SEM 100 Instruction Manual

Security Engineered Machinery Co., Inc

OPERATIONAL & MAINTENANCE MANUAL

SEM Model 0100 SLEDGEHAMMER

Rev 3

Security Engineered Machinery Co., Inc

NATIONWIDE SERVICE

Phone Toll Free 1(800)225-9293

Email: [email protected]

Fax: (508)366-6814

Website: WWW.SEMSHRED.com

For NATIONWIDE SERVICE CALL 1(800)225-9293 2

CONTENTS

SAFETY PROCEDURES ...................................................................................................................................... 3

PARTS BREAKDOWN......................................................................................................................................... 4

TOOLS REQUIRED FOR ASSEMBLY OR MAINTENANCE .......................................................................... 5

INSTALLATION AND SET-UP........................................................................................................................... 6

CHANGE SETTINGS and MAINTENANCE....................................................................................................... 8

OPERATION........................................................................................................................................................ 13

PRODUCT SPECIFICATION ............................................................................................................................. 16

RECOMMANDED ACCESSORIES................................................................................................................... 16

For NATIONWIDE SERVICE CALL 1(800)225-9293 3

SAFETY PROCEDURES

Your new SEM 0100 Sledgehammer delivers a staggering 6,000 pounds of force to a conical punch causing

catastrophic trauma to the hard drive chassis while destroying the internal platter, serious and permanent

injury may result if proper precautions are not followed.

1. This equipment should never be operated by children or individuals that are

untrained or incapable of understanding these safety precautions!

2. Do not reach into the feed opening for any reason! Never insert fingers, hands,

other extremities, or objects not meant to be crushed into the feed opening!

3. Do not operate or come into close proximity to this equipment wearing loose

clothing, neckties, dangling jewelry, or long hair which may become entangled in

the crushing chamber.

4. Maintenance or repair of this equipment should be performed only by trained,

authorized service personnel.

5. Eye protection is recommended for flying debris while crushing hard drives and

DLT tapes

WARNING: SEE YOUR INTERNAL SAFTY OFFICER AND ASK ABOUT YOUR PPE

(PERSONAL PROTECTION EQUIPMENT) FOR AREA OPERATION.

For NATIONWIDE SERVICE CALL 1(800)225-9293 4

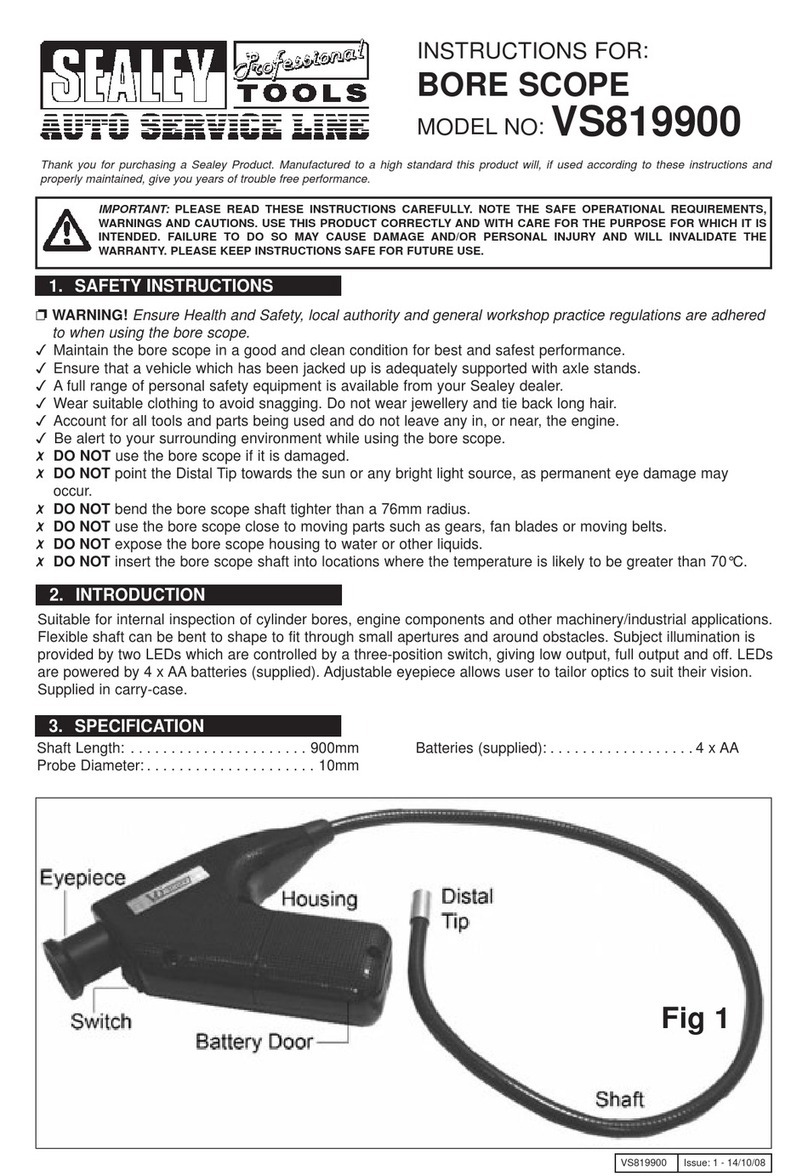

PARTSBREAKDOWN

Figure A

1

2 & 3

9

8

4, 5, 6 & 7

For NATIONWIDE SERVICE CALL 1(800)225-9293 5

PARTS LIST Reference Figure A

NUMBER QTY PART NUMBER DESCRIPTION

1 1 600HDD0100 Press

2 1 850HDCANVIL Anvil

3 MC91074A136 Anvil Lock Washer

4 1 851MCHANDLE Handle (Long)

5 2 8519753K82 Handle End Cap

6 1 851MCHANDLES Handle (Short)

7 2 8519753K2A Handle End Cap

8 1 M10 Set Screw

9 1 5mm Hex L-Key

10 2 3/8-16 x 4” Bolts

11 4 3/8 x 2” Fender Washer

12 2 3/8-16 Nylon-Insert Lockout

TOOLS REQUIRED FOR ASSEMBLY OR MAINTENANCE

Large Adjustable Wrench

5/8 Wrench

9/16 Wrench

Socket Wrench

9/16 Deep Socket

Flat head Screw Driver

5 mm Hex L-Keys (Included)

For NATIONWIDE SERVICE CALL 1(800)225-9293 6

INSTALLATION AND SET-UP

After removing the 0100 Sledgehammer from its packaging, be sure that all paperwork and any loose items that

may have been shipped with the 0100 Sledgehammer have been removed from the packaging as well. Please

note that all packaging should be retained by the customer for (30) days from the time of receipt. In the

event that this unit needs to be returned for replacement or repair, this packaging will be required to do so.

Should the packaging have been discarded before the (30) day requested period, packaging costs will be

incurred by the customer.

1) Place the 0100 Sledgehammer on a strong and sturdy surface. Such as a work table or SEM’s Optional

Heavy Duty Stand.

Note: if your table is to light, the table may tip over while trying to operate the model 0100

Sledgehammer. Table may need to be anchored to floor or wall as well.

2) Bolt down the model 0100 sledgehammer to your work table down with the supplied hardware (2) 3/8-16 x

4” bolts, (4) 3/8 x 2” fender washers, and (2) 3/8-16 nylon-insert locknut.

Note: If you are using a work table you will need to drill holes in the work table to match the predrilled

holes in the unit. The optional heavy duty stand already has the mounting holes predrilled.

Also (1) bolt with (2) washers and (1) locknut in two places

Tools required: 9/16 Wrench and Socket Wrench with 9/16 Deep Socket

IMPORTANT: The model 0100 Sledgehammer must be bolted down on a work table or SEM’s Option Heavy

Duty Stand. DO NOT OPERATE THE 0100 SLEDGEHAMMER if unit is not bolted down!

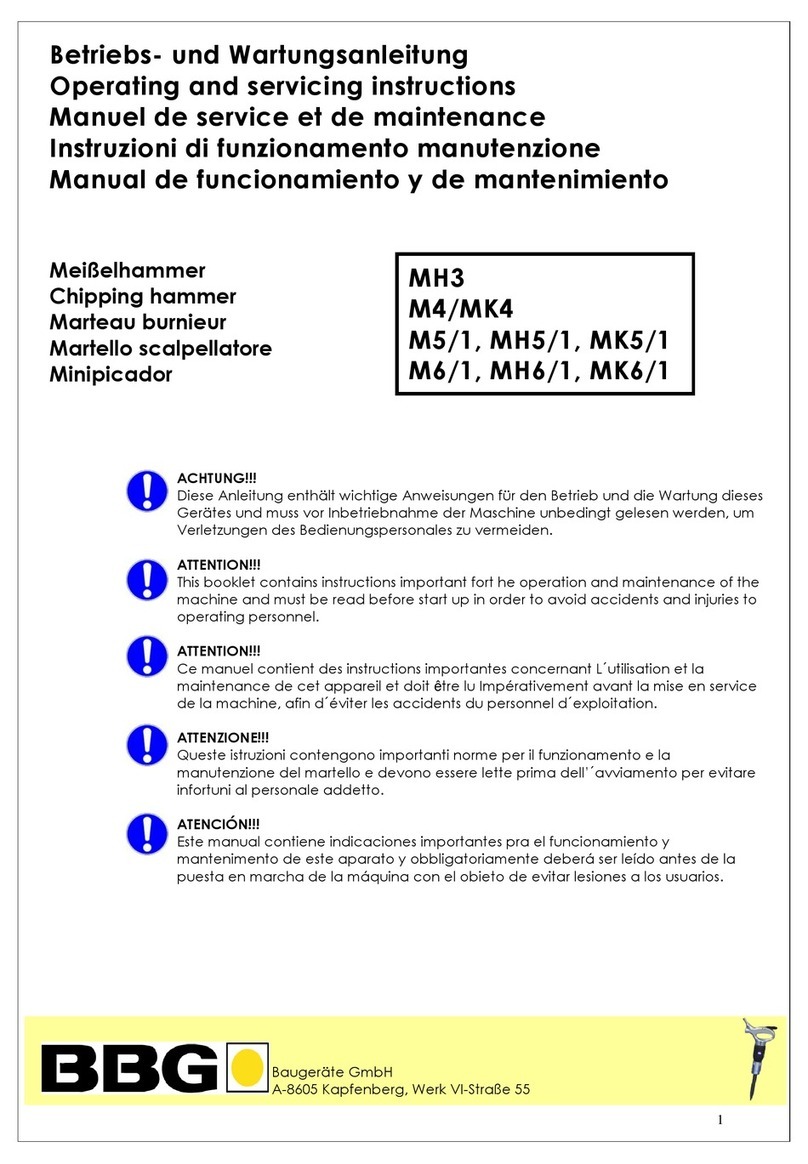

3) Before handle gets inserted, place a hard drive under anvil. The handle insert hole should be at

approximately 45° as shown in picture below.

For NATIONWIDE SERVICE CALL 1(800)225-9293 7

INSTALLATION AND SET-UP Cont….

Note: Need to turn shaft by hand to place hard drive or tape. If shaft will not turn may need to loosen

two center bolts with jam nuts on them.

Tool required: 5/8 Wrench

4) Insert handle and tighten set screw. (For best results only allow handle to extend about a 1” out of back side

of hole). Then tighten set screw.

Tool required: 5mm Hex L-Key.

Note: SEM has included two handles (long and short handle).

IMPORTANT: Long handle MUST be used when crushing hard drives.

Warning: While operating the model 0100 Sledgehammer pieces of material can eject. See your internal

safety officer and ask about your PPE for area of operation. We recommend wearing safety glasses.

5) Ready to operate

Handle Insert

Hole

Center bolts

with jam nuts

For NATIONWIDE SERVICE CALL 1(800)225-9293 8

CHANGE SETTINGS and MAINTENANCE

Change angle of handle

1) Remove Handle

Tool required: 5 mm Hex L-Key

2) Loosen set screw on shaft collar than remove.

Tool required: M6 Alan Wrench

For NATIONWIDE SERVICE CALL 1(800)225-9293 9

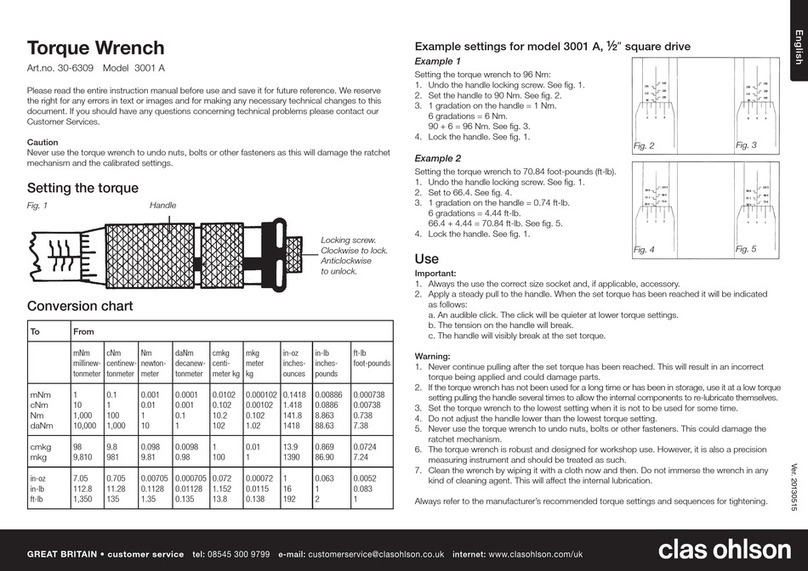

CHANGE SETTINGS and MAINTENANCE Cont…..

3) Pull shaft out until the teeth are no longer engaged.

4) Lift anvil to desired height.

5) Once desired height is reached, lock down the center bolts with the jam nuts on them.

Tool required: 5/8 Wrench

Center bolts

with jam nuts

For NATIONWIDE SERVICE CALL 1(800)225-9293 10

CHANGE SETTINGS and MAINTENANCE Cont…..

6) Turn shaft until the hole for the handle is approximately set at 45°, and then push back in.

Note: Once handle insert hole is set at approximately 45°, you may have to slightly twist the shaft to

align teeth to slide shaft back into place. Insert hole angle may slightly change but will still be

approximately 45°.

7) Put shaft collar back on and tighten set screw.

Tool required: M6 Alan Wrench

For NATIONWIDE SERVICE CALL 1(800)225-9293 11

CHANGE SETTINGS and MAINTENANCE Cont…..

Replacing or Removing the Anvil

1) Lift handle so anvil is clear of any obstructions.

2) Lock down the center bolts with the jam nuts on them.

Tool required: 5/8 Wrench

3) Remove anvil

Tool required: Large Adjustable Wrench

Note: Do not lose the lock washer on the top of the anvil, as this must be put back on anvil.

For NATIONWIDE SERVICE CALL 1(800)225-9293 12

CHANGE SETTINGS and MAINTENANCE Cont…..

Remove or Replace Coupling

1) Lift handle so anvil is clear of any obstructions.

2) Lock down the center bolts with the jam nuts on them.

Tool required: 5/8 Wrench

For NATIONWIDE SERVICE CALL 1(800)225-9293 13

OPERATION

Punching Hard Drives

Warning: Unit is shipped ready to destroy 1” hard drives, you may want to reset if punching 1.65” hard

drives (refer to the Changing Settings and Maintenance on page 5)

1) Lift handle to insert hard drive.

Note: It is recommended to punch the hard drives on the PC board side. Do not try to punch center hub

of hard drive. The device is designed to punch the platters inside the drive

2) Pull or push handle down to penetrate hard drive.

For NATIONWIDE SERVICE CALL 1(800)225-9293 14

OPERATION Cont…

Note: Anvil will not penetrate thru the entire hard drive. The model 0100 Sledgehammer pierces and

deforms hard drive to disable the drive.

3) Pull or push handle up to remove hard drive. If more deformation is needed turn hard drive 180° to penetrate

opposite side.

For NATIONWIDE SERVICE CALL 1(800)225-9293 15

OPERATION Cont…

Punching DLT tapes

1) Lift handle to insert DLT tape.

Note: It is recommended to punch the top side in the center of tape.

2) Pull or push handle down to penetrate DLT tape.

Warning: DLT tape is not considered destroyed. Only the metal is removed to make the tape inoperable.

For NATIONWIDE SERVICE CALL 1(800)225-9293 16

PRODUCT SPECIFICATION

Drive Types Personal Computer and/or Notebook style Hard Disk Drives

regardless of their size, format or type from .65” to 1.6” thickness

Destruction Time 5 second full cycle….can also destroy up to 2 notebook drives

in one 5 second cycle.

Dimensions / Weight 8” W x 24”H x 16”D / 88 Pounds

Operation Unit needs to be bolted to a table or work bench. Pre-drilled holes

are included in the base.

RECOMMANDEDACCESSORIES

Heavy Duty Stand Part # 600HDDSTAND

Replacement Anvil Part # 850HDC ANVIL

Other manuals for 100

1

Table of contents

Other SEM Tools manuals