Seikom Electronic NLSW 75-AEx User manual

UserManual

NLSW®75-A Ex (Gg)&

Sensor F3.x Ex

24 V AC, 24 V DC, 230 V AC

Version 1.0

User Manual

NLSW®75-A Ex (Gg) & Sensor F3.x Ex

Page 2

+49 2058 2044 •info@seikom-electronic.com •www.seikom-electronic.com

The person installing the devices as well as the system operator are obligated to ensure the

satisfaction of the mandatory national ex-legislation.

Electrostatic charges on plastic parts and wires must be avoided.

The devices must be protected from any damage. Stray radiation must be avoided.

The wire connecting the flow sensor must be attached to stationary surfaces and must be

protected from any harm.

The product fulfills the requirements specified in the European directives WEEE 2012/19/EU

and RoHS 2011/65/EU.

User Manual

NLSW®75-A Ex (Gg) & Sensor F3.x Ex

+49 2058 2044 •info@seikom-electronic.com •www.seikom-electronic.com

Page 3

CONTENT

1. PREAMBLE ....................................................................................................................... 4

1.1 Safety Instructions .................................................................................................................. 4

2. GENERAL INFORMATION ON EXPLOSION PROTECTION..................................................... 4

2.1 Electrical specifications for Ex-i ............................................................................................... 5

2.2 Intrinsically safe parameters.................................................................................................... 5

2.3 Sensor Properties for Series F3.x Ex ......................................................................................... 6

2.4 Type code ............................................................................................................................... 6

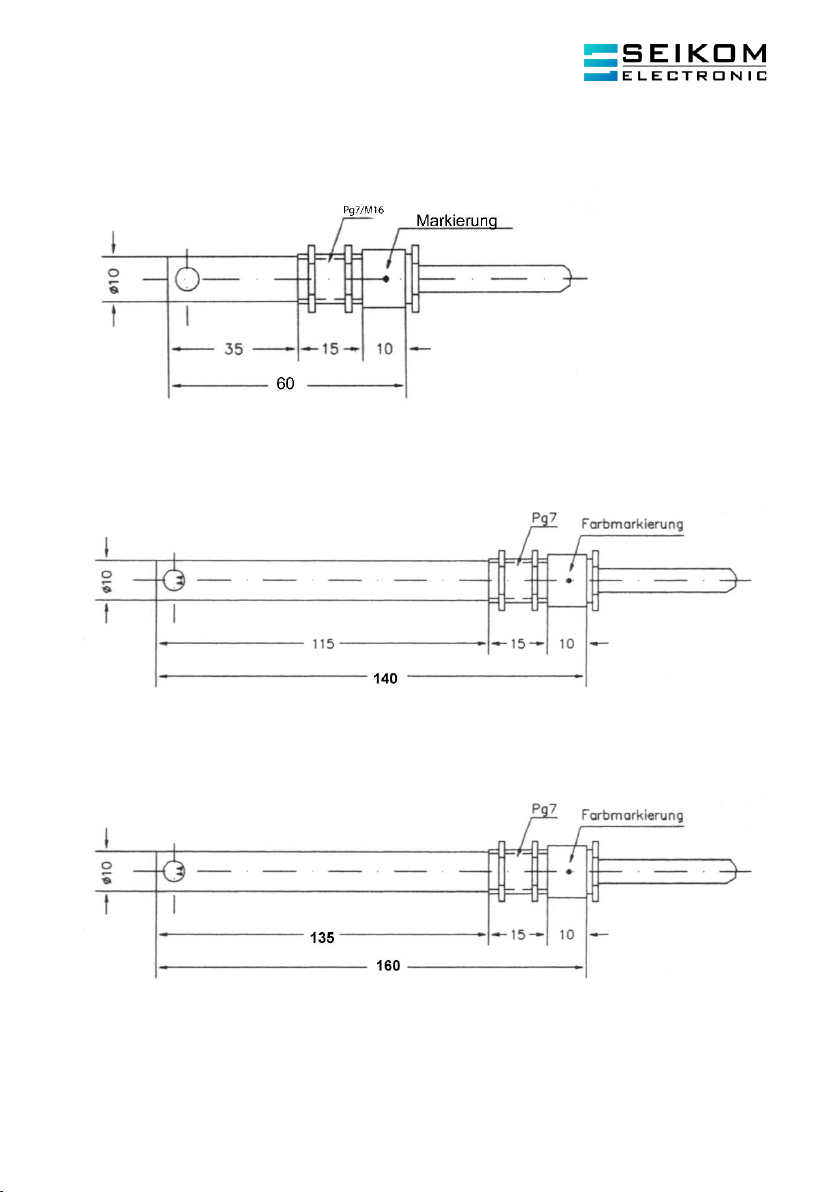

2.5 Dimensions of the air flow sensors F3.x Ex ............................................................................... 7

2.5.1 F3 Ex ................................................................................................................................... 7

2.5.2 F3.1 Ex ................................................................................................................................ 7

2.5.3 F3.2 Ex ................................................................................................................................ 7

2.6 Temperature class .................................................................................................................. 7

2.7 General requirements ............................................................................................................. 8

2.7.1 Intended use........................................................................................................................ 8

2.7.2 General safety instructions .................................................................................................. 8

3. INSTALLATION AND COMMISSIONING .............................................................................. 8

3.1 Installation conditions of the air flow sensors F3.x Ex..............................................................10

3.2 Installation.............................................................................................................................10

4. MAINTENANCE AND SERVICE ......................................................................................... 11

4.1 Definitions .............................................................................................................................11

5. TROUBLESHOOTING....................................................................................................... 12

6. DISPOSAL ...................................................................................................................... 12

7. LABELLING OF THE AIR FLOW SENSORS F3.X EX............................................................. 12

8. GENERAL DESCRIPTION NLSW®75-A EX.......................................................................... 13

9. TECHNICAL DATA OF THE AIR FLOW MONITORS NLSW®75-A EX...................................... 13

10. INSTALLATION OF THE AIR FLOW MONITORS NLSW®75-A EX .......................................... 14

10.1 Commissioning and switch-point adjustment......................................................................14

11. EU KONFORMITÄTSERKLÄRUNG ............................................... Error! Bookmark not defined.

User Manual

NLSW®75-A Ex (Gg) & Sensor F3.x Ex

Page 4

+49 2058 2044 •info@seikom-electronic.com •www.seikom-electronic.com

1. PREAMBLE

1.1 Safety Instructions

Please read the entire operating instructions to ensure the full operational capability of the devices

and your own safety before starting their installation. If questions arise you may contact the

manufacturer SEIKOM Electronic GmbH & Co.KG directly. The directions, contained in these

operating instructions, must be followed.

The following standards were considered in the evaluation of the product:

a) IEC 60079-0:2017 Ed. 7 ”Explosive atmospheres –Part 0: Equipment –General

requirements “

b) IEC 60079-11:2011 Ed. 6 + Corr. 2012 / EN 60079-11:2012 ”Explosive atmospheres –Part

11: Equipment protection by intrinsic safety “i” “

c) TRGS 727:2016 “Vermeidung von Zündgefahren infolge elektrostatischer Aufladung“

2. GENERAL INFORMATION ON EXPLOSION PROTECTION

The intrinsically safe air flow sensor measures air flow velocities in the range of 0.1 ... 20.0 m/s via

the calorimetric principle. According to the operating principle either the degree of cooling (cooling

method) or the required amount of heat, necessary to maintain the heating sensor elements’

temperature constant (constant temperature method), is determined to indicate flow.

The air flow sensors of the series F3.x Ex are built for commercial use and shall only be used according

to the technical documentation provided by SEIKOM-Electronic GmbH & Co.KG and specifications on

their labels. The air flow sensors shall only be operated with certified products via an intrinsically safe

electrical circuit, which is fed by Zener-barriers. These barriers satisfy valid standards and provisions.

The general provisions on the construction of facilities in areas exposed to explosion hazards (e.g.,

EN 60079-14) need to be considered. Additional important details can be found in the alongside

delivered EC type examination certificate.

The requirements regarding simple electrical utilities applicable within areas exposed to explosion

hazards due to gases in zone 1 according to EN 60079-11 are satisfied.

In accordance with its label, the air flow sensor can be used as specified below:

➢In zone 2 (Gas-Ex, EPL Gc) in ex-groups IIA, IIB und IIC.

The qualification concerning the surface temperature is T4. The equipment does not present an

ignition source for any gases, vapours and fogs with an ignition temperature above 135 °C.

The permissible ambient temperature range for the air flow sensor is -10°C ≤Ta ≤50°C. The

permissible ambient temperature range for the NLSW®75-A Ex evaluation electronics goes from -20°C

≤Ta ≤50°C. The permissible media temperature (air flow sensor) is 0°C ≤T ≤60°C.

Self-heating is generally negligible; in case of failure the threshold values of temperature class T4

may be reached.

User Manual

NLSW®75-A Ex (Gg) & Sensor F3.x Ex

+49 2058 2044 •info@seikom-electronic.com •www.seikom-electronic.com

Page 5

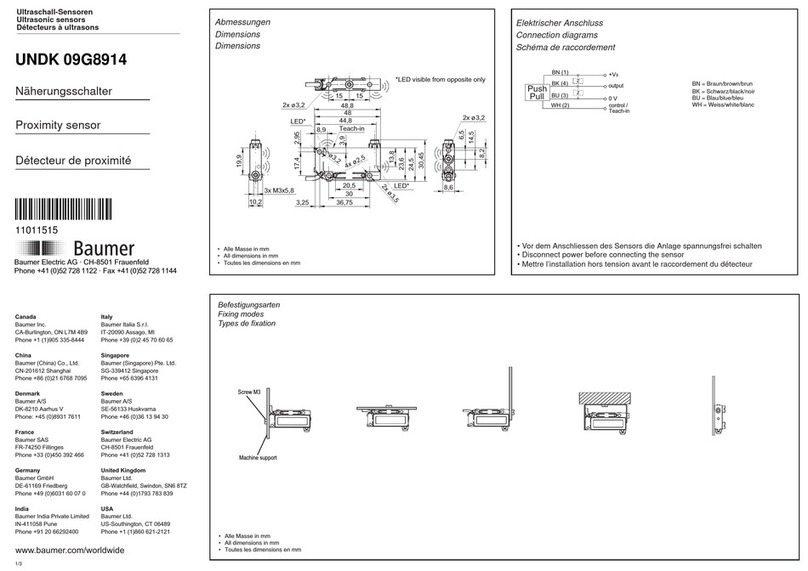

2.1 Electrical specifications for Ex-i

When installing, please note that the Z- barriers BZE804 and BZE805 have different values.

If the barriers are swapped, the airflow monitor NLSW®75-A Ex will not work properly.

2.2 Intrinsically safe parameters

Type

Value

Ui

25 V DC

Ii

80 mA

Pi

0.35 W @ 40°C

0.24 W @ 110°C

Ci

negligible

Li

negligible

User Manual

NLSW®75-A Ex (Gg) & Sensor F3.x Ex

Page 6

+49 2058 2044 •info@seikom-electronic.com •www.seikom-electronic.com

2.3 Sensor Properties for Series F3.x Ex

Type

F3 Ex

F3.1 Ex

F3.2 Ex

F3.3 Ex

Article-No.

50276Ex/50

50276Ex/130

50276Ex/165

50276Ex/300

Approx. Immersion depth

50 mm

130 mm

165 mm

300 mm

Permissible

media temperature

0°C … 60°C

Permissible

ambient temperature

-10°C … 50°C

Temperature gradient

10 K/min

Connection

PG7

Probe tube material

CuZn39Pb2, nickel-plated

Compression strength

10 bar

Electrical connection

2.5 m / 3 x 0.75 mm2

Protection class

IP67

Evaluation unit

NLSW®45-3 Ex, NLSW®75-A Ex

Wire colors

Black numbered

Tested according to DIN EN 61010-1:2011-07

by TÜV Nord

2.4 Type code

There is only one kind of flow sensor F3, the different types vary only by their length. Please review

the table shown above.

User Manual

NLSW®75-A Ex (Gg) & Sensor F3.x Ex

+49 2058 2044 •info@seikom-electronic.com •www.seikom-electronic.com

Page 7

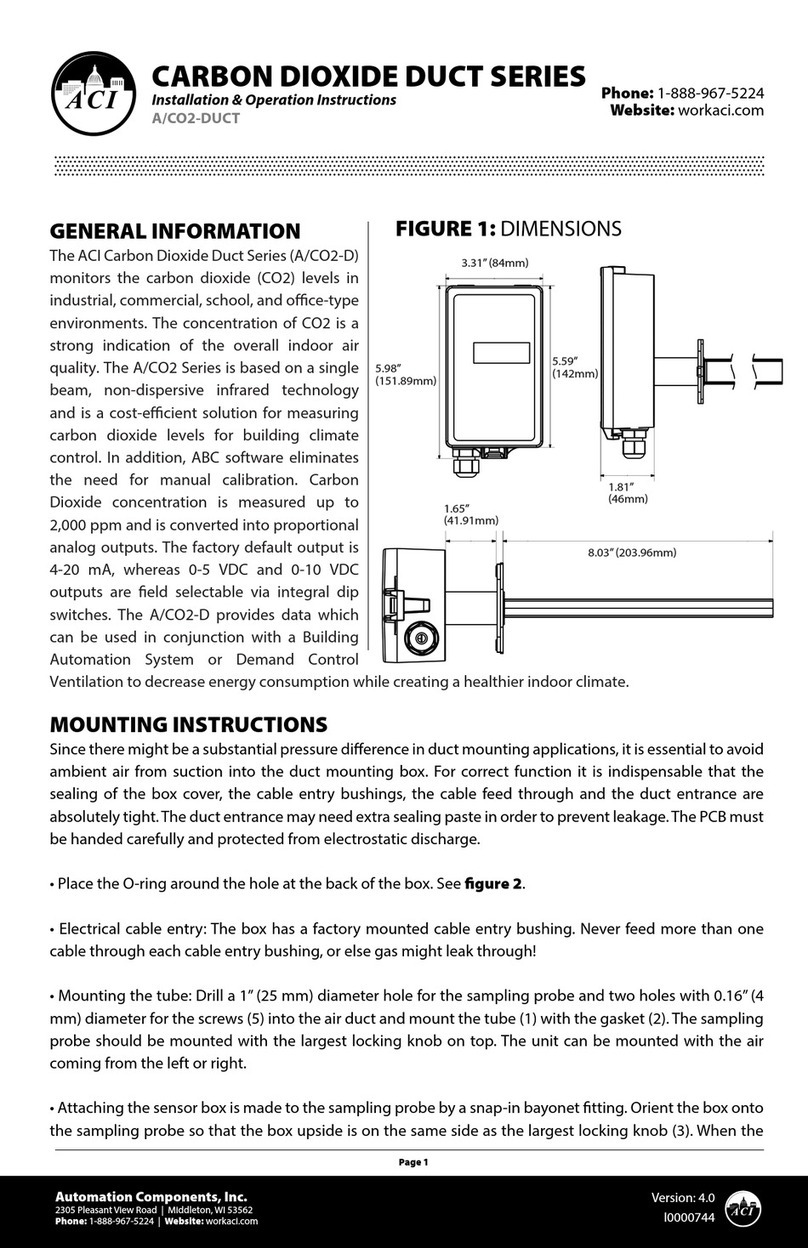

2.5 Dimensions of the air flow sensors F3.x Ex

2.5.1 F3 Ex

2.5.2 F3.1 Ex

2.5.3 F3.2 Ex

2.6 Temperature class

The sensors are suitable for use with temperature class T4.

User Manual

NLSW®75-A Ex (Gg) & Sensor F3.x Ex

Page 8

+49 2058 2044 •info@seikom-electronic.com •www.seikom-electronic.com

2.7 General requirements

2.7.1 Intended use

a) Safe use can only be ensured if the devices are used according to the specifications of the

operating instructions provided in this document. Moreover, the legal and safety

requirements specific to the individual use must be satisfied. This is also applicable to the

use of additional equipment such as accessories.

b) Incorrect use of the product or deviation from the directions contained by this instruction

result in a cancellation of our liability. Furthermore, any warranty on products or spare

parts will be cancelled.

c) The products are no safety features in the scope of their dedicated use.

d) Only original parts from the manufacturer can be used.

2.7.2 General safety instructions

The sensor corresponds to the best available technology and is reliable in operation. If installed

or operated incorrectly, for instance due to installation or operation by unqualified personnel, a

residual risk may arise from the sensor.

Any person conducting the installation, start-up, maintenance or repair of the air flow sensors

and monitors must have read and understood the operating instructions and especially the

safety instructions.

a) Consider general engineering rules and the dedicated use when choosing a product.

b) All electrical and mechanical equipment must be suitable for their intended use.

c) Pay attention to the information provided in this manual as well as the permissible

operating conditions printed on the label/type plate of the respective product.

d) Ensure that only products with the required ignition protection type, depending on the

zone, are installed!!

e) The products are only approved for their designated and appropriate use in ordinary

industrial atmosphere. Immersion in liquids is impermissible.

f) Ensure that no falling objects may hit the product. In connection with rust (corrosion),

light metal and kinetic energy an exothermal, ignitable reaction can result.

g) The operator has to ensure the lightning protection according to local regulations.

h) Follow general engineering rules when choosing and operating products.

i) The person performing the installation of the air flow sensors and their connection to the

flow monitors is responsible for their correct function and must ensure that they are

eligible for their intended use.

j) The intrinsically safe connection, including the air flow sensors, must be carried out via

approved flow monitors, which, if necessary, must be installed with suitable Zener-

barriers or switching amplifiers.

3. INSTALLATION AND COMMISSIONING

Depending on the IP protection class time intervals for cleaning of the equipment (accumulation of

dust) must be set. Additional important facts:

a) The product can be installed in zone 2 (Cat. 3G, EPL Gc) or in zone 1 (Cat. 2G, EPL Gb) in

intrinsically safe electrical circuits by professionals equally competent to qualified

personnel according to TRBS 1203.

b) The information provided on the label must be followed bindingly during installation.

User Manual

NLSW®75-A Ex (Gg) & Sensor F3.x Ex

+49 2058 2044 •info@seikom-electronic.com •www.seikom-electronic.com

Page 9

c) The products can only be operated in ordinary industrial atmosphere. The manufacturer

must be contacted if the atmosphere contains aggressive components. In case of adverse

ambient conditions, the sensors need to be protected accordingly.

d) Usage of the devices is only permissible when they are fully mounted and connected in an

intact condition. Damages would enable a zone entrainment which must therefore be

considered by the operator. Usage of devices with damaged casing is not permitted.

e) The defined permissible ambient conditions must be met, the products must be protected

from adverse ambient conditions.

f) Thermal radiation of other components and products must be considered.

g) The air flow sensors must be protected from impermissible inflow of liquids and/or

pollution.

h) Tight or stuck parts, e. g. due to frost or corrosion, cannot be loosened with force if

exposed to an explosive atmosphere. Icing must therefore be avoided.

i) The air flow sensors can only be exposed to minor vibrations, see IEC 34-14.

j) To ensure the dissipation of electrostatic charges, national regulations must be considered.

k) Especially capacities that build up in an isolated manner must be avoided.

l) The flow sensor housing should be connected to the potential equalization

electrostatically, a threshold value of 1MΩis permissible.

m) Only Zener-barriers and switching amplifiers with Ex-area approved output circuits can be

used. In Europe the use within zone 1 requires an EC type examination for the relevant

equipment, issued by a for explosion protection appointed authority.

n) The power P0 of all supply units combined must be lower or equal to the power Pi of the

air flow sensors.

o) The supply voltage of the supply units must be lower or equal to the voltage Ui of the air

flow sensors.

p) The current Io of all supply units combined must be lower or equal to the current Ii of the

air flow sensors.

q) For the installation of an intrinsically safe electrical circuit, a block diagram (system

description) is necessary, which must be provided by the builder or operator.

r) If a Zener-barrier is used, a potential equalisation between the grounding connection and

the flow sensor casing alongside the intrinsically safe electrical circuit must be ensured.

s) The certificates including the therein defined special conditions must be considered.

t) Tight or stuck parts, e. g. due to frost or corrosion, cannot be loosened with force if

exposed to an explosive atmosphere.

u) The flow sensors cannot be used in facilities with cathodic corrosion protection. Although

special precautions might enable the use of the flow sensors in this special case, the

manufacturer must be contacted in any scenario. Parasitic currents cannot be discharged

via the construction.

v) Within the area exposed to an explosion hazard the installation must comply with local

regulations.

The following conditions must be met:

a) Installation and maintenance may only be executed in atmospheres without any explosion

hazard and in compliance with the applicable national regulations depending on the

location of operation.

b) Additional precautions must be made if hydrogen sulphide, ethylene oxide or carbon

monoxide may be or are present. These substances require only very low energy to ignite.

c) In case these substances and a substance of explosion group IIC and a presumably

explosive atmosphere are present only non-arcing tools can be used!

User Manual

NLSW®75-A Ex (Gg) & Sensor F3.x Ex

Page 10

+49 2058 2044 •info@seikom-electronic.com •www.seikom-electronic.com

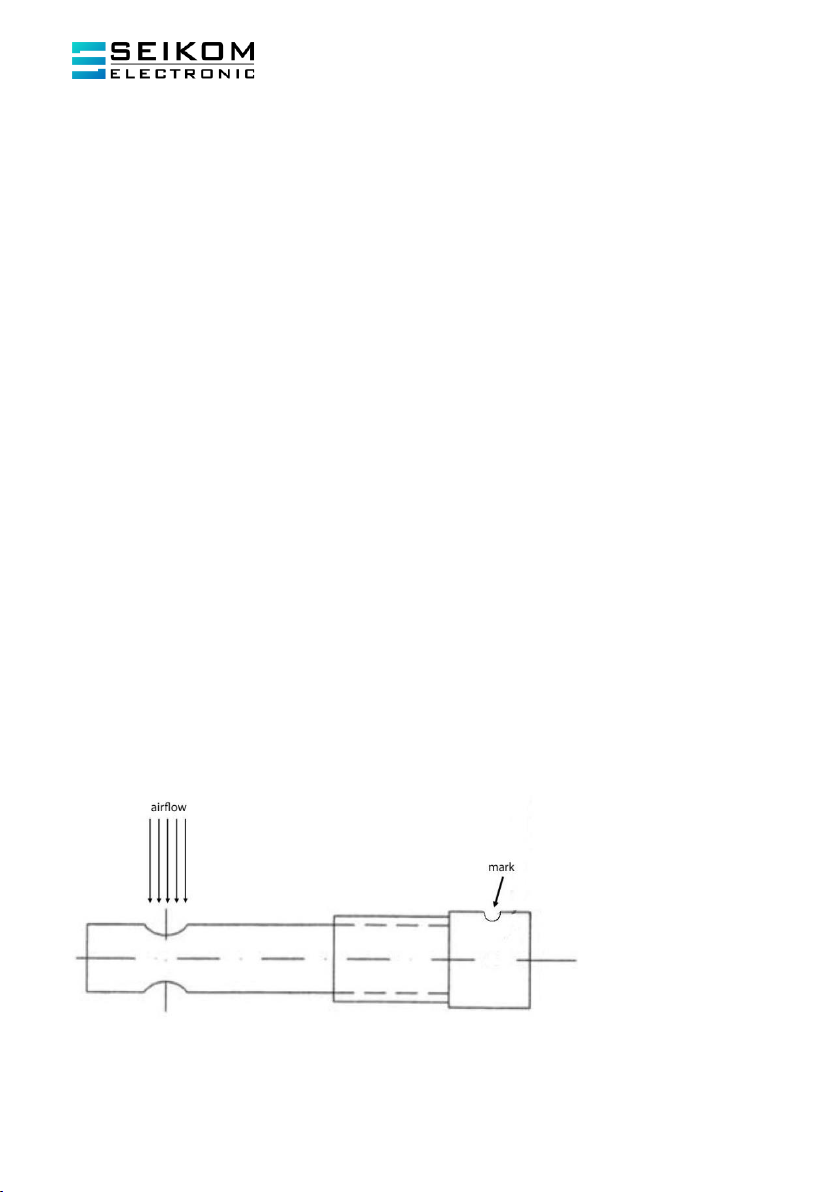

3.1 Installation conditions of the air flow sensors F3.x Ex

Please consider the following points while mounting the air flow sensors to avoid any malfunction:

a) The tip of the sensor should be placed in the centre of the tube. The gaseous medium

must fully flow through the drilled hole located within the tip section of the sensor.

b) The mark on the base of the sensor may be used to verify whether the opening of the

drilled hole points in the direction of the flow.

c) In case of vertical tubing the direction of flow should be upwards. An inlet zone of 5xD,

before the sensor, and an outlet zone of 3xD, after the sensor should be maintained

(D=inner diameter of the pipe).

d) The air flow sensor must be connected with the air flow monitor according to the block

diagram. Any alteration of the connections leads to malfunction and may result in defects.

e) The shield must be connected to the potential equalization.

f) An extension of the sensor wiring (shielded) is only permitted if the wiring is used in non-

explosive atmosphere. Yet, a total length of 30 m at a minimum cross section of 1,5 mm²

cannot be exceeded.

During operation the following points concerning the wiring must be considered:

a) In case of flexible mounting the applicable temperature range is -5 °C up to +80 °C with a

minimum bend radius of 10x wire diameter.

b) In case of stationary mounting the applicable temperature range is -40 °C up to +80 °C

with a minimum bend radius of 10x wire diameter.

The wiring is not eligible for outdoor use or burying in the ground. Please contact the manufacturer if

the present operating conditions deviate from the specifications.

3.2 Installation

The sensor can be mounted via the PG7 connected to the sensor housing. Furthermore, mounting

can be supported by the alongside delivered PG7-nuts. During mounting the mark may be used to

ensure the correct orientation of the hole within the tip of the sensor, so that the medium can fully

flow through it. During startup of the device with media temperatures below 0 °C and strong air flow,

the start-up time may increase to 60 s.

User Manual

NLSW®75-A Ex (Gg) & Sensor F3.x Ex

+49 2058 2044 •info@seikom-electronic.com •www.seikom-electronic.com

Page 11

4. MAINTENANCE AND SERVICE

4.1 Definitions

Definitions according to IEC 60079-17:

Maintenance and repair: A combination of activities, carried out to maintain an object in a certain

condition or to regain this condition, which satisfies the requirements of the relevant specifications

and ensures the ability to perform the demanded functions.

Inspection: An activity, involving the thorough investigation of an object, with the aim of obtaining a

reliable conclusion regarding the condition of the object, which is conducted without removal of the

object, or if necessary with partial removal, complemented by actions such as measurements.

Visual Inspection: A visual inspection is an examination during which visible faults may be

recognized (e.g. missing screws) without application of any tools or gaining further access.

Close Inspection: An inspection that exceeds the visual inspection, during which faults may be

recognized (e. g. loose screw) that require further access or the utilization of tools. Neither opening a

housing nor switching to zero potential is usually required for a close inspection.

Detailed Inspection: An inspection that exceeds the close inspection, enabling the detection of

faults (e. g., loose connections) that can only be recognized if a housing is opened and/or, if

necessary, tools and testing equipment are utilized.

a) Maintenance activities can only be performed by qualified personnel.

b) Accessories used within areas exposed to explosion hazards have to satisfy the

requirements of the European directives and national legislation.

c) Maintenance activities involving the removal of sensors can only be performed in areas

without any explosion hazards.

d) Only original parts, dedicated for the use within areas exposed to explosion hazards, can

be used for the replacement of components.

e) Products within the area exposed to an explosion hazard must be serviced and cleaned

regularly. The intervals must be determined by the operator according to the

environmental stress on site.

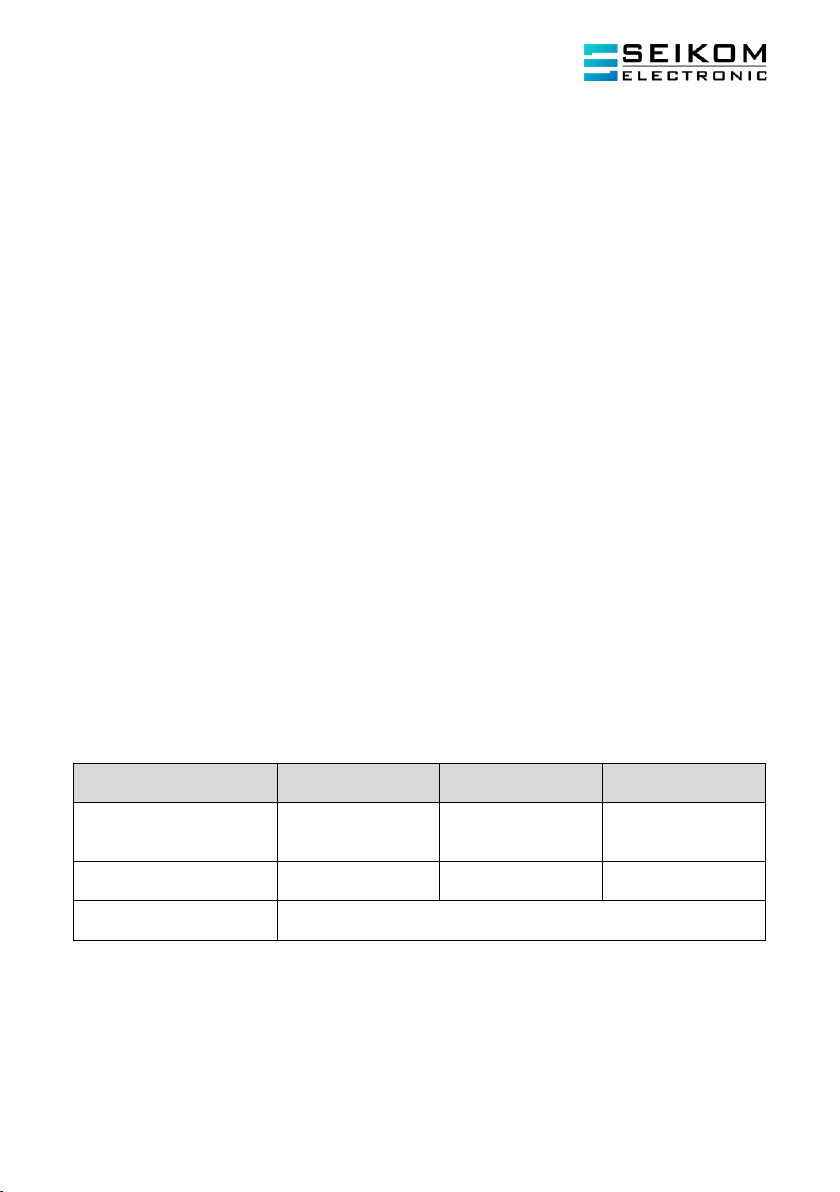

Activity

Monthly visual

inspection

Close inspection

every 6 month

Detailed inspection

every 12 month

Visual check of the sensors

regarding damage, removal

of accumulated dust

●

Inspection regarding

intactness and function

●

Inspection of the entire

facility

Responsibility of the operator

Polluted air flow sensors shall only be cleaned in lukewarm soapy water. Before reinstallation the

sensors should be air-dried completely. Never use hard or sharp objects (e. g. screwdriver, steel

brush) for cleaning.

User Manual

NLSW®75-A Ex (Gg) & Sensor F3.x Ex

Page 12

+49 2058 2044 •info@seikom-electronic.com •www.seikom-electronic.com

5. TROUBLESHOOTING

Products used in areas exposed to explosion hazards cannot be altered or modified. Repair of the

product can only be performed by qualified and authorised personnel which has received

specialised education in this field.

Problem

Cause

Solution

NLSW®75-A Ex does not

work

No or wrong supply voltage

Check supply voltage and

connection

NLSW®75-A Ex cannot

identify flow

Sensor not installed correctly or

the measured range does not

correspond to the technical

data

Check installation conditions

and installation

NLSW®75-A Ex shows

changed behaviour

Sensor is polluted

Clean the sensor with lukewarm

soapy water

NLSW®75-A Ex switches in

case of fast temperature

increase

The temperature gradient

exceeds the technical data

Re-adjust switchpoint /

reinforcement / zero point

6. DISPOSAL

The disposal of the packaging materials and used parts must be in accordance with the national

regulations relevant in the location of operation of the product.

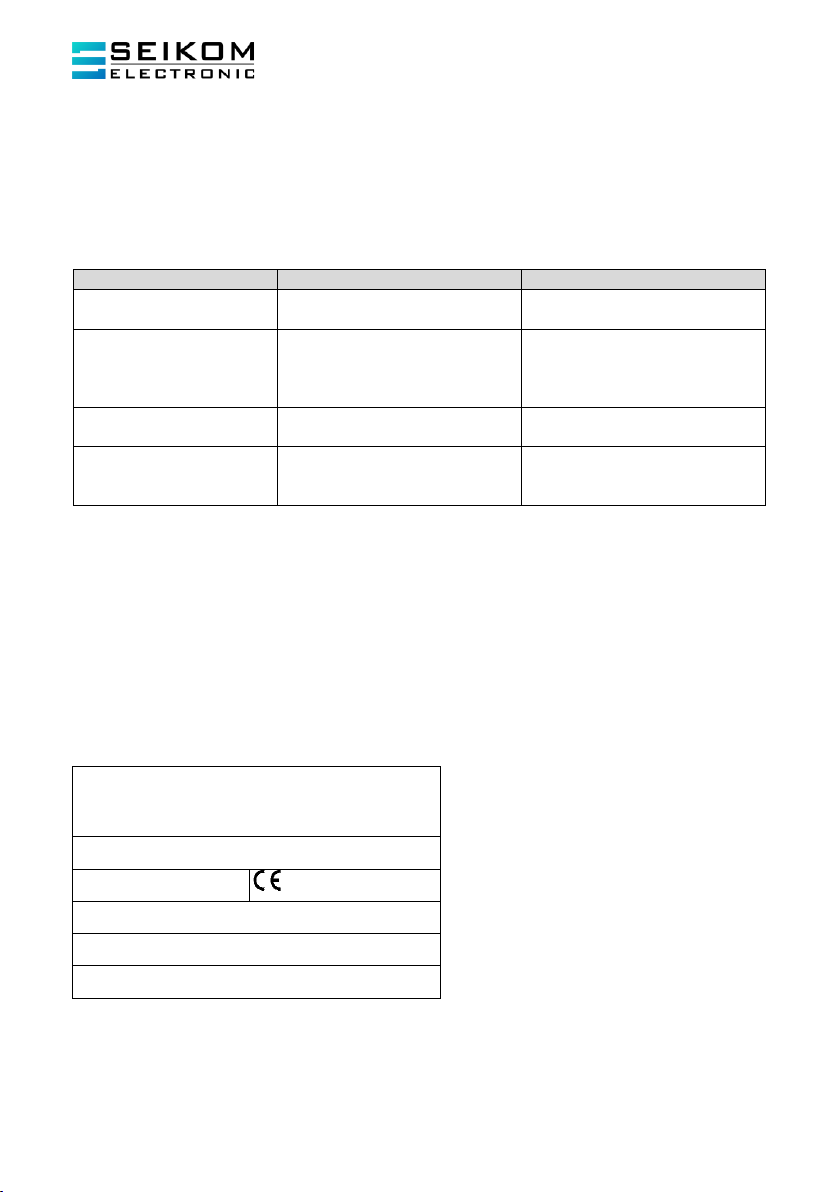

7. LABELLING OF THE AIR FLOW SENSORS F3.X EX

Every air flow sensor of the series F3.x Ex carries a readable label which specifies the required

explosion protection class as specified below. The label cannot be removed. Generally, a readable

identification of the required explosion protection class in field use must be attached before the first

use of the product.

SEIKOM-Electronic GmbH & Co.KG

Fortunastraße 20

D-42489 Wülfrath

Type: F3.x Ex

[Serial number]

[Year of construction]

TFR: 18 ATEX 0003

EII 3G Ex ic IIC T4 Gc

0 °C ≤Ta ≤60 °C

A sensor, that was once used in a not intrinsically safe electric circuit, cannot be used in intrinsically

safe electric circuits subsequently.

User Manual

NLSW®75-A Ex (Gg) & Sensor F3.x Ex

+49 2058 2044 •info@seikom-electronic.com •www.seikom-electronic.com

Page 13

8. GENERAL DESCRIPTION NLSW®75-A EX

With this air flow monitor, you can depict air flows via an externally connected display or realize a

min-max-control via a limiting value transmitter. The monitor also has a continuously adjustable

change-over contact. You can adjust the analog outputs by setting 0V in the absence of flow and

10 V at maximum flow (20 mA). The switch-point of the output relay can be adjusted in the range of

0 …10 V.

9. TECHNICAL DATA OF THE AIR FLOW MONITORS NLSW®75-A EX

Type

NLSW®75-A Ex

Article-No.

70789Ex/DC

70789Ex/AC

60620Ex

Operating voltage

24 V DC

24 V AC

230 V AC

Voltage tolerance

± 5%

Overvoltage category

II

Signal display, voltage

Green LED

Max. power

consumption.

5 VA

Permissible ambient

temperature

-20°C … 50°C

Signal output flow

1 change-over contact

Switch function in case

of flow

Relay contact changes

Current and contact

rating

250 V AC, 6 A, 1,5 kVA

Signal display flow

Yellow LED

Analog outputs

0 …10 V / 4 …20 mA relative

Burden

200 Ω

Applicable range of

media temperature

0°C … 60°C

Switch-point

Adjustable via potentiometer

Measurable range

Adjustable via potentiometer, 0,5m/s… 20.0 m/s

Flow sensors

F3Ex, F3.1Ex, F3.2Ex, F3.3Ex

Z-Barrier

2 pcs. included in delivery

Electrical connection

16 clips, 2.5 mm²

Protection class casing

IP20

Protection class clips

IP20

Casing

Standard housing N75

Casing dimensions

(L x W x H)

112 mm x 75 mm x 73 mm

Mark of conformity

User Manual

NLSW®75-A Ex (Gg) & Sensor F3.x Ex

Page 14

+49 2058 2044 •info@seikom-electronic.com •www.seikom-electronic.com

10. INSTALLATION OF THE AIR FLOW MONITORS NLSW®75-A EX

The air flow monitors of the series NLSW®75-A Ex must be mounted together with the safety barriers,

outside of the area exposed to an explosion hazard. The protection class IP20 of the housing must be

considered.

Connection and start-up must be conducted by qualified personnel. The mandatory competence of

qualified personnel includes knowledge of the types of ignition protection as well as provisions and

regulations concerning equipment in ex-zones! Verify whether the classification (according to these

instructions and the labelling of the devices) is sufficient for the dedicated use.

The housing enables mounting on a profile rail NS35/7,5 according to DIN EN 50022-35. If the profile

rail is exposed to larger vibrations, it has to be mounted in a vibration-reducing manner. Please

follow the provisions of DIN EN 60034-14 (IEC34-14).

Furthermore, the following points must be considered:

a) For the installation of an intrinsically safe electrical circuit a block diagram (system

description) is required, which must be supplied by the builder or operator

b) The installation can only be conducted in a cleared status

c) The start-up can only be performed after the mounting and electrical connection have

been finished

d) The permissible ambient conditions specified in this operating instruction cannot be

exceeded

ATTENTION: It is not permitted to connect the connection “N” of the supply voltage

with b2 (strand no. 2) of the sensor wire when using a 24 AC and DC air flow monitor of

the series NLSW®75-A Ex!

10.1 Commissioning and switch-point adjustment

The relation between air flow velocity and resistance change is non-linear. In the lower section

(small flow) the change of resistance is large. The change of resistance becomes smaller with

constant increase of them flow velocity in the upper section. This characteristic should be

considered when adjusting the switch-point. Moreover, the following requirements must be taken

into account:

Small changes of flow in the high section of flow velocity: The switch-point must be chosen

close to the usual value of the flow, because the changes of the measured value are very small with

changing flow. Since the temperature compensation lags behind the real change of temperature,

such a kind of switch-point adjustment is only possible in use cases with slow temperature change.

Small changes of flow in the small section of flow velocity: The switch-point can be selected

with a certain distance to the usual value of the flow, since changes in the measured value are large

for changing flow. Temperature changes are not influencing the switching behavior.

Large changes of flow: In this case a yes/no response is desired (e. g. to verify that a fan is working

or not).Therefore a large interval may be selected, so that neither temperature changes nor

turbulences may impact the switching behavior.

User Manual

NLSW®75-A Ex (Gg) & Sensor F3.x Ex

+49 2058 2044 •info@seikom-electronic.com •www.seikom-electronic.com

Page 15

For the start-up the following approach is recommended:

1. Install the air flow sensor and monitor according to the instructions.

2. Connect analog measuring equipment.

3. Set potentiometer “Reinforcement” to minimum sensitivity (left stop).

4. Switch Supply voltage; the green LED lights up and the device is ready to operate within

two seconds.

5. Without flow, adjust the the output voltage or current with potentiometer “Zero Point” to

0V or 4mA.

6. Activate the flow generation.

7. At maximum flow, adjust the output voltage or current to 10V or 20mA with

potentiometer “Reinforcement”.

8. Turn the potentiometer „switch-point“ slowly towards maximum until the yellow LED

lights up and the potential-free switcher operates; in order to obtain stable switching

conditions the potentiometer “airflow” should be turned slightly over the switch-point.

9. Review the settings: In order to review the settings turn the air flow off, the yellow LED

extinguishes, the potential-free switcher operates, activate the air flow, the yellow LED

lights up, the potential-free switcher operates again.

The air flow monitor is now adjusted to monitoring function.

Please find the relation between air flow and switching position of the potential-free switcher below:

Flow ≥Threshold value

Signal output switches

Yellow LED „airflow“ lights up

Flow < Threshold value

Signal output does not operate

Yelow LED „airflow“ does not light up

Please do not hesitate to contact us in case of questions or problems.

Technical development and errors reserved, Revision status: 01/2021

User Manual

NLSW®75-A Ex (Gg) & Sensor F3.x Ex

Page 16

+49 2058 2044 •info@seikom-electronic.com •www.seikom-electronic.com

11. EU DECLARATION OF CONFORMITY

User Manual

NLSW®75-A Ex (Gg) & Sensor F3.x Ex

+49 2058 2044 •info@seikom-electronic.com •www.seikom-electronic.com

Page 17

Page 18

+49 2058 2044 •info@seikom-electronic.com •www.seikom-electronic.com

Wachsendes Netz lokaler Vertriebshändler online verfügbar

www.seikom-electronic.com

Unser Produktportfolio

Strömung

Temperatur

Druck

Luftqualität und CO2

Zener Barrieren

Universal Transmitter

+49 2058 2044

info@seikom-electronic.com

www.seikom-electronic.com

SEIKOM-Electronic GmbH & Co. KG

Fortunastraße 20

42489 Wülfrath

This manual suits for next models

1

Table of contents

Popular Security Sensor manuals by other brands

Honeywell

Honeywell Fire-Lite Alarms SD365T Installation and maintenance instructions

ZKTeco

ZKTeco LD01 user manual

Buckingham

Buckingham 2139 ASSEMBLY & ATTACHMENT INSTRUCTIONS

B.E.G.

B.E.G. LUXOMAT Indoor 180/R-2W UK Operating and mounting instructions

SECO-LARM

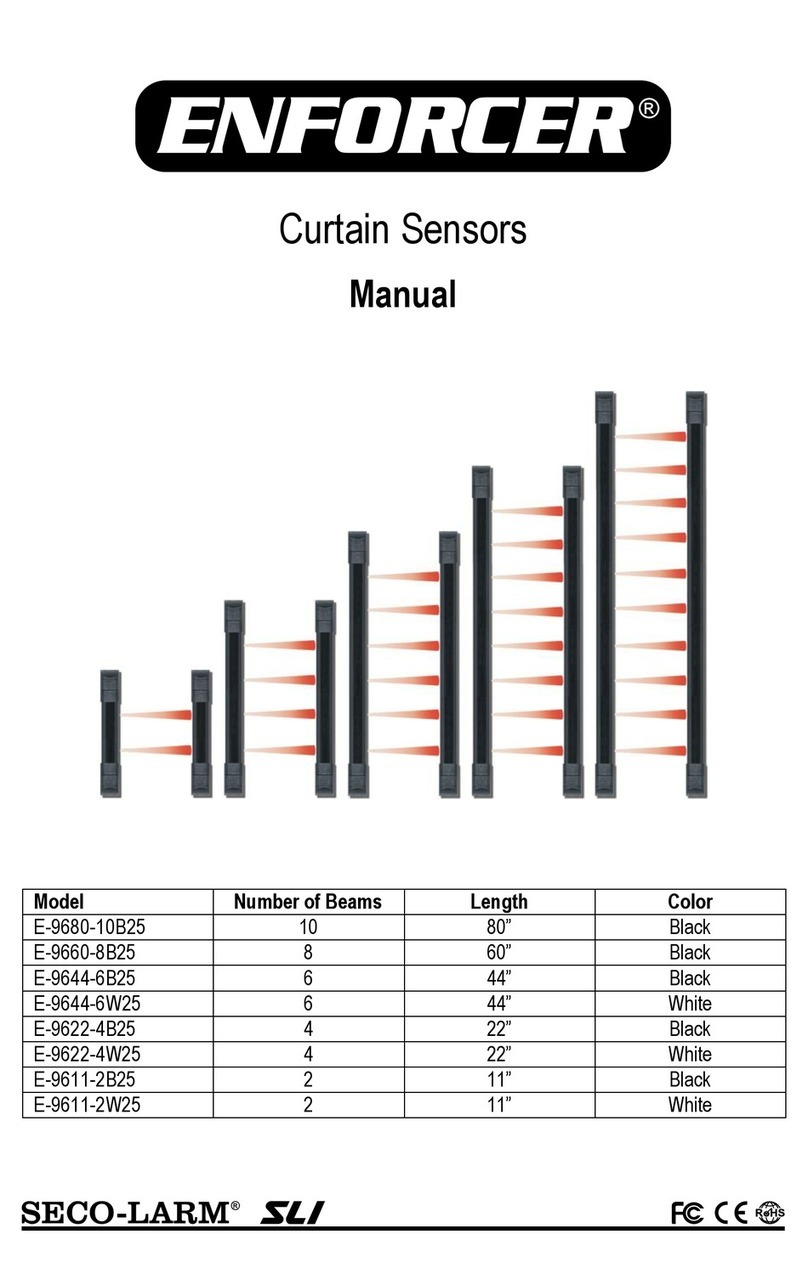

SECO-LARM Enforcer series manual

Hytronik

Hytronik HC403VRC-KD Installation and instruction manual