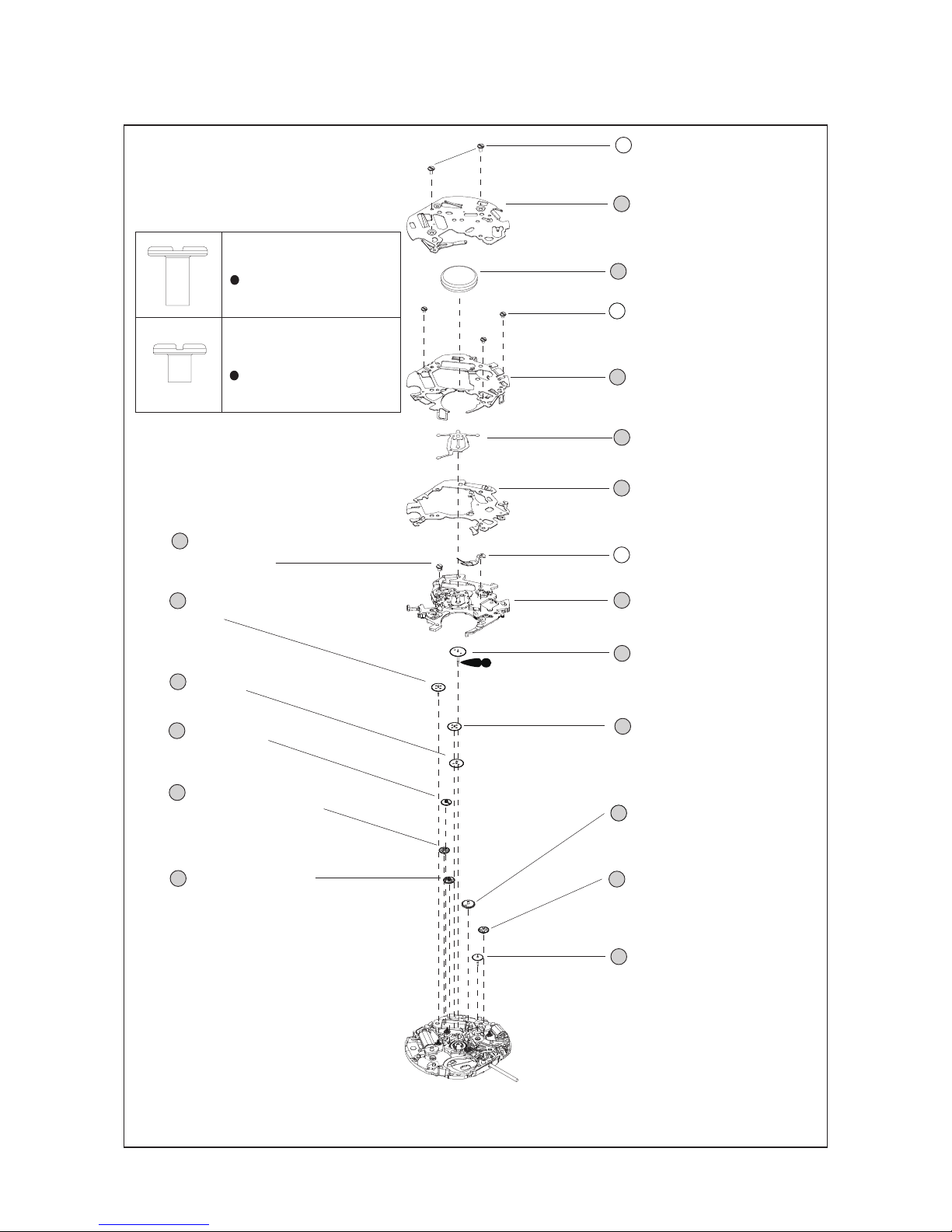

Seiko 7T04A Quick start guide

Other Seiko Watch manuals

Seiko

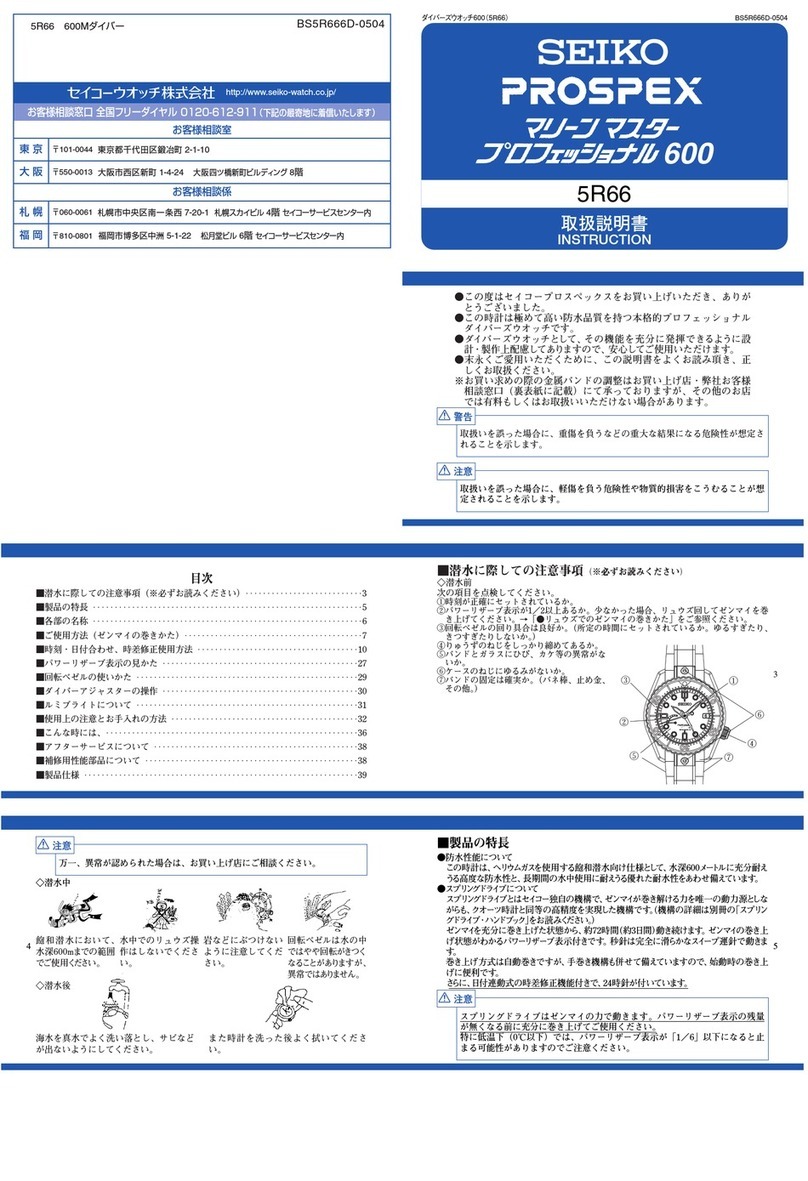

Seiko 5R86 User manual

Seiko

Seiko SSC141P1 User manual

Seiko

Seiko M-16 User manual

Seiko

Seiko 4F32A User manual

Seiko

Seiko AUTO CALENDAR J User manual

Seiko

Seiko GRAND SEIKO User manual

Seiko

Seiko 9R66 User manual

Seiko

Seiko Presage SSA457J User manual

Seiko

Seiko 4R35A Quick start guide

Seiko

Seiko Conceptual SUR517P User manual

Popular Watch manuals by other brands

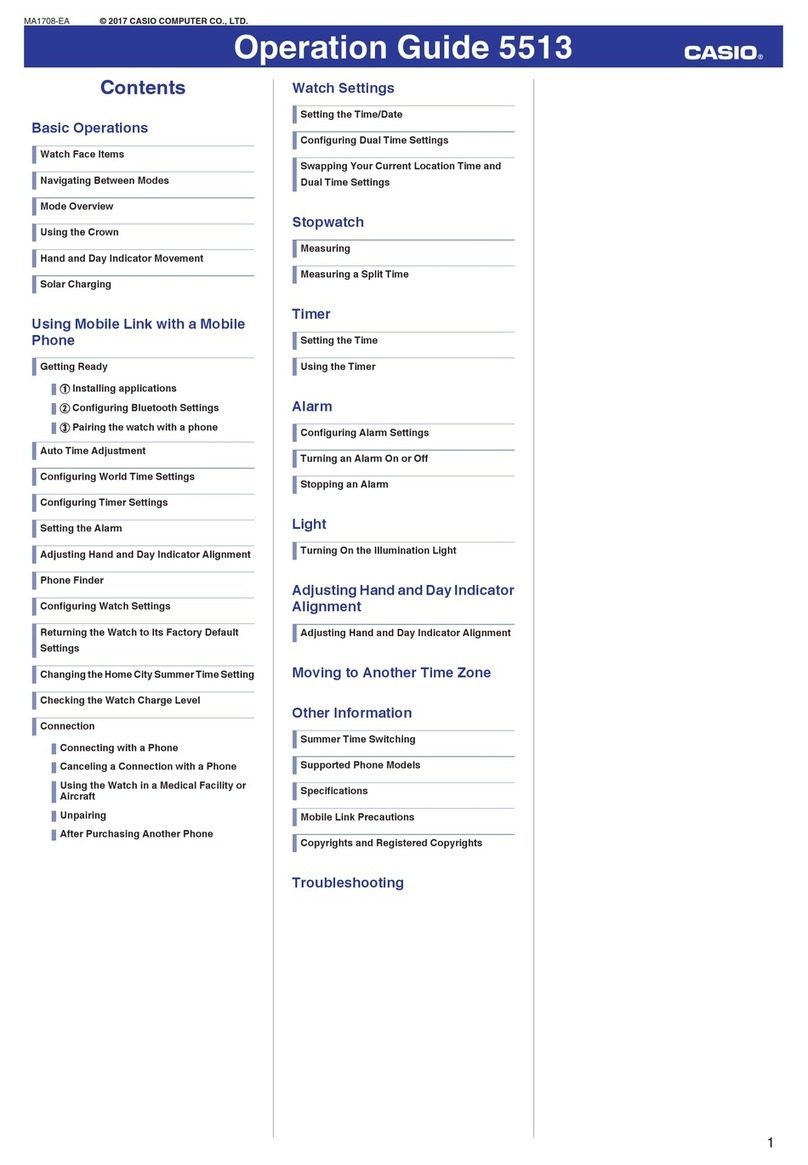

Casio

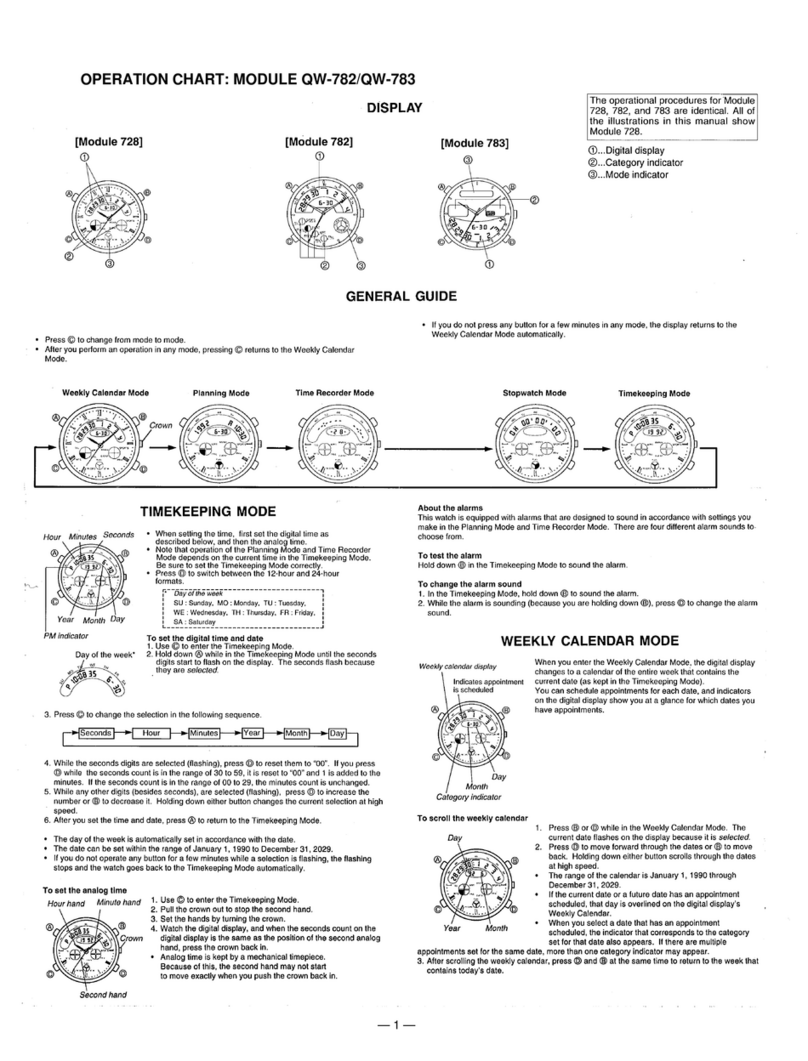

Casio QW 5513 Operation guide

Piaget

Piaget 560P Instructions for use

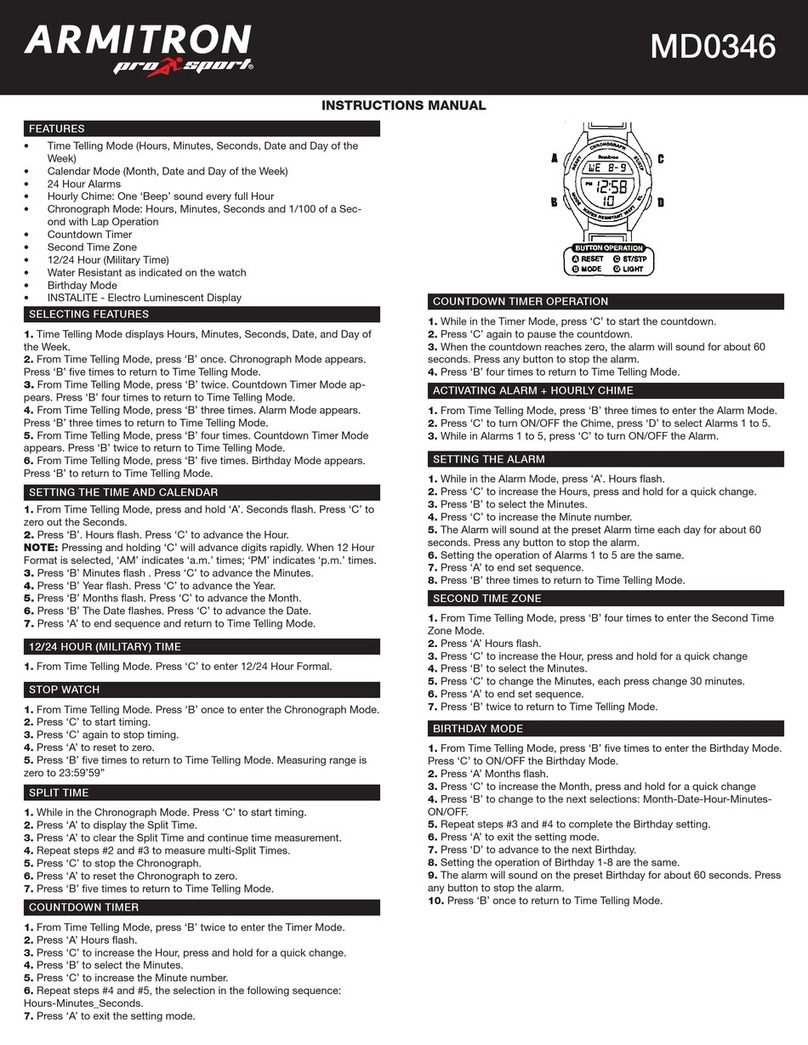

Armitron

Armitron pro sport MD0346 instruction manual

West Marine

West Marine BlackTip 13411293 Instruction Booklet and Care Guide

Jaeger-leCoultre

Jaeger-leCoultre HYBRIS MECHANICA CALIBRE 184 manual

FOREVER

FOREVER iGO PRO JW-200 user manual