Safety Precautions

© Copyright Reserved Autonics Co., Ltd. vii

Safety Precautions

Following these safety precautions will ensure the safe and proper use of the product and

help prevent accidents, as well as minimizing possible hazards.

Safety precautions are categorized as Warnings and Cautions, as defined below:

Warning Failure to follow the instructions may lead to a serious injury

or accident.

Caution Failure to follow the instructions may lead to a minor injury

or accident.

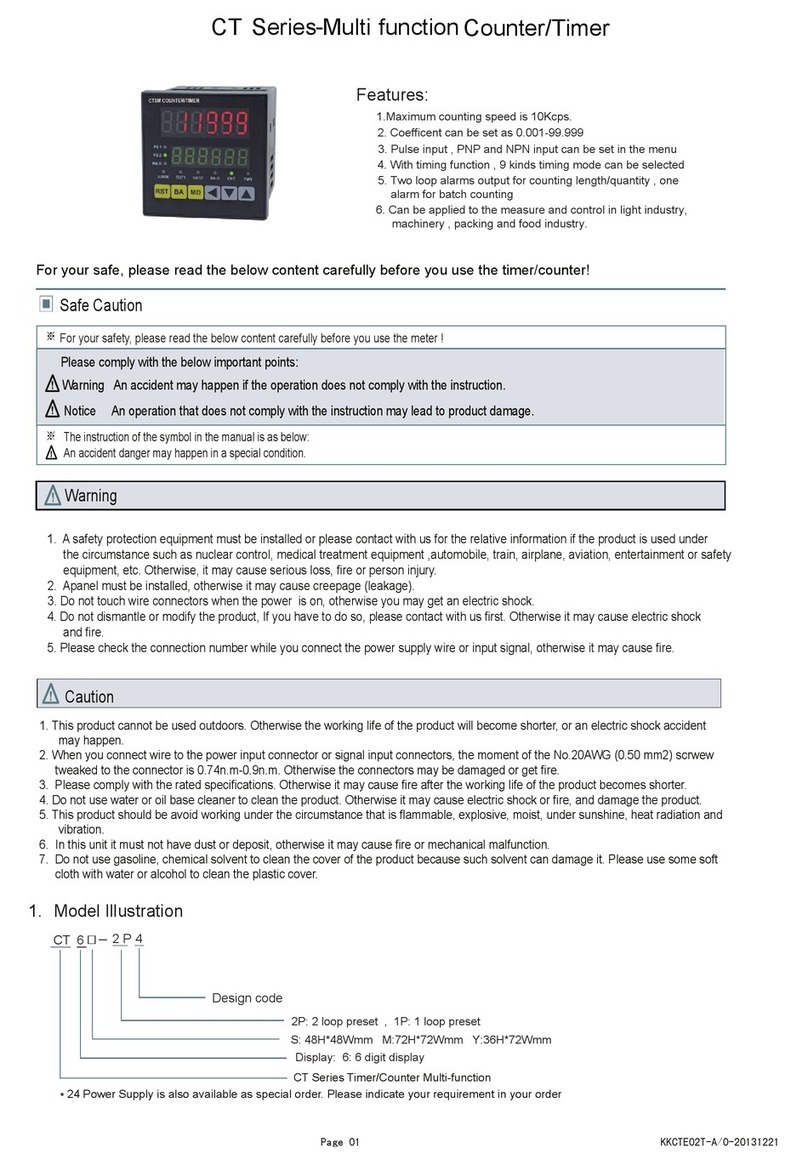

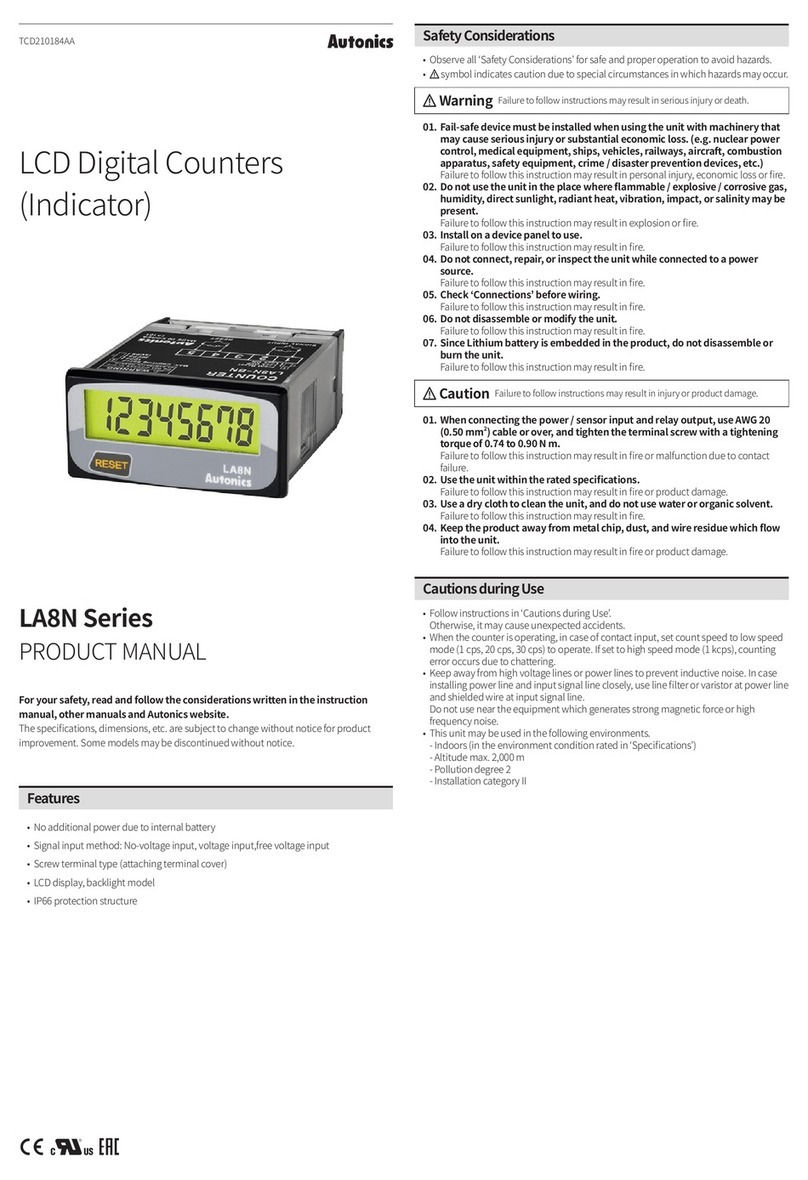

Fail-safe device must be installed when using the unit with machinery that may cause

serious injury or substantial economic loss. (e.g. nuclear power control, medical equipment,

ships, vehicles, railways, aircraft, combustion apparatus, safety equipment, crime/disaster

prevention devices, etc.)

Failure to follow this instruction may result in personal injury, fire, or economic loss.

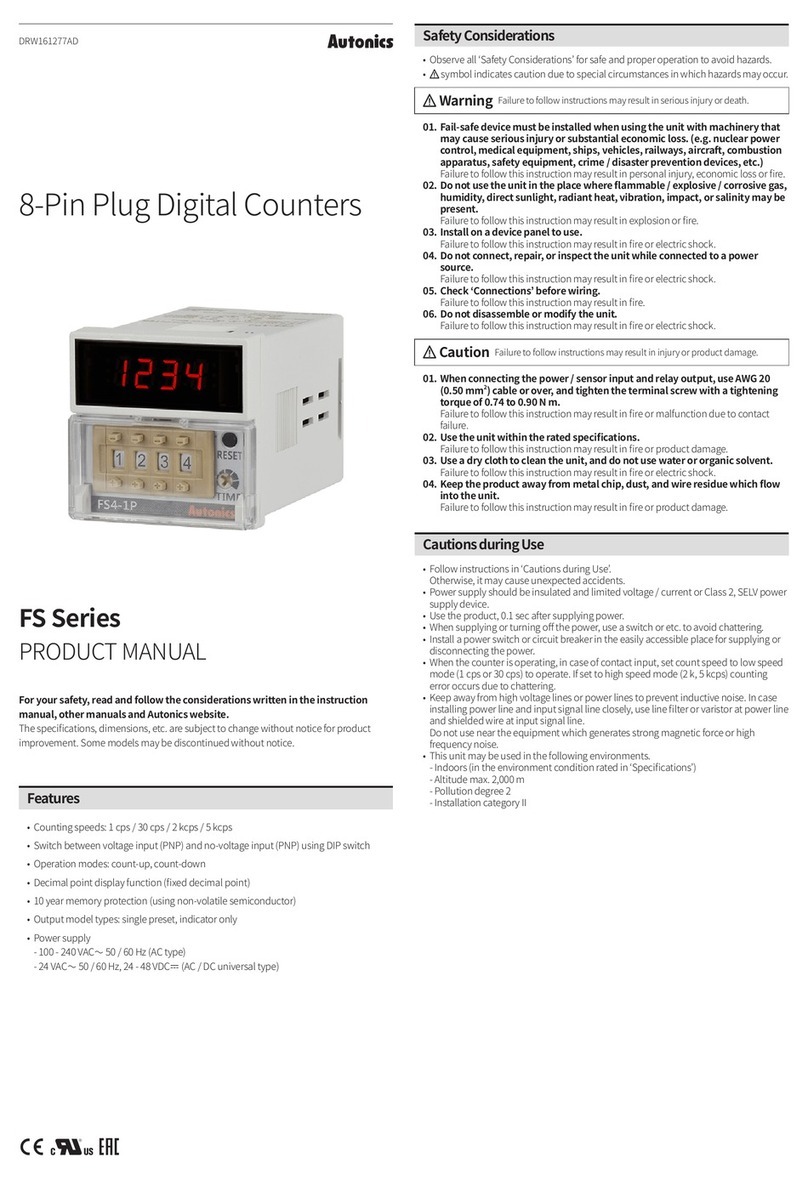

The unit must be installed on a device panel before use.

Failure to follow this instruction may result in electric shock.

Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in electric shock.

Do not disassemble or modify the unit. Please contact us if necessary.

Failure to follow this instruction may result in electric shock or fire.

Do not use the unit outdoors.

Failure to follow this instruction may result in shortening the life cycle of the unit, or electric

shock.

When connecting the power input and relay output cables, use AWG20 (0.50mm2) cables

and make sure to tighten the terminal screw bolt above 0.74N·m to 0.90N·m.

Failure to follow this instruction may result in fire due to contact failure.

Use the unit within the rated specifications.

Failure to follow this instruction may result in shortening the life cycle of the unit, or fire.

Do not use loads beyond the rated switching capacity of the relay contact.

Failure to follow this instruction may result in insulation failure, contact melt, contact failure,

relay broken, or fire.

Do not use water or oil-based detergent when cleaning the unit. Use dry cloth to clean the

unit.

Failure to follow this instruction may result in electric shock or fire.

Do not use the unit where flammable or explosive gas, humidity, direct sunlight, radiant heat,

vibration, or impact may be present.

Failure to follow this instruction may result in fire or explosion.