4

PRE-INSTALLATION GUIDELINES

Beforebeginningthe installation ensurethatyou obtain anynecessary

buildingpermits, andthatyourinstallationwillconformwith allfederal

and municipal building code requirements.

WARNING: DO NOT PLACE ANY INSULATING MATERIALS OR

RUN ANY ELECTRICAL WIRING WITHIN THE REQUIRED AIR

CLEARANCE SPACE SURROUNDING THE CHIMNEY.

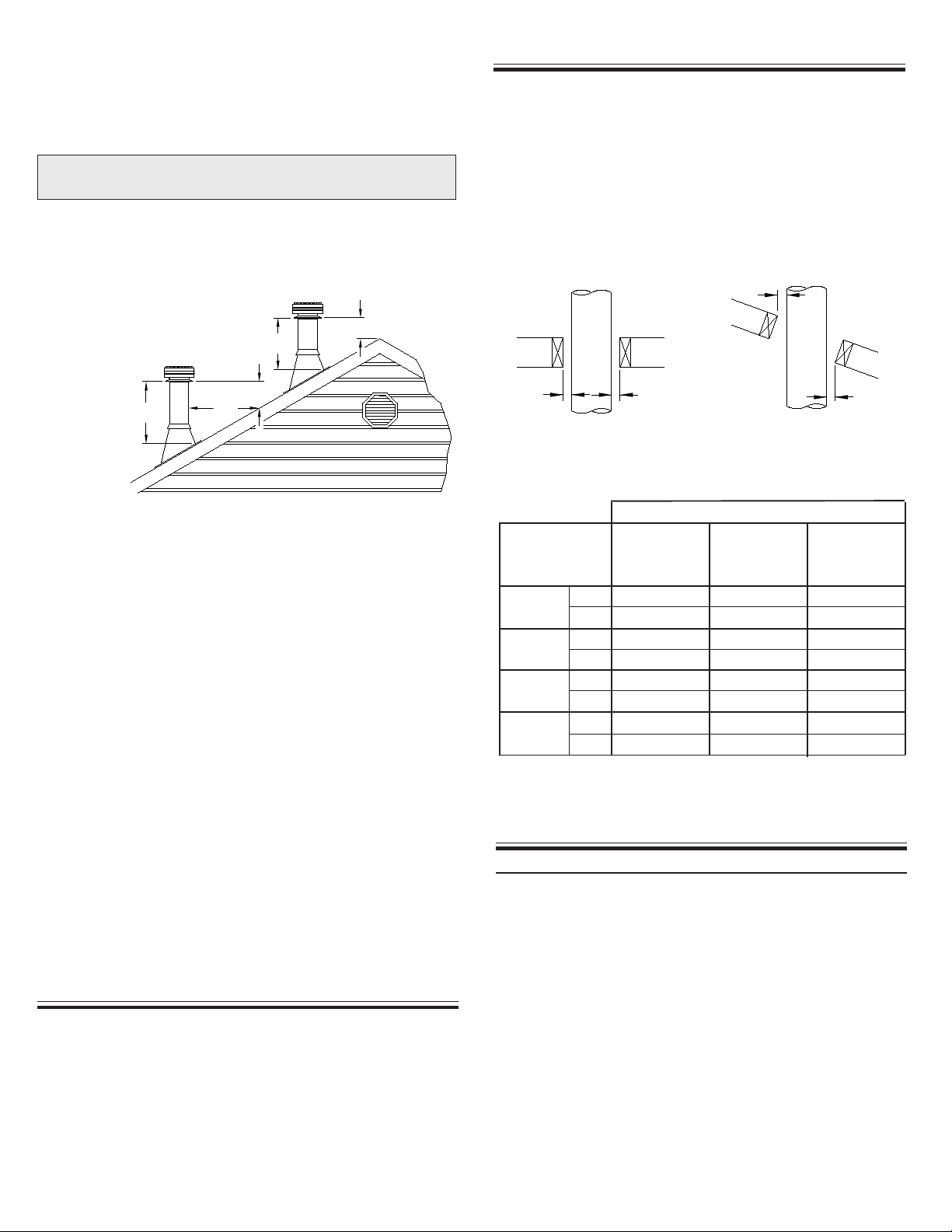

Ifthechimneymust be installedonanexterior wall itisrecommended

that the chimney be enclosed below the roof line to protect the

chimney from cold outdoor temperatures, this may help reduce

condensation, creosote formation and enhance draft. Ensure extra

space is provided for an access door by the Insulated Tee for chimney

inspection and cleaning. The exterior enclosure may be insulated,

maintainingtherequiredminimumair spaceclearanceof 2" toanypart

of the chimney. Consult local building codes for cold climate

application.

TYPE OF APPLIANCES

If you choose to have your product professionally installed, we

recommend these products be installed by professionals who are

certified in the U. S. by NFI (National Fireplace Institute).

Your SuperVent/SuperProchimneyandconnectingstovepipediameter

should be sized in accordance with the appliance manufacturer’s

recommendations.

Plantheinstallationofyour appliance and chimney insuchawaythat

both your chimney and your stove pipe run is as short and straight

aspossible. Byhavingtoo long andormultiplebendinstallations you

can reduce system draft which can affect the operation, and or

performance of your appliance and or chimney system. The chimney

shouldbelocatedwithinthebuildingsoasto avoid cutting or altering

load bearing members such as joists, rafters, studs, etc. If you require

to cut or alter an existing load bearing member, special reframing

methods are required which often include doubling of adjacent

members. If such a case arises, contact your local Building Code

Official regarding local regulations and proper installation methods.

Sections of the SuperVent/SuperPro chimney which pass through

accessible areas of the building such as through closets, storage areas,

occupied spaces or any place where the surface of the chimney could

be contacted by persons or combustible materials must be enclosed

in a chase to avoid personal contact and damage to the chimney. The

chase may be fabricated using standard building materials. Drywall

CANADA APPLICATIONS

In Canada, Model SuperVent/SuperPro is intended for connection to

liquidfuelor gasfiredresidentialtype appliancesandbuildingheating

appliances, in which the maximum continuous flue gas temperatures

donotexceed540ºC(1000°F)asperULC-S604. It hasbeentestedand

approvedtowithstandtemperaturesofupto925°Cforthree30minutes

intervals.

May also be used with specific factory-built fireplaces listed to

UL 127 and CAN/ULC-S610 when specified in the fireplace

manufacturer's installation instructions.

Thefluediameter ofgasor oilappliancesshould complywithNational

and Provincial Building Code of Canada and appropriate Installation

Codes;CAN/CSA-B149forgasandCAN/CSA-B139 foroil.

mounted on 2” x 4” studs is typically used in this situation. The space

betweentheouter wallofthe chimneyandtheenclosure mustbea least

aminimumof2inches.

MAINTAIN A 2" MINIMUM AIR SPACE CLEARANCE

BETWEEN INSULATED CHIMNEY SECTIONS AND COMBUSTIBLE

MATERIALS OR AS ESTABLISHED BY SUPPORT ASSEMBLY.

CONTACT LOCAL BUILDING OR FIRE OFFICIALS

ABOUT RESTRICTIONS AND INSTALLATION

INSPECTION IN YOUR AREA.

U.S.A. APPLICATIONS

IntheU.S.A.,Model SuperVent/SuperPro has beentestedperUL103

as a "Type HT" chimney by Underwriters Laboratories, Inc. As such

it is code approved for connection to solid, liquid or gas fueled

appliances in which the maximum continuous flue gas temperatures

do not exceed 1000°F. It has been tested and approved to withstand

temperatures of up to 2100°F for three ten minutes intervals.

Factory built chimneys are intended for installation in accordance

with NFPA 211 (Standard for Chimneys, Fireplaces, Vents and Solid

Fuel Fired Appliances), and/or local and regional codes such as the

International Mechanical Code and Uniform Mechanical Code, etc.

The flue diameter of gas or oil fired appliances should comply

with the appropriate NFPA or ANSI Installation Codes; NFPA 54,

ANSIZ223.1,andNFPA 31.

This chimney system is suitable for venting gas, oil or solid fuel fired

appliances including wood stoves, furnaces, boilers and fireplaces.

TheNationalFireProtectionAssociation Standard211states:Factory-

built chimneys that pass through floors of buildings requiring the

protection of vertical opening shall be enclosed with approved walls

having a fire resistance rating of not less than 1 hour where such

chimneys are located in a building less than four stories in height, and

not less than 2 hours where such chimneys are located in a building

four or more stories in height.

YOUR CHIMNEY HAS BEEN TESTED, AND LISTED USING ALL

OF THE SUPPORTS, SHIELDS, ETC., DESCRIBED HEREIN.

DELETION OR MODIFICATION OR ANY OF THE REQUIRED

PARTS OR MATERIALS MAY SERIOUSLY IMPAIR THE SAFETY

OF YOUR INSTALLATION,AND VOID THE CERTIFICATION AND

OR WARRANTY OF THIS CHIMNEY

AnAtticInsulation Shieldmustbeinstalled where thechimneypasses

into an attic space. It is designed to keep insulation materials or debris

from coming into contact with the chimney. It must accomodate the

amount of insulation as required by the National Building Code.

Whereheightrestrictions willnotpermitthe useoftheAttic Insulation

Shield, it is permissible to construct an enclosure with a 2” air space

clearancetothe outer pipealltheway totheundersideof theroofdeck.

In this application you need to install a Firestop Radiation Shield on

the ceiling side and a Rafter Radiation Shield at the roof level.

At the level where the chimney penetrates the air/vapour barrier,

special attention is required. Seal the vapour barrier to the Firestop

Spacer or Ceiling Support assembly or Wall Thimble using an appro-

priate caulking compound as per the requirement of local authorities.

Theideallocation foryourchimney iswithinthebuildingenvelope. In

cold climates, the use of external chimneys may result in operational

problems such as poor draft, excessive condensation of combustion

products and rapid accumulation of creosote. Under these circum-

stances, the installation of the chimney within the building is strongly

recommended.