Selbit ANTD-03 User manual

AUTOMATIC CUT THICKNESS CONTROLLER

FOR 2-

HEAD BANDSAWING MACHINE

INSTALLAOR AND USER MANUAL

ANTD-03

AUTOMATIC CUT THICKNESS CONTROLLER

HEAD BANDSAWING MACHINE

INSTALLAOR AND USER MANUAL

AUTOMATIC CUT THICKNESS CONTROLLER

HEAD BANDSAWING MACHINE

www.selbit.pl 2

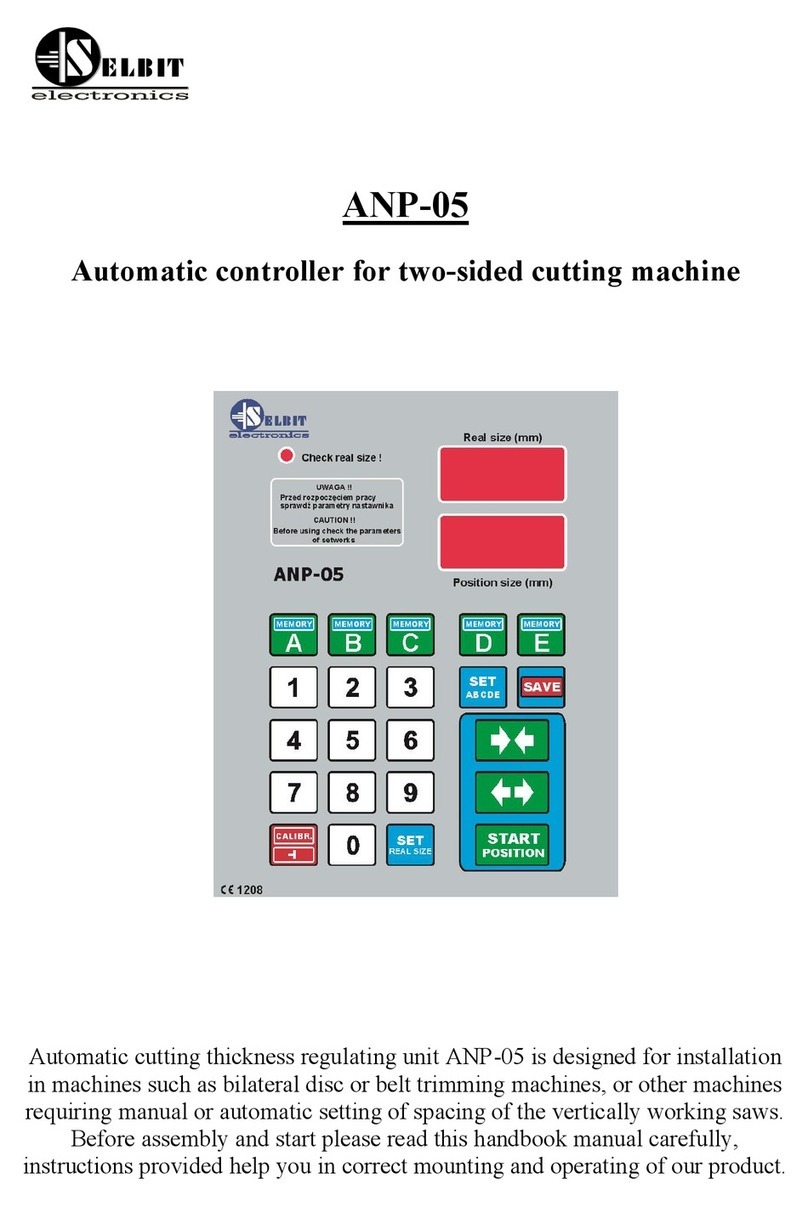

(1) Controller Installation and Connection

In installation of the controller, one must follow the instructions stated in this manual.

Before installation in the control panel (fig. 1), it is necessary to cut a rectangular hole with

dimensions 175 x 140 mm. The hole should be madeaccurately, so that the rubber seal of the

control panel will fit tightly on the whole length. Possible irregularities left after the cutting

ought to be flatten with a small file and protected from corrosion with a high-quality paint or

lacquer.

If there is not enough free space on the control panel to install the controller, it can be

installed in any location as an additional, stand-alone device (fig. 2).

Fig. 1 – installation of the controller in the control panel of the machine

A – front panel with electronics board

B – rubber seal

C – installation frame

D – frame and panel fixing screws

(8 units, 4.1 x 12 mm)

E – Machine control panel with a cut out

175 x 140 mm hole

Fig. 2 – installation of the controller as a stand-alone device

A – front panel with electronic board

B – rubber seal

C – nut for the PG chokes

D – screw fixing back of the case

(6 units, 4.1 x 10 mm)

E – Installation element (because of the different

type of machines, the set does not contain this

element)

F – PG chokes for introduction of the cables

G – Screws fixing the case to a support or the machine

(4 units, 4.1 x 10 mm)

H – hole plugs for the holes of fixing

screws

I – back of the case

www.selbit.pl 3

When the controller is installed as a stand-alone device, one can after the installation screw it

directly on the machine with 4 units of 4.1 x 10 screws included in the set, or, if necessary,

make an additional installation element, which after screwing it on to the case will serve as a

distance support.

(2) Electrical installation

CAUTION!

Because of the risk of electric shock, all connections shall be performed only

when the machine is disconnected from power. The best way to do that is to

turn off the main switch of the machine.

All connections should be done with double-insulated cables, intended for controlling

devices powered from 230V AC network. The cables which enter the case ought to be

round, with the diameter adjusted to the chokes installed in the back of the case.

Endings of the cables should cleaned and have sleeves, or be tinned before screwing.

This is important for correct and fail-safe operating of the controller in the future.

In order to assure correct and fail-safe operation, the wiring ought to be performed in

accordance with the following instructions. Incorrect wiring can result in disturbing the

work of the controller, and thus impeding its operation.

The machine, in which the controller is installed, should have operational limit

switches, and feed contractors ought to have a blockade preventing both of

them to be turned on at once!

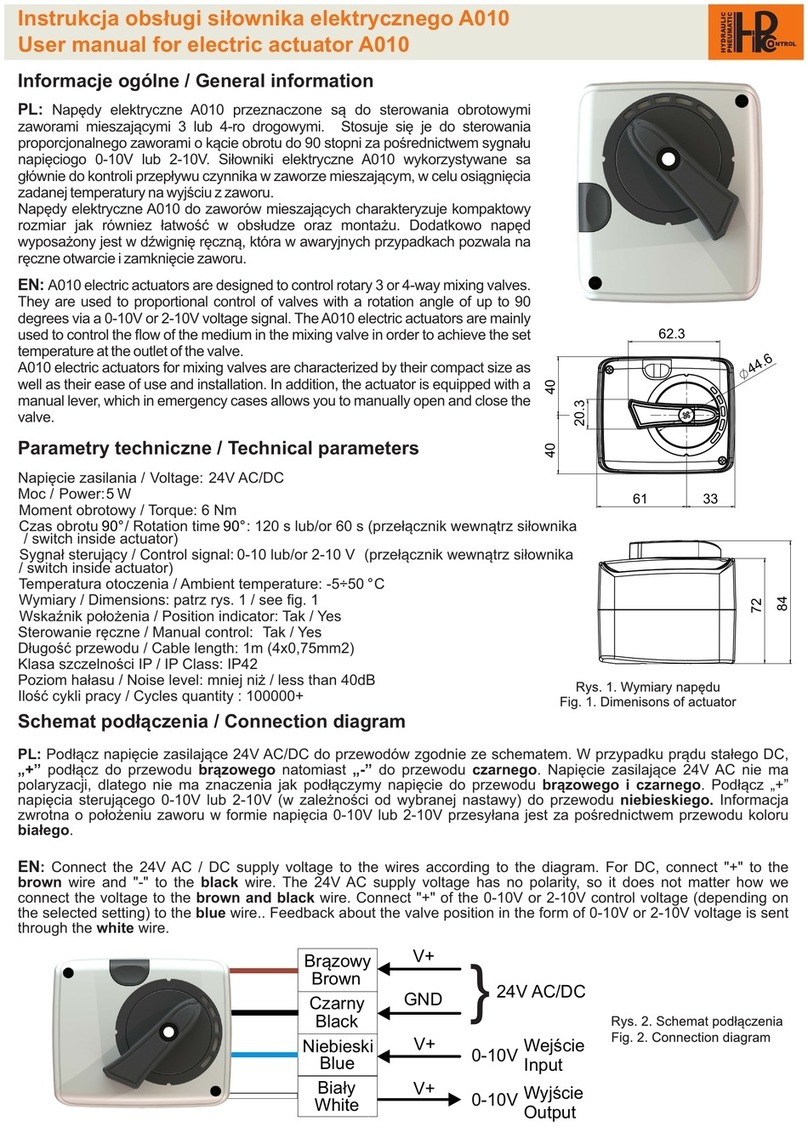

(3) Installation of the TSS-8/24 power transformer

TheTSS-8/24 230/24V power transformerincluded in the set ought to be installed in the

power supply cabinet of the machine.

The transformer is intended for a standard TSS-35 fixing rail, commonly used in electric

machines. The location of the transformer ought to be maximally away from other electric

elements (electrical converters, contractors, other transformers). It is important, because

otherwise electromagnetic noise may penetrate the electronic system of the controller through

the transformer.

The cables providing 230V power should be connected to the transformer clamps marked as

PRI 230V. The transformer should be installed in the circuit which includes neither

contractor inductors nor an inverter.

230V power cables ought to be laid as far from other cables in the cabinet as possible.

The cables transmitting power to the electronic board should be connected to the transformer

clamps marked as SEC 24V. Similarly as in the previous connection, these cables ought to be

laid as far from other cablesas possible, including the 230V cables powering the transformer.

Length of the power cables (24V) should be adequate to the location of the controller.

The cables going from the SEC 24V transformer clamps should in the final stage of the

installation be connected to controller board clamps marked as PWR.

(4) Installation of the interference suppressors (CPZ)

www.selbit.pl 4

Interference suppressors CPZ (RC 100nF 100 Ohm 440VAC) included in the set prevent

excessive emission of the electromagnetic noise, which is generated when the contractors

installed in the machine are operating. Their proper installation is crucial for correct work of

the controller.

CPZ suppressors ought to be connected parallel to the inductors of the contractors which

control the move of each of the two heads of the machine (H1, H2), according to the

following picture:

CPZ 1-4 – WX1P 224M 440V suppressors

S1, S2, S3, S4 – inductors controlling the movement of heads H1 and H2

(5) Installation of the encoders in the machine heads

Installation of the linear magnetic encoder MSK-320 and magnetic tape MB-3200.

The magnetic measuring tape consists of two elements, each of which has a layer of self-

adhesive tape.

The first part, thicker one, is to be stuck on a smooth, flat, and straight surface (after it has

been carefully cleaned and degreased with acetone or alcohol).

During the sticking, one should remove only part of the foil protecting the glue, then stick the

first part, starting from the top. Then, gradually, one should remove further pieces of the foil,

while sticking the freed piece of the tape to the surface.

A rubber roller might be used for pressing after the sticking, to provide a better pressure. The

tape should be stuck carefully, to avoid any bulges and stick the tape exactly straight. After

sticking the first part, protecting steel tape ought to be stuck on the top of the tape, with the

same precautions as in the case of the first sticking. Both tapes should be stuck exactly one on

top of another. MSK 320 sensor with a cable should be installed on a non-moving part of the

machine (with respect to the controller), so there will be no movements of the cable which

may lead to its damage. When the sensor is installed in the moving position, its cable must

be protected with moving rails preventing bending of the cable.

The sensor ought to be fixed with two screws going through the case in such a way that it will

be exactly 1 to 1.5 mm above the tape, in aparallel position.

www.selbit.pl

In laying the sensor cable, it is important to pu

cables and electric devices. The tape, above which the sensor is moving, cannot be

located close to any source of magnetic field (magnets, electromagnets) before, during

and after installation. Otherwise, it may be da

The surface of the tape ought to be regularly cleaned from dust and dirt with a soft brush. It is

prohibited to hit the tape or the sensor. The sensor should be installed in a position in which

the sticker SCALE SIDE

in pointing towards the magnetic

Both the sensor and tape

should be installed in such a way that in performing the whole

movement, the sensor constantly remains in the range of the tape located below.

Special attention should be put to stability of the sensor and tape installation,

vibrations of these elements while they are at work.

The manner of the magnetic sensor and tape installation

Distance of the sensor

and magnetic tape

Maximal allowed tilt of the sensor and the

vertical axis

Maximal allowed tilt of the sensor and the

horizontal axis

5

In laying the sensor cable, it is important to pu

t the cable as far away from the other

cables and electric devices. The tape, above which the sensor is moving, cannot be

located close to any source of magnetic field (magnets, electromagnets) before, during

and after installation. Otherwise, it may be da

maged!

The surface of the tape ought to be regularly cleaned from dust and dirt with a soft brush. It is

prohibited to hit the tape or the sensor. The sensor should be installed in a position in which

in pointing towards the magnetic

tape.

should be installed in such a way that in performing the whole

movement, the sensor constantly remains in the range of the tape located below.

Special attention should be put to stability of the sensor and tape installation,

vibrations of these elements while they are at work.

The manner of the magnetic sensor and tape installation

Distance of the sensor

and tape

and magnetic tape

Maximal allowed tilt of the sensor and the

Maximal allowed tilt of the sensor and the

t the cable as far away from the other

cables and electric devices. The tape, above which the sensor is moving, cannot be

located close to any source of magnetic field (magnets, electromagnets) before, during

The surface of the tape ought to be regularly cleaned from dust and dirt with a soft brush. It is

prohibited to hit the tape or the sensor. The sensor should be installed in a position in which

should be installed in such a way that in performing the whole

movement, the sensor constantly remains in the range of the tape located below.

Special attention should be put to stability of the sensor and tape installation,

to prevent

The manner of the magnetic sensor and tape installation

Distance of the sensor

and tape

www.selbit.pl 6

Magnetic sensor of heads H1 and H2 movements should be connected as presented in the

figure below.

When the controller is turned on for the first time, it might be necessary to invert the direction

of counting in one or both sensors. It is done in accordance with the description of the first

launch, by switching places of orange and red sensors.

Connecting of the sensors MSK – 320 to ANTD-03 connectors

(5a) Rotating encoder installation

If rotating encoder is being installed (for the machines with a saw moving with a

trapezoidal screw), it should be done as follows:

Rotating encoder transforms rotating movement of the screw which moves the head into

electric impulses contrived to the controller. The number of impulses per rotation of the screw

depends on its pitch. This dependency is presented in Table 1.

The trapezoidal screw moving the machine head should have free one end, so it will be

possible to drill a hole to screw in the clutch of the encoder.

In most bandsawing machines available on the market, this free end of the screw is located on

the top.

The hole should be drilled exactly centrically. Otherwise, the installed encoder may sway,

what can result in its damage. After drilling the hole of ca. 15 mm depth, it should be tapped

with M8 tap. Now, the encoder can be fixed with a fixing band included in the set (fig. 4).

The band should be fixed on the machine with a support which, given the differences in

mechanical constructions available on the market, must be supplied by the client. Fig. 4a

presents as typic look of the encoder installed on the top end of a trapezoidal screw.

www.selbit.pl 7

Fig. 4 Fig. 4a

Table 1

Screw Pitch (mm/r) Encoder type Divider

3 Rotating 42 imp / min 28

4 Rotating 42 imp / min 21

5 Rotating 50 imp / min 20

6 Rotating 48 imp / min 16

7 Rotating 42 imp / min 12

8 Rotating 48 imp / min 12

9 Linear MSK 320 + MB 320 5

10 Rotating 50 imp / min 10

Chain Bandsawing Machine Linear MSK 320 + MB 320 5

The data presented in the table should be used to check the controller parameters

Connection of the rotating encoder cables to ANT-2G connections

During the first launch of the controller, it might be necessary to change the direction of

counting for one or both encoders. It is done in accordance with the description of the first

launch by switching places of the white and black encoder.

The rotating encoder cables should be lied away from other electric cables. Through fixing it

with fixing bands it is introduced to the location where the controlled will be installed.

www.selbit.pl 8

Caution! The encoder cable must be screwed tight, to ensure in turn the proper

tightness of the connection!

Caution! Incorrect cable connection will result in a serious damage to the

encoder.

(6) Connecting the cables controlling the contractors

Buttons controlling the up- and downwards movement of the heads, which the machine

should have installed in the factory, ought to be of the clasping type, without sustaining (i.e.

they should clasp the junctions while pressed on, and unclench when the button is released).

To the buttons in the machine control panel which control the movement of the head, one

should connect a wire which consists of four pairs of cables, with double, round insulation,

with a diameter small enough to put them through the bigger choke in the back of the case of

the controller. Two pairs of cables should be connected parallel to the clamps of the upward

and downward movement of head 1 buttons, and the other two, analogously, should be

connected to the clamps of the buttons of head 2. It is important to remember to put the

sleeves or tinthe junctions. The cables should have different colours, what will facilitate their

further correct connection to the right clamps on the controller board. The cables ought to be

laid away for other electric cables and lead to a place where the controller panel will be

located.

The machine in which the controller is installed should have operational limit switches

and feed contractors of up- and downward movement ought to be prevented from both

being turned on at once!

The cables connecting the contractors ought to be connected according to the following

picture:

The manner of connecting the contractors control

After all connections have been made, you can proceed to assemble the controller casing.

Before putting the front panel into the back part of the casing or the workbench, check

whether the rubber gasket is placed in the grove running around the panel where it is

supposed to be. It is important for ensuring proper tightness of the connection and prevents

dirt from getting inside the casing.

www.selbit.pl 9

After the panel has been placed in the back part of the casing, screw in the six 4.1x12 screws

included in the set. Before the finally installing the controller and tightening the connection to

the machine, it is recommended to check whether it works correctly according to the next

section titled ‘First launch’. Having ensured that the controller is connected properly and

works as described, you can place the end caps securing screw holes and install the controller

in the machine.

The installation of the controller in the workbench is analogous to the above, except the front

panel screws, which are screwed in from the back with a plastic frame and through the metal

casing of the workbench.

After the screws have been fixed, gently stretch the cables running out of PG chokes to

remove excess cables from inside the casing (do not pull the cables too hard to avoid

damaging connections between them and the choke terminals), and then tighten the outer nuts

of the PG chokes that seal the cable entries.

In the case of installation as an independent device, you can now install the entire set in the

machine or the brackets using four 4.1x10 screws which are to be placed in the designated

holes in the back part of the controller casing.

First launch

The controller has a multi-level menu available by pressing the MENU/EXIT key.

After entering the menu, use the up and down arrow keys to select the next menu (the

current menu is shown against the dark background).

To enter the next menu (selected and highlighted using the dark background), use the right

arrow key. To go back to the previous menu, press the left arrow key, and to exit the entire

menu altogether at any moment, press the MENU/EXIT key.

www.selbit.pl 10

After

www.selbit.pl 11

turning the power on, check if the controller logo is shown on the display. If not, check the

TSS 8/24 transformer connection and repeat the attempt.

Input divider validation

Enter the appropriate divider value depending on the type of encoder connected to the

controller.

In the case of MSK-320 linear encoders working with MB-3200 magnetic tape, the input

divider value is 5 !.

To check or set the divider value, enter the main menu (press the MENU/EXIT key) and

select SERVICE and then DIVIDER.

It is possible to change the divider value after entering the three digit access code, the default

code being 123.

After the checking and possibly modifying the divider value, confirm the change by pressing

the ENTER/START key or exit the menu if you do not want to save changes.

The divider value is entered only once when the controller is launched, and there is no

need to interfere with this setting later on unless it is suspected that the controller has

decalibrated, e.g. after a power supply overvoltage.

Verification of saw kerf width setting in controller memory

To enter or verify the kerf width value, enter the main menu, select SETTINGS, then SAW

KERF and choose the relevant saw (horizontal saw or vertical saw).

Remember that the kerf width has impact on the accuracy of the controller, the kerf width of

the saws should be measured as precisely as possible. Kerf width is entered with the

precision of 0.1 mm!

After checking or entering the width of the saws currently in use in the gang saw, confirm the

change with the ENTER/START key or exit the menu if you do not want to save changes.

Controller connection verification

To check the motion contactor connections, carry out the direction test.

To do so, enter the main menu and then select SERVICE followed by DIRECTION TEST.

After entering the test menu, the display shows two counters both at 500.

The left hand side counter corresponds to left and right movement, the right hand side

counter corresponds to the up and down movement.

Now, use the arrow keys to test movement as follows:

Left-right movement test

After pressing the left arrow key, the head of the machine should start moving left, and after

pressing the right arrow key, the head of the machine should start moving right.

Up and down movement test

After pressing the down arrow key, the head of the machine should start moving down, and

after pressing the up arrow key, the head of the machine should start moving up.

If the machine does not respond correctly to the keys being pressed, check whether W1-

W4 control outputs of the controller have been correctly connected to the relevant

contactors.

Horizontal counting test

www.selbit.pl 12

After pressing the left arrow key, the value of the left hand side counter should decrease,

and after pressing the right arrow key, the value of the left hand side counter should grow.

Vertical counting test

After pressing the down arrow key, the value of the right hand side counter should

decrease, and after pressing the up arrow key, the value of the right hand side counter

should grow.

If the horizontal or vertical test results in an incorrect counting direction, turn off

the power and swap the red and orange cables of the MSK-320 sensor (the one

relevant to the direction where the incorrect counting observed) that are connected

to the INPUT joints on the controller panel.

The direction test is carried out only after the controller has been installed, at the first

launch, there is no need to perform it again during further operation of the machine.

If movement and counting directions are correct, exit the direction test menu and remember to

set the proper counter value corresponding to the actual elevation above the bed as described

below.

Setting the actual elevation above the bed

The controller is equipped with a counter showing the actual elevation of the saw above the

bed of the machine.

In order to make the controller work properly, take care to ensure that the elevation

displayed on the controller is equal to the actual physical elevation of the saw in the

machine.

To change (set) the displayed value, enter the main menu and then select SETTING and then

SET ELEVATION. At this point, check the actual elevation of the saw (e.g. using a

mechanical measuring tool the machine is equipped with), enter the value and confirm using

the ENTER/START key.

It is recommended to check whether the value shown on the display corresponds

to the actual value each time before starting work with the machine.

Autocalibration

Each machine has certain inertia depending on numerous factors, such as internal

temperature, internal resistance after lubricating the guide rails, etc.

To ensure the maximum precision of dimension settings, calibrate the controller

automatically as often as necessary.

It is recommended to carry out automatic calibration at least once a weak and

each time after applying lubricant to mechanical elements responsible for moving the

heads of the machine.

To perform an automatic calibration, enter the main menu, select SETTING and

AUTOCALIBRATION.

Then move the saws the middle location, and, having ensured that starting the machine will

not pose a threat to other people, start autocalibration by pressing the ENTER/START key.

During the autocalibration, the controller moves the heads of the machine, while displaying

the progress bar and the correction factor measurements for the subsequent movements.

Upon the completion of the autocalibration process, the controller displays a relevant

message.

www.selbit.pl 13

Menu language selection

The controller allows the user to select the language used for displaying the menu. To choose

the language, enter the main menu, then SERVICE, JĘZYK/LANGUAGE and select the

language version. Having changed the language, confirm your choice by pressing

ENTER/START.

Operation of the ANTD-03 controller

The ANTD-03 is equipped with an LCD graphic display that shows the functions carried out

by the controller and the settings.

Main window

ANTD-03 controller key function

To change the cut width setting, use the SIZE H-V key, select the setting to be changed (the

selected setting is displayed against a dark background), and enter the relevant dimension

using the numeric keys. The setting should be entered without undue delay between the digits

where the setting consists of several digits.

The selected setting is active until a contradicting one is chosen.

Additional symbols of

performed functions Saw elevation above

the bed

Vertical movement

setting Horizontal movement

setting

Confirm return point

for saw movement

Enter/exit menu

Change active setting (H-V) Start moving to position

Select movement

direction

Start return movement

of the saw

Load manual program

Load and set up

memory program

www.selbit.pl 14

Automatic positioning for single cut mode

To start automatic move, select the desired direction by using the relevant arrow key

followed by the ENTER/START or RETURN key depending on the direction of the move.

The controller allows the following movement sequences:

•- Movement down by a distance defined by the vertical setting

(down arrow plus START),

•- Movement right by a distance defined by the horizontal setting

(right arrow plus START),

•- Simultaneous movement down and right by a distance defined by both settings

(down arrow plus right arrow plus START).

•- Movement upby a distance defined by the vertical setting

(up arrow plus START),

•- Movement leftby a distance defined by the horizontal setting

(left arrow plus START),

•- Return movement in the horizontal plane to the previously set reference point

(left arrow plus RETURN),

•- Return movementin the horizontal plane to the previously set reference point with

the simultaneous down movement by a distance defined by the vertical setting

(left arrow plus down arrow plus RETURN),

•- Horizontal and vertical return movement to the previously set reference point

(up arrow plus left arrow plus RETURN).

The controller has a memory storing the reference point set by the users at any place within

the movement range of the horizontal head. After selecting the point that the horizontal head

should return to, press the MEMO RETURN key shortly. After confirming the key, it is

active (its symbol is shown on the display) until it is changed. The reference point is

deleted after power has been turned off and it is impossible to use without prior

confirmation.

Cutting programs

ANTD-03 offers the option to set the dimension for the worked material from the level of the

bed up.

1 - Manual program.

To use the dimension setting function, lift the head with the saw up to the starting material

cutting line, and press the MANUAL PROGRAM button shortly.

The controller enters the dimension setting mode and shows words ‘manual program’ at the

top of the display, below (description reads ‘STAYS’) is the current possible cutting

dimension (which depends on the elevation of the vertical head saw) and the number of the

current position (P-) and its dimension.

www.selbit.pl 15

You can enter the first dimension from the bed at the P-1 position and then use up arrow key

to change the position to a higher one enter other dimensions.

While entering the dimensions, the controller calculates and shows the remaining distance to

the saw elevation.

When the sum of the dimensions exceeds the elevation of the saw, the controller replaces the

word ‘STAYS’ with horizontal lines and the background of the neighbouring digits alternates

between light and dark.

At this point you can:

- press the ENTER/START key to set the saw at the elevation of the last position

- change the dimension of the last position

- lower the position number

- manually raise the saw head

When the required number of position has been set, you can confirm the cutting program.

This is done by pressing the MANUAL PROGRAM key shortly.

It is possible to confirm the program only if the ENTER/START key has already been used

and the controller has placed the saw in the proper position, which is shown by caption

‘Position ready – press manual program’ on the display.

An attempt to confirm the program without having pressed the ENTER/START key results in

a ‘Press Start’ message.

When the program has been confirmed, the controller displays the ‘Program saved’ message.

At this point, the cutting process can be started in a manner analogous to the manual mode.

In the programmed cutting mode, the vertical saw position is set according to the subsequent

positions in the programme, and the dimension of the horizontal saw movement is selected by

the operator, and it is shown at the bottom of the display as ‘horizontal’

In the programmed mode, the following movement sequences are possible:

•- Movement downby a distance defined by the current position setting

(down arrow plus START),

•- Simultaneous movement down and right by a distance defined by the currently

visible program position setting and horizontal dimension entered by the operator

(left arrow plus right arrow plus START),

•- Movement leftby a distance defined by the horizontal setting

(left arrow plus START),

•- Movement rightby a distance defined by the horizontal setting

(right arrow plus START),

After reaching position No. 1, the display shows the ‘Program completed’ message and

movement further down is not possible, it is only possible to move the head left and right.

To leave the program mode, press the MENU/EXIT key shortly.

2 - Memory program.

The ANTD-03 controller has the option to set up and save an individual cutting program that

can be loaded from the memory at any moment.

www.selbit.pl 16

To set up an individual cutting program, press and hold the MEMORY PROGRAM key for

about 3 seconds.

The controller enters the program set up mode, a ‘memory program’ caption is shown at the

top of the display, and the current position number and dimensionis shown at the bottom.

Now, enter all the necessary cutting position and dimensions as it is done in the manual

program, using the arrow keys and the numeric keypad.

After entering the last needed position, press the MEMORY PROGRAM key shortly. The

controller confirms that the program has been saved by displaying the ‘program saved’

message and automatically exits the program set up mode.

To use a saved program, just like in the case of a manual program, raise the head with the saw

to the starting line and then press the MEMORY PROGRAM button shortly.

After loading the memory program, the controller automatically displays the calculated final

possible position in related to the current position of the saw.

Other actions in the memory program are identical to those in the manual programme.

Operating recommendations

In order to maintain good cutting parameters, it is recommended to perform autocalibration at

least twice a week following the instruction in the section titled ‘Autocalibration’.

Warning! The controller should be operated only in temperatures ranging from -10 to

+45 degrees Celsius.

Before starting work, check if the saw elevation displayed on ANTD-03 conforms to the

elevation shown by the mechanical measuring tool.

Should there be a discrepancy, enter the proper elevation according to the instructions in the

section titled: ‘Setting the actual elevation above the bed’.

Do not press any keys on the controller with hard objects or too hard as this can cause

irreversible damage.

If the keypad is dirty, you can use popular cleaning agents, remembering not to press the

membrane keypad too hard. Excessive pressure on the keys may lead to damage and the

necessity to replace the entire keypad.

The controller should not be exposed to direct contact with water or other liquids.

www.selbit.pl 17

If a specific movement is impossible for reasons independent of the controller

(limit switch engaged, damaged encoder or controller connections), the

controller unit stops any movement and displays relevant messages.

Error messages and their causes

Message type

Cause of error

Reference point not saved At attempt at a return movement without

having saved a reference point.

No signal, movement stopped

Press ENTER, reset controller A head movement limit switch has been

engaged.

Interrupted MSK-320 connection.

Damaged MSK-320 sensor.

Improper input divider.

Autocalibration failed

Press ENTER, reset controller A head movement limit switch has been

engaged.

Interrupted MSK-320 connection.

Damaged MSK-320 sensor.

Improper input divider.

Warning wrong direction An attempt to perform a contradicting

movement (e.g. simultaneous movement up

and down).

Invalid entry The entered divider value or kerf width is out

of the permitted range.

Warning set head elevation Decalibrated elevation counter.

Warning vert. setting too high The vertical movement setting too high in

relation to the actual elevation of the head

over the bed.

EMC compliance

The ANTD-03 controller complies with the binding electromagnetic compatibility (EMC)

standards.

The ANTD-03 controller should be installed and set up according to the European and

national standards. Installers of the electric machine steering system are liable for the

adjustment of the device, and they have to comply with the EMC directive.

The ANTD-03 controller has to be considered as a component because it is not a machinery

or a ready-to-use appliance according to European directives (Machinery Directive and EMC

Directive). Liability for compliance with those standards lies with the end user installing an

ANTD-03 controller.

The product and fittings described in this manual may be changed and modified from time to

time both in terms of the technical aspect and the manner of use.

The description may not in any way be regarded as a contract.

Table of contents

Other Selbit Controllers manuals

Popular Controllers manuals by other brands

HP

HP A9890A - Smart Array 6402/128 RAID... installation guide

AccuDual

AccuDual ACD-52300 user guide

Mitsubishi Electric

Mitsubishi Electric MELSEC iQ-R Series user manual

Mitsubishi Electric

Mitsubishi Electric R64MTCPU user manual

Deif

Deif SGC 410 user manual

THOMSON

THOMSON Electrak 1 Series Operation manual