1F3SJ-AM

Quick Installation Manual

Introduction

Thank you for purchasing the F3SJ-AM

P

Series Multi-beam Safety Sensor (hereinafter referred to as the "F3SJ-AM").

This document is a brief description from wiring to pre-operation checklists / maintenance checklists of F3SJ-AM.

For details, download and read F3SJ-AM user's manual from Omron's website. If you Login / Signup, you can

download the PDF of the Manual.

http://www.omron.com.au/products/family/1581/download/manual.html

Table of Contents

1. What is Included ................................................................................................................................ 1

2. System Components .........................................................................................................................2

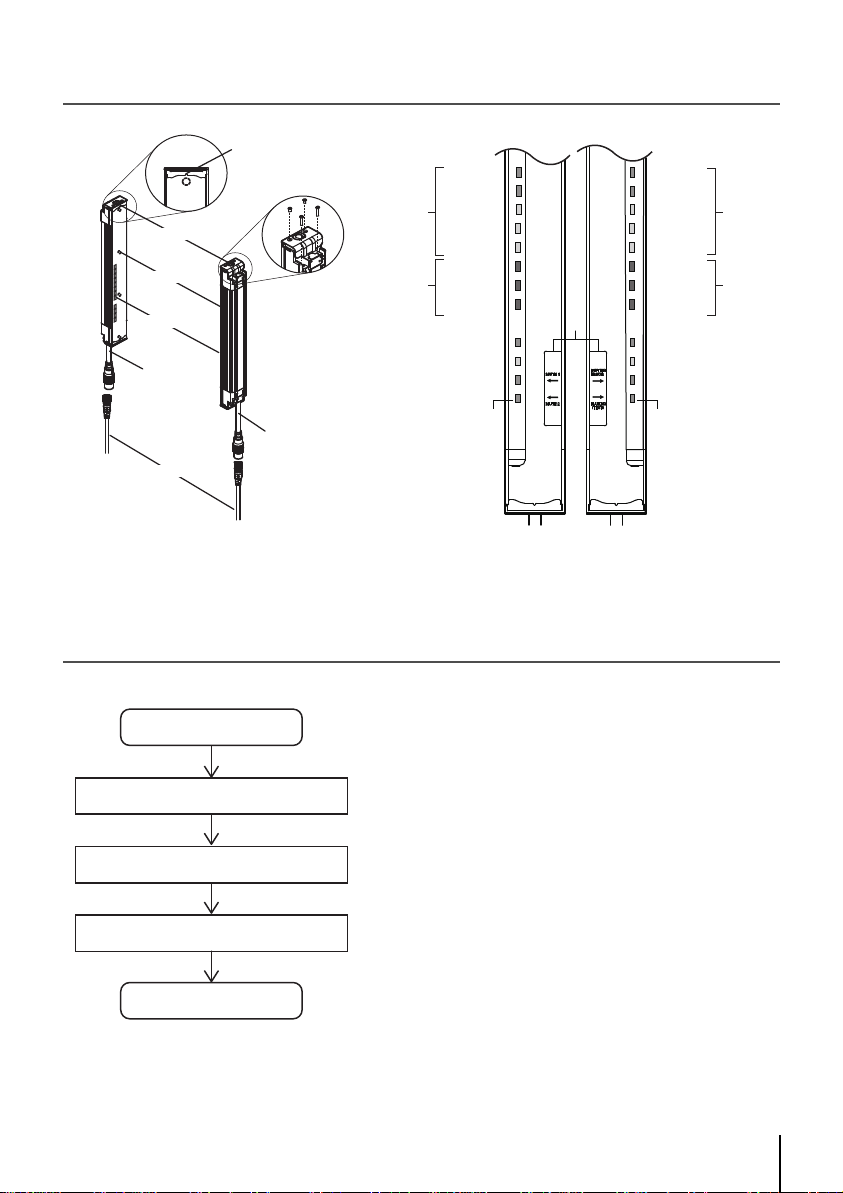

3. Light Curtain Setup Flow ...................................................................................................................2

4. Function Selection Flow Chart .......................................................................................................... 3

5. Mounting and Beam Alignment .........................................................................................................4

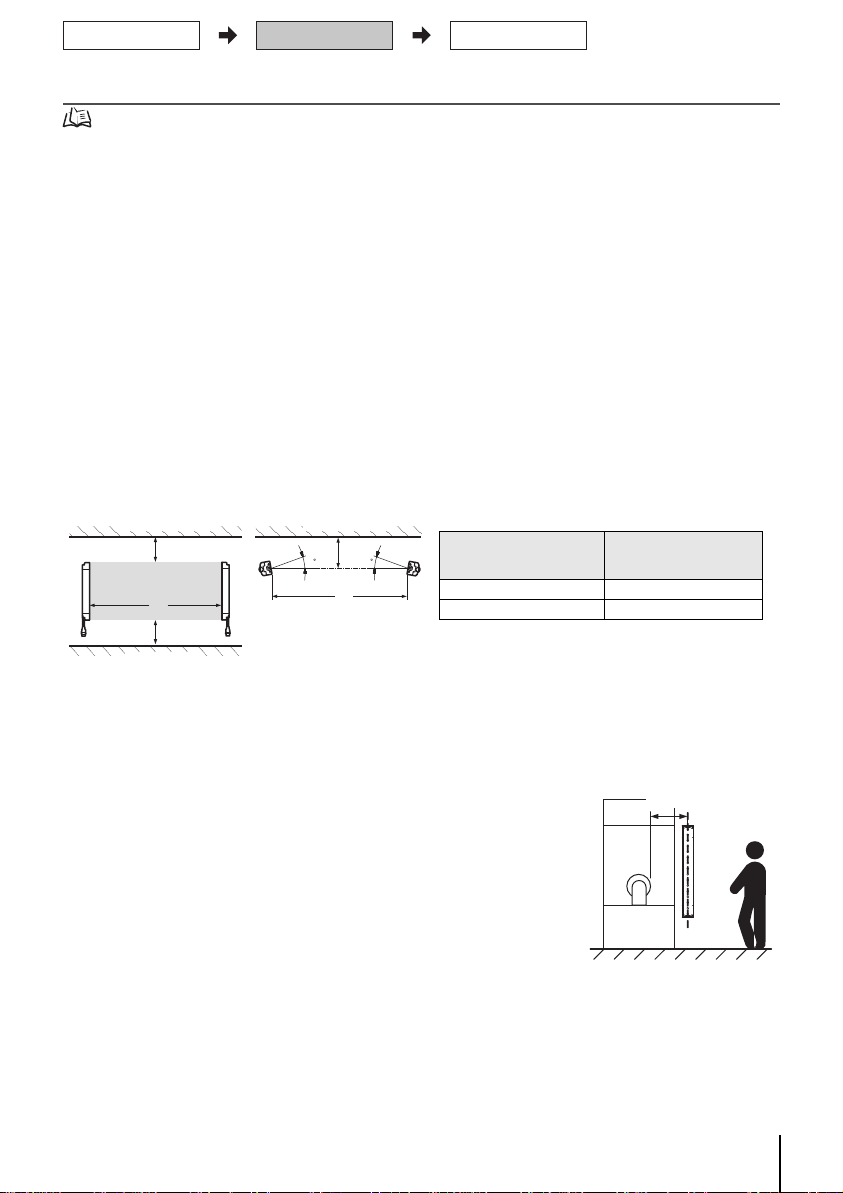

5-1. Mutual Interference Prevention .................................................................................................4

5-2. Distance from Reflective Surfaces ............................................................................................4

5-3. Safety Distance .........................................................................................................................4

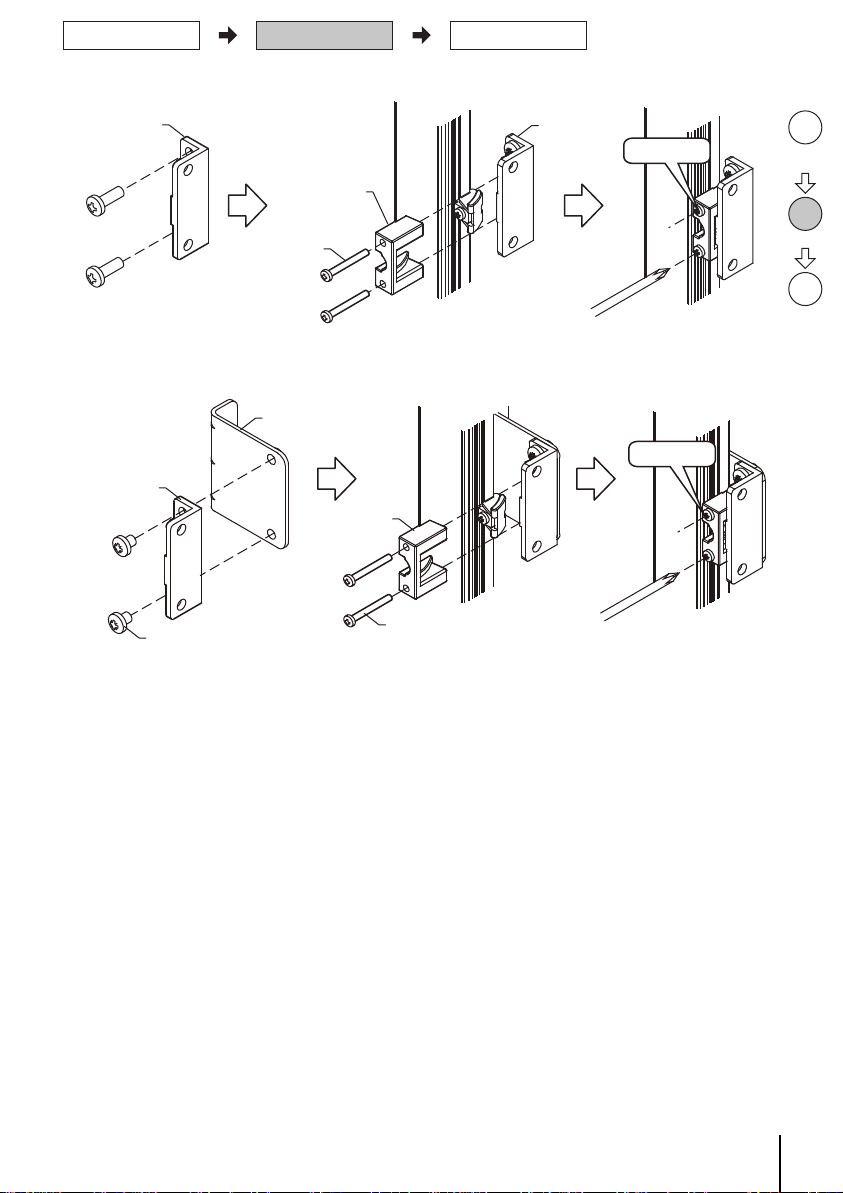

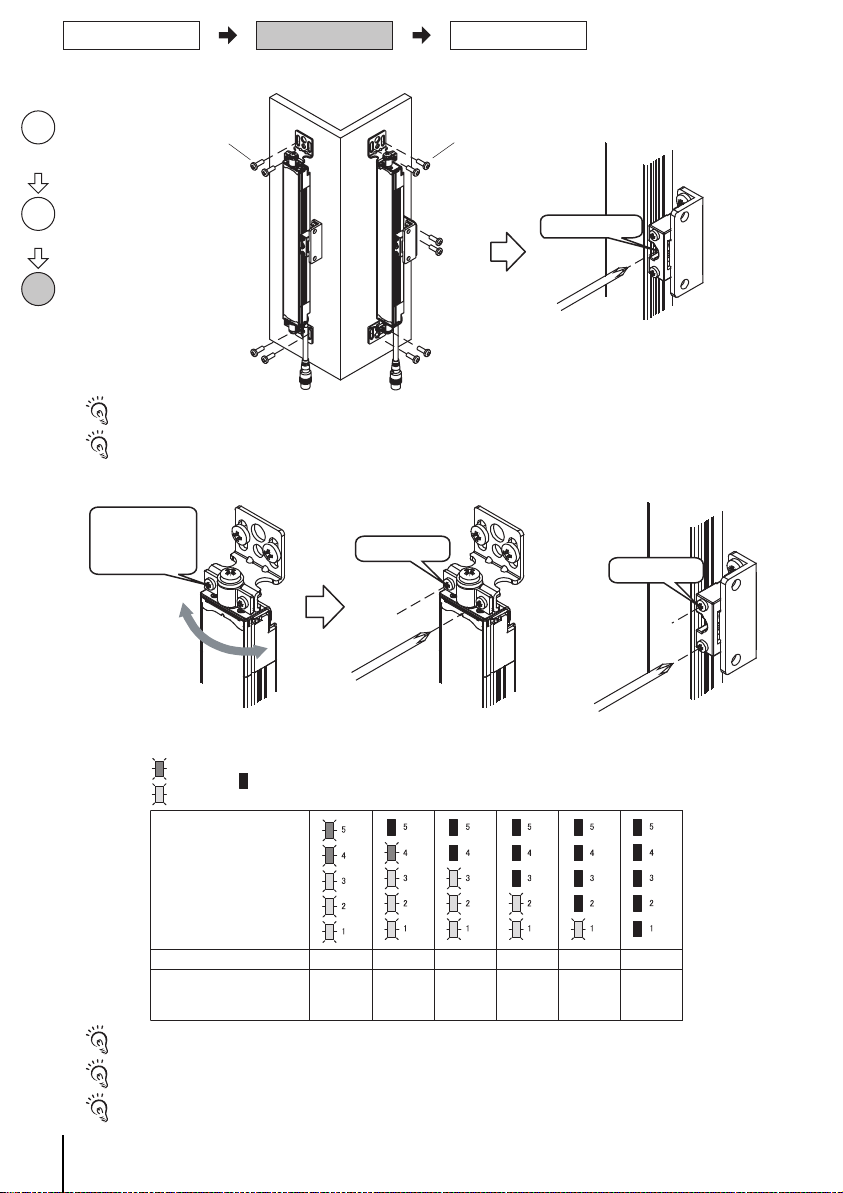

5-4. External dimensions to attach the brackets included in the product (F39-LJ1/F39-LJ3) ..........5

5-5. Mounting and Beam Alignment .................................................................................................7

6. Pre-Operation Checklists / Maintenance Checklists........................................................................10

Suitability for Use/Contact Information ................................................................................................13

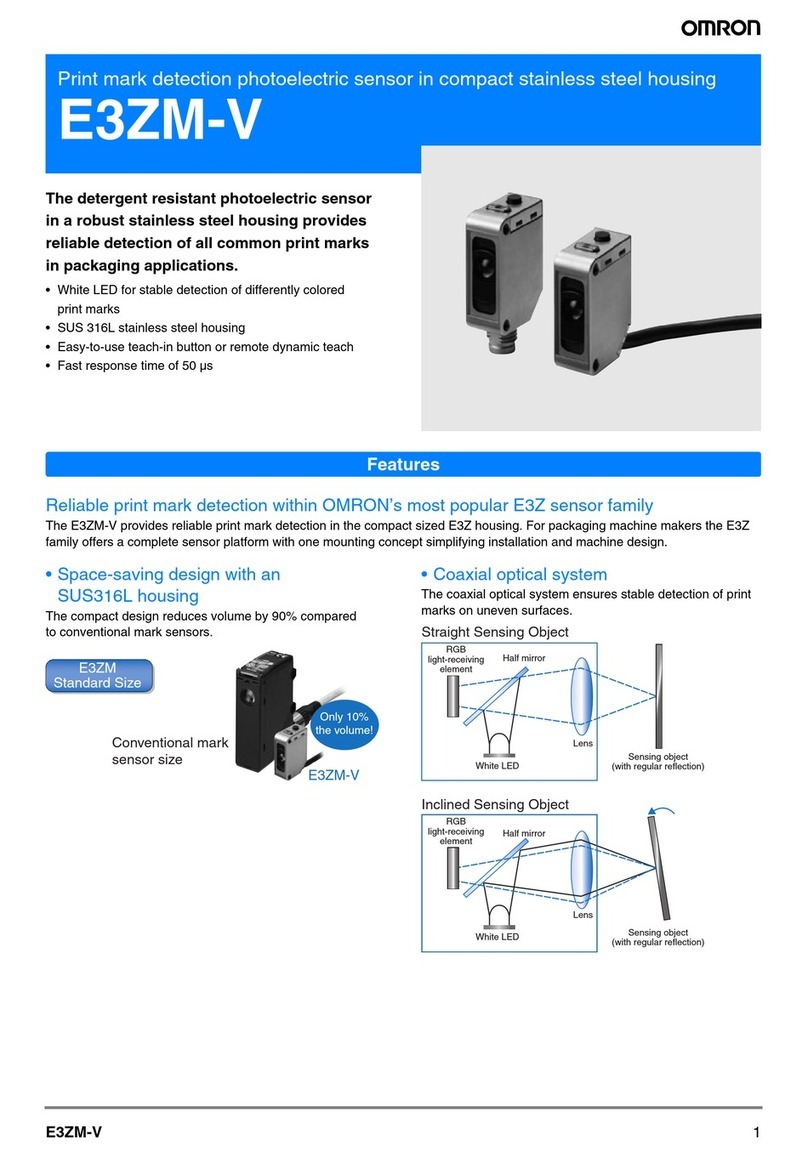

1. What is Included

For ratings/specifications, input/output circuit, LED indicator status and troubleshooting, refer to F3SJ-AM Series User's Manual.

Product Quantity

F3SJ-AMP main unit Emitter x 1, Receiver x 1

For details, refer to F3SJ-AM series user's manual.

4

The number of brackets to be included in the product depends on the model.

F3SJ-AM2P300: Not included

F3SJ-AM3P300: 1 set included

F3SJ-AM4P300: 1 set included

F3SJ-AM2P400: Not included

F3SJ-AM3P400: 1 set included

F3SJ-AM4P400: 2 sets included

F3SJ-AM2P500: Not included

Error Mode Label 1

Operation Manual 2

Quick Installation Manual (this document)

1

Functional Settings

*1 Vs here means the voltage value under use environment.

Function Setting

External Test Enabled when 9V to Vs*1 applied

Interlock

Switching between manual reset mode and auto reset mode is available by wiring

External Device Monitoring (EDM)

Switching between enable/disable is available by wiring

Auxiliary Output

Auxiliary Output 1: Control Output Information (NOT output mode: Enabled)

Auxiliary Output 2: Total Power ON Time Information (ON when 30000 hours passed)

Functional settings can be changed by the setting tool (option)

External Indicator

Enabled when External indicator set (F39-A01P□-PAC)/

Universal indicator cable (F39-JJ3N) attached

In case of Basic System

External Indicator 1: Control Output Information (NOT output

mode: Enabled)

External Indicator 2: Error/Lockout Information

In case of Muting System

External Indicator 1: Muting/Override Information

External Indicator 2: Muting/Override Information

Muting Enabled when muting Key Cap F39-CN6 attached

Override Enabled when muting Key Cap F39-CN6 attached

Top/Bottom

Mounting Bracket

Intermediate

Mounting Bracket