Deif SGC 410 User manual

User manual

Single Genset Controller

SGC 410

DEIF A/S · Frisenborgvej 33 · DK-7800 Skive · Tel.: +45 9614 9614 · Fax: +45 9614 9615 · [email protected] · www.deif.com

Document no.: 4189341243A

1. Introduction

1.1 About SGC 410............................................................................................................................................................................................................................ 4

1.2 Key functions............................................................................................................................................................................................................................... 4

1.3 Product overview....................................................................................................................................................................................................................... 4

1.4 Passwords..................................................................................................................................................................................................................................... 5

1.5 Overview of controller buttons...........................................................................................................................................................................................6

1.6 Legal information.......................................................................................................................................................................................................................6

2. Safety instructions

2.1 General safety instructions.................................................................................................................................................................................................. 7

2.2 Electrical safety...........................................................................................................................................................................................................................7

2.3 In operation safety.....................................................................................................................................................................................................................7

3. Technical_specifications

3.1 Terminals........................................................................................................................................................................................................................................ 8

3.2 Power supply................................................................................................................................................................................................................................8

3.3 Genset voltage and frequency measurements..........................................................................................................................................................9

3.4 Genset current measurements...........................................................................................................................................................................................9

3.5 Earth leak measurements......................................................................................................................................................................................................9

3.6 Digital inputs..............................................................................................................................................................................................................................10

3.7 Analogue resistive sensor inputs.................................................................................................................................................................................. 10

3.8 Analogue inputs used as digital inputs.......................................................................................................................................................................11

3.9 Site battery inputs................................................................................................................................................................................................................... 11

3.10 Magnetic pick-up (MPU) input........................................................................................................................................................................................11

3.11 Digital outputs........................................................................................................................................................................................................................ 12

3.12 D+ Charger alternator.........................................................................................................................................................................................................12

3.13 Sensor common point........................................................................................................................................................................................................12

3.14 Communication ports.........................................................................................................................................................................................................13

4. Installation

4.1 Dimensions.................................................................................................................................................................................................................................14

4.2 Mounting in panel....................................................................................................................................................................................................................14

4.3 Terminal details........................................................................................................................................................................................................................ 15

4.4 Typical wiring diagram......................................................................................................................................................................................................... 17

5. Monitoring mode

5.1 Monitoring mode......................................................................................................................................................................................................................18

6. Configuration mode

6.1 Configuration mode............................................................................................................................................................................................................... 20

6.2 Configurable parameters.................................................................................................................................................................................................... 20

6.2.1 Configurable parameters..............................................................................................................................................................................................20

6.2.2 Module..................................................................................................................................................................................................................................21

6.2.3 Digital inputs...................................................................................................................................................................................................................... 23

6.2.4 Analogue inputs................................................................................................................................................................................................................23

6.2.5 Outputs.................................................................................................................................................................................................................................30

6.2.6 Timers...................................................................................................................................................................................................................................30

6.2.7 Generator............................................................................................................................................................................................................................31

6.2.8 Mains.................................................................................................................................................................................................................................... 34

6.2.9 Engine.................................................................................................................................................................................................................................. 35

6.2.10 Maintenance....................................................................................................................................................................................................................38

6.2.11 Password ID.................................................................................................................................................................................................................... 38

USER MANUAL 4189341243A UK Page 2 of 78

6.3 Digital input source selection...........................................................................................................................................................................................39

6.4 Digital output source selection........................................................................................................................................................................................39

7. Running modes

7.1 Auto mode...................................................................................................................................................................................................................................42

7.2 Manual mode..............................................................................................................................................................................................................................43

7.3 Start and stop sequences...................................................................................................................................................................................................45

8. Load detection

8.1 Load detection in Auto mode........................................................................................................................................................................................... 47

8.2 Load detection in Manual mode......................................................................................................................................................................................47

9. Features

9.1 About Features......................................................................................................................................................................................................................... 48

9.2 Auto config exit mode...........................................................................................................................................................................................................48

9.3 Load histogram........................................................................................................................................................................................................................ 48

10. Alarms

10.1 Alarms.........................................................................................................................................................................................................................................49

11. Modbus communication protocol

11.1 About the Modbus communication protocol.........................................................................................................................................................53

11.2 Modbus connection details............................................................................................................................................................................................. 53

11.3 Modbus functions.................................................................................................................................................................................................................53

12. Modbus communication settings

12.1 Modbus communication settings................................................................................................................................................................................ 54

12.2 Register map (function code 03).................................................................................................................................................................................. 54

12.3 Register map (function code 16).................................................................................................................................................................................. 61

13. Engine communication

13.1 Introduction to engine communication.................................................................................................................................................................... 62

13.2 Default settings......................................................................................................................................................................................................................62

13.3 Supported engines...............................................................................................................................................................................................................62

13.4 Engine values on the display......................................................................................................................................................................................... 62

13.5 Engine communication settings...................................................................................................................................................................................63

13.6 Generic J1939......................................................................................................................................................................................................................... 64

13.7 Wiring.......................................................................................................................................................................................................................................... 65

14. CAN communication

14.1 About the CAN communication protocol................................................................................................................................................................ 66

14.2 CAN communication structure......................................................................................................................................................................................66

14.3 CAN packet structure......................................................................................................................................................................................................... 76

15. Troubleshooting

15.1 Troubleshooting.................................................................................................................................................................................................................... 77

USER MANUAL 4189341243A UK Page 3 of 78

1. Introduction

1.1 About SGC 410

SGC 410 is a modern genset controller with user friendly HMI, full graphics LCD, and a highly versatile software. Extensive inputs

and outputs support a wide variety of industry standard features in diesel/gasoline genset applications.

SGC 410 offers Site battery monitoring which significantly reduces fuel consumption. The controllers support Shelter temperature

monitoring, Auto (Remote start /stop, Cyclic and Exercise mode), Manual and Test modes.

The DEIF Smart Connect software offers flexibility to configure each individual input and output for a specific function or application.

All parameters can also be configured on the controller.

The powerful micro controller in SGC 410 supports a range of complex features, for example:

• LCD display

• True RMS voltage and current monitoring

• RS-485 base communication

• Monitoring of engine and alternator parameters

• Configurable inputs and outputs for a wide range of functions

1.2 Key functions

• Genset controller with configurable inputs:

◦ Nine digital inputs

◦ Eight analogue inputs (configurable as digital inputs)

• Seven digital outputs

• Auto (Site battery backup, Remote start/stop, Cyclic and Exercise) modes, Manual and Test modes

• Site battery monitoring

• Shelter temperature monitoring

• Real time clock

• Fuel theft alarm

• Cyclic timer

• RPM sensing using genset’s output frequency

• Backlit full graphics display

1.3 Product overview

Features Specifications

Digital switch input 9

Analogue resistive inputs 5

Analogue current/voltage inputs 2

Differential input (± 60 V DC) for Site battery voltage Yes

DG alternator voltage input, D+ charging alternator I/O Yes

Digital outputs 7

Event logs Yes

USB port for PC based configuration Yes

RS-485 for Modbus communication Yes

USER MANUAL 4189341243A UK Page 4 of 78

Features Specifications

Operating battery supply voltage (with -32 V reverse protection) 8 to 32 V DC

Operating temperature range (°C) -20 to 65

Protection class with gasket (included) IP65

Warning auto clear enable/disable Yes

Fuel reference selection input Yes

1.4 Passwords

The controller is protected from set-up changes with a four digit password.

There are two password levels:

Level Access Factory setting

1 Full access (read and write) 0123

2 Limited access (read) 1111

The passwords can be changed on the controller:

1. Go to Configuration mode.

2. Log on with password level 1.

3. Use the Up and Down buttons to go to Configuration ID, select with the Start button.

4. Use the Up and Down buttons to go to the password to be changed, select with the Start button.

5. Use the Up and Down buttons to choose the first digit for the new password, select with the Start button.

6. Repeat for the next three digits.

7. When all four digits are chosen, the display shows

PASSWORD 1

Password changed

USER MANUAL 4189341243A UK Page 5 of 78

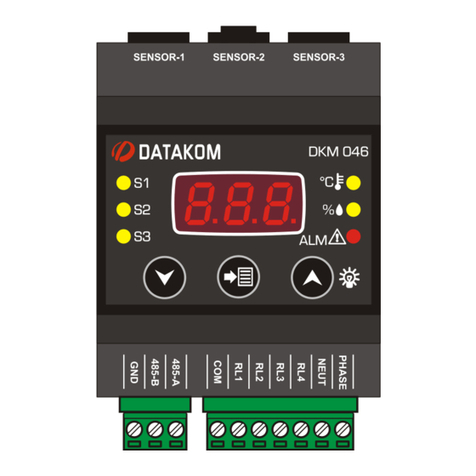

1.5 Overview of controller buttons

Shutdown Alarm

Warning Alarm

Notification

1. Display

2. Stop/Config button

3. Start button

4. Menu navigation up button

5. Menu navigation down button

6. Genset contactor latching button

7. Acknowledge button

8. Mode selection button

1.6 Legal information

Warranty

WARNING

The controller is not to be opened by unauthorised personnel. If the controller is opened anyway, the warranty will be lost.

Disclaimer

DEIF takes no responsibility for installation or operation of the generator set. If there is any doubt about how to install or operate the

engine/generator controlled by the SGC controller, the company responsible for the installation or the operation of the set must be

contacted.

DEIF A/S reserves the right to change any of the contents of this document without prior notice.

The English version of this document always contains the most recent and up-to-date information about the product. DEIF does not

take responsibility for the accuracy of translations, and translations might not be updated at the same time as the English document.

If there is a discrepancy, the English version prevails.

Copyright

© Copyright DEIF A/S 2020. All rights reserved.

USER MANUAL 4189341243A UK Page 6 of 78

2. Safety instructions

2.1 General safety instructions

This document includes important instructions that should be followed during installation and maintenance of the controller.

Installation and maintenance must only be carried out by authorised personnel, and always in accordance with all applicable state

and local electrical codes. Efficient and safe operation of the controller can be acquired only if the equipment is correctly operated,

configured and maintained.

The following notations found in this document can indicate potentially hazardous conditions to the operator, service personnel or

the equipment.

NOTE Highlights an essential element of a procedure to ensure correctness.

CAUTION

Indicates a procedure or practice, which could result in damage or destruction of equipment, if not strictly observed.

WARNING

Indicates a procedure or practice, which could result in injuring personnel or loss of life, if not followed correctly.

2.2 Electrical safety

• Electric shock can cause severe personal injury or death.

• Ensure that the genset is grounded before performing any installation or service.

• Generators produce high electrical voltages, and direct contact with it can cause fatal electrical shock. Prevent contact with

terminals, bare wires, connections, etc., while the generator and related equipment are running. Do not tamper with interlocks.

• To handle the maximum electrical current, the wires used for electrical connections and wirings must be of appropriate size.

2.3 In operation safety

• Before installing the controller, ensure that all power voltage supplies are positively turned off at the source. Disconnect the

generator’s battery cables and remove the panel fuse to prevent accidental start up. Disconnect the cable from the battery post,

indicated by a NEGATIVE, NEG, or (–) first. Reconnect the negative cable last. Failure to do so will result in hazardous and

possibly fatal electrical shock.

• Remove the electric power supply before removing the controller or touching other electrical parts.

• Use extreme caution when working on electrical components. High voltage can cause injury or death.

• With floors of metal or concrete, use rubber insulation mats placed on dry wood platforms when working near the generator or

other electrical equipment.

• Do not wear damp clothing (particularly wet shoes) or allow skin surface to be damp when handling electrical equipment.

• Do not operate any electrical device or wires while standing in water, while barefoot, or while hands or feet are wet. It may result

in severe electrical shock.

• Do not wear jewellery. Jewellery can cause a short circuit within electrical contacts and cause shock or burning.

In case of an accident caused by electric shock, immediately shut down the electrical power source. If this is not possible, try to

release the victim from the live conductor. Avoid direct contact with the victim. Use a non-conducting object (for example a rope or a

wooden stick) to release the victim from the live conductor. If the victim is unconscious, apply first aid and get immediate medical

help.

USER MANUAL 4189341243A UK Page 7 of 78

3. Technical_specifications

3.1 Terminals

The SGC 410 uses two types of terminal blocks:

Connectors of 5.08 mm pitch Connectors of 10.16 mm pitch

Table 3.1 Terminals

Connector type Pitch Male (on controller) Female (mating part) Quantity

3-pin 5.08 mm 5447366 5441977 1

4-pin 5.08 mm 5447379 5448637 1

5-pin 5.08 mm 5447382 5448640 1

6-pin 5.08 mm 5441919 5441964 1

8-pin 5.08 mm 5441935 5441951 1

9-pin 5.08 mm 5447395 5448653 1

10-pin 5.08 mm 5447405 5448666 1

4-pin 10.16 mm 5474274 5453499 2

3.2 Power supply

Category Specification

Controller terminals 1 (Ground)

2 (Battery or DC+)

Supply voltage range Nominal voltage: 12/24 VDC

Operating range: 8 to 32 V DC

Cranking drop out period 50 ms

Maximum reverse voltage protection -32 V DC

Measurement accuracy (battery voltage) ±1 % full scale

Resolution 0.1 V

Maximum current consumption ~ 200 mA, 12/24 V DC (excluding the current load for the DC outputs)

Standby current consumption 180 mA, 12 V DC

140 mA, 24 V DC

USER MANUAL 4189341243A UK Page 8 of 78

3.3 Genset voltage and frequency measurements

Category Specifications

Controller terminals

54 (Neutral)

55 (L3)

56 (L2)

57 (L1)

Measurement type True RMS

Phase-to-neutral voltage 32 to 300 V AC RMS

Phase-to-phase voltage 32 to 520 V AC RMS

Voltage accuracy ±1 % of full scale for phase-to-neutral

±1.5 % of full scale for phase-to-phase

Voltage resolution 1 V AC RMS for phase-to-neutral

2 V AC RMS for phase-to-phase

Frequency range 5 to 75 Hz

Frequency accuracy 0.25 % of full scale

Frequency resolution 0.1 Hz

NOTE For single phase applications, it is mandatory to connect the genset phase and neutral cables to the genset controller's

phase L1 and neutral terminals.

3.4 Genset current measurements

Category Specifications

Controller terminals

43 and 42 (for phase L1)

45 and 44 (for phase L2)

47 and 46 (for phase L3)

Measurement type True RMS

Maximum CT secondary current rating 5 A

Burden 0.25 VA

Measurement accuracy ±1.4 % of nominal

3.5 Earth leak measurements

Category Specifications

Controller terminals 48 and 49

Measurement type True RMS

Maximum CT secondary current rating 5 A

Burden 0.25 VA

Measurement accuracy ±1.4 % of nominal

NOTE Follow the recommended phase sequence while connecting the current transformer (CT).

USER MANUAL 4189341243A UK Page 9 of 78

3.6 Digital inputs

Category Specifications

Controller terminals 33, 34, 35, 36, 37, 38, 39, 40, 41

Number of inputs 9

Type Negative sensing (connect to ground for activation)

Software configurable options Emergency stop, Remote start/ stop, and more (see Controller overview,

Configurable parameters in the User manual for more details).

3.7 Analogue resistive sensor inputs

Category Specifications

Controller terminals

11 (Oil pressure)

12 (Fuel)

13 (Temperature)

14 (Aux 1)

15 (Aux 2)

Number of inputs 5

Type Ratio-metric sensing

Range 10 to 5000 Ω

Open circuit detection Above 5.5 kΩ

Measurement accuracy ±2 % of full scale (up to 1000 Ω)

SCP connection

SCP connections for Analogue inputs 1 to 4*:

Battery

Engine body

Sensor

input

Sensor

common

T erminal 16

Terminal 2

Terminal 1

Supply

SGC 4xx series

Analogue

resistive

sensor

*SCP connections for Analogue input 2 used as Fuel level sensor with the reference configured as Battery Negative

Battery

Sensor

input

Sensor

common

Terminal 2

Terminal 1

Supply

SGC 4xx series

Analogue

resistive

sensor

USER MANUAL 4189341243A UK Page 10 of 78

3.8 Analogue inputs used as digital inputs

Analogue inputs can be used as digital inputs when wired as shown.

F1

8-32

V DC

+

-

3.9 Site battery inputs

Category Specifications

Controller terminals 24, 25

Number of inputs 2

Type Differential

Range ±60 V

Resolution 0.1 V

Accuracy ±2 % of full scale

Site battery run hours

In this feature, controller calculates the run hours for which the site runs on the battery backup. Site battery run hours are

incremented only when the genset contactors are not latched and when site battery voltage is greater than low battery voltage

threshold.

3.10 Magnetic pick-up (MPU) input

Category Specifications

Controller terminal 22

Measurement type Single ended

Frequency range 10 to 10 kHz

Input voltage range 200 mV to 45 V AC RMS

The Magnetic pick-up (MPU) is an inductive sensor fitted on the engine flywheel for the engine speed sensing. The output of the

MPU is a sine-wave signal.

USER MANUAL 4189341243A UK Page 11 of 78

3.11 Digital outputs

Category Specifications

Controller terminals 3, 4, 5, 6, 7, 8, 9

Number of outputs 7

Type DC outputs

Maximum current rating 5 A (3 and 4)

1 A (5, 6, 7, 8, 9)

Software configurable options

Start relay, Fuel relay, Close genset contactor, Stop solenoid and many more

(see Controller overview, Configurable parameters in the User manual for

more details).

NOTE • Do not connect the Starter motor relay and the Stop solenoid directly to the controller's output terminals. It is

recommended to connect terminals 3 and 4 to Start and Stop.

• Genset contactor latching relays should be compiled against 4 kVA surge as per IEC-61000-4-5 standard.

3.12 D+ Charger alternator

Category Specifications

Controller terminal 10

Voltage range 0 to VBATT

VBATT = 8 to 32 V DC

Excitation PWM (power limited to 3 W, 12 V/250 mA, 24 V/125 mA)

Accuracy ±2 % of full scale

The charge fail is a combined input and output terminal. When the genset starts, the terminal provides controlled power output to

excite the charging alternator. After the excitation is successfully done, the controller reads the charging alternator's output voltage

for monitoring its health. The action for charge fail is configurable.

3.13 Sensor common point

Category Specifications

Controller terminal 16

Range ±2 V

Accuracy ±2 % of full scale

The sensor common point (SCP) terminal 16 must be connected directly to an electrically sound point on the engine body. This point

serves as a common reference point for all analogue sensors. The electrical cable used for the connection must not be shared with

any other electrical connection. This wiring practice is strongly recommended to ensure that there is negligible potential difference

between the engine body and the controller's SCP terminal, and that predictable and accurate analogue sensor measurements are

always available in a wide variety of field conditions.

USER MANUAL 4189341243A UK Page 12 of 78

3.14 Communication ports

Category Specifications

USB USB 2.0 type B for connection to PC with DEIF Smart Connect software

RS-485 Serial Port

Half Duplex

Max. Baud Rate 115200

Data connection 2-wire

Termination resistor of 120 Ω is provided between output terminals A and B

Common-mode operating range

Maximum distance of line is 200 m

Controller terminals

30 (GND)

31 (A)

32 (B)

CAN

Baud rate: 250 kbps

Packet size: 8 bytes

Termination resistor of 120 Ω is provided

Controller terminals for CAN 58 and 59

NOTE • The RS-485 port on the controller supports a protocol based on Modbus.

• Use two core shielded twisted pair cable for Modbus RS-485 connection.

• Terminal 30 should be connected to master’s isolated ground only.

• Keep terminal 30 connection open if shielded cable is not available.

• Do not connect terminal 30 to the negative battery terminal (DC -).

USER MANUAL 4189341243A UK Page 13 of 78

4. Installation

4.1 Dimensions

38.5

(1.52)

38.5

(1.52)

Shutdown Alarm

Warning Alarm

Notification

233.0 (9.17)

173.0 (6.81)

Dimensions

Dimensions

Length: 233.0 mm (9.17 in)

Height: 173.0 mm (6.81 in)

Depth: 38.5 mm (1.52 in)

Panel cut-out

Length: 219.0 mm (8.62 in)

Height: 158.0 mm (6.22 in)

Tolerance: ± 0.3 mm (0.01 in)

4.2 Mounting in panel

To mount the controller into the panel, use the fixing clips provided along with the controller.

1. Panel surface.

2. Mounting clips.

a. Insert the mounting clips into the slots on the controller.

b. Press the mounting clips backwards until they "click" in place.

c. Turn the screws to tighten the mounting clips (max. torque: 0.19 Nm).

CAUTION

Over-tightening the screw may damage the controller casing.

USER MANUAL 4189341243A UK Page 14 of 78

4.3 Terminal details

Rear view of the controller with terminal details.

USB

Terminal Text Description Connector

1 GND Power ground

BCP-508-10GN

2 BATT + Power supply positive

3 DIG OUT A DC output - A

4 DIG OUT B DC output - B

5 DIG OUT C DC output - C

6 DIG OUT D DC output - D

7 DIG OUT E DC output - E

8 DIG OUT F DC output - F

9 DIG OUT G DC output - G

10 D+ CHG ALT Input for charging alternator control

11 ANLG LOP / DIG J Analogue input from Lube Oil Pressure Sensor/

Digital Input J

BCP-508-6GN

12 ANLG FUEL LEVEL / DIG K Analogue input from Fuel Level Sensor/Digital

Input K

13 ANLG ENG TEMP / DIG L Analogue input from Engine Temperature Sensor/

Digital Input L

14 ANLG AUX 1 / DIG M Analogue input auxiliary/Analogue input from

Shelter Temperature Sensor/Digital Input M

15 ANLG AUX 2 / DIG N Analogue input auxiliary/Digital Input N

16 SCP Sensor common point

17 Reserved - N/A

18 Reserved - N/A

19 Reserved - N/A

USER MANUAL 4189341243A UK Page 15 of 78

Terminal Text Description Connector

20 Reserved - N/A

21 ANLG AUX 3/DIG 0 Analogue input auxiliary/0-5 V/4-20 mA (LOP)/

Digital Input O

BCP-508-5GN

22 MPU Input from engine speed sensor (Inductive)

23 ANLG AUX 4/DIG P Analogue input auxiliary/0-5 V/4-20 mA/Digital

Input P

24 Site BATT I/P Input 1 from Site battery

25 Site BATT I/P Input 2 from Site battery

26 Reserved - N/A

27 Reserved - N/A

28 Reserved - N/A

29 Reserved - N/A

30 RS 485 GND RS-485 GND

BCP-508-3GN

31 RS 485 A RS-485 A

32 RS 485 B RS-485 B

33 DIG IN A Input from switch A

BCP-508-9GN

34 DIG IN B Input from switch B

35 DIG IN C Input from switch C

36 DIG IN D Input from switch D

37 DIG IN E Input from switch E

38 DIG IN F Input from switch F

39 DIG IN G Input from switch G

40 DIG IN H Input from switch H

41 DIG IN I Input from switch I

42 GEN CT IN L1-2 CT input 2 from Phase L1

BCP-508-8GN

43 GEN CT IN L1-1 CT input 1 from Phase L1

44 GEN CT IN L2-2 CT input 2 from Phase L2

45 GEN CT IN L2-1 CT input 1 from Phase L2

46 GEN CT IN L3-2 CT input 2 from Phase L3

47 GEN CT IN L3-1 CT input 1 from Phase L3

48 GEN CT IN EL2 CT input 2 from Earth Leakage

49 GEN CT IN EL1 CT input 1 from Earth Leakage

50 Reserved -

BCP-508-7GN-4PA

51 Reserved -

52 Reserved -

53 Reserved -

54 GEN V N Voltage input from Gen Neutral

55 GEN V L3 Voltage input from Gen L3

56 GEN V L2 Voltage input from Gen L2

57 GEN V L1 Voltage input from Gen L1

USER MANUAL 4189341243A UK Page 16 of 78

Terminal Text Description Connector

58 CAN L (Reserved) CAN Low

BCP-508-4GN

59 CAN H (Reserved) CAN High

60 Reserved -

61 Reserved -

4.4 Typical wiring diagram

Figure 4.1 SGC 410 typical wiring

‐

120

G

+

+ -

+

1 2 3 4 5 6 7 8 9 1610 11 12 13 14 15 21 22 24 25 31 32 58 59

33 34 35 36 37 38 39 40 41 50 51 52 5354 55 56 5743 4842 45 44 47 46 49

‐

ECU

Tacho

Engine

body

G

D+

B+

F1

Outputs

Supply

DC (+)

DC (-)

Output

Output

Output

Output

Output

Output

Output

Analogue inputs

Input

Input

Input

Input

Input

Input

D+

Tacho

BTS

battery

DC (+)

DC (-)

Data + (A)

Data - (B)

RS485

Low

High

CAN

ECU

USB

Digital inputs (configurable)

Input

Input

Input

Input

Input

Input

Input

Input

Input

AC current CT

AC voltage

genset

N

L1

L2

L3

L1 (s1)

L4 (s2)

L1 (s2)

L2 (s1)

L2 (s2)

L3 (s1)

L3 (s2)

L4 (s1)

F4

s2

s1

P2

P1

L1

L2

L3

N

L1

L2

L3

N

GB

s2s1

P2P1

s2s1

P2P1

P2P1

s2

s1

Sensor

common

NOTE • Wiring diagrams are examples. Use the application's wiring diagram during installation.

• Genset and mains contactor latching relays should be compiled against 4 kV surge as per IEC-61000-4-5 standard.

• Relay cards used with the controller should be protected against reverse battery voltages.

• Analogue input 2 used for Fuel level sensor can be wired with the reference to Battery Negative, see Specifications,

Analogue resistive sensor inputs.

• Communication ports for CAN ( terminals 58 and 59) and RS-485 (terminals 31 and 32) have built-in 120 Ω termination

resistors.

• If a digital output is connected to a relay, the relay must include freewheeling diodes.

USER MANUAL 4189341243A UK Page 17 of 78

5. Monitoring mode

5.1 Monitoring mode

In Monitoring mode, the display views shift automatically after a pre-defined time. This delay time can be configured in the

configuration menu.

The views can also be changed manually with the Up and Down buttons.

Engine status and operating mode

Product info Manual mode Auto mode

Auto - Site mode Auto - Cyclic mode Auto - Exercise mode

Generator voltage Genset power factor Load apparent power*

2.1

kVA

Load power* Load current* Load reactive power*

Generator cumulative energy Engine lube oil pressure Engine fuel level

Engine temperature Shelter temperature Engine speed

USER MANUAL 4189341243A UK Page 18 of 78

Engine run time Site run time Auxiliary sensor

Histogram Engine/Site battery voltage Alarm (example)

USER MANUAL 4189341243A UK Page 19 of 78

6. Configuration mode

6.1 Configuration mode

To configure the controller, follow these steps:

1. Press and hold the Stop/Config button for at least three seconds.

2. The display shows

3. To see the configuration, press the Stop/Config button. To change the configuration, press the Start button.

4. The display shows

PASSWORD

5. To enter the the four digit password:

• Scroll through the digits with the Up and Down buttons.

• Select a digit with the Start button.

6. To leave the Configuration mode, press and hold the Stop/Config button.

7. Until the configuration is saved, the display shows

6.2 Configurable parameters

6.2.1 Configurable parameters

The tables give an overview of configurable parameters.

Level 1 (table titles) and Level 2 texts are shown twice:

• DEIF Smart Connect software: Normal sentence case, for example Power on Mode.

• Controller display: Capital case in brackets, for example (POWER ON MODE)

USER MANUAL 4189341243A UK Page 20 of 78

Table of contents

Other Deif Controllers manuals

Deif

Deif AGC 200 Series User manual

Deif

Deif CGC 200 Installation and operation manual

Deif

Deif GC-1F User manual

Deif

Deif SGC 420 Mk II User manual

Deif

Deif CGC 400 User manual

Deif

Deif AGC 150 User manual

Deif

Deif PICUS PPM 300 User manual

Deif

Deif AGC-4 Mk II User manual

Deif

Deif 4189340315C User manual

Deif

Deif AGC 200 Series User manual