DIRECT DRIVE DAMPER ACTUATOR M847D

95C-10905—02 2

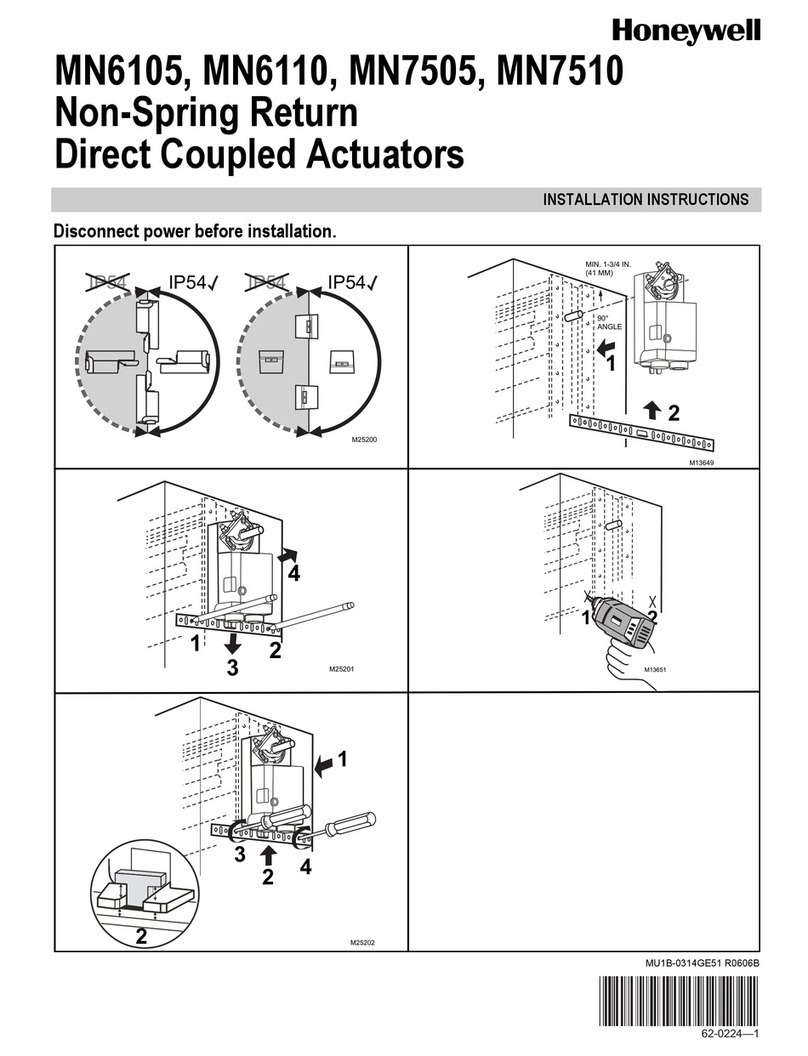

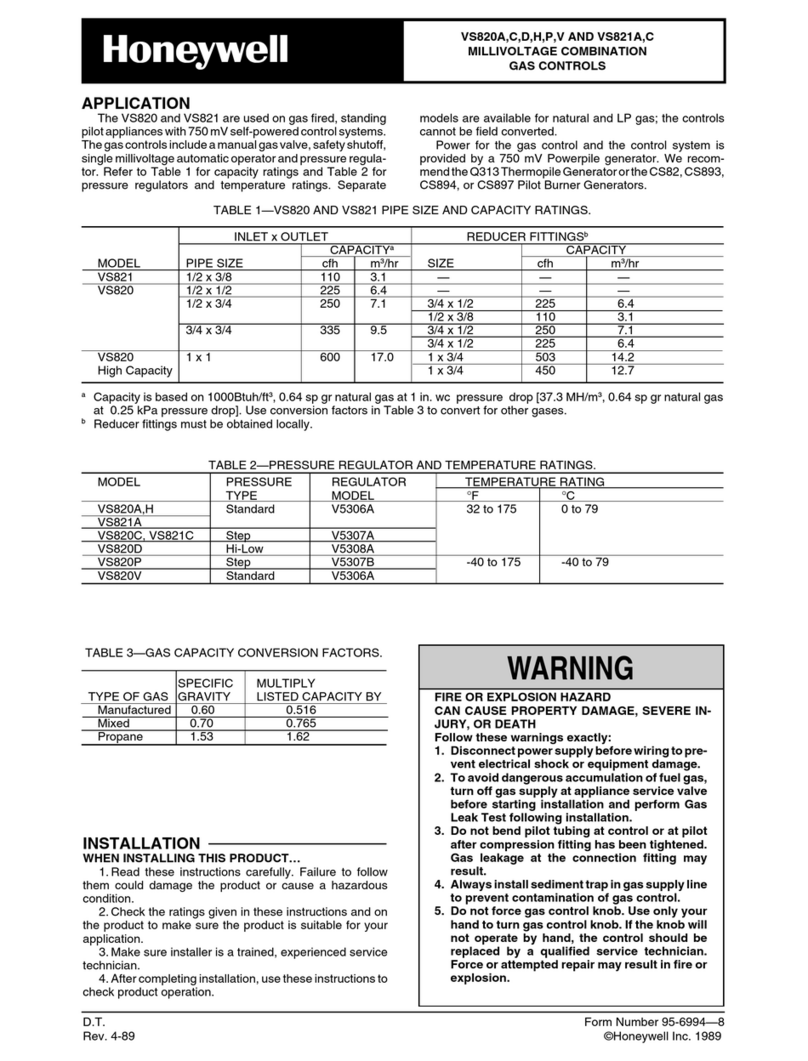

Fig. 1. Dimensional Details.

INSTALLATION AND

CHECKOUT

1. Read these instructions carefully. Failure to follow them

could cause a hazardous condition.

2. Disconnect power supply before beginning of installa-

tion and wiring of control to prevent electrical shock or

equipment damage.

3. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

4. All wiring must comply with local electrical codes, ordi-

nances, and regulations.

5. Installer must be a trained, experienced service techni-

cian.

6. After installation is complete, check out the product

operation as provided in these instructions.

1. DO NOT install this actuator on a flue damper.

2. DO NOT attempt to rotate the actuator by turning

the connection coupling or the damper shaft when it

is connected to the actuator or damage to the gear

train may occur.

STANDARD MOUNTING (For 5/16” dia. damper shaft)

The M847D can be attached directly to the protruding 5/16”

diameter damper shaft using the sleeve of the output shaft.

Drill a 5/16” (8 mm) hole 1-5/16” (33.5 mm) directly below the

damper shaft opening to accept the anti-rotation shaft

protruding from the base of the motor. The length of the

damper shaft to which the connection coupling is attached is

such as to firmly hold the actuator in a position to adequately

engage the anti-rotation pin in the warm air duct. See Figure 1

for the critical dimensions.

Replacing M847D on a Trol-A-Temp® ARD damper

1. Disconnect the motor wiring.

2. Using a 1/8 in. hex wrench to loosen the motor coupling

from the blade shaft, remove the existing motor assem-

bly.

3. Observe that the damper blades are in the normal,

spring open or spring closed position.

4. Place the new motor onto the shaft and tighten the cou-

pling.

5. Reconnect the motor wiring.

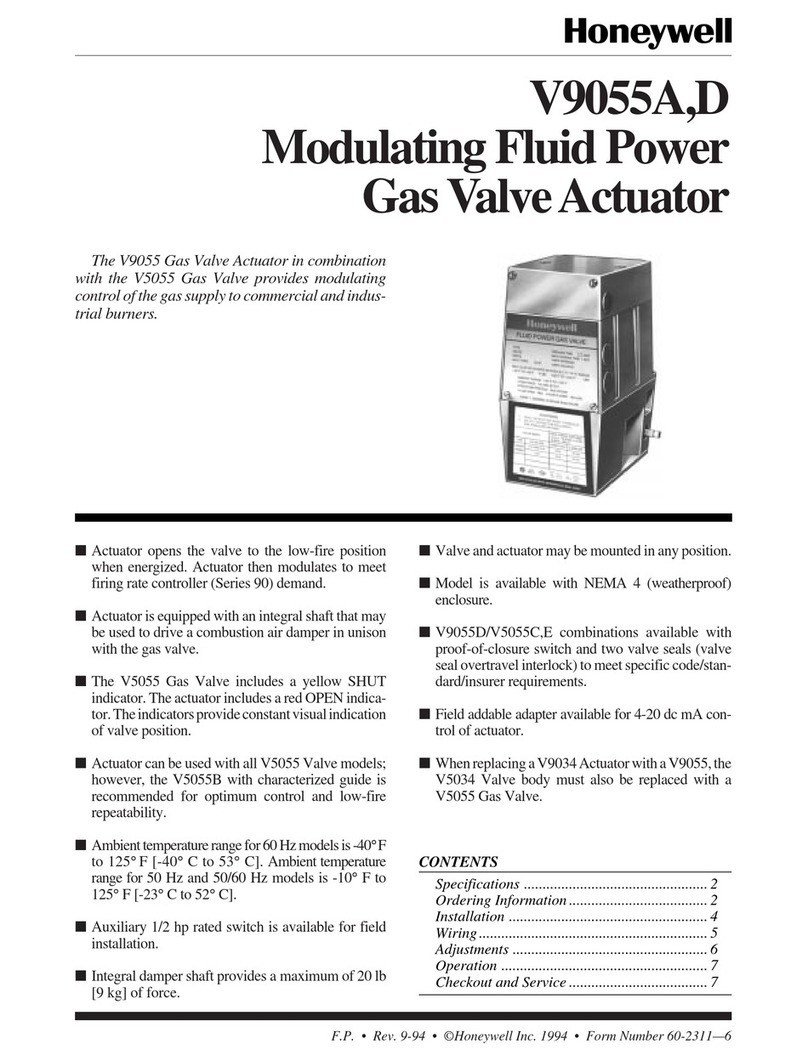

ALTERNATE MOUNTING (For 7/16” dia. coupling style

dampers)

Before installing the M847D actuator to a damper with a 7/16”

coupling, insert the drive shaft extension into the drive shaft

and tighten with the set screw provided. See Fig. 2. Also

install the anti-rotation extension to the end of the anti-rotation

rod. Install the actuator on the damper and tighten the

coupling screw.

Fig. 2. For 7/16” Coupling Models Only.

Replacing M847D on a Trol-A-Temp® ZDS or ZDB damper

1. Disconnect the motor wiring.

2. Using a 3/16 in. hex wrench to loosen the Allen screw

located above the faceplate at the motor coupling.

3. Remove the existing motor.

4. Observe that the damper blades are in the open posi-

tion with the setscrew pointing toward the damper label.

5. Attach the new motor to the coupling. Make sure that

the standoff on the motor is positioned in the grommet

on the faceplate.

6. Tighten the set screw.

7. Reconnect the motor wiring.