Select Medical OLA 8 User manual

User Manual

Dynamic Pressure Redistribution Mattress

& Mattress Overlay

USER MANUAL - OLA 8 & 4

TABLE OF CONTENTS

Statements and Symbols.......................................

Important Noce...................................................

Introducon...........................................................

Contact Informaon..............................................

Product Overview..................................................

Safety.....................................................................

Symbols & Denions............................................

Control Unit & Maress Parts................................

Installaon.............................................................

Operaon...............................................................

Cleaning & Decontaminaon................................

Storage..................................................................

Troubleshoong.....................................................

Maintenance..........................................................

Specicaons.........................................................

Electromagnec Compability..............................

Warranty and Service............................................

2

2

2

2

3

4

6

8

10

12

16

18

20

21

23

24

29

1

Thank you for choosing the OLA 8 or OLA 4 pressure redistribuon

system. This manual should be read carefully before using the maress

as it contains important safety and maintenance informaon to ensure

long lasng and reliable service.

INTRODUCTION

IMPORTANT NOTICE

STATEMENTS AND SYMBOLS

Before operang this medical equipment, it is important to read this

manual and understand the operang instrucons and safety

precauons. If you have any quesons regarding the use of this

equipment please contact your supplier.

Refer to manual

NB: Tips or informaon users should be aware of

Warning to highlight potenal hazards that, if disregarded, could lead to

injury or death.

CONTACT INFORMATION

For any service, warranty, sales or customer service informaon on this

product please contact your supplier or if in doubt contact Select Medical Ltd.

at the following address:

Select Medical Ltd, Unit 10 Philips Rd, Whitebirk Ind Estate, Blackburn,

BB1 5NA.

Customer Service: +44 (0)1254 685535 Sales: +44 (0)1254 668899

Email: info@selectmedical.co.uk

www.selectmedical.co.uk

PRODUCT OVERVIEW

Environment

Your dynamic maress system is intended for use in the following

environments:

• A care environment where medical supervision and monitoring are

provided (e.g. nursing homes, care home, rehabilitaon facilies etc).

• A domesc environment where the maress is used to alleviate or

compensate for an injury or disability.

Intended Use

OLA 8 is an 8” replacement, dynamic pressure redistribuon system

suitable for individuals up to very high risk of developing a pressure ulcer or

for those with exisng ssue damage.

OLA 4 is a 4” pressure relieving overlay suitable for individuals up to high risk

of developing a pressure ulcer or for those with exisng ssue damage.

OLA 8 & 4 provide regular periods of pressure reducon to vulnerable ssue

areas, aiding blood and lymphac ow which is vital to maintaining healthy

ssue. The maress system is designed to be used on standard or proling

beds.

For assistance in seng up, using or maintaining your dynamic maress

system, or to report unexpected operaon refer to the contact details found

on page 2.

Features

OLA 8 & 4 Maress:

• One in two cell-cycle design giving opmum therapy

• Mul-stretch, waterproof and vapour permeable cover

• CPR pull cord for rapid deaon

• Machine washable up to 95°C

• 1 year warranty

Cauon to highlight potenal hazards that if disregarded could lead to

equipment damage or failure.

2 3

OLA 8 Control Unit (Q2-02):

• Audible low pressure alert

• Pressure adjustment for opmum therapy

• External, easy replacement pump lters

OLA 4 Control Unit (D30):

• Low pressure alert

• Pressure adjustment for opmum therapy

• External, easy replacement pump lters

• The maress system & control unit must be installed and used

in accordance with the informaon provided in this manual.

• The maress system is typically not suitable for children. If it is

to be used by a child ensure a risk assessment has been

undertaken.

• Before using the system ensure that the mains lead is free from

damage and is posioned so as not to cause an obstrucon or

trip hazard.

• Exposure of the control unit to any liquid while it is plugged in

could cause a severe electrical hazard.

• Use care when handling or transporng the control unit.

Dropping or other sudden impacts may result in damage to the

unit.

• Do not open the control unit or aempt to repair or service

the unit. Repairs and servicing should always be undertaken by

suitably trained personnel.

• If the control unit is not funconing properly, or has been

damaged, unplug the unit and take it out of service

immediately.

• Do not use the system near a heat source or naked ame.

• Do not use with hot water boles or electric blankets.

• Do not use liquids near the control unit if plugged in.

• Do not place any objects, such as blankets, on or over the

control unit.

SAFETY

General Safety

• Do not use the control unit near ammable gas or in oxygen rich

environments as this poses a re risk or risk of explosion.

• Always assess the risk of intenonal or unintenonal tampering

of the control unit.

Risk Assessment

It is the responsibility of the carer/care provider to carry out the necessary

risk assessment to ensure the safety of the paent. This should be carried out

before using the maress system.

A risk assessment should include, but is not limited to:

• Product combinaons (bed frame, maress, side rails etc.)

• Extent of ssue damage (if any)

• Entrapment

• Paent falls

• Small adults (and children)

• Paents with learning dicules

• Unauthorised people with access to the controls

Contraindicators

Paent condions for which the applicaon of pressure relief on an

alternang maress system is a contraindicaon are as follows:

• Cervical or skeletal tracon

• Unstable spinal fractures

Other contraindicaons may be relevant which are specic to the paent or

care environment.

Maress Load

4 5

OLA 8 OLA 4

Minimum Weight Limit 32kg (5 stone) 32kg (5 stone)

Maximum Weight Limit 190kg (30 stone) 114kg (18 stone)

SYMBOL DEFINITIONS: CONTROL UNIT & MATTRESS

Control Unit

Warning: beware of potenal hazard

Refer to manual: failure to do so could introduce a hazard

Type BF Applied Part

Applied Part: The parts of the device that come into physical

contact with the user/occupant in order for it to carry out its

intended funcon.

Type BF: Applied parts which are electrically isolated from earth

and other parts of the medical equipment - Complying with

specic requirements for protecon against electric shock to

IEC 60601-1

W.E.E.E Label

(Waste Electrical and Electronic Equipment)

Class II electrical device

The user/occupant is protected by at least two layers of insulaon

between the current carrying parts (e.g. mains cable) – If damage

is noced to the control unit or mains cable assembly turn o at

the mains supply and contact your provider or Select Medical Ltd.

immediately.

IP21 Protected from touch by ngers and objects greater than 12

millimeters. Protected from condensaon.

The following symbols are found on the control unit:

6 7

The following symbols are found on the maress:

Disinfect by wiping the surface using a hypochlorite soluon diluted

1000ppm

95 Machine wash up to 95°C

Tumble dry on a low seng

Do not use harsh abrasives or Phenol cleaners

Do not iron

Ensure system is dry before storing

Do not place heavy objects on surface of cover other than the

paent

Do not use when damp, ensure surface is dry before use

Do not fold. Roll pack the system

Do not use sharp objects

Only use in conjuncon with appropriate medical advice

Maress

CONTROL UNIT/MATTRESS PARTS

Control Unit

Maress

1. Top Cover

2. Air Cells

3. Male Air Connector

4. Base Cover

5. Securing Straps (elascated corner straps only on OLA 4)

6. CPR Pull Cord

89

OLA 8 - Q2-02 Control Unit OLA 4 - D30 Control Unit

1. Control Panel

2. On/O switch

3. Mains Power Cable

4. Female Air Connector Port

5. Air Filter

6. Fuse Holders

7. Cushion Bar

8. Hooks

1. Control Panel

2. On/O switch

3. Mains Power Cable

4. Female Air Connector Port

5. Air Filter

6. Cushion Bar

7. Hooks

1. Carefully open the packaging.

2. Although unlikely, please check the product for any signs of damage. Do

not use if damaged and contact your provider or Select Medical Ltd (see

page 2).

3. Place the maress on top of the bed frame (OLA 8), or on top of the

exisng maress (OLA 4), with the top cover facing upwards and the air

hose at the foot end of the bed.

4. Aach the maress to the bed frame by securing with the adjustable

straps. Addionally, OLA 4 has elascated corner straps to tuck under the

exisng maress.

5. Check the CPR pull-cord is securely in posion.

6. Using the hooks on the back of the control unit, hang the unit over the

frame/board at the foot end of the bed. If there is no foot frame/board

lay the unit on the oor, under the bed with the front control panel facing

upwards.

7. Aach the male air connector on the maress to the female air

connector port on the control unit/pump, ensuring the air hose is not

kinked or trapped between parts of the bed frame/other equipment.

8. Plug the mains cable into a suitable mains supply and switch on the

control unit. At this stage both the mains power and low pressure

indicators will illuminate.

9. The maress will start to inate and will be completely inated within

30 - 40 minutes.

10. Once fully inated, adjust the straps that aach the maress to the bed

frame, ensuring the maress is held in place securely.

11. Cover the maress loosely with a sheet, ensuring it does not interfere

with cell alternaon.

10 11

INSTALLATION

Before installing the maress system please read the warning and

cauon notes carefully. These highlight risk areas to ensure paent

safety.

• Ensure the maress is only used with compable equipment/

accessories.

• Ensure the maress is of the correct type for the paent.

• Ensure the CPR pull-cord is easily accessible at all mes.

• Ensure the plug is accessible at all mes so the maress can be

disconnected from the mains supply quickly, if required.

• Ensure the mains cable is plugged into an appropriate power

source at all mes.

• Ensure the mains cable is not taut, parcularly if being used on

a proling bed that moves up and down (check all posions).

• Ensure that the mains cable does not become compressed,

trapped or damaged by the bed frame or other equipment.

• Replace any damaged cable immediately as these cables can

create a risk of electrocuon and/or re.

• A CE marked extension cable must only be used when it is not

possible to reach a wall socket with the equipment mains cable.

• If an extension cable is used never overload it by plugging in

appliances that together will exceed the maximum current

rang stated for the extension cable.

• Do not use block adaptors.

• Ensure extension cables or sockets are not placed under the

bed frame as liquids could leak onto them posing an electrical/

re risk.

• Ensure the mains supply is compable with the control unit

(see page 23 for electrical specicaon)

• Avoid placing the maress system in direct sunlight as this

could damage the maress cover.

• On proling beds it is essenal that adjustable straps are

secured around the movable secons of the bed frame,

otherwise the maress may be damaged.

• If you are placing the control unit on the oor it is advisable to

place the unit on a rm surface.

• Ensure the mains cable is posioned so as not to cause a trip

hazard.

12 13

Maress Operaon

1. Turn on the power on the control unit. The pump starts to inate the

maress to the pressure selected on the dial.

2. The low pressure indicator (orange) will illuminate as inaon commences.

3. OLA 8 /Q2-02 only - the audible alert is acvated, press the ‘alert mute’

buon to mute the alarm and its indicator will ash.

OPERATION

Control Panel

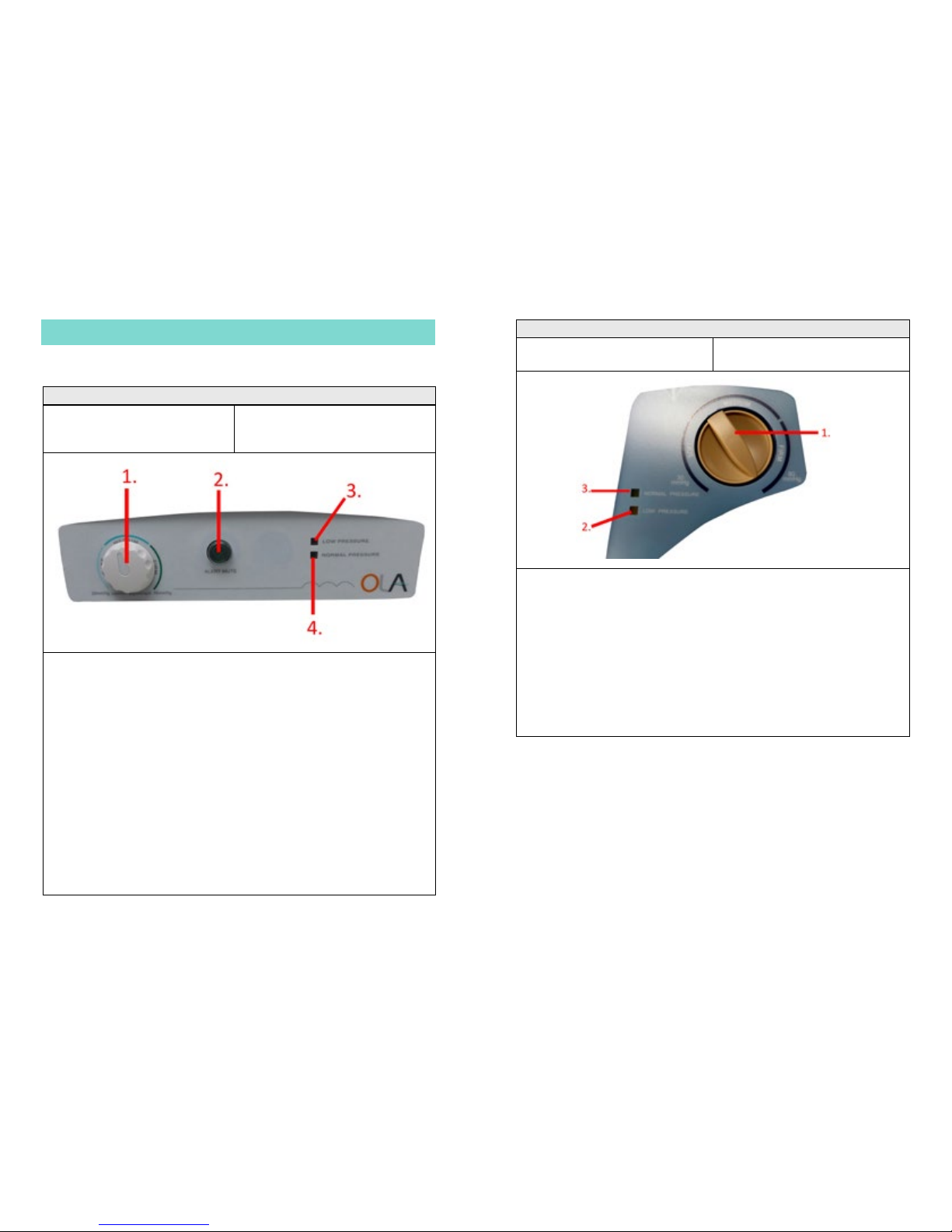

OLA 8 - Q2-02 Control Unit

1. Pressure Adjustment Dial

2. Alert Mute/Reset

3. Low Pressure Indicator

4. Normal Pressure Indicator

1. Pressure Adjustment Dial

Turn the dial to set the system for opmum performance.

2. Alert Mute/Reset

The audible/visual alarm idenes when the pressure is low. To mute the

audible alarm press the buon. The visible alarm indicator will now ash.

Re-press the buon to reset the alarm.

3. Low Pressure Indicator

A visible indicator (orange) warns that the pressure is below an acceptable

level.

4. Normal Pressure Indicator

A visible indicator (green) idenes that the pressure has reached the

preset level.

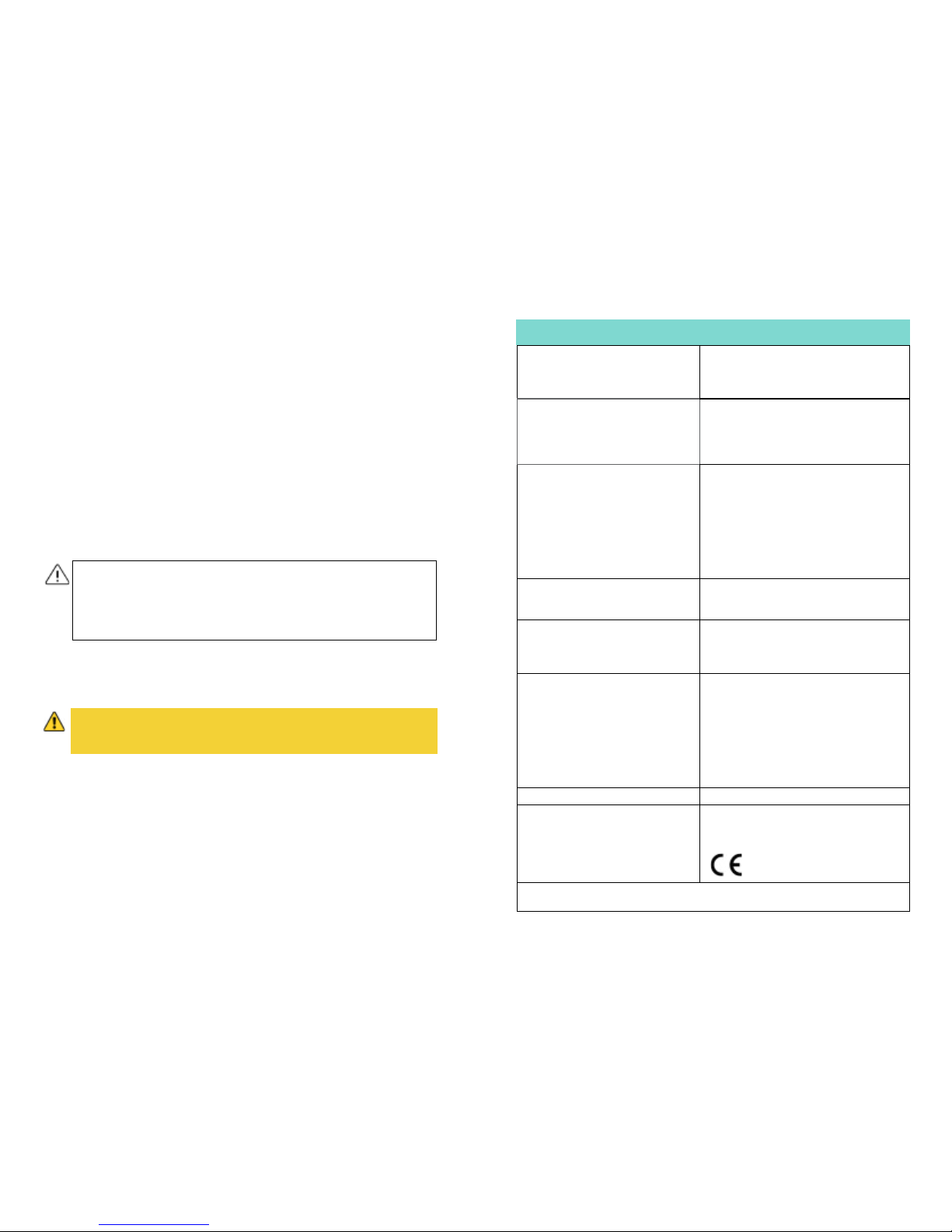

OLA 4 - D30 Control Unit

1. Pressure Adjustment Dial

2. Low Pressure Indicator

3.Normal Pressure Indicator

1. Pressure Adjustment Dial

Turn the dial to set the system for opmum performance.

2. Low Pressure Indicator

A visible indicator (orange) warns that the pressure is below an acceptable

level.

3. Normal Pressure Indicator

A visible indicator (green) idenes that the pressure has reached the

preset level.

14 15

4. Once opmum pressure is reached (about 30-40 minutes) the ‘normal

pressure’ indicator will come on and the ‘low pressure’ indicator (and audible

alarm on the OLA 8/Q2-02 ) will turn o.

NB: If the ‘low pressure’ indicator (audible alarm) will not go o, refer to

troubleshoong on page 20.

5. Adjust the ‘pressure/comfort control’ dial to provide a comfortable

pressure level for the paent. Pressure range:

• OLA 4 / D30: 30-80mmHg

• OLA 8 / Q2-02: 20-60mmHg

NB: Hand check - to check if the pressure is adequately supporng the

paent, slide one hand between the air maress and the bed frame under

the paent’s boom. You should be able to slide the hand in-between and

the opmum range is 25 - 40mm (1” to 1.5”).

6. Using clinical judgement and with connuous monitoring of the paent

for up to 72 hours, increase or decrease the pressure levels using the dial to

suit the paents comfort levels. If possible, having regular dialogue with the

paent is key.

NB: The maress can be used in an upright posion, however the pressure

seng may need to be increased. Use clinical judgement to ensure paent

comfort and eecve pressure relief is maintained.

CPR Funcon

In an emergency rapid deaon of the maress may be required. The CPR

pull cord is located at the head end of the maress.

Using Inconnence Products with the Maress

Inconnence products, such as sheets or pads, can be used with the system,

however this may compromise the eecveness of the alternang pressure

distribuon.

Transporng the Maress & Power Cuts

If the maress is disconnected from the power supply so it can be moved, or

in the event of a mains power failure, carry out the following procedure to

maintain maress inaon:

1. Disconnect the male connector from the power unit by squeezing the two

tabs (A) and pulling away from the control unit (B).

To re-inate push the CPR cord back into the closed posion. The maress

will start to inate. Wait for opmal pressure to be reached before using the

maress.

2. Seal using the cap marked “Transport” which for safety is aached to the

male connector.

NB: Complete the acon quickly to limit air

loss.

3. Switch o the control unit.

4. Disconnect from the power supply.

5. The maress can now be moved.

• Carers/care providers should always familiarise themselves with

the posion of the CPR valve.

• If inconnence products are being used it is important to carry

out a risk assessment and regular paent skin checks.

Maress

N.B: Before aempng to clean the maress the top cover should be checked

for physical signs of damage that may lead to strike-through (ingress of uid

through cover). Staining to the underside of the top cover is a sign of

strike-through.

16 17

CLEANING & DECONTAMINATION

Cleaning

Cleaning is required regularly between paents to prevent cross infecon. It is

therefore important to clean and decontaminate the control unit and

maress following these procedures.

Control Unit

1. Check for external damage – do not use if damage is found.

2. Place the pump on a work surface and using a clean cloth wipe the outside

of the case with a prepared sodium hypochlorite soluon (1000ppm).

3. The control unit should be cleaned by starng with the cleanest parts and

systemacally moving to the direst parts. Extra care should be taken around

areas where excess dirt or dust may gather.

4. Change the cloth if it becomes dirty.

5. Once clean, wipe down with a new clean cloth moistened with clean

water to remove detergent residue.

6. Dry o with a paper towel. Always allow the surfaces to dry thoroughly

before pung back into use.

• The maress will remain inated for up to 24 hours - return the

system to the mains supply as soon as possible.

• Whilst unplugged alternang mode will not be operaonal and

pressure relief will not be provided.

• Do not remove the maress from the bed frame if the occupant

is sll on the maress.

• If it is essenal that the paent is moved whilst remaining on the

maress, the maress must be re-plugged in immediately once

the desired locaon has been reached to reduce the risk of ssue

damage.

• Never drag the maress, always carry it.

• Disconnect the mains cable from the power socket before

aempng to clean the control unit.

• Do not immerse or soak the pump.

• Do not spray any cleaning soluon directly on the surface of the

control unit.

• If any of the cleaning/washing instrucons are not followed the

product warranty will be invalidated.

• Do not use phenol based cleaning soluons, solvents, neat

bleach or abrasive products to clean the casing as this may

cause damage.

• Frequent or prolonged exposure to higher concentraon

disinfectant soluons may prematurely age the fabric cover of

the maress.

• Do not use the cover if strike-through or damage is found – risk

of cross infecon. Replace with a new top cover.

• Do not use solvents or alcohol-based cleansers e.g. Phenicol,

Hibiscrub, Clearsol, Stericol or Hycoline as these will destroy the

maress materials.

• Do not autoclave.

18 19

Decontaminaon

1. Unzip the top cover from the maress.

2. The top cover/base cover can be machine washed up to 95°C and tumble

dried on a cool seng.

3. Unsnap the air cells from the maress base on both sides.

4. Carefully clean with (1000ppm) prepared soluon of sodium hypochlorite

and allow to dry completely.

5. Make sure to disconnect all the air cells and spray the cleaning soluon on

all sides, including the connecng tubes and hoses.

6. Re-assemble the maress and lay it out at.

7. Ensure the maress is completely dry before either storing or using for

another paent.

STORAGE

Environmental Condions

The following condions should be followed when storing the maress

system:

• Ambient temperature: -25°C to +70°C

• Humidity: < 93% max, non-condensing

General Cleaning:

1. Wipe down with a clean cloth moistened with a mild detergent and diluted

in warm water (40˚C).

2. Rinse with cold clean water and a clean cloth and allow to fully dry before

use.

• The maress system must be decontaminated prior to any

storage to avoid risk of cross contaminaon.

• Do not fold, crease or stack maresses.

• Do not stack control units.

• Do not store whilst inated.

Storage

1. Detach the control unit from the maress.

2. Pull the CPR cord unl it is open.

3. Ensure there is no air trapped in the cells.

4. Lay the maress out at and roll the maress from the foot end towards

the head end.

5. Store in a sealed polythene bag to protect from dirt, debris, uids etc. with

a suitable idencaon tag.

6. Store the control unit in a separate, sealed polythene bag to protect from

dirt, debris, uids etc. with a suitable idencaon tag.

20

MAINTENANCE

General Maintenance

Select Medical recommend that frequent visual and operaonal

inspecons are undertaken. Clean the air lter, found at the back of the

control unit, once a month with mild detegent. If there are any signs of

damage, or the system is not performing as it should, withdraw it from

service unl the system has been repaired and is t for use again.

Yearly Maintenance

• Check the air lter is in good condion and replace or clean as required.

• Check that all electrical funcons operate correctly on the control unit.

• Check that all audible and visual indicators work appropriately (when

plugged in and unplugged from mains supply).

• Check that the baery is sll funconal and operates in the event of a

power loss.

• Check that the maress reaches the required pressures.

• Check the CPR connecon on the maress.

• Check the cover for tears, punctures, abrasion marks and split seams.

21

TROUBLESHOOTING

Problem Acons

Power Failure 1. Turn o the control unit to silence the alarm and unplug from

the mains supply (NB: the mute buon on OLA 8, Q2-02 does not

silence the power failure indicaon).

2. Check the mains socket is working - plug in a device that is

known to work.

3. Plug the control unit back into the wall socket.

4. Turn on the control unit. If control unit sll fails to operate:

5. Turn o the control unit at the wall & replace plug fuse.

6. Turn on the control unit. If control unit sll fails to operate:

7. Replace control unit fuses – See page 23 for fuse types.

8. Turn on the control unit. If control unit sll fails to operate, turn

o at the mains and contact your approved service provider.

Incomplete

inaon/low

pressure

1. Ensure the maress air connector is properly connected to the

control unit, is not constricted in any way and has no kinks.

2. Ensure the CPR pull-cord is rmly in place and no air is leaking.

3. Turn the unit o and then on again to clear the indicator.

If the ‘low pressure’ indicator connues to illuminate:

4. Remove the top cover and ensure there is no air leakage within

the maress – cells, tubing and connectors.

5. Turn the unit o and then on again to clear the indicator.

If a low pressure indicator is sll evident turn o at the mains and

contact your approved service provider

Alternang

mode failure

1. Turn o the control unit.

2. Disconnect the male air connector to reduce cell pressure.

3. Reconnect air connector.

4. Turn on the control unit.

5. If alternang mode is sll inoperable turn o at the mains and

contact your approved service provider.

Paent is

booming out.

1. Ensure the paent is suited to the rang of the maress.

2. Ensure the paent is centrally posioned on the maress.

3. Increase the pressure seng – Refer to ‘Maress Operaon’

pg 13-14

• DO NOT open the control unit - risk of electrocuon

• If mains plug, cable or outer casing is visibly damaged turn o at

the mains and contact your approved service engineer.

• Always disconnect the control unit from the mains power supply

prior to performing any maintenance procedures (when viable).

• No modicaon of this equipment is allowed.

• The maress system should be vacated by the paent before any

maintenance or inspecon takes place. If this is not possible due

to the paent’s mobility, care should be taken for the service

engineer not to make contact with the paent when working on

electrical items.

• Only Select Medical approved components specied for OLA 8 &

4 are to be used - if in doubt contact Select Medical Ltd or your

local distributor.

• Only authorised service personnel or Select Medical service

engineers should carry out repairs or service acvies. Failure

to do so may result in the product warranty becoming void.

• The maress system should be serviced once a year, as a

minimum.

Classicaon: Electrical shock protecon: Class II, Type BF

Applied Part: Maress

Liquid ingress protecon: IP21

Not AP or APG equipment*

Supply Rang:

Fuse Rang:

Mains Plug:

230V, 50Hz, 12W

Mains Plug – 5A

Q2-02 Control Unit - T1A, 250VAC

D30 Control Unit - T1A, 250VAC (internal)

Type G/BS1363

Maress Dimensions (inated):

Maximum Paent Weight:

No. of cells:

Alternang Therapy:

Cycle Time:

Pressure Range:

OLA 8: 2000mm x 900mm x 200mm

OLA 4: 1850mm x 900mm x 102mm

OLA 8: 190kg (30 stone)

OLA 4: 114kg (18 stone)

OLA 8: 20 OLA 4: 17

AB paern

12 minutes

OLA 8 / Q2-02: 20-60mmHg

OLA 4 / D30: 30-80mmHg

Control Unit Dimensions:

Control Unit Weight:

OLA 8: (L) 206mm x (W) 280mm x (D) 104mm

OLA 4: (L) 260mm x (W) 140mm x (D) 100mm

OLA 8: 2.6kg OLA 4: 2.4kg

Cover Material:

Cell Material:

Base Material:

Polyurethane coated mul-stretch nylon

Nylon/PVC

OLA 8: Nylon/PU

OLA 4: PVC mesh

Transport and Storage Condions:

Operaonal Condions:

Atmospheric Pressure:

Operang Altude:

Polluon:

UV:

Noise level:

Ambient Temp: -25°C to +70°C

Humidity: < 93%, non-condensing

Ambient Temp: +5°C to +40°C

Humidity 15% - 93%, non-condensing

700hPa to 1060hPa

≤ 2000m

Degree 2

Intended for indoor use only

<40dB(A)

Warranty: 1 year

Safety Standards: IEC 60601-1: 2005

IEC 60601-1-2:2007

IEC 60601-1-11:2010

* Not suitable for use in the presence of ammable anaesthec mixtures with air, oxygen or

nitrous oxide.

SPECIFICATION

22 23

The control unit is tested and CE

marked in line with Medical Device

Direcve 93/42/EEC

• Check for signs of of strike-through (uid ingress) to the underside of the

cover.

• Check that all piping and cells within the maress are in good condion

and that there is no kinking evident.

• Check the control unit housing is not cracked or damaged, if damaged the

control unit must be removed from operaon immediately.

• Check that the mains cable and plug are in good condion, if either is

damaged it must be replaced with a complete assembly, the plug must

never be re-wired.

Disposing of Parts

When the electrical system has come to the end of its useful life, contact your

provider or Select Medical Ltd. (see pg 2) to arrange for collecon,

alternavely follow local recycling and W.E.E.E. (Waste Electrical and

Electronic Equipment) policies.

The metal and plasc components used in both the maress and control unit

are also to be separated and disposed of following local recycling policy as

these can also be recovered and reused/recycled.

• The control unit should not be disposed of in general municipal

waste. Some of the electrical components could be harmful

to the environment and where viable the components can be

recovered and reused/recycled.

• The maress system is to be decontaminated before disposal to

avoid risk of cross contaminaon.

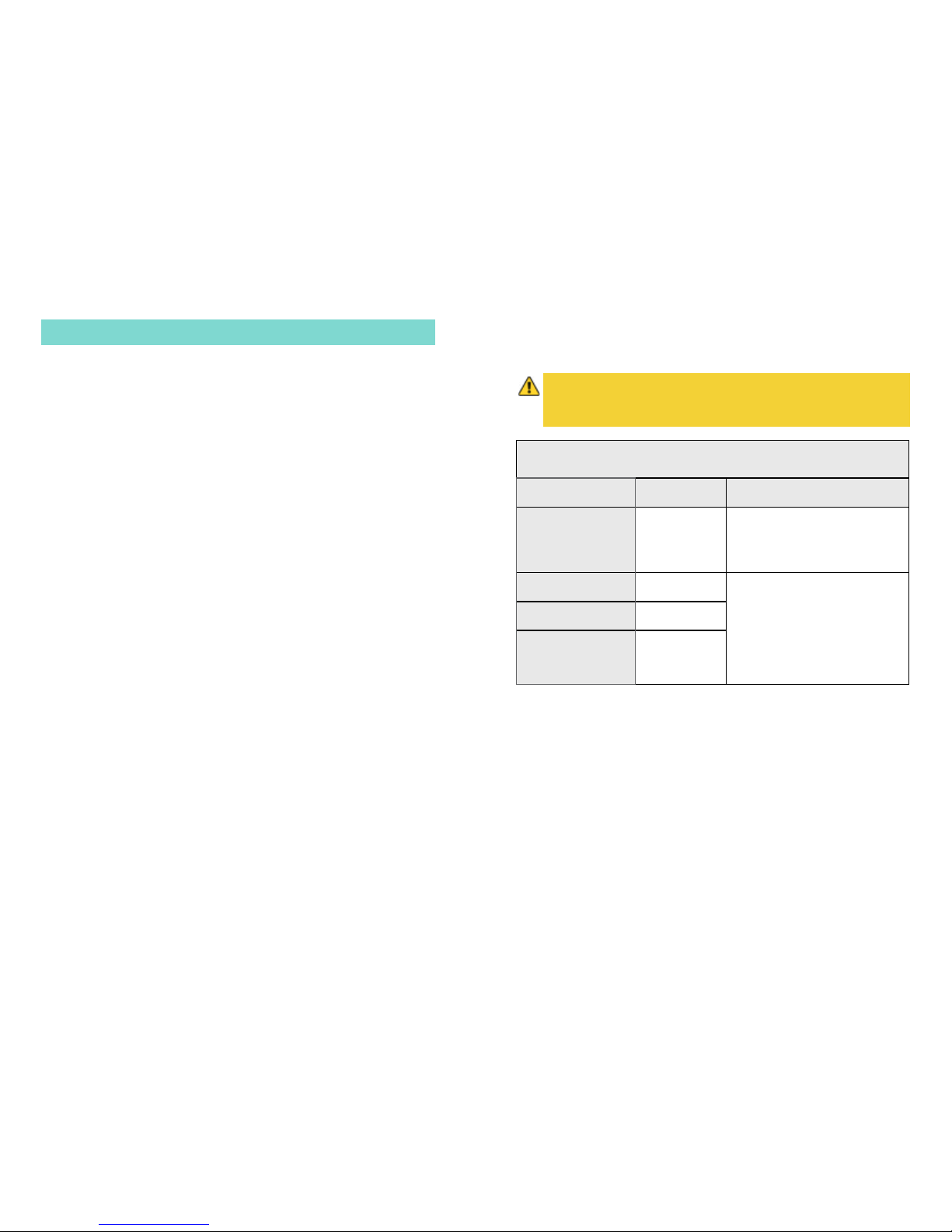

Requirements according to IEC 60601-1-2:2007

OLA 8 & 4 are intended for use in the electromagnec environment specied

below.

Guidance and manufacturer’s declaraon –

electromagnec emissions

Emission test Compliance Electromagnec

environment – guidance

RF emission

CISPR 11

Group 1 The control unit uses RF energy only for

its internal funcon. Therefore, its RF

emissions are very low and are not likely

to cause any interference in nearby

electronic equipment.

RF emission

CISPR 11

Class B OLA 8 & 4 are suitable for use in all

establishments, including domesc

establishments and those directly

connected to the public, low-voltage

power supply network that supplies

buildings used for domesc purposes.

Harmonic emissions

IEC 61000-3-2

Class A

Voltage uctuaons/

icker emissions

IEC 61000-3-3

Complies

24 25

ELECTROMAGNETIC COMPATIBILITY

• The control unit should not be used next to or stacked with

other equipment where possible. If this is unavoidable the

control unit should be observed to verify normal operaon.

The control unit has been designed to meet the EMC requirements of IEC

60601-1-2:2007. This standard denes the levels of immunity to

electromagnec interferences as well as maximum levels of electromagnec

emissions for medical devices. They are in place to provide reasonable

protecon against dangerous interference in a medical or residenal

environment.

Immunity to electromagnec interference - this refers to the levels of

electromagnec interference that the control unit can withstand from

nearby sources radiang radio frequency (RF) energy (e.g. from mobile

phones, network devices etc).

Electromagnec emissions - this refers to the levels of RF energy the control

unit emits.

The immunity levels are set out in the following manufacturers guidance. If

these levels are exceeded then the system may not operate correctly or stop

operang. It is important therefore to try to ascertain the source of the

interference by turning nearby equipment o. There are simple measures

that can be taken to correct the problem:

• Remove or relocate the interfering equipment

• Increase the separaon distance between the control unit and the

interfering equipment

The RF emissions are set out in the following manufacturers guidance. The

control unit generates very low RF energy, however interference to sensive

equipment is sll possible. If interference to radio/tv recepon and/or other

equipment is suspected, turning the control unit o and on can determine if

this is the case. There are simple measures that can be taken to correct the

problem:

• Relocate the receiving antenna

• Increase the separaon distance between the control unit and aected

equipment

Due to the increasing number of wireless devices, such as laptops and mobile

phones, it is important that the system is installed following the

manufacturer’s guidance to ensure connued and reliable operaon.

26 27

Guidance and manufacturer’s declaraon –

electromagnec immunity

Immunity test IEC 60601 test

level

Compliance

level

Electromagnec environment –

guidance

Conducted RF

IEC 61000- 4-6

Radiated RF

IEC 61000- 4-3

3 Vrms

150 kHz to 80

MHz

3 V/m

80 MHz to 2.5

GHz

3 Vrms

3 V/m

Portable and mobile RF communicaons

equipment should be used no closer to

any part of the control unit, including

cables, than the recommended separaon

distance calculated from the equaon

applicable to the frequency of the

transmier.

Recommended separaon distance

d = 1.2√P

d = 1.2√P 80 MHz to 800 MHz

d = 2.3√P 800 MHz to 2.5 GHz

Where P is the maximum output power

rang of the transmier in was (W)

according to the transmier manufacturer

and d is the recommended separaon

distance in metres (m). Field strengths

from xed RF transmiers, as determined

by an electromagnec site survey*,

should be less than the compliance level

in each frequency range**.

Interference may occur in the vicinity of

equipment marked with the following

symbol:

N.B: At 80 MHz and 800 MHz, the higher frequency range applies. These guidelines may not

apply in all situaons. Electromagnec propagaon is aected by absorpon and reecon

from structures, objects and people.

* Field strengths from xed transmiers cannot be predicted theorecally with accuracy. To

assess the electromagnec environment due to xed RF transmiers, an electromagnec

site survey should be considered. If the measured eld strength in the locaon in which the

OLA 8 or 4 is used exceeds the applicable RF compliance level above, OLA 8 or 4 should

be observed to verify normal operaon. If abnormal performance is observed, addional

measures may be necessary, such as re-orienteering or relocang the system.

** Over the frequency range 150 kHz to 80 MHz, eld strengths should be less than 3 V/m.

Guidance and manufacturer’s declaraon –

electromagnec immunity

Immunity test IEC 60601 test level Compliance level Electromagnec

environment –

guidance

Electrostac

discharge (ESD)

IEC 61000-4-2

±6 kV contact

±8 kV air

±6 kV contact

±8 kV air

Floors should be

wood, concrete or

ceramic le.

If oors are

covered with

synthec material,

the relave

humidity should be

at least 30%.

Electrical fast

transient/burst

IEC 61000-4-4

±2 kV for power

supply lines

±1 kV dierenal mode

±2 kV common mode

Mains power

quality should be

that of a typical

commercial or

hospital

environment.

Surge

IEC 61000-4-5

± 1 kV line(s) to line(s) ± 1 kV dierenal mode Mains power

quality should be

that of a typical

commercial or

hospital

environment.

Voltage

dips, short

interrupons and

voltage

variaons

on power supply

input lines

IEC 61000-4-11

<5% UT (>95% dip in UT)

for 0.5 cycle

40% UT (60% dip in UT)

for 5 cycles

70% UT (30% dip in UT)

for 25 cycles

<5% UT (>95% dip in UT)

for 5 sec

<5% UT (>95% dip in

UT) for 0.5 cycle

40% UT (60% dip in UT)

for 5 cycles

70% UT (30% dip in UT)

for 25 cycles

<5% UT (>95% dip in

UT) for 5 sec

Mains power

quality should be

that of a typical

commercial or

hospital

environment.

PPower

frequency

(50/60Hz)

magnec eld

IEC 61000-4-8

3A/m 3A/m Power frequency

magnec elds

should be at levels

characterisc of a

typical locaon in a

typical commercial

or hospital

environment.

N.B: UT is the a.c. mains voltage prior to applicaon of the test level.

WARRANTY & SERVICE

28 29

OLA 8 & 4 are intended for use in an electromagnec environment in which

radiated RF disturbances are controlled. The customer/user of OLA 8 or 4 can

help prevent electromagnec interference by maintaining a minimum

distance between portable and mobile RF communicaons equipment

(transmiers) and the OLA 8 & 4 system as recommended below, according to

the maximum output power of the communicaons equipment.

Recommended separaon distances between portable and

mobile RF communicaons equipment and the control unit

Rated maximum output

power of transmier (W)

Separaon distance according to frequency of transmier (m)

Electromagnec environment – guidance

150 KHZ TO 80 MHZ

D = 1.2√P

80 MHZ TO 800 MHZ

D = 1.2√P

800 MHZ TO 2.5

GHZ D = 2.3√P

0.01 0.12 0.12 0.23

0.1 0.38 0.38 0.73

1 1.2 1.2 2.3

10 3.8 3.8 7.3

100 12 12 23

For transmiers rated at a maximum output power not listed above, the recommended

separaon distance d in metres (m) can be esmated using the equaon applicable to the

frequency of the transmier, where P is the maximum output power rang of the transmit-

ter in was (W) according to the transmier manufacturer.

N.B: At 80 MHz and 800 MHz, the separaon distance for the higher frequency range

applies. These guidelines may not apply in all situaons. Electromagnec propagaon is

aected by absorpon and reecon from structures, objects and people.

• Select Medical Ltd guarantees this equipment under normal use for a

period of 1 year aer delivery to the original purchaser, proof of

purchase must be presented with any claim.

• For any equipment returned within the warranty period and proven to be

defecve we agree to either:

a) correct the defect by product repair

b) replace the product with one of the same or similar design or

c) refund the purchase price, without charge.

Repaired or replaced parts and products are warranted for the remainder

of the original warranty period. You will be charged for repair or

replacement of the product made aer the expiraon of the warranty

period.

• This warranty excludes equipment damage or failure through acts of god,

an incidence of excess voltage or current, shipping, tampering, improper

maintenance, carelessness, accidental damage, negligence or misuse,

or products which have been altered, repaired or dismantled other than

with the manufacturer’s wrien authorizaon and by its approved

procedures and by properly qualied technicians.

• In no event shall Select Medical be liable for any direct or indirect

damages or losses resulng from the use of the equipment.

Contact Information

www.selectmedical.co.uk

Registered in England No. 4281283 | VAT Reg No. 785 7314 91

Other manuals for OLA 8

1

This manual suits for next models

1

Table of contents

Other Select Medical Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual