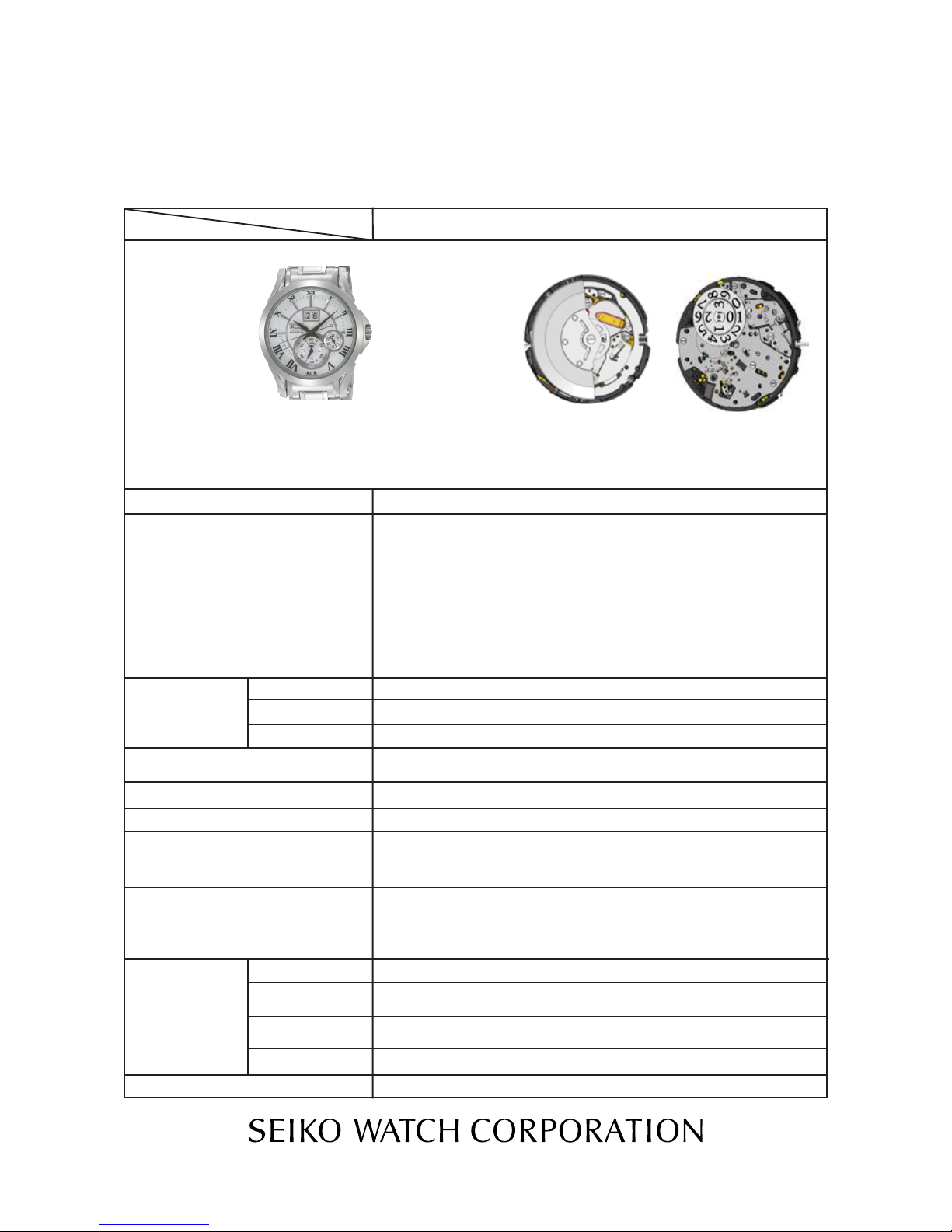

Cal.7D56A

2/44

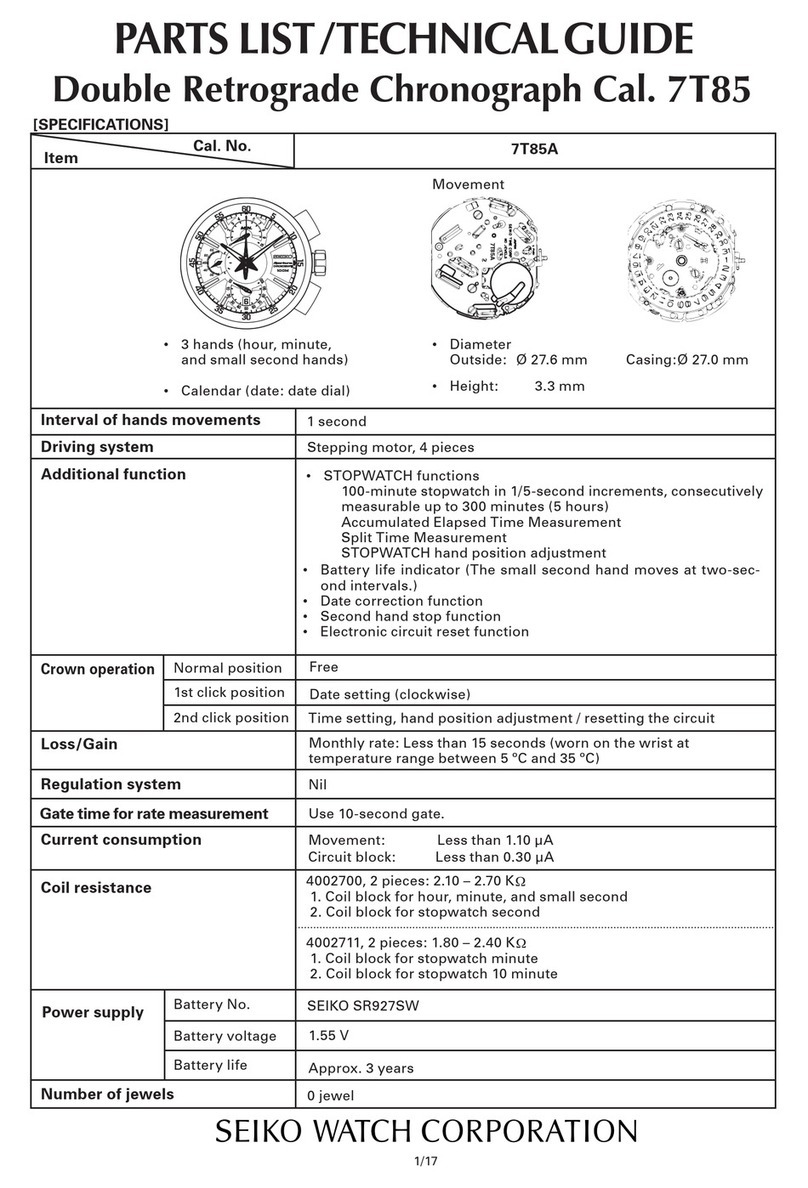

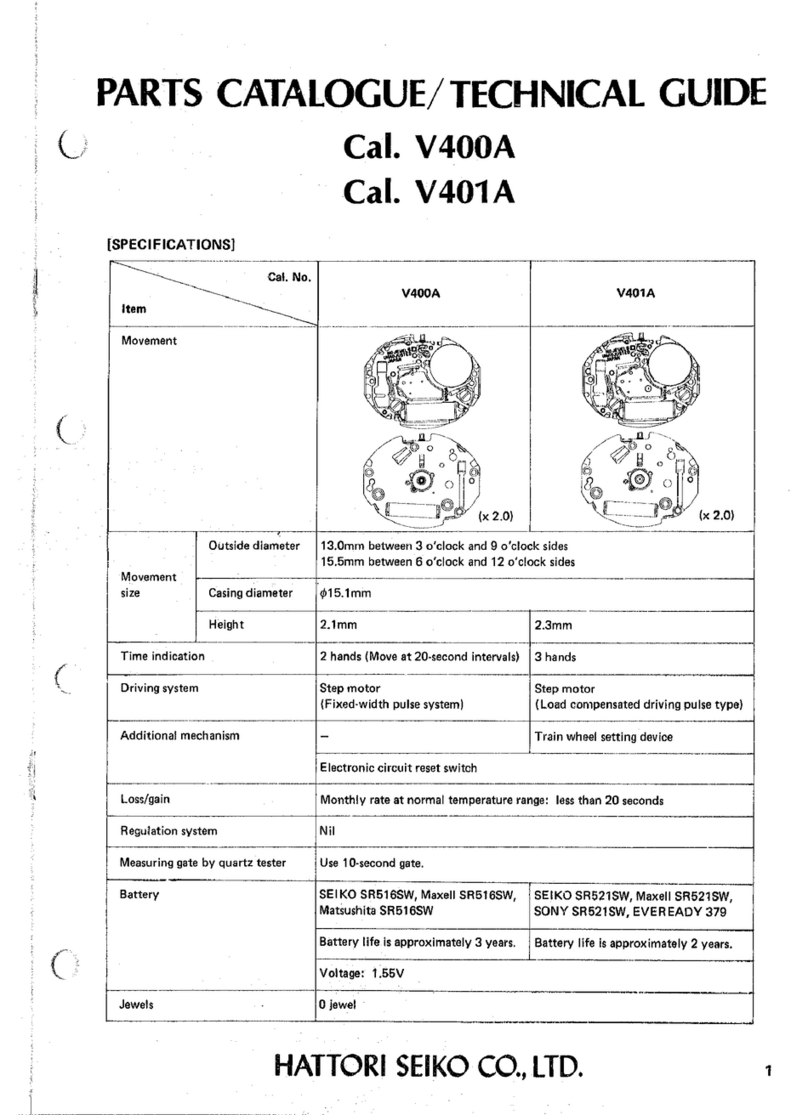

SPECIFICATIONS

SEIKO Kinetic Perpetual Cal. 7D56 is developed based on the design of SEIKO Kinetic Auto Relay Cal.

5J series with a newly designed perpetual calendar mechanism featuring a unique big date display.

Although Cal.7D series features new functions, the experience of repairing the existing KINETIC series

watches will be helpful. In repairing Cal. 7D series, you are requested to have the full knowledge of its

functions and strictly observe the repairing and checking instructions provided in this guide so that

the watch will be repaired correctly.

● POWER SAVE FUNCTION AND TIME RELAY FUNCTION

In order to conserve the stored electrical energy, the watch automatically enters power save mode

to stop the hands from moving approximately 24 hours after the watch is taken off the wrist. When

you decide to wear the watch again, simply swinging the watch several times will awaken it and

the hands will indicate the correct time to resume normal operation.

* The time retrieved by the time relay function may include a certain amount of time loss or gain within

the range of accuracy of the watch (15 seconds per month).

* In a case that the fully charged watch enters the power save mode, the time relay function of the

watch remains operable for approximately four years.

<Remarks on Power Save Function>

●When the watch is left untouched for approximately 24 hours (approximately one day), the

power save function is automatically activated.

* While the second hand is moving at two-second intervals, the power save function cannot be

activated.

●When the power save function is activated, the hour, minute, second and 24-hour hands will

stop moving.

* While the watch is in power save mode, the calendar continues to function normally.

* When the watch is left untouched in power save mode and if the date does not change correctly,

the stored electrical energy is being depleted. Recharge the watch until the watch resumes the

usual one-second interval movement, and then reset the time and calendar before starting to wear

it again.

* When the watch wakes up from power save mode while it is running on extremely low electrical

power, the second hand starts moving at two-second intervals.

● PERPETUAL CALENDAR FUNCTION

●Once set, the calendar automatically adjusts for odd and even months including February of

leap years. (Exceptionally, the manual adjustment at the end of February is required for

the years that are divisible by four but are not leap years, which comes only once every

hundred years, for example, the year 2100.)

* It takes approximately two seconds for the calendar to change its display. However, it may take

two minutes if the temperature is low or the stored electrical energy is being depleted.

●While the watch is in power save mode, the perpetual calendar continues to function.

●Even if the watch is completely stopped due to a shortage of stored electrical energy, the

calendar can be manually adjusted by simple procedures.

1. Each calendar item should be adjusted in sequence of year, month and

then date.

Pull out the crown to the first click.

* If your watch has a screw lock type crown, unscrew the crown first,

and then pull it out to the first click.

2. Turn the crown until the year becomes adjustable.

* Each calendar item becomes adjustable in sequence of date, month

and then year, by turning the crown.

* The calendar can be adjusted by turning the crown in either

direction upward or downward.

* The year indicator shows the number of the year(s) past since the

last leap year. When setting the year, check whether the year you

are going to set is a leap year or not, if it is not a leap year, check

how many years have passed (1, 2 or 3) since the last leap year.

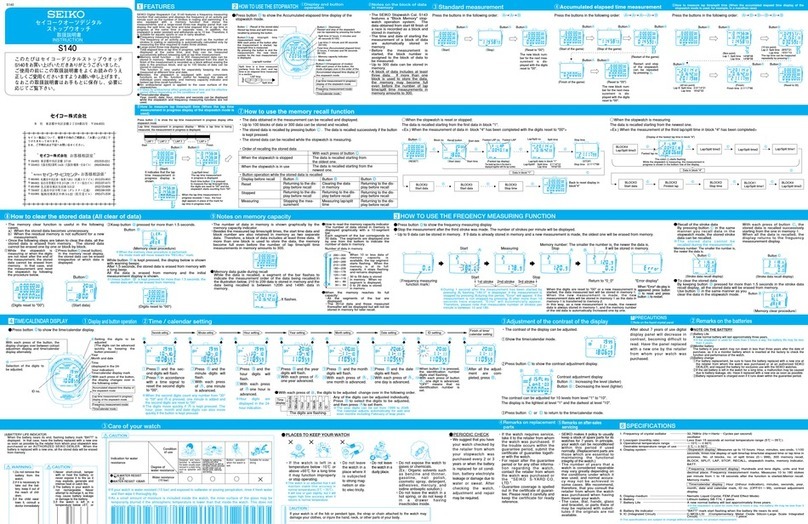

FEATURES