Selkirk DIRECT-TEMP 4DT-CCK User manual

GENERAL

Two different types of direct vent conversion systems

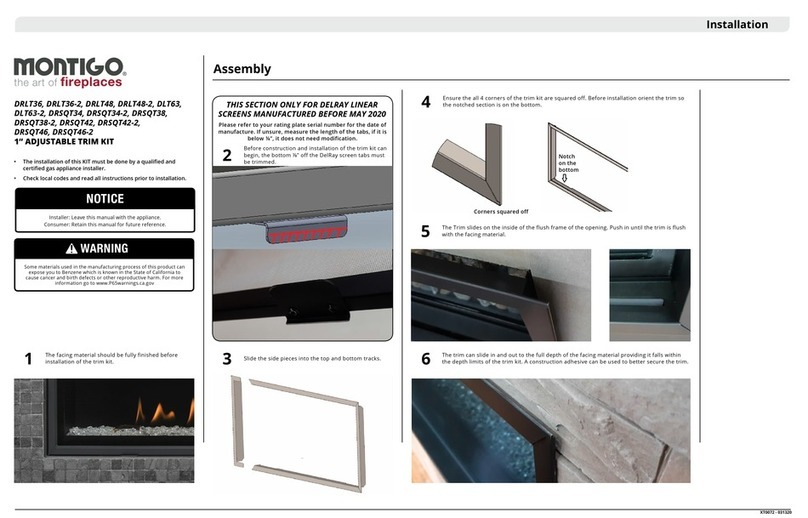

are described here. One is through an existing factory

built metal chimney going through the ceiling. The other

isthroughthewallofanexistingmasonrychimney.Follow

the appropriate directions for your situation.

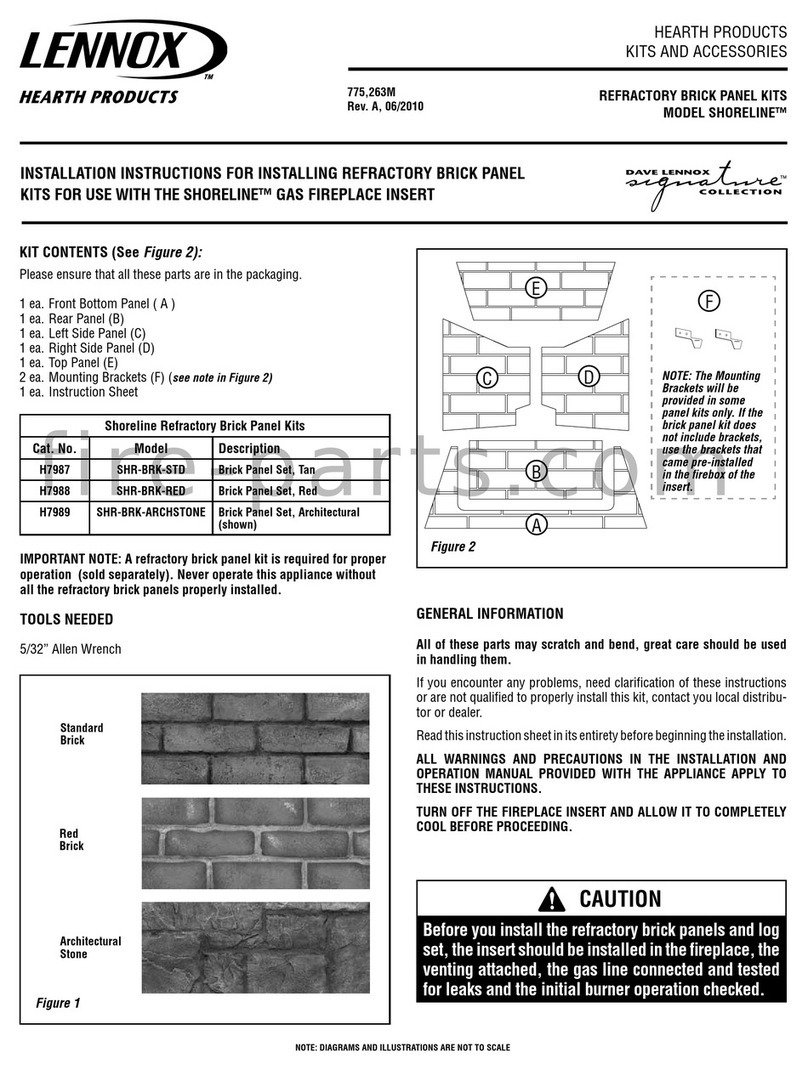

A typical direct vent conversion to a factory built metal

chimney is shown in Figure 1. The concept of direct vent

conversion is to connect an adapter to an Underwriters

Laboratories listed 4” aluminum flex pipe for direct vent

gas appliances. (Selkirk ModelAFCLis an example of a

UL listed flex pipe or 4” stainless steel flex pipe for

Direct-Temp for Pellet Stoves applications. Selkirk

Model SFCL is an example of a UL listed stainless steel

flexpipe).The flex isthenpassed down throughthecenter

ofthe existingmetal chimneysystem.

TheChimneyInletConnectoristhenattachedtothebottom

of the flex pipe. Both the Outlet Connector and Inlet

Connectorare attached tothe existingchimney with sheet

metal screws. The appliance is then connected to the

chimney with appropriate black direct vent pipe, and an

adjustable length section.

A typical conversion to an existing masonry chimney is

shown in Figure 6. For installation through the wall of an

existing masonry chimney, a Chimney Outlet Connector

and Flashing are used at the top of the masonry chimney.

The flex pipe liner is connected to the adapter and is

passed down the chimney and out through the masonry

wall. This is attached to the Chimney Inlet Connector

which in turn is attached to the masonry wall and is then

connectedto thedirect ventpipe leadingto the appliance.

MODEL DT DIRECT VENT INSTALLATION

INSTRUCTION SUPPLEMENT

ADAPTING MODEL DT TO FACTORY BUILT AND MASONRY CHIMNEYS

CONVERSION TO A FACTORY BUILT

METAL CHIMNEY

1. Remove the existing chimney cap.

2. Measure the distance from the top end of the chimney

to the bottom of the ceiling support, add 3-inches to this

measurement, and cut a section of flex pipe to that length

(theflex shouldalready be extended to itsnormal length).

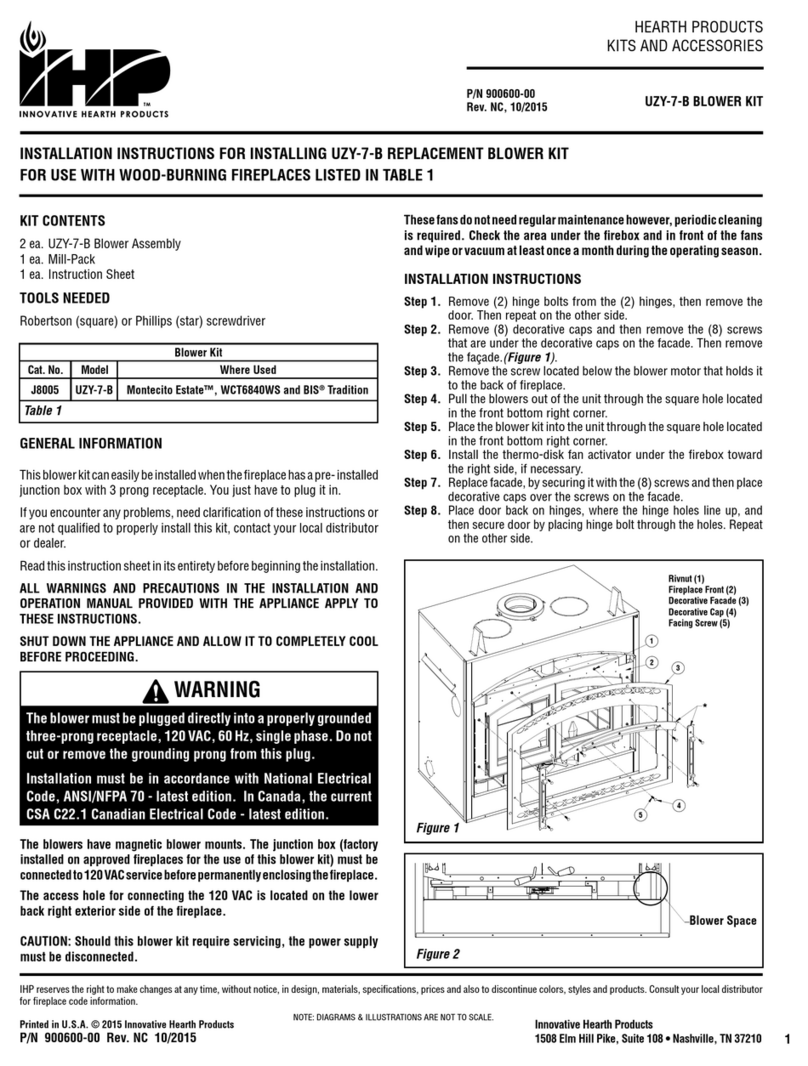

3.Connectthe endofthe flex pipesectionto theunderside

oftheChimneyOutlet Connectoryouhaveselected, using

three sheet metal screws. Refer to Figure 2.

4. Pass the flex pipe down through the center of the

chimney system, and center the Outlet Connector on the

topofthe chimney pipe.Drillfour1/8-inch diameterholes

through the adapter, and into the chimney top. Insure

thatyou arein fact,drilling into themetal onthe chimney.

Install the Termination Cap onto the Outlet Connector.

Refer to Figures 3 and 4.

5. Pull the flex pipe down through the ceiling support

box, until it protrudes approximately 3-inches. Connect

the flex pipe to the Chimney Inlet Connector by slipping

it into the sleeve on the top side of the Connector. Use

three sheet metal screws, to assemble these two parts.

6. Push the flex pipe back up into the ceiling support,

center the Chimney Inlet Connector, and attach it to the

support box, or decorative sleeve for double wall solid

packed pipe, with the sheet metal screws furnished. The

holes in the connector are pre-punched. Refer to Figure

5.

7.The connectionbetweentheappliance andtheChimney

InletConnector may becompleted withsections of black

direct vent pipe, together with an adjustable length.

4DT-MCK (Masonry Chimney Conversion Kit)

4DT-CCK (Factory-Built Chimney Conversion Kit)

DIRECT-TEMP®

WARNING

!

Failure to follow the instructions could cause

FIRE, CARBON MONOXIDE POISONING, OR DEATH. If

you are unsure of installation requirements, call the Phone

Numberlistedontheinstructionsorvisitwww.selkirkcorp.com

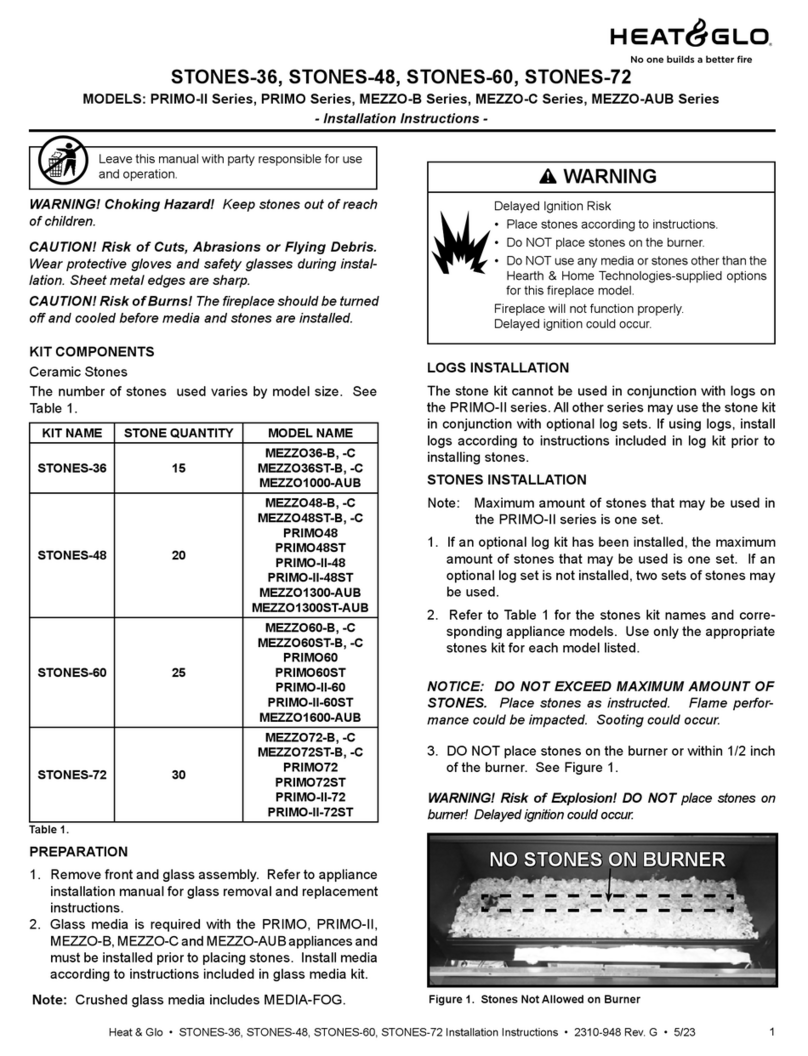

Termination Cap

ChimneyOutlet

Connector

Existing Metal

ChimneySystem

FlexPipe

ChimneyInlet

Connector

(Adapts to

Support) Any DT Black

Direct Vent Pipe

Fig 1

Fig 2

Fig 3

Fig 4

Chimney Outlet Con-

nector

Sheet metal

Screws Here

Chimney

Outlet Connec-

tor

Termination Cap

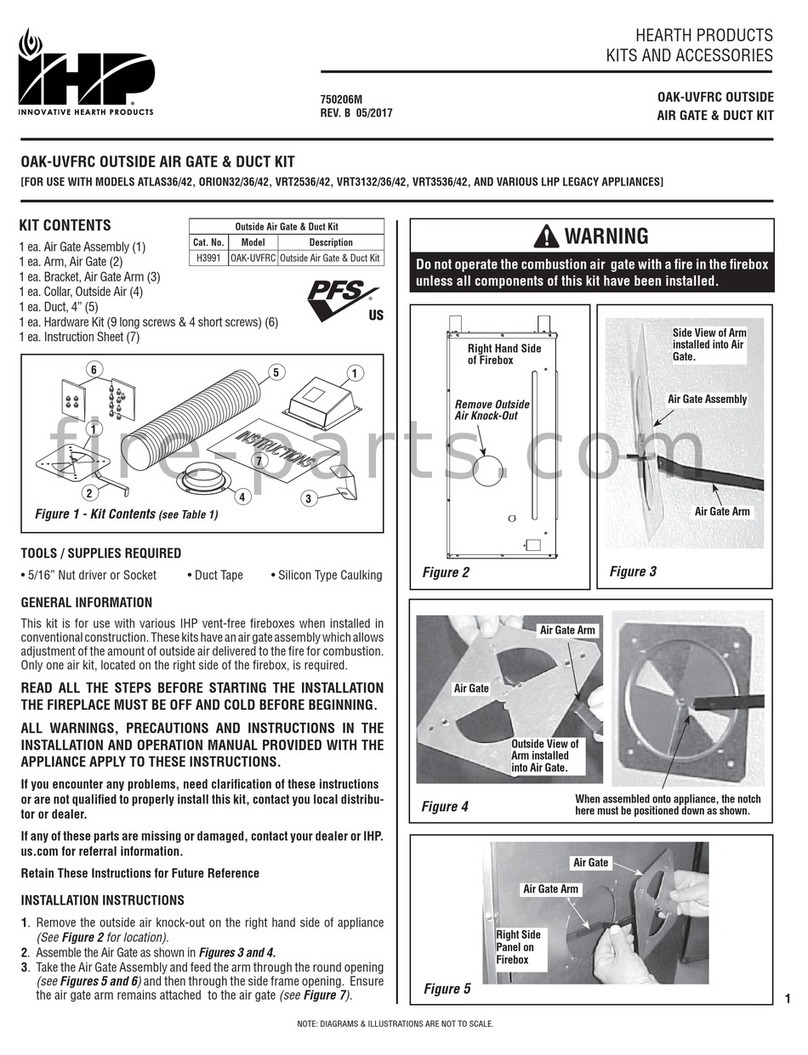

CONVERSION TO A MASONRY

CHIMNEY

IMPORTANT: The existing masonry flue opening needs

to have an area of at least 35-square inches to insure

proper intake/exhaust flow.

1.Before cuttingany holes,assemble thedesired sections

of black direct vent pipe to determine the center of the

masonry penetration.

2. Once the center point of penetration has been

determined, cut a 6-inch diameter hole in the masonry.

Be careful, if the hole is too large, the Chimney Inlet

Connector might not mount properly, and if the hole is

too small, then the appliance might starve for intake air.

If there is a frame wall in front of the masonry wall, cut

and frame a 10" clear square opening in wall (centered

around the 6" masonry opening). If there is sheet rock

only (no studs) in front of the masonry, the 10" clear

opening is still needed, but does not need to be framed.

This allows the Chimney Inlet Connector to mount

directly on the masonry and provide clearance to the

combustibles. Refer to Figure 11.

3. Secure the Flashing to the top of the masonry chimney

using a bead of non-hardening mastic sealer. If the

Flashing is larger than the top of the chimney, then cut

and fold flashing as needed to fit chimney.

See Figure 7.

4.Todetermine thelength of flex required, measure from

3" above the top of the Flashing down to the level of the

opening.Add to this measurement the distance from the

centerof the chimney to outthrough the wall. Cut apiece

of 4-inch flex to this length (the flex should already be

extended to its nominal length).

5. Connect the 4-inch flex liner to the Chimney Outlet

Connectorusing three sheetmetal screws.Referto Figure

2.

6. Feed the 4-inch flex liner through the Flashing into the

chimney. Continue to feed the liner out through the

opening in the masonry wall.

7. Secure the Chimney Outlet Connector to the Flashing.

Use three sheet metal screws through the side of the

adapterintothe flangeonthe Flashing, asshownin Figure

8.

8. Install the Termination Cap on to the Chimney Outlet

Connector.

8. Attach the flex to the Chimney Inlet Connector. Use

three sheet metal screws to attach the flex liner to the

Connector. Sec Figure 9.

9. Slide Chimney Inlet Connector against the masonry

wall and secure with masonry bolts. Re-drill larger holes

on connector as needed. Be careful to insure that the

connector is centered in the opening and the mounting

holesline up with the masonry wall. Ifyou havea framed

wall in front of the masonry, use wood screws to mount

the Connector to the framed wall, shown in Figure 11. If

needed,add a section of directvent pipeto the Connector

in order to extend through the opening.

10. The connection between the appliance and the

Chimney Inlet Connector may be completed with the

section of black direct vent pipe, together with an

adjustable length pipe section.

Fig 6

ChimneyInlet

Connector

FlexLiner

Black Direct

Vent Pipe

TerminationTop Chimney Outlet

Connector

Flashing

Fig 7

Fig 8

Fig 9

Fig 10

5030 Corporate Exchange Blvd., SE, Grand Rapids, MI 49512 1-800-992 VENT (8368)

Cut and Bend Flashing

as Appropriate to Fit

Chimney Termination Cap

ChimneyOutlet

Connector

3 Sheet Metal

Screws Here

Flashing

ChimneyInlet

Connector

6” Diameter Hole

inMasonry Wall

ChimneyInlet

Connector

Fig 11

MasonryChimney

Studwall

10” x 10” Framed

OpeninginWall

ChimneyInlet

Connector

Mastic Sealant

Here

0015206 - 0712

This manual suits for next models

1

Other Selkirk Fireplace Accessories manuals

Popular Fireplace Accessories manuals by other brands

RealFlame

RealFlame 310 Instructions and warnings for use

Heat & Glo

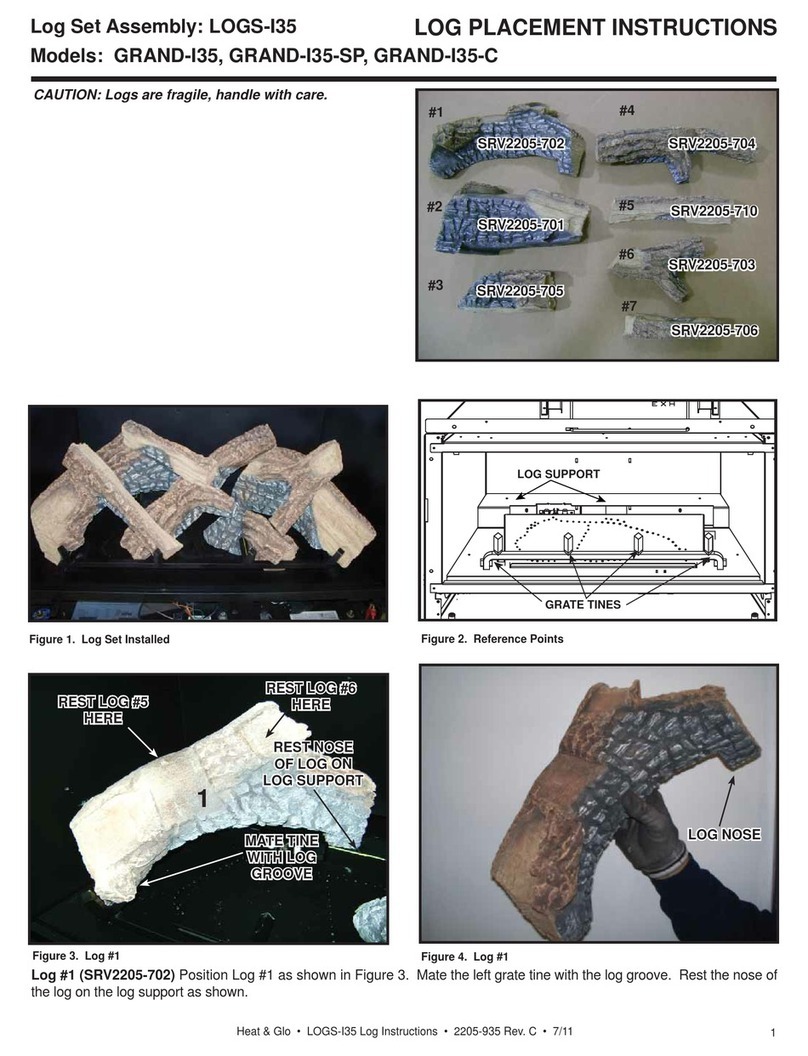

Heat & Glo LOGS-I35 Log Placement Instructions

Travis Industries

Travis Industries 98500677 quick start guide

European Home

European Home 95 installation guide

Valor

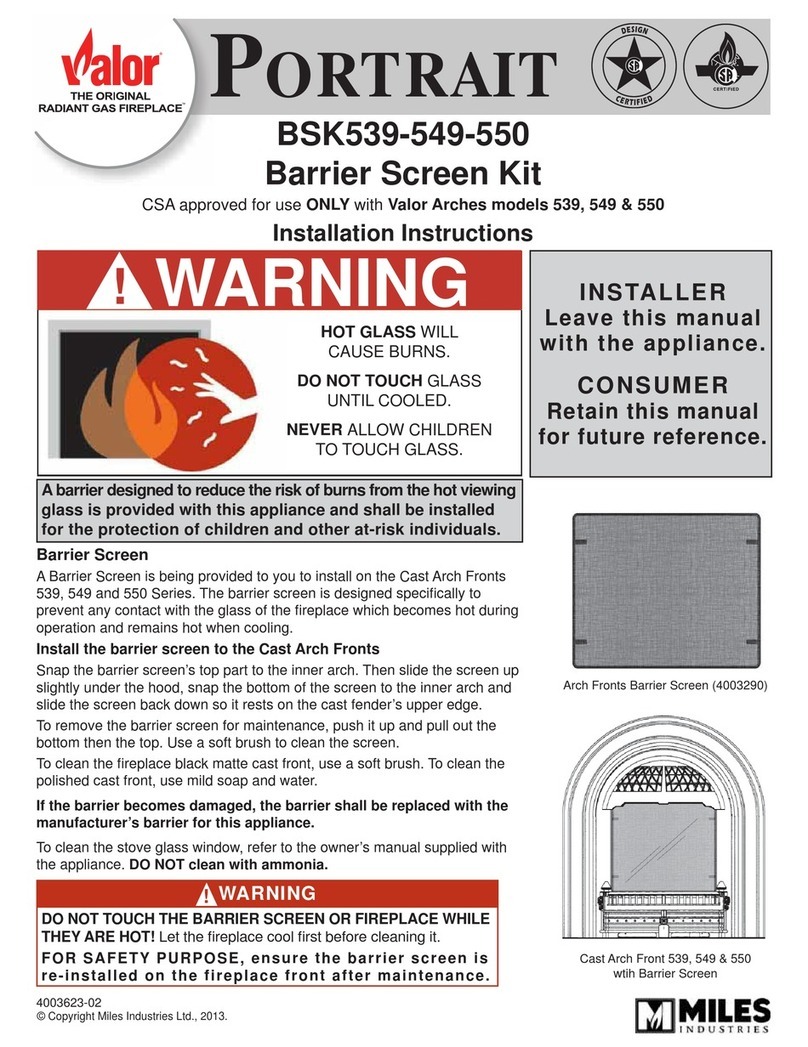

Valor PORTRAIT BSK539-549-550 manual

Napoleon

Napoleon W175-0344 instructions