirm correct pump voltage and

not functioning properly. and pump. wires matched to correct control

panel

Loose connection in control panel. Confirm all connections are tight

or electrical system. and secure.

Defective Pump(s) Replace Pump(s)

Oil Smart Control Panel Troubleshooting Guide

Any technical questions on this product should be directed to See Water, Inc at 888-733-9283.

Other See Water Control Panel manuals

See Water

See Water WS Series Setup guide

See Water

See Water WD3P-4-302 Series User manual

See Water

See Water Oil Smart OSSIM-30 User manual

See Water

See Water Oil Smart OSD1P-102 Series User manual

See Water

See Water OSSIM-TP-100 Series User manual

See Water

See Water WS1P-TP-1001 User manual

See Water

See Water Oil Smart OSD3P-30 Series User manual

See Water

See Water OSSIM-TP-30 Series User manual

See Water

See Water WS Series Setup guide

See Water

See Water WS Series User manual