Sencon 387-WR User manual

387-WR BODYMAKER SENSOR SYSTEM

INSTRUCTION MANUAL

RELEASE 1.1

© 1993, 1996 Sencon Incorporated Page 1 387-WR Bodymaker Sensor System

DESCRIPTION

ALUMINUM-ON-PUNCH BODYMAKER SENSOR SYSTEM

T e Aluminum-on-Punc Bodymaker Sensor System detects t e presence of wall-ironed aluminum on t e

forming punc of a bodymaker. T e system is made up of a specialty sensor, t e 387-S1, and a control

module, t e BCM387-WR. T e system automatically compensates for t e magnetic properties of t e punc

and mounting ardware, eliminating t e need for a different sensor for eac punc composition. T is also

eliminates problems associated wit magnetic variations attributed to carbide batc tolerances and minimizes

t e effect of variations due to temperature. T e system profiles t e punc , w ic allows t e sensor to detect

tearoffs and s ort cans accurately before t e punc fully extends, t us providing more time to stop t e

mac ine. T e Sensor System detects aluminum over a variety of punc materials, including ceramic punc es

t at ave steel nose pieces. T is makes it ideal for plants c anging from one punc type to anot er.

T e Bodymaker Sensor System offers an immediate stop mode. In t is mode, t e module immediately opens

two transistor switc es t at can interrupt 2 Amperes at 24 Volts w en it detects a defect. A sync ronized stop

can be done t roug t e mac ine PLC logic by monitoring t e sensor output signal.

T e calibration of t e sensor requires some c anges in t e mac ine control logic. T is tunes t e sensor to

t e punc material and profile. T e system needs t ree or more dry strokes (mac ine strokes wit out cans in

process) to calibrate t e sensor. T e sensor maintains calibration information internally in EEPROM,

eliminating t e need to recalibrate every time t e power to t e sensor cycles. T e system needs recalibration

w enever any of t e following conditions appen:

1. t e sensor is c anged;

2. t e sensor to punc gap is c anged;

3. t e punc is rotated;

4. t e punc is c anged;

5. or t e timing window is c anged.

T e 9H-387-S1 sensor as an integral cable and t e 11H-387-S1 sensor is terminated using a quick

disconnect cable. A ose fitting designed to accept 0.75" I.D. [19.1 mm] ydraulic tubing surrounds t e

connector. Use a stainless steel ose clamp to provide a positive mec anical and ydraulic seal of t e ose

to t e fitting. T is aids in s ielding t e sensor and connector from t e bodymaker coolant.

© 1993, 1996 Sencon Incorporated Page 2 387-WR Bodymaker Sensor System

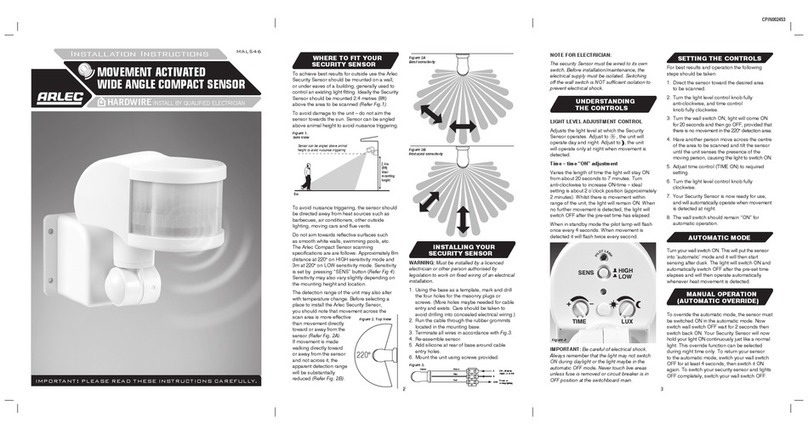

DIMENSIONS

9H-387-56 Sen or

11H-387-S1 Sen or

BCM387-WR Module

© 1993, 1996 Sencon Incorporated Page 3 387-WR Bodymaker Sensor System

SPECIFICATIONS

Input Supply Voltage

Module

24 VDC ±2.4 VDC

Input Supply Current

Module

400 mA Plus Load Current at 24 VDC

Module

Signal Inputs

Configuration

Sour e or Sink (Set with Jumper)

A tive High or A tive Low (Set with Jumper)

Voltage

Range

Minimum

-0.7 VDC

Maximum

Input Supply Voltage Value

Threshold

High State

55% of Input Supply Voltage

Low State

45% of Input Supply Voltage

Impedan e

5 kΩ

Allowable Leakage

400 µA

Reverse Polarity

Sensor

Prote ted

Case Isolation

Sensor

200 VDC

Storage Temperature

Module

+ 40° F to +185° F [+ 4° C to +85° C]

Sensor

+ 40° F to +185° F [+ 4° C to +85° C]

Operating Temperature

Module

+32° F to +158° F [0° C to +70° C]

Sensor

+32° F to +158° F [0° C to +70° C]

Environment

Module

IP20 - Requires mounting in an IP65 or NEMA 12 en losure.

Sensor

IP65 or NEMA13 when installed with a hydrauli hose and

stainless steel lamp.

GENERAL CHARACTERISTICS

Weight

Module

1 lb [450 g]

Sensor

5 oz. [140 g]

Case

Module

Poly arbonate

Sensor

Stainless Steel

Termination

Module

S rew terminals re essed to prote t against a idental onta t.

11H-387-S1 Sensor

Qui k Dis onne t with Hose Fitting - Use ONLY the mating onne tor

available through Sen on. Other onne tors whi h appear to be

equivalent may not be ompatible. Refer to Te hni al Data Sheet #

096-00007-xx (Cables for DC Sensors).

9H-387-S1 Sensor

10' [3 m] Cable with Hose Fitting

SENSOR OPERATING CHARACTERISTICS (RANGE TO TARGET)

Pun h Material

Aluminum on Carbide

Pun h (Ni kel Binder)

Aluminum on

Steel Pun h

Aluminum on

Cerami Pun h

Aluminum on Carbide

Pun h (Cobalt Binder)

Sensing Range

0.065" to 0.100"

[1.7 to 2.5 mm]

0.065" to 0.300"

[1.7 to 7.6 mm]

0.150" to 0.250"

[3.8 to 6.4 mm]

0.065" to 0.180"

[1.7 to 4.6 mm]

Setting Distan e

0.080" [2.0 mm]

0.205" [5.2 mm]

0.200" [5.1 mm]

0.120" [3.0 mm]

© 1993, 1996 Sencon Incorporated Page 4 387-WR Bodymaker Sensor System

MODULE SOLID STATE SWITCH OUTPUT CHARACTERISTICS

Maximum Load

40 mA, Typi al ON resistan e at 25 mA is 25 Ω

500 mW maximum power through the swit h

Voltage Range

0 to 50 VAC (peak) or 0 to 50 VDC

Leakage Current

< 1 mi roamp

Output Type

Bi-dire tional, opti ally isolated solid state swit hes.

Output Configuration

Suitable for DC sour e, DC sink, or AC.

Output State

Calibration

ON when Sensor Calibrated to Pun h

Sensor

Output

ON

(Good Can)

Normal output state when no defe t is dete ted or during

alibration.

OFF

(Reje t)

Full an Mode - Signal is present from the time the defe t is

dete ted until 70 ms following the trailing edge of the window

signal.

Trimline Mode - Signal is present approximately 2 ms after the

end of the window signal until 70 ms following the trailing edge of

the window signal.

Sensor

Output 2

ON

(Good Can)

Normal output state when no defe t is dete ted or during

alibration.

OFF

(Reje t)

Signal refle ts the a tual state of the sensor. Is useful in

determining the point along the pun h where the defe t is first

dete ted.

MODULE TRANSISTOR SWITCH OUTPUT CHARACTERISTICS

Maximum Load

2 A DC Resistive/Indu tive

Voltage Range

-0.7 VDC to 30 VDC

Voltage Drop

0.6 VDC at 1 A, 0.9 VDC at 2 A

Short Cir uit Prote tion

Momentary (10 se onds)

Output State

Determined by the operating state. Refer to the `Operation' se tion of this TDS for

details.

Output Configuration

Opti ally Isolated FET Transistor Swit h, Condu tive in the A tive State

© 1993, 1996 Sencon Incorporated Page 5 387-WR Bodymaker Sensor System

INSTALLATION

MECHANICAL INSTALLATION

BCM387-WR Module Mounting

T e BCM387-WR controller mounts in a control

cabinet, protected from moisture and ydraulic

fluids. Mount t e unit on a 35-mm DIN rail or wit

two fasteners. Recommended screw fasteners

are #8 or M4.

387 Sen or Mounting

Securely mount t e sensor as s own in t e

diagrams. Use t e table below for t e proper

setting distance between t e sensor and t e

punc . T e centerline of t e sensor must be

perpendicular to t e centerline of t e punc

and must pass t roug t e center of t e punc .

Make sure to seat fully and tig ten t e cable

connector on t e 11H-387 sensor. Also install

and clamp t e ydraulic tubing over t e fitting.

Pun h Material

Aluminum on Carbide

Pun h (Ni kel Binder)

Aluminum on

Steel Pun h

Aluminum on

Cerami Pun h

Aluminum on Carbide

Pun h (Cobalt Binder)

Setting Distan e

0.080" [2.0 mm]

0.205" [5.2 mm]

0.200" [5.1 mm]

0.120" [3.0 mm]

© 1993, 1996 Sencon Incorporated Page 6 387-WR Bodymaker Sensor System

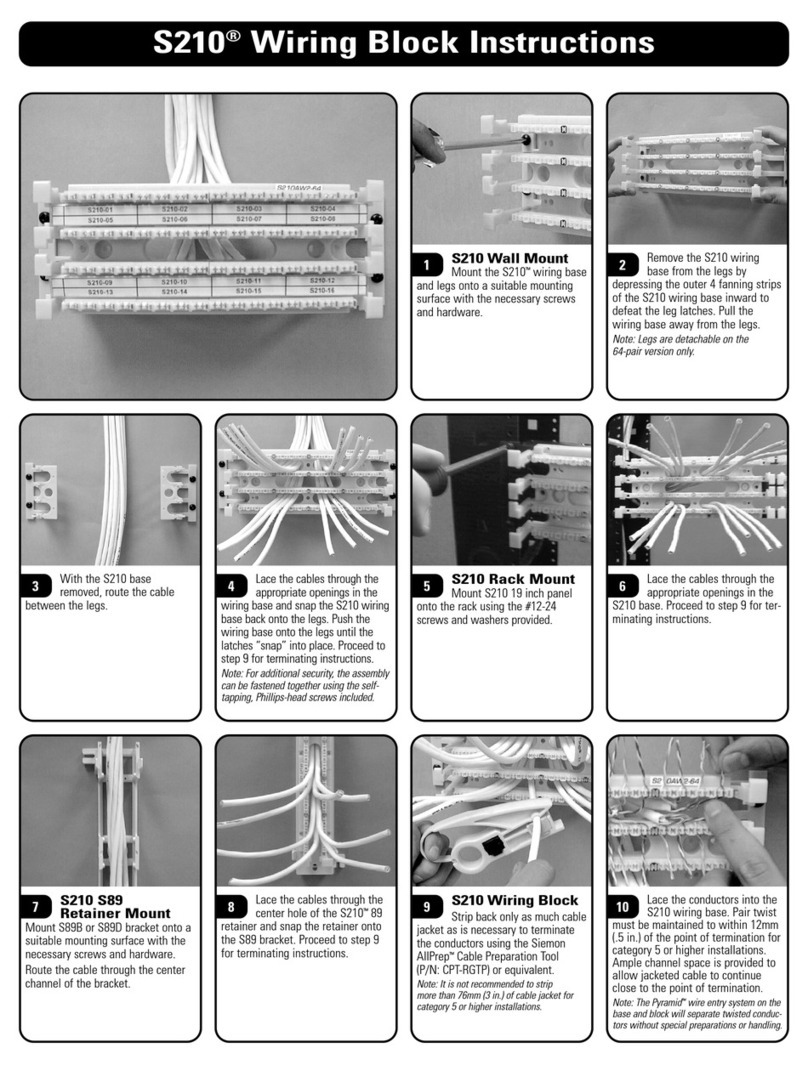

ELECTRICAL INSTALLATION

T e inputs and outputs to t e BCM387-WR are s own ere. Electrical connection is made to t e unit wit

screw terminals. T e terminals are recessed to reduce t e c ances of accidentally contacting t em.

387 Sen or Interconnection

Make sure to seat fully and tig ten t e cable connector on t e 11H-387 sensor. Also install and clamp t e

ydraulic tubing over t e fitting. Ot erwise, liquid may infiltrate t e connector and degrade performance.

(Black)

(Green)

(Yellow)

(White)

(Blue) NC

(Red/Black)

(Green)

(Red/Yellow)

(Red/White)

9H 387

Sen or

11H- 387

Sen or

© 1993, 1996 Sencon Incorporated Page 7 387-WR Bodymaker Sensor System

DC Signal Input

Configure t e input signals as s own in t e diagram below. Settings are made wit minijumpers accessible

under t e top cover of t e unit. Remove t e top cover by inserting a flat screwdriver blade in t e slot s own

and rotating t e blade to `pop' t e cover off. T is operation MUST be done wit power off to avoid damaging

t e unit.

If an input is active ig , t e presence of a voltage above t e t res old at t e input terminal is ON, and voltage

below t e t res old at t e terminal is OFF. T e reverse is true if an input is active low. T e transition from

OFF to ON is t e leading edge of t e signal. T e transition from ON to OFF is t e trailing edge of t e signal

© 1993, 1996 Sencon Incorporated Page 8 387-WR Bodymaker Sensor System

Solid State Switch Output

T ese outputs are optically isolated from t e supply voltage w en t e jumper is set to ‘Output Common’.

T erefore, t e COM terminal is floating and can be connected to any reference t at falls wit in t e specified

voltage range. Connect not ing to t e COM terminal if t e jumper is set to ‘Output Current Source’ or to

‘Output Current Sink’.

FET Tran i tor Switch Output

T e system as t ree FET transistor switc es for

control of t e bodymaker clutc /brake solenoids and

t e dump valve. T e contacts are FET transistors

t at are optically isolated from t e internal power

supply.

IMPORTANT SAFETY NOTICE - The tran i tor

witche provided with thi unit mu t not be the

only mean of controlling the bodymaker clutch

mechani m. Good de ign practice dictate the

u e of afety lockout on any device that tart

and top automatically that can cau e per onal

injury to operating or maintenance per onnel.

The BCM387-WR mu t be u ed only with indu try

approved afety lockout contact , otherwi e

eriou per onal injury may re ult.

© 1993, 1996 Sencon Incorporated Page 9 387-WR Bodymaker Sensor System

OPERATION

MODULE SIGNAL INPUTS

T e Bodymaker Sensor System requires t e five inputs described ere. T ese inputs are not optically

isolated from t e BCM387-WR internal power supply.

Input

Description

Calibrate

T e Calibrate input sends a calibrate command to t e sensor. W en t e module

detects a good calibration, t e Good Calibration output turns ON. T is takes at least

t ree cycles. T e Calibrate input must be OFF before t e cup feed turns on.

Window

T e Window signal is active w en t e punc is in position for sensing. T e trailing

edge of t e window signal corresponds to t e can body trimline.

Mode Select 1

and

Mode Select 2

T e state of t ese inputs sets t e mode of t e BCM387 Module.

Trimline/

Fullcan

T e system does a Fullcan c eck w en t is input is OFF. For a Fullcan c eck, t e

sensor profiles t e punc and evaluates t e can at various points along t e punc .

T e system does a Trimline c eck w en t is input is ON. For Trimline c eck, t e

system only evaluates t e trimline of t e can.

SOLID STATE SWITCH LOGIC OUTPUTS

T e Bodymaker Control Module as t ree solid state switc outputs. T ese outputs are bidirectional and

isolated from t e BCM387-WR internal power supply if t e appropriate jumper is set to t e ‘Output Common’

position. T e outputs can be wired for DC source, DC sink, and AC. T ey are rated for 40 mA (maximum) at

up to 50 VAC (peak) or 50 VDC.

Output

Description

Good

Calibration

T e Good Calibration output is ON (current flow allowed) after t e sensor as been

calibrated and remains ON w ile t e sensor calibration is good.

Sensor Output

and Sensor

Output 2

T e Sensor Output and Sensor Output 2 s ow s ort cans and tearoffs. T ey also

pulse once eac mac ine cycle to s ow t e system is functioning (backstop c eck).

See t e timing diagrams for details.

Note: If t e sensor fails, t e backstop c eck will not occur.

© 1993, 1996 Sencon Incorporated Page 10 387-WR Bodymaker Sensor System

TRANSISTOR SWITCH CLUTCH/SOLENOID CONTROL OUTPUTS

T e driver outputs are FET transistor switc es and are isolated from t e supply power. T e rated load is two

amperes maximum at 30 volts. Observe t e proper polarity.

Output

Mode

Description

Clutc 1,

Clutc 2, and

Dump Valve

Transistor Switc es Held Open

T e outputs are always open.

Transistor Switc es Held Closed

T e outputs are always closed.

Immediate Mode

T e outputs are closed w ile t ere are no faults.

T ey remain closed until a fault occurs. W en a

fault occurs, t e outputs open immediately and

remains open 70 milliseconds after t e end of

t e Window signal.

OPERATIONAL MODE SELECTION

T e operational mode is set wit t e state of t e Mode Select 1 and Mode Select 2 inputs. T is table s ows

t e t ree modes.

Mode Select 1

Mode Select 2

Mode

Comment

Off

Off

Transistor Switc es Held Open

T e transistor switc es are

always open.

On

On

Transistor Switc es Held

Closed

T e transistor switc es are

always closed.

On

Off

Immediate Mode

T e transistor switc es follow t e

sensor error signal.

FULLCAN CHECK AND TRIMLINE CHECK

T e system normally does a full can c eck w en it is evaluating a can for defects. T e sensor evaluates t e

punc at various points during t e window. Trimline c eck differs from t is in t at t e system only evaluates

t e trimline. T e system can be forced into trimline c eck wit t e Trimline/Fullcan input. T e system goes

into trimline c eck w en t e signal is applied, and will remain in t is mode until t e signal as been removed.

© 1993, 1996 Sencon Incorporated Page 11 387-WR Bodymaker Sensor System

WINDOW AND CALIBRATE SIGNAL TIMING

T e diagram below describes t e relations ip between t e Window signal, t e Calibrate signal, and t e

position of t e punc . T e Window signal becomes active sometime after t e nosepiece of t e punc as

passed t e sensor, and remains active until t e trimline is reac ed. T e Calibrate signal must be active a

minimum of 20 milliseconds before t e leading edge of t e Window signal.

Parameter

Symbo

l

Limits (Degrees of Travel)

Dome Offset

d

DOME

Approximately 0.5" [13 mm]

(from the end of the pun h to the enterline of the sensor)

Setup Time

t

SU

20 mse . (minimum)

Window Time

t

WINDO

W

3.5 mse . (minimum) to

50 mse . (maximum)

T e maximum allowable variation in t e Window time (t

WINDOW

) between successive mac ine strokes is ±20%.

Make sure not to exceed t is limit w en t e mac ine accelerates or decelerates from one speed setting to

anot er. If t e t

WINDOW

time c anges by more t an ±20% between successive mac ine strokes, t e system

may not detect a tear off until t e trimline c eck is made.

© 1993, 1996 Sencon Incorporated Page 12 387-WR Bodymaker Sensor System

REJECT AND BACKSTOP CHECK TIMING

T e system provides a signal s owing t at it is working properly, commonly called t e backstop c eck. T e

Sensor output will turn off 35 milliseconds after t e trailing edge of t e Window and will remain off for 35

milliseconds. T is does not indicate t e detection of a defect, but s ows t at t e system is operating properly.

T e system s ows a defect w en t e Sensor output turns off w ile t e Window signal is on, or turns on wit in

2 milliseconds after t e trailing edge of t e Window signal. T e Sensor output stays on until 70 milliseconds

after t e trailing edge of t e Window signal.

T e Sensor Output 2 follows t e state of t e 387 sensor, no matter if t e BCM387 is in Trimline or Fullcan

mode. T is is useful in determining w ere t e defect was first detected w en t e system is in Trimline mode.

T e Sensor Output 2 does not latc . If t e system detects a tear off at an intermediate point along t e punc

t at turns out to be invalid, t is output toggles off momentarily and t en back on.

© 1993, 1996 Sencon Incorporated Page 13 387-WR Bodymaker Sensor System

CALIBRATION

T e 387-S1 sensor must be calibrated to t e punc before operation. If t e first two digits of t e sensor serial

number are ‘71' or ig er, t en t e sensor saves t e calibration information in non-volatile EEPROM. A

Calibrate signal from t e sensor 100 milliseconds after power up s ows t e sensor as calibration information

stored in EEPROM. Earlier model sensors do not save calibration information and need calibration every time

t ey ave power applied to t em.

T e calibration is done by cycling t e mac ine at least t ree times wit t e Calibrate input on and wit out cans

in process. T ese cycles allow t e sensor to calibrate to t e punc material and to profile t e punc wit in t e

timing window. Subsequent starting and stopping of t e mac ine will not affect t e calibration.

T e Good Calibration output will turn on once t e sensor as successfully calibrated itself to t e punc . T is

signal will remain on w ile cans are in process. T e Calibrate input must go inactive after t e Good

Calibration output turns on and before t e cup feed turns on. Recalibration can be done by periodically

interrupting t e cup feed and setting t e Calibrate input.

TRANSISTOR SWITCHES HELD CLOSED

Use t is mode to stop t e bodymaker sync ronous to mac ine timing. T e transistor switc es are eld

closed. T e state of t e Sensor output can allow t e PLC to execute a normal stop sync ronized wit t e

backstop logic. T e action required to stop t e bodymaker must be done in t e PLC.

© 1993, 1996 Sencon Incorporated Page 14 387-WR Bodymaker Sensor System

IMMEDIATE STOP MODE

Use t e immediate stop mode to stop t e bodymaker async ronous to t e mac ine timing markers (t at is, as

fast as possible). T e transistor switc es will open w en t e system detects t e defect, allowing an immediate

stop to occur. T e switc es are guaranteed to be open only 70 milliseconds, so furt er action in t e PLC is

required to keep t e mac ine from restarting. T e state of t e Sensor output indicates to t e PLC t at a

defect as occurred.

TRANSISTOR SWITCHES HELD OPEN

T e transistor switc es will remain open, interrupting t e flow of current to t e solenoid coils. T e mode of t e

BCM module can be c anged during t e backstop c eck. T erefore, if t e system stops in immediate mode,

t e module can be switc ed to t is mode to keep t e switc es open.

© 1993, 1996 Sencon Incorporated Page 15 387-WR Bodymaker Sensor System

MAINTENANCE

T e system needs no periodic maintenance. However, t ere are some procedures to follow w en replacing

t e sensor or t e punc .

INSTALLING A REPLACEMENT 387 SENSOR

Install a replacement 387 sensor as s own on page 5 of t is manual. Make sure to seat t e connector fully

and to clamp t e ose securely. T ere are two special considerations to make w en replacing a sensor.

1. T e replacement sensor MUST be wired wit no power to t e module. T is ensures t at t e sensor

and module communicate properly.

2. T e sensor MUST be recalibrated once power is applied. Alt oug a newer style sensor wit t e

calibration information stored in EEPROM may s ow t at it is calibrated, it must be recalibrated to t e

punc on t e bodymaker.

INSTALLING A REPLACEMENT PUNCH

After installing a replacement punc , make sure to remount t e sensor as s own on page 5 of t is manual.

T e sensor MUST be recalibrated to t e replacement punc for proper operation.

SENSOR CALIBRATION

Sensor calibration MUST be done w enever any of t e following conditions appen:

1. t e sensor is c anged;

2. t e sensor to punc gap is c anged;

3. t e punc is rotated;

4. t e punc is c anged;

5. or t e timing window is c anged.

T e calibration procedure is described on page 13 of t is manual.

ORDERING INFORMATION: For price quotes or applications information, contact t e SENCON

sales office listed below:

SENCON INCORPORATED (Nort /Central/Sout America)

6385 West 74t Street, Bedford Park, IL 60638 USA

PHONE: +1-708-496-3100 FAX: +1-708-496-3105

SENCON (UK) LTD. (Europe/Middle East/Asia)

Stonebridge Cross Business Park

Droitwic WR9 0LW

UK

Tel: +44 1905 827800

Fax: +44 1905 795876

www.sencon.com

PUBLISHED 21 March 2006 16 TECHNICAL DATA SHEET# 096-38702-03

Please Note: Due to product improvement, specifications are subject to c ange wit out notice.

This manual suits for next models

1

Table of contents