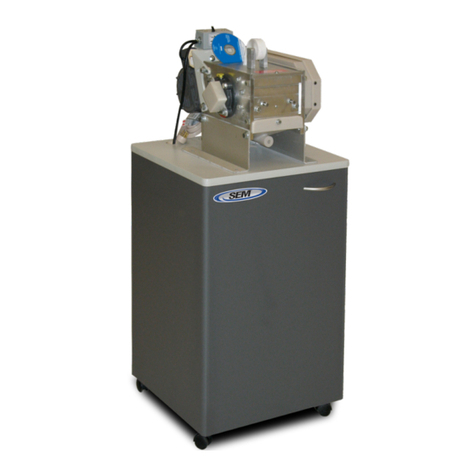

SEM 4140CLK Assembly instructions

.-~~. -

Pleaseread this manual carefull~ It will answer all your questions

regarding installation, operation and trouble-shooting.

IMPORTANT:

Be sure to adhere to all safety suggestions listed.

Read carefully before using.

THE WORLD LEADER IN DOCUMENT AND SENSITIVE WASTE DESTRUCTION

SOLUTIONS

WaJ _.W;. SHREDDERS. DISINTEGRATORS.SECURITYWASTE

~Z:1~21 CONTAINERS.DEGAUSSERS

5 Walkup Drive . Westboro,MA01581

http://www.monomachines.com

http://www.monomachines.com

READ CAREFULLY BEFORE USING

These Paper Shredders are designed for the in-office destruction of paper documents to

an unidentified waste. Be sure to remove staples and paper clips from the materials

to be destroyed. Proper care and use of your shredder will insure many years of trouble

free operation.

Content. . . . . . . . . . .. . . .. . . . . . . . . . . . .. . . .. . . . . .PageNo.

InstallationandSet-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Operation 3

Overloading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

DoorOpening/BagFulllndicator 4

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

TechnicalData. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

UsingandOrderingSpareParts 5

OptionalItemsAvailable. . . . . . . . . . . . . . . .".. . . . . . . . . . . . . . . . . . . . . . . . .5

CustomerService. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Operation 7

HousingDiagramand PartsBreakdown. . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

CuttingHeadDiagramsandPartsBreakdown. . . . . . . . . . . . . . . . . . . . . .10-13

DriveDiagramandPartsBreakdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-17

ElectricDiagramandPartsBreakdown. . . . . . . . . . . . . . . . . . . . . . . . . . .18-21

http://www.monomachines.com

http://www.monomachines.com

Yournewpapershredderincorporatespowerful.heavydutycuttingmechanisms.

Serious and permanentinjury may result if properprecautionsarenotfollowed.

1. This equipment should never be operated by children or individuals

untrained in or incapable of understanding the safety precautions!

2. Do not reach into the feed o~ning for any reason! Never insert fingers,

hands, other extrematies or objects not meant to be shredded into the

feed openings!

3. Do not operate or come in close proximity to this equipment wearing long

hair, necktie, loose clothing or Jewelry, wnich may activate a photoelectric

on/off switch and/or be puned Into the machine!

4 Maintenance or repair of this equipment should be perfonned only by

trained, authorized service personnel.

5. Always disconnect electric power (unplug) before removi"9 or opening

the cover or other panel giving access to internal mechanisms.

http://www.monomachines.com

http://www.monomachines.com

Openthe cabinetdoorby lightlypullingonthe upperrightcomerofthedoor. Pullthewasteboxfor-

wardandoutof thecabinet. Insertthe plasticwastebaginthe wasteboxfoldingthe excessover.

Pushthe boxinandclosethedoor. PlugShredderinto20ampwalloutlet.

These models canbeoperatedbyturning the switch in the back of the shredder on and by using the

'forward', 'stop', and 'reverse' touch type push buttons. Use these buttonswhen cleaning the cutter

system or to clear a jam.

IMPORTANT: Materialsother than common office paper mayjam and/or damage the cutting unit.

Paper clips and staples should be removed from material being destroyed, to prolong life and trouble-

free operation of the cutting unit.

Iftoo much paper isfed into the machine, it will switch off automatically. Following a brief pause, the

machine will reverse automatically and the excess paper can be easily removed. Thin out the quanti-

ty of paper before resuming shredding. If the cutting mechanism is frozen, do not attempt to run the

shredder alternately in the forward and reverse modes until the clogged material is released. Call for

service.

The motor is protected by a thermal overload device. Should the motor overheat, the thermal over-

load unit will automatically stop the motor. Should this occur, wait a brief period of time and let the

motor cool off.

For safety reasons, the shredder will not operate when the cabinet door is open.A red indicator light

on the control panelwill alert the user if the door is ajar.

Whenthewastebagisfull,the shredder will shut offautomatically.A redindicatorlightonthe control

3

http://www.monomachines.com

http://www.monomachines.com

panel will alert the user that it is time to change the waste bag.

LUBRICATION

IMPORTANT:To preventjamming and/or clogging the shredder, it is necessary to frequently lubricatethe

cutting unit and run it in reverse. For continuous shredding, the unit should be lubricated every 15 minutes.

Alternatelyrun the machine forward and then in reverse several times to clean the cutting unit. Squirt the

SEM shred oil directly onto a piece of paper in a figure 8 motion, then feed into machine. Then run it in

reverse. This avoids getting oil into the optics. Too much oil is better than not enough. Youare again ready

to start shredding.

Two to three preventative maintenance calls per year are recommended. Only authorized service person-

nel should be allowed to service the shredder.

IMPORTANT:Always unplug the shredder before performingany maintenance. If shredding capacity drops

or the machinejams easily, clean and lubricate the cutting system as outlined in the "Lubrication" section of

this manual.

Shred Capacity:

Shred Size:

Throat Width:

Speed:

Horsepower:

Dimensions

(H x W x D):

Weight:

Power:

4140CLK

up to 11Sheets

1/32" x 1/2"

16"

20 FPM

1-1/4HP

41"x22-5/8"x20-3/8"

195 Ibs.

115/1/60

5140CLK

up to 14Sheets

1/32" x 7/16"

16"

30 FPM

2.2 HP

41"x23-3/4"x21-1/2"

209Ibs.

115/1/60

5140P

up to 35 Sheets

5/16" x 1-7/8"

16"

40 FPM

2.2 HP

41"x23"x20"

285 Ibs.

115/1/60

4

http://www.monomachines.com

http://www.monomachines.com

. use

• Only

Only use original

original SEM

SEM spare

spare part

part replacements

replacements

.

• We

We guarantee

guarantee their

their quality

quality and

and functional

functional reliability

reliability

Warranty

Warranty claims

claims on

on parts

parts and/or

and/or service

service must

must be

be approved

approved by

by SEM's

Customer

Customer Service

Service Manager

Manager SEMis

HINTS

HINTS

FOR

FOR

ORDERING

ORDERING

SPARE

SPARE

PARTS

PARTS

list shhowsThe

The spare

spare parts

parts shown

shown on

on the

the following

following pages

pages have

have part

part numbers.

numbers. This

This spare

spare parts

parts list shhows

the

the following

following information

information with

with respect

respect to

to the

the spare

spare parts

parts to

to be

be ordered.

ordered.

.PartNo. .Dimensions .

• Part No. • Dimensions • Quantity

Quantity

. . ItemNo.

• Designation

Designation • Item No.

In

In

order

order to

to aviod

aviod errorss

errorss and

and the

the delivery

delivery of

of

wrong

wrong parts,

parts, each

each parts

parts order

order should

should contain

contain the

the

following

following information.

information.

.

• Machine

Machine Type

Type and

and Serial

Serial No.

No.

(See

(See nameplate)

nameplate)

.

• Part

Part No.

No. and

and designation

designation of

of

desired

desired spare

spare parts

parts

.

• Quantity

Quantity of

of

desired

desired spare

spare parts

parts

.

• Desired

Desired mode

mode of

of

shipment

shipment (e.g.

(e.g. post,

post, freight,

freight, express)

express)

.

• Full

Full billing

billing &

& shipping

shipping addresses,

addresses, including

including contact

contact person

person &

& telephone

telephone

OPTIONAL

OPTIONAL

ITEMS

ITEMS

AVAILABLE

AVAILABLE

Replacement

Replacement Plastic

Plastic Waste

Waste Bags

Bags Part

Part No.

No. 639SB140

639SB140

Shredder

Shredder Lubricating

Lubricating Oil,

Oil, Case

Case of

of

8

8 pints,

pints, Part

Part No.

No. 64901L8

64901L8

Shredder

Shredder Lubricating

Lubricating Oil,

Oil, Case

Case of

of

16

16 pints,

pints, Part

Part No.

No. 64901L

64901L16

16

Shredder

Shredder Lubrication

Lubrication Oil,

Oil, Case

Case of

of

8

8 400z

400z bottles

bottles Part

Part No.

No. 6490ILCLK

6490ILCLK (Used

(Used w/CLK

w/CLK Models)

Models)

5

5

http://www.monomachines.com

http://www.monomachines.com

Toorder spare parts or optional items you may contact the Authorized Service Rep. for your area, or SEM's

Customer Service Dept. directly at the following address:

Security Engineered Machinery

P. O. Box 1045

Westboro, MA 01581

Tel: 800-225-9293

Fax: 508-366-6814

Website: Commerical www.semshred.com

Govern ment www.fedshred.com

8

http://www.monomachines.com

http://www.monomachines.com

Please

Please Read

Read and

and Observe

Observe the

the Operating

Operating and

and Safety

Safety Instructions

Instructions

is designedThe

The machine

machine is designed for

for shredding

shredding smooth

smooth sheets

sheets of

of

papers.

papers. Automatic

Automatic operation

operation with

with manual

manual

feeding

feeding of

of

paper.

paper.

I

For

Forcarrying

carrying the

the machine,

machine, use

use handle

handle rod

rod (12).

(12).

The

The handle

handle rod

rod is

is located

located at

atthe

the left

left of

of

the

the substructure.

substructure. This

This plug-in

plug-in unit

unit is

is ready

ready for

for operation,

operation,

on - -Details

Details on the

the nameplate

nameplate (9)

(9) -Voltage

Voltage "V',

"V', Frequency

Frequency "Hz",

"Hz", Current

Current consumption

consumption "A"

"A" -must

must be

be in

in

accordance

accordance with

with the

the mains

mains supply.

supply. Connect

Connect the

the machine

machine to

to power.

power.

If

If

the

the green

green LED

LED (3)

(3) illuminates

illuminates the

the machine

machine is

is ready

ready for

for operation.

operation.

Feed

Feed paper

paper into

into the

the middle

middle of

of

the

the paper

paper insert

insert (1).

(1).

After

After shredding

shredding the

the machine

machine switches

switches off.

off.

When

When paper

paperjams

jams

in

in

the

the paper

paperfeeder

feeder (1):

(1):

-

-Remove

Remove paper

paper

-

-Feed

Feed small

small amount

amount of

of

paper.

paper.

-Indicator

Indicator

(6)

(6) illuminates

illuminates -waste

waste receptacle

receptacle (13)

(13) is

is

full.

full.

-

-Open

Open door

door

- - Pullout

-Press

Press down

down cut

cut waste

waste into

into the

the receptacle.

receptacle. -Pull out receptacle

receptacle and

and empty.

empty.

-Door

Door switch

switch indicator

indicator (7)

(7) illuminates

illuminates -door

door is

is open

open

-

-Close

Close the

the door

door

NOTE:

NOTE:

-is only

-Machine

Machine is only ready

ready for

for operation

operation when

when the

the door

door is

is closed.

closed.

-

-Regularly

Regularly check

check the

the function

function of

of

the

the door

door switch.

switch.

If

If

the

the door

door

is

is

opened,

opened, the

the machine

machine will

will

immediately

immediately shut

shut

down.

down.

Problem:

Problem: Start

Start switch

switch (4)

(4) doesn't

doesn't function

function and

and green

green LED

LED (3)

(3) does

does

not

not illuminate.

illuminate.

Remedy:

Remedy: Wait

Wait approx.

approx. 15

15 to

to 20

20 minutes

minutes for

for motor

motor thermal

thermal overload

overload

to

to reset.

reset.

Problem:

Problem: Machine

Machine does

does not

not automatically

automatically switch

switch off.

off.

Remedy:

Remedy: Clean

Clean LED

LED (1)

(1) with

with a

a brush.

brush.

7

7

http://www.monomachines.com

http://www.monomachines.com

DIAGRAMS

DIAGRAMS

&

&

PART

PART

NUMBERS

NUMBERS

http://www.monomachines.com

http://www.monomachines.com

http://www.monomachines.com

http://www.monomachines.com

Item Part No. Designation Remark Qty.

1

2 SE31532004-17

SE044260016 cabinet

caster incl./door 1

4

3 SE042084361 nut M5 8

4 SE041654305 screw M5x30 1

5 SE04189 0039 wood screw M4x20 1

6 SE042302216 washer 1

7 SE042151010 rubber mount 1

8 SE041890030 wood screw M3.5x15 12

9

10 SE044453224

SE31532003 hinge

door 3

1

11 SE044390020 door handle 1

12 SE41462015 door angle before serial #153.004999 1

13 SE41536001 collection bin 1

14 639S8140 waste bag 1DO/box 1

15 SE41532001 cabinet support 2

16 SE041890033 wood screw M4x14 12

17 SE41410001 lifting tube d=25x1x774 1

18 SE047580013 hole plug 2

19 SE044460012 cover support 1

20 SE041890021 wood screw M3x25 2

21 SE041890034 wood screw M4x15 2

25 SE147520733 on/off switch 1

26

27

28

SE41534011

SE41374019

SE042302209

plate

pushbutton mounting plate

washer

1

1

4

29 SE041863608 screw M2.9x13 4

30

31

32

SE41381029

SE31412004

SE04890003

top cover hinge

top cover hinge mount

screw

right

right

M4x16

1

1

4

33 SE041340310 screw M4x8 2

34

35 SE31412006

SE041340310 angle

screw M4x8 1

3

36

37 SE41374012

SE31534005 pushbutton backing plate

pushbutton PC-board 1

1

38 SE31534008 pushbutton cover 1

39 SE41381030 top cover hinge left 1

41 SE31412005 top cover hinge mount left 1

42

43 SE42507039

SE31532003 spacer

front grate 2

1

44 SE041890021 wood screw M3x25 3

46 SE41381036 vent 2

47 SE41413021 seal 1

48 SE31531001 top cover 1

49

51 SE044117544

SEX9003287 plastic grommet

safety label 2

1

52 SE41533031 mount after serial #153.005000 4

53

54 SE41534015

SE041890029 mounting plate

wood screw after serial #153.005000

after serial #153.005000 1

1

55

56 SEX2201205

SEX9002984 casing

door open switch after serial #153.005000

after serial #153.005000 1

1

57 SE042080624 nut M8 4

58 SE041201358 screw M8x40 2

59 SE042342275 washer 2

60 SE31534006 door open switch before serial #153.004999 1

61 SE041890041 screw before serial #153.004999 2

62 SE040890011 screw before serial #153.004999 2

http://www.monomachines.com

http://www.monomachines.com

http://www.monomachines.com

http://www.monomachines.com

Item Part No. Designation Remark Qty.

SE41533004 deflector shaft 4

2 SE41533022 deflector .8 x12 mm 510

3 SE31533004 bag full flap 1

4 SE41533010 end plate richt 1

5 SE41533008 bearing plate 6

6 SE042462120 washer 8

7 SE042080627 nut M10 8

10 SE31533016 coverplate 1

15 SE41404027 seal

16 SE41533009 end plate left 1

17 SE043264021 key M8x7x40 1

18 SE31533011 long cutter shaft w/deflectors must 1

be purchased w/Pos #20

19 SE043264019 key M8x7x22

20 SE31533012 short cutter shaft w/deflectors 1

must be purchased w/Pos #18

21 SE41584001 optic holder 1

22 SE042342256 washer 2

23 SE041340302 screw M3x5 2

30 SE41534001 motor support 1

31 SE042342275 washer same as Pos # 9 8

32 SE042080624 nut M8 same as Pos # 8 16

33 SE041601458 threaded shaft rightM8x60 2

34 SE041601460 threaded shaft left M8x80 2

35 SE042462116 washer 4

36 SE042462116 washer 4

11

http://www.monomachines.com

http://www.monomachines.com

http://www.monomachines.com

http://www.monomachines.com

Item

Item

1

1

2

2

3

3

4

4

5

5

6

6

7

7

1010

15

15

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

31

31

32

32

36

36

40

40

41

41

Part

Part

No.

No.

SE41533004

SE41533004

SE41533015

SE41533015

SE31533004

SE31533004

SE41533010

SE41533010

SE41533008

SE41533008

SE042462120

SE042462120

SE042080627

SE042080627

SE31533012

SE31533012

SE41404027

SE41404027

SE41533009

SE41533009

SE043264021

SE043264021

SE31533009

SE31533009

SE043264019

SE043264019

SE31533007

SE31533007

SE41584001

SE41584001

SE042342256

SE042342256

SE041340302

SE041340302

SE042342275

SE042342275

SE042080624

SE042080624

SE04202102

SE04202102

SE41534017

SE41534017

SE041131354

SE041131354

Designation

Designation

deflector

deflector shaft

shaft

deflector

deflector

bag

bag full

full flap

flap

end

end plate

plate

bearing

bearing plate

plate

washer

washer

nut

nut

cover

cover plate

plate

seal

seal

end

end plate

plate

key

key

long

long cutter

cutter shaft

shaft w/deflector

w/deflector

must

must be

be purchased

purchased w/Pos

w/Pos #20

#20

key

key

short

short cutter

cutter shaft

shaft w/deflectors

w/deflectors

must

must be

be purchased

purchased w/Pos

w/Pos #18

#18

optic

optic holder

holder

washer

washer

screw

screw

washer

washer

nut

nut

washer

washer

motor

motor support

support

screw

screw

Remark

Remark

3.8x48

3.8x48 mm

mm

right

right

M10

M10

left

left

M8x7x40

M8x7x40

M8x7x22

M8x7x22

M3x5

M3x5

Same

Same as

as Pos

Pos #9

#9

M8

M8 same

same as

as Pos

Pos #8

#8

M8x20

M8x20

Qty.

Qty.

4

4

102

102

1

1

1

1

6

6

8

8

8

8

1

1

1

1

1

1

1

1

1

1

1

1

11

1

1

2

2

2

2

8

8

1616

4

4

1

1

8

8

13

13

http://www.monomachines.com

http://www.monomachines.com

14

http://www.monomachines.com

http://www.monomachines.com

Item

Item

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

16

16

17

17

18

18

19

19

20

20

25

25

26

26

27

27

28

28

29

29

30

30

31

31

34

34

35

35

36

36

37

37

38

38

39

39

40

40

41

41

42

42

43

43

44

44

47

47

50

50

51

51

52

52

Part

Part

No.

No.

SE41533011

SE41533011

SE41413021

SE41413021

SE41530007

SE41530007

SE041382704

SE041382704

SE31534010

SE31534010

SE042080610

SE042080610

SE042402102

SE41534010

SE41534010

SE041380313

SE041380313

SE31534016

SE31534016

SE041142720

SE041142720

SE046030016

SE046030016

SE042392287

SE042392287

SE042552133

SE042552133

SE047590004

SE047590004

SE047590005

SE047590005

SE047590006

SE047590006

SE047590007

SE047590007

SE041382715

SE041382715

SE9003755

SE9003755

SE041131359

SE041131359

SE042080624

SE042080624

SE042302325

SE042302325

SE042402116

SE042402116

SE042462116

SE042462116

SE41703013

SE41703013

SE41534019

SE41534019

SE41533007

SE41533007

SE41533032

SE41533032

SE042402102

SE41533006

SE041380313

SE041380313

SE041340302

SE041340302

SE042342256

SE042342256

SE41584001

SE41584001

SE047680035

SE047680035

SE041142722

SE041142722

SE31533021

SE31533021

SE042552160

SE042552160

SE9004393

SE9004393

SE041382708

SE041382708

SE042302213

SE042302213

SE41533000

Designation

Designation

cover

cover plate

plate

seal

seal

distance

distance shim

shim

screw

screw

bag

bag full

full switch

switch

nut

nut

washer

washer

bag

bag full

full switch

switch actuator

actuator

screw

screw

switch

switch mount

mount

screw

screw

ball

ball bearing

bearing

spacer

spacer

0

o ring

ring

Groin

Groin

Cover

Cover

Cover

Cover

Plate

Plate

Screw

Screw

Motor

Motor

Screw

Screw

Nut

Nut

washer

washer

spring

spring tooth

tooth disc

disc

fuse

fuse

ring

ring

chain

chain

toothed

toothed wheel

wheel

chain

chain wheel

wheel

toothed

toothed wheel

wheel

lens

lens screw

screw

countersunk

countersunk scew

scew

washer

washer

support

support

capacitor

capacitor

screw

screw

cutting

cutting head

head

locking

locking ring

ring

interference

interference filter

filter

lens

lens screw

screw

washer

washer

Remark

Remark

M3x16

M3x16

bag

bag full

full sensor

sensor

M4

M4

M4x12

M4x12

M5x10

M5x10

z=23

z=23

z=39

z=39

z=23

z=23

Qty.

Qty.

1

1

1

1

2

2

2

2

1

1

2

2

2

2

1

1

1

1

1

1

8

8

4

4

4

4

4

4

1

1

1

1

1

1

1

1

3

3

1

1

4

4

8

8

4

4

4

4

4

4

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

1

1

1

1

2

2

1

1

1

1

15

15

http://www.monomachines.com

http://www.monomachines.com

http://www.monomachines.com

http://www.monomachines.com

Item

Item

Part

Part

No.

No.

Designation

Designation

Remark

Remark

Qty.

Qty.

11 SE41533011

SE41533011 cover

cover plate

plate 1

1

2

2 SE41413021

SE41413021 seal

seal 1

1

3

3 SE41530001

SE41530001 distance

distance shim

shim 2

2

4

4 SE041382704

SE041382704 screw

screw M3x16

M3x16 2

2

5

5 SE31534010

SE31534010 bag

bag full

full switch

switch bag

bag full

full sensor

sensor 1

1

6

6 SE04208061 0

SE042080610 nut

nut M4

M4 2

2

7

7 SE0424021 02

SE042402102 washer

washer 2

2

8

8 SE41534010

SE41534010 bag

bag full

full switch

switch actuator

actuator 1

1

9

9 SE041380313

SE041380313 screw

screw M4x12

M4x12 1

1

10

10 SE31534016

SE31534016 switch

switch mount

mount 1

1

11

11

SE041142720

SE041142720 screw

screw M5x10

M5x10 8

8

12

12 SE046030016

SE046030016 ball

ball bearing

bearing 4

4

13

13 SE042392287

SE042392287 spacer

spacer 4

4

14

14 SE042552133

SE042552133 0

o ring

ring 4

4

15

15 SE042080624

SE042080624 nut

nut M8

M8 5

5

16

16 SE042342275

SE042342275 washer

washer 5

5

17

17 SE41374009

SE41374009 speed

speed detector

detector mount

mount before

before serial

serial #

# 153.004999

153.004999 1

1

18

18 SE41374017

SE41374017 threaded

threaded plate

plate before

before serial

serial #

# 153.004999

153.004999 1

1

19

19 SE042302213

SE042302213 washer

washer before

before serial

serial #

# 153.004999

153.004999 2

2

20

20 SE04138031 0

SE041380310 screw

screw before

before serial

serial #

# 153.004999

153.004999 2

2

21

21

SE41434013SE41434013 distancedistance ringring before

before serial

serial #

# 153.004999

153.004999 2

2

22

22 SE31374010

SE31374010 speed

speed detector

detector before

before serial

serial #

# 153.004999

153.004999 1

1

23

23 SE0424621 06

SE042462106 washer

washer before

before serial

serial #

# 153.004999

153.004999 22

24

24 SE041380342

SE041380342 screw

screw M3x12

M3x12 before

before serial

serial #

# 153.004999

153.004999 2

2

26

26 SE41374018

SE41374018 threaded

threaded plate

plate before

before serial

serial #

# 153.004999

153.004999 1

1

27

27 SE041380311

SE041380311 screw

screw M4x8

M4x8 3

3

29

29 SE14751

SE147510057

0057 motor

motor w/gear

w/gear box

box 1

1

30

30 SE042342275

SE042342275 washer

washer 4

4

31

31

SE041131358

SE041131358 screw

screw M8x35

M8x35 2

2

32

32 SE41534004

SE41534004 sprocket

sprocket z=16

z=16 before

before serial

serial #

# 6081122

6081122 1

1

32

32 SE41534007

SE41534007 z=13sprocket

sprocket z=13 after

after serial

serial #

# 6081122

6081122 1

1

33

33 SE042552127

SE042552127 0

o ring

ring 1

1

3333 SE41534002

SE41534002 chain

chain after

after serial

serial #

# 6081122

6081122 1

1

34

34 SE41534003

SE41534003 chain

chain before

before serial

serial #

# 6081122

6081122 1

1

35

35 SE41533007

SE41533007 timing

timing gear

gear long

long z=23

z=23 1

1

36

36 SE41533005

SE41533005 sprocket

sprocket 2

2

37

37 SE41533006

SE41533006 timing

timing gear

gear z=23

z=23 1

1

38

38 SE041380313

SE041380313 screw

screw M4x12

M4x12 1

1

3939 SE41584001

SE41584001 optic

optic holder

holder 1

1

40

40 SE042342256

SE042342256 washer

washer 2

2

41

41

SE041340302

SE041340302 screw

screw M3x15

M3x15 2

2

42

42 SE047680036

SE047680036 capacitor

capacitor 80UF

80UF 1

1

43

43 SE041142722

SE041142722 hexagon

hexagon screw

screw 2

2

44

44

SE31533002

SE31533002 cutting

cutting head

head complete

complete 5140P

5140P 1

1

44

44 SE31533003

SE31533003 cutting

cutting head

head complete

complete 5140C

5140C before

before sn

sn 6081122

6081122 11

44

44 SE1201106

SE1201106 cutting

cutting head

head complete

complete 5140C

5140C after

after sn

sn 6081122

6081122 1

1

45

45 SE31484001

SE31484001 speed

speed detector

detector magnet

magnet before

before serial

serial #

# 153.004999

153.004999 1

1

46

46 SE041201356

SE041201356 screw

screw M8x30

M8x30 before

before serial

serial #

# 153.004999

153.004999 1

1

47

47 SE042552160

SE042552160 0

o ring

ring

.7

.7

http://www.monomachines.com

http://www.monomachines.com

http://www.monomachines.com

http://www.monomachines.com

Other manuals for 4140CLK

1

This manual suits for next models

2

Other SEM Paper Shredder manuals