Your Trusted Source for Quality Control Panels.

®

Single Phase Simplex Control Panel

Installation and Operation Manual

OSSIM-30

SEE WATER, INC.

Panel Installation:

1. Caution: To maintain the NEMA 4X rating, make all wiring connections

with seal tight cable grips or conduit connections.

2. Run pump cable and Oil Smart® cables through conduit. Make eld

connections as shown on wiring schematic.

3. Run power line conductor through conduit. Wire to terminals per

enclosed schematic.

4. Branch circuit protection to be provided by installer.

5. Panel circuit breakers are closed

6. Mount Oil Smart® pump switch and Liquid Smart® alarm sensor with

provided mounting hardware to pump discharge pipe. The ‘OFF’ sensor

of the Oil Smart® pump switch shall be positioned at least 3” above

the impeller of the pump.

7. Mounting of the Liquid Smart® Sensor is application driven and is

to be placed where a high liquid is deemed necessary. The Liquid

Smart® Sensor is typically mounted 3” - 6” above the Oil Smart®

Pump Switch.

8. Connect service conductors 120/208/240VAC to proper location

Enclosure Mounting: NEMA 4X RATED

Mounting Brackets - A mounting bracket and screw pack are provided

with the premium enclosures. To assemble, turn the enclosure upside down

on a at surface, place the mounting bracket over the square boss either

horizontally or vertically, and fasten the mounting bracket with the 1/4”-20

x 0.5 SS, countersunk phillips drive screws or vertically, with the mounting

brackets in any cong., using any acceptable fastening technique.

Covers/Doors - Covers/doors have a gasket pre-assembled to seal

against the base.

Note: The control panel should not be mounted in a location that may be

subject to submersion.

Additional Panel Options:

28 - Power on Dry Contact

• Normally open 60V AC/DC

DPR - Pump Run Dry Contact

• Normally open 60V AC/DC

24 - Pump Exerciser

• Auto cycles pumps daily, weekly or monthly.

Run Time Options:

• Position A: 50ms (DIP Switch 1,2, and 3)

• Position B: 100ms

• Position C: 4s

• Position D: 8s

Remote Monitoring Dry Contacts:

1. Normally Open dry contacts for high oil, high water, and

general high liquid alarm.

Oil Smart® Simplex System: 120/208/240VAC

The Oil Smart® OSSIM-30 System incorporates pump controls and alarm

sensors that differentiate between oil and water, allowing companies to

responsibly discharge the water without the risk of pumping oil. Installation of

the OSSIM-30 keeps companies in compliance with Elevator Code

ASME A17.1 and State/Federal regulations while reducing the risk of adverse

publicity, nes, and expensive cleanup cost.

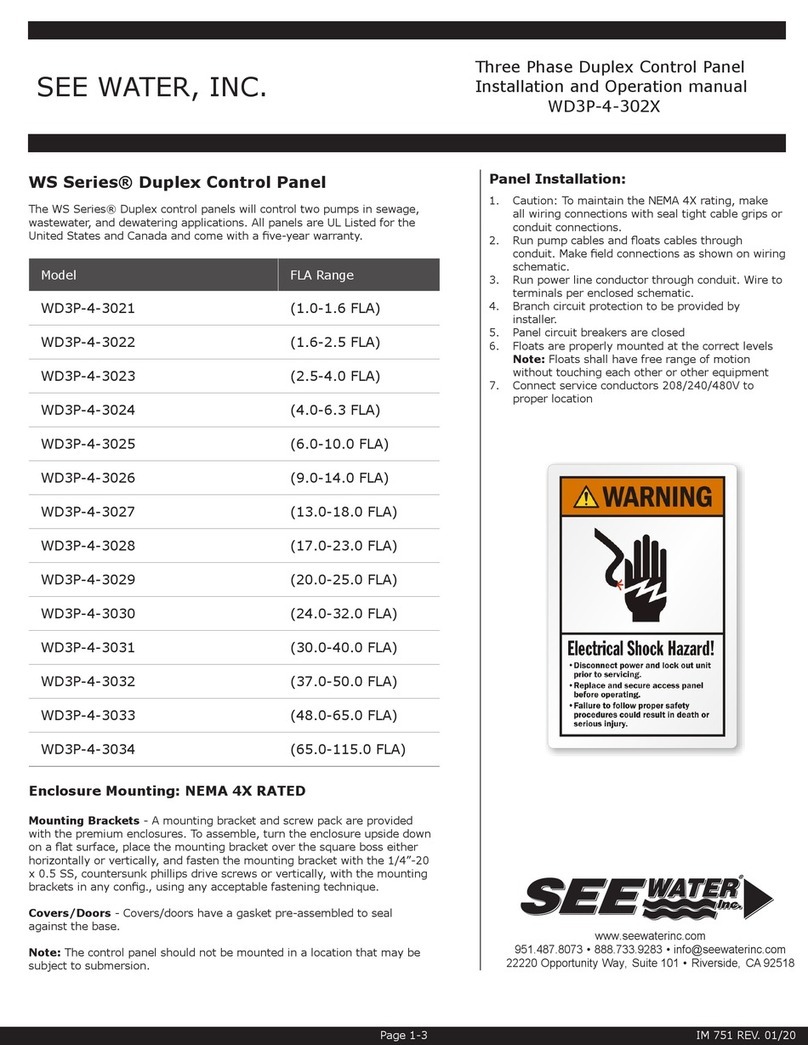

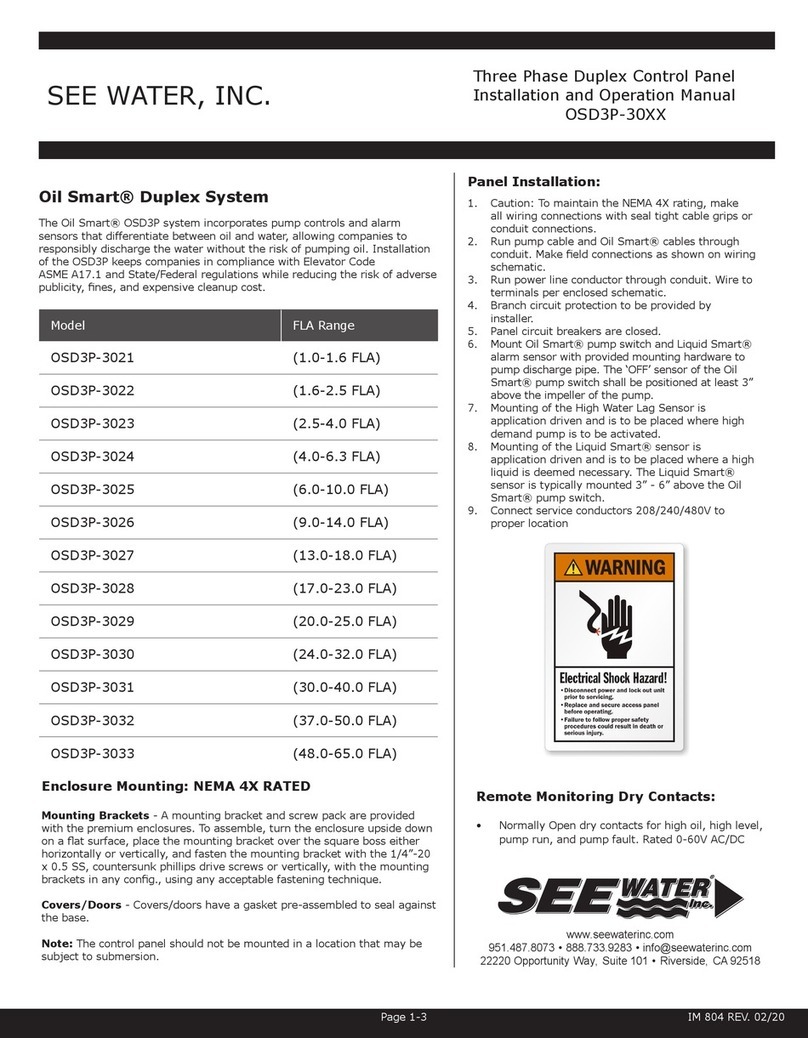

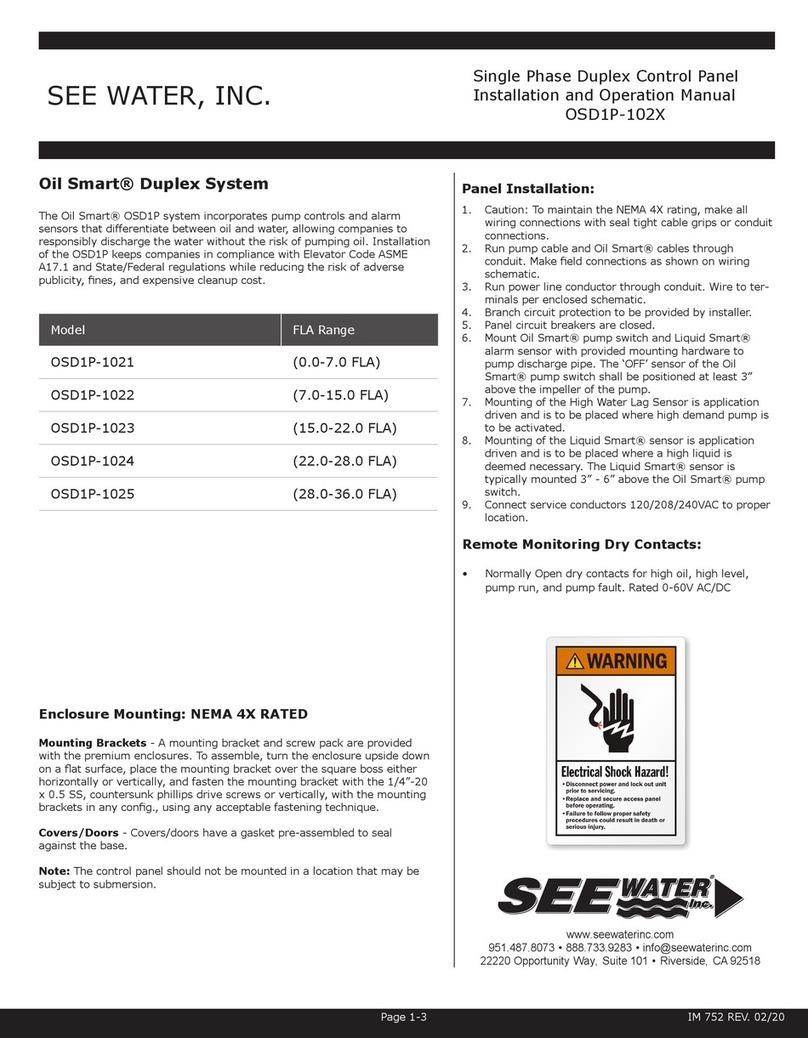

Model FLA Range

OSSIM-30 (0.0-16.0 FLA)

OSSIM-30-CB (0.0-16.0 FLA)

22220 Opportunity Way, Suite 101 • Riverside, CA 92518

Page 1-3 IM 752 REV. 11/18