Sensit VMD Installation manual

SENSIT® VMD

SETUP &OPERATING INSTRUCTIONS

2

FOR YOUR SAFETY

NOTICE: This safety symbol is used to indicate a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury.

WARNING: Disassembly and maintenance is forbidden in explosive atmosphere.

WARNING: Follow the manual instructions and testing methods.

WARNING: Any disassembly or repair of the instrument must be done by a factory certified technician.

WARNING: Clean lenses prior to each use with a lint free or microfiber cloth for best results.

WARNING: When not in use refer to transport position recommendation to prevent potential damage.

WARNING: While the VMD is weather resistant, it is recommended to remove the instrument and store it in the

vehicle when necessary to avoid prolonged exposure to extreme weather (i.e. heavy rain or snow).

DANGER: Use extreme caution when monitoring the tablet computer when driving. Rely on the audible alarm

instead of any visual indication while driving. Any adjustment should be made only when the vehicle is safely

stopped and away from traffic.

3

CONTENTS

For Your Safety....................................................................................................................................................................................2

Contents...............................................................................................................................................................................................3

Parts and Accessories..........................................................................................................................................................................4

Standard Parts (Included)................................................................................................................................................................. 4

Mounting Kit (VMD)..........................................................................................................................................................................4

Accessories......................................................................................................................................................................................4

Mounting Kit (Tablet)........................................................................................................................................................................4

Product and Technology Description....................................................................................................................................................5

Specification.........................................................................................................................................................................................6

Sensor Specifications.......................................................................................................................................................................6

Product Specifications......................................................................................................................................................................6

Explanation of ppm/m...........................................................................................................................................................................7

Installation............................................................................................................................................................................................ 8

Install VMD Instrument.....................................................................................................................................................................8

Install Tablet Computer ..................................................................................................................................................................10

Getac Tablet Connections.............................................................................................................................................................. 11

User Interface.....................................................................................................................................................................................12

Description of Interface Buttons .....................................................................................................................................................13

User Setup Tab .............................................................................................................................................................................. 15

Operation and Use............................................................................................................................................................................. 16

Calibration.......................................................................................................................................................................................... 17

Advanced Calibration ......................................................................................................................................................................... 18

Plotting Surveys ................................................................................................................................................................................. 19

Converting to .kml and Exporting ...................................................................................................................................................19

Pairing a PMD....................................................................................................................................................................................20

Importing Calibration Data Into SCAL ................................................................................................................................................21

Export Data from Tablet to Removable Media................................................................................................................................21

Import Data into SCAL....................................................................................................................................................................21

Troubleshooting..................................................................................................................................................................................22

Communication Issues and Re-Pairing Bluetooth Connection....................................................................................................... 22

Double Check the Following Items:............................................................................................................................................22

Power Cycle VMD and Tablet ....................................................................................................................................................22

Re-Pairing Bluetooth Connection ...............................................................................................................................................23

Notes..................................................................................................................................................................................................25

Warranty............................................................................................................................................................................................. 28

4

PARTS AND ACCESSORIES

STANDARD PARTS (INCLUDED)

360-00481 VMD Bluetooth antenna

360-00482 Tablet Bluetooth antenna

385-00159 Tablet Bluetooth antenna extension cable

(right angle)

330-00097 Tablet Bluetooth antenna clamp

360-00471 Tablet GPS antenna

385-00114 VMD power harness assembly

385-00160 Tablet vehicle power supply

360-00517 Tablet dock

882-00092-SN Calibration cell (with mounting arm and

thumbscrew)

882-00137 Extra power harness cover

360-00430 5A automotive fuse for power harness

MOUNTING KIT (VMD)

870-00428 Mounting kit (includes parts below)

330-00078 Hitch pins (2)

360-00426 Jam bolt

360-00427 L-bracket

360-00428 VMD bar bracket

360-00429 Hitch stabilizer

ACCESSORIES

870-00076 VMD shield

MOUNTING KIT (TABLET)

870-00074 Mounting kit (includes parts below)

360-00473 Base w/ 2” Ball & Clamps

360-00474 Arm

360-00475 Plate (VESA 75)

5

PRODUCT AND TECHNOLOGY DESCRIPTION

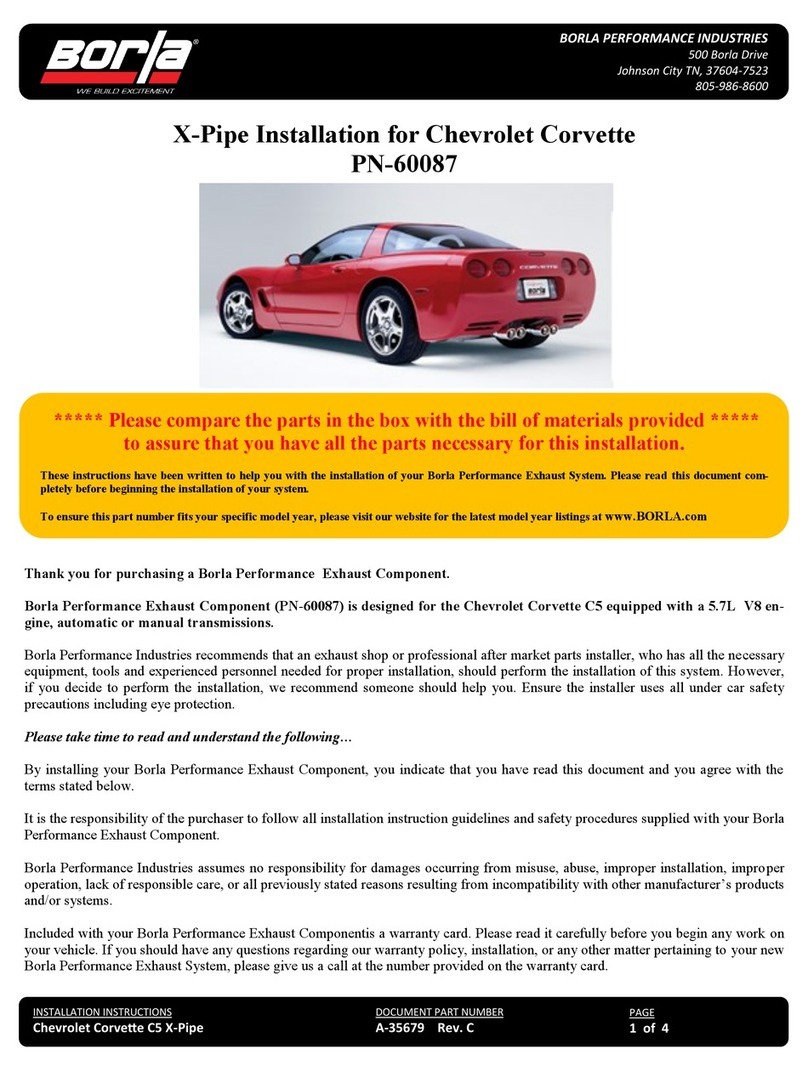

The SENSIT VMD is a vehicle-mounted natural gas leak survey instrument. It uses IR Absorption Spectroscopy technology

for extremely accurate and consistent readings that are entirely methane specific. The SENSIT VMD uses an open-path

system, which consists of 2 modules that are mounted on a bar. One half emits a light source, which travels through the

space between the modules into the other half which receives the signal. The amount of natural gas (methane) in the path

affects how much of the light source is absorbed, which is translated into a parts-per-million-per-meter (ppm/m) reading.

The entire assembly is mounted to the front of a vehicle on a large L-bracket, which is received by a 2” hitch. The SENSIT

VMD is powered by a single cable coming from the battery of the vehicle, and can be removed easily to allow for very fast

and simple removal and storage of the instrument. The data it gathers is sent via Bluetooth to a rugged tablet computer in

the cab of the vehicle. The user is shown readings in real time (at a rate of one reading every 200ms), on a very easy to

read graphical interface.

The SENSIT VMD, in addition to using Bluetooth communication, also utilizes a built-in GPS module in the tablet. Combined

with the software’s logging capabilities, the user can map a survey directly into Google Earth, to see a detailed map of the

survey with a breadcrumb trail of the path driven and readings found.

6

SPECIFICATION

SENSOR SPECIFICATIONS

Sensitivity: 0.1 ppm/meter methane at a max speed of 25mph

Measurement Range: 1.0 to 1000 ppm/meter

Display Range: Automatic

Accuracy: ±10%

Alarms: Audible with adjustable set point

PRODUCT SPECIFICATIONS

System Voltage: 10-16 VDC

System Power Requirements: 84 watts max @ 12 VDC

VMD Size: 4 ft. to 8 ft. path length (5 ft. Standard)

Tablet Weight: 1.94lbs (0.88kg)

Tablet Size: 8.93” x 5.94” x 0.94” (227 x 151 x 24mm)

VMD Weather Resistance: IP54

Tablet Weather Resistance: IP65

Operating Temperature Range: -20˚F to 122˚F

Operating Humidity Range: 5 to 100% relative humidity

Installation Time: < 2 hours (typical)

7

EXPLANATION OF PPM/M

The SENSIT VMD displays its readings in parts per million per meter. This is a representation of the average gas

concentration over 1 meter, or roughly 3.3 feet. Many types of IR and laser based technology in the industry uses this

standard. For implementations that are not fixed point, and have a variable path length, the unit used is ppmm (parts per

million meter). The difference being that the reading would be a factor of the total distance of the path length, which can

change as the size of the gas plume changes.

In the case of the VMD, the path length is fixed at slightly more than 1m, which is taken into account in the software, and we

therefore say the reading is “per meter”, meaning over the total length, since it never changes.

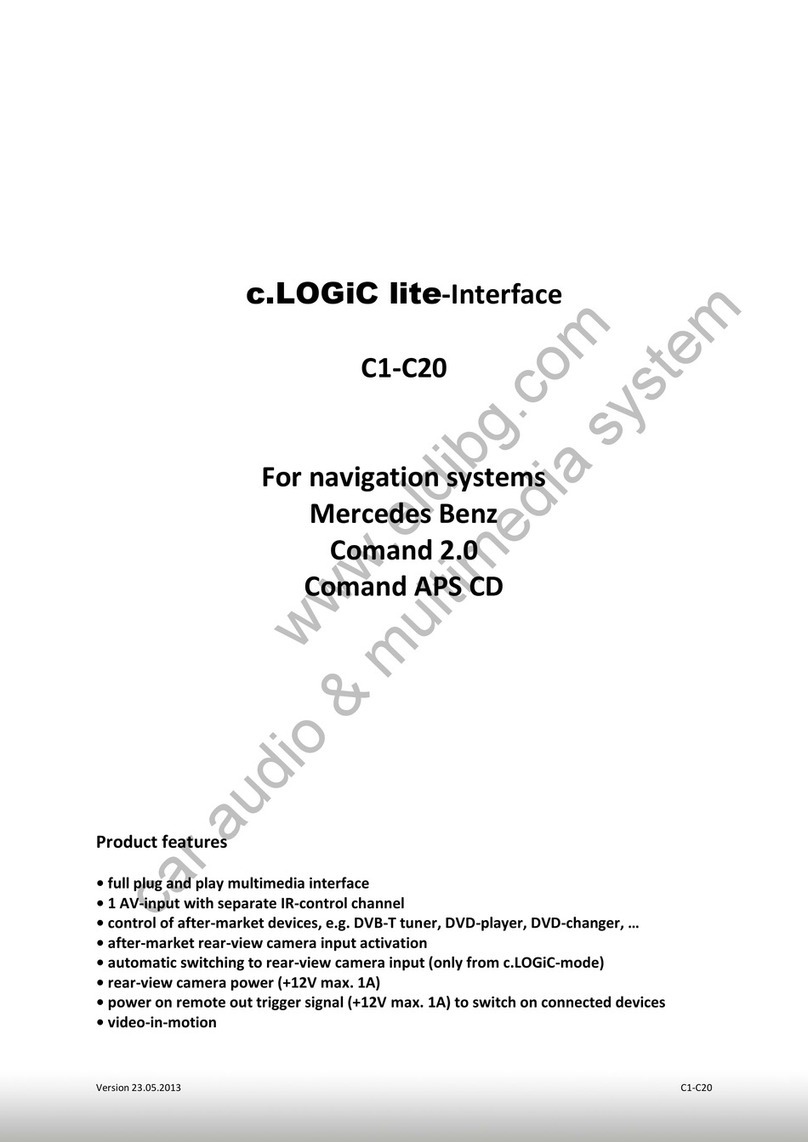

However, this reading is still essentially an average. For example, consider the following images:

On the left, there is a natural gas plume with a concentration of 40ppm, spanning 0.5m. On the right, there is a plume with

a concentration of 80ppm, spanning 0.25m. Both of these scenarios will yield the same reading of 20ppm/m. The plume

on the right is double the concentration, but half the distance, meaning the average concentration over the path length will

remain the same.

~1 meter

0.5 meter

40ppm

0.25 meter

80ppm

8

INSTALLATION

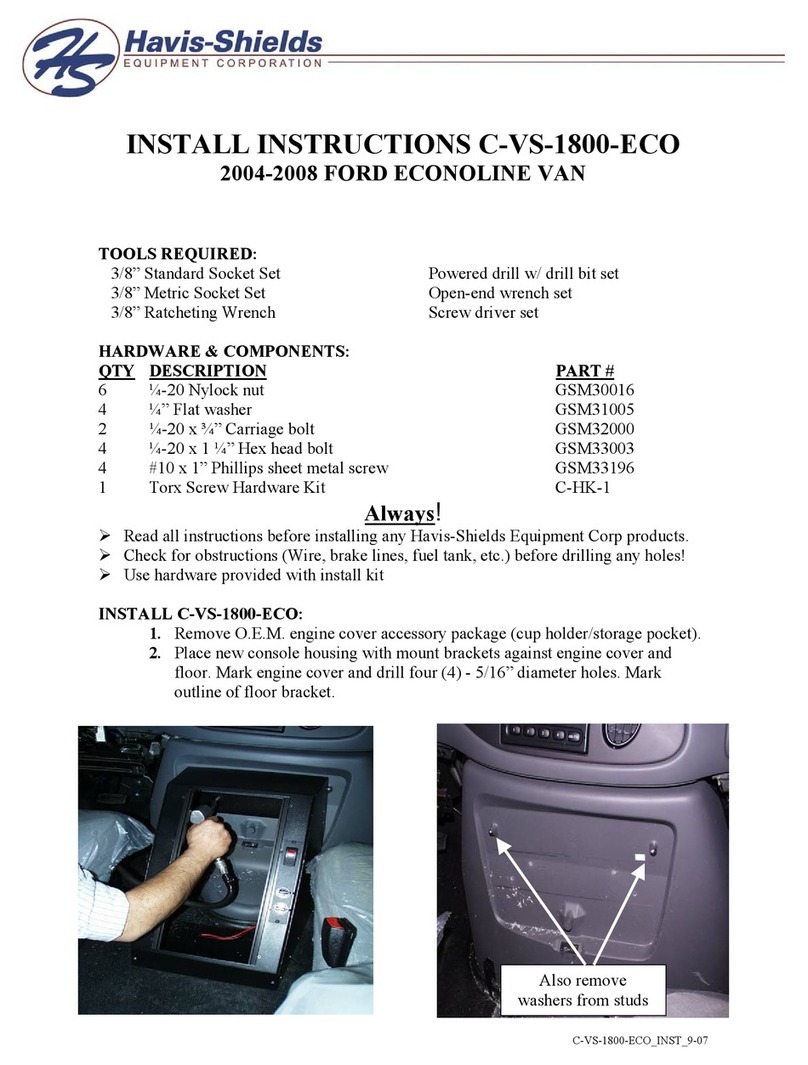

INSTALL VMD INSTRUMENT

1. Install a 2” front-mount hitch on the front of the vehicle. If a bolt on hitch cannot be sourced, a local welding shop should

be able to mount one for you as pictured below.

2. Insert the short end of the L-bracket into the hitch with the long side facing up. There are several adjustment holes for

distance in and out from the bumper. Insert the pin and install and tighten the hitch stabilizer. The hitch stabilizer

tightens the L-bracket to the hitch, and therefore the frame of the vehicle. This ensures that no extra vibrations are

transferred to the VMD.

9

INSTALLATION

3. Ensure that the jam bolt is backed out from the

bracket that is mounted to the VMD. Slide the

VMD and mounting bracket over the L-bracket,

lower the VMD to the desired position, and insert

the pin. Tighten the jam bolt. It is recommended

to use an anti-seize compound on the jam bolt.

4. Install the power harness assembly.

a. Route the power harness through the grill

and engine compartment to the battery. The

harness is 10ft long and should have some

slack left over.

b. The battery end of the power harness has two exposed wires, red for the positive terminal of the battery and black

for negative. Secure these wires to the battery. One method is to use crimp-on ring terminals that can then be

bolted to the battery terminals.

c. Plug in the power connector to the VMD.

d. It is recommended to use dielectric grease on

all connections to prevent corrosion.

10

INSTALLATION

INSTALL TABLET COMPUTER

There are various methods for mounting the tablet computer. There is not a universal mounting system that will fit all

vehicles, and therefore Sensit does not provide a full tablet mounting solution. What is provided is a ball-joint bracket and

mounting arm. The ball-joint and mounting arm can be attached to the back of the tablet with the provided hardware. The

arm can then be secured to a pole that is mounted in the cab of the vehicle (not provided). On an ATV or utility vehicle

application, there will usually be a roll bar or other similar structure that the arm can be attached to.

Alternatively, after market computer/tablet mounts are available from a variety of vendors. Most commonly, these will use

an arm or adjustable pole that will bolt to the front-passenger seat mounting points. This can either be the full solution

(which will mount to the tablet) or can sometimes be used in conjunction with the provided ball-joint and arm.

If you need assistance with this, contact SENSIT Technologies.

11

INSTALLATION

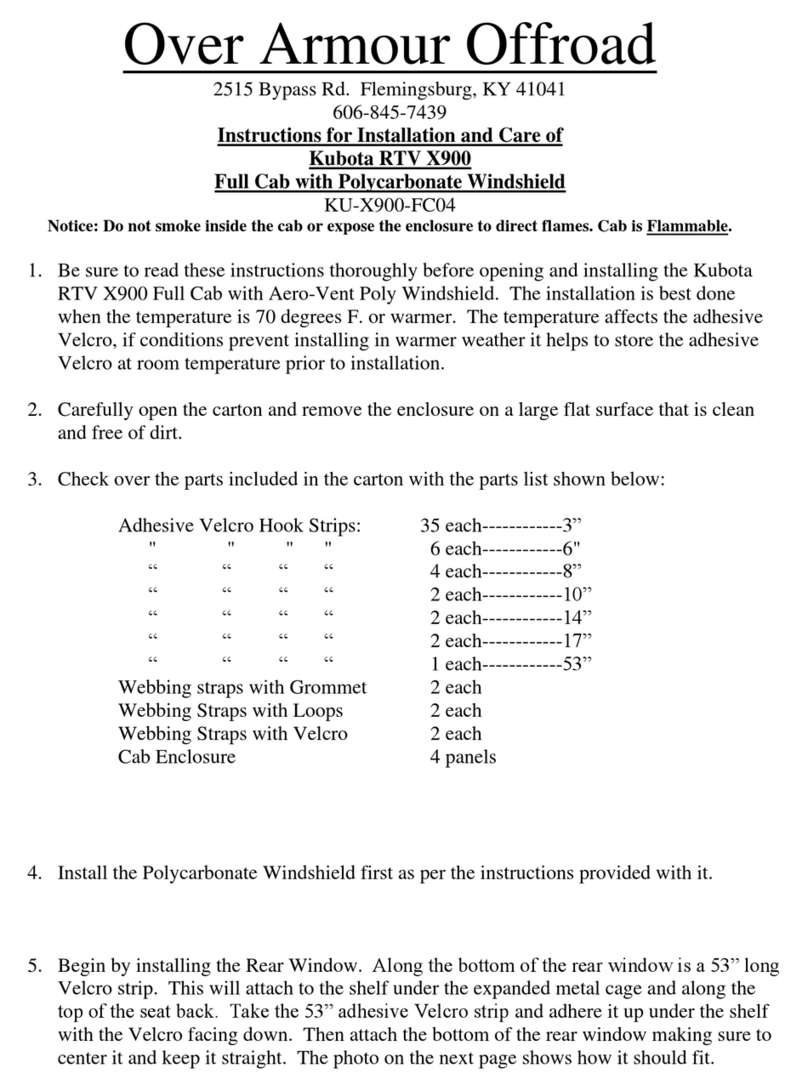

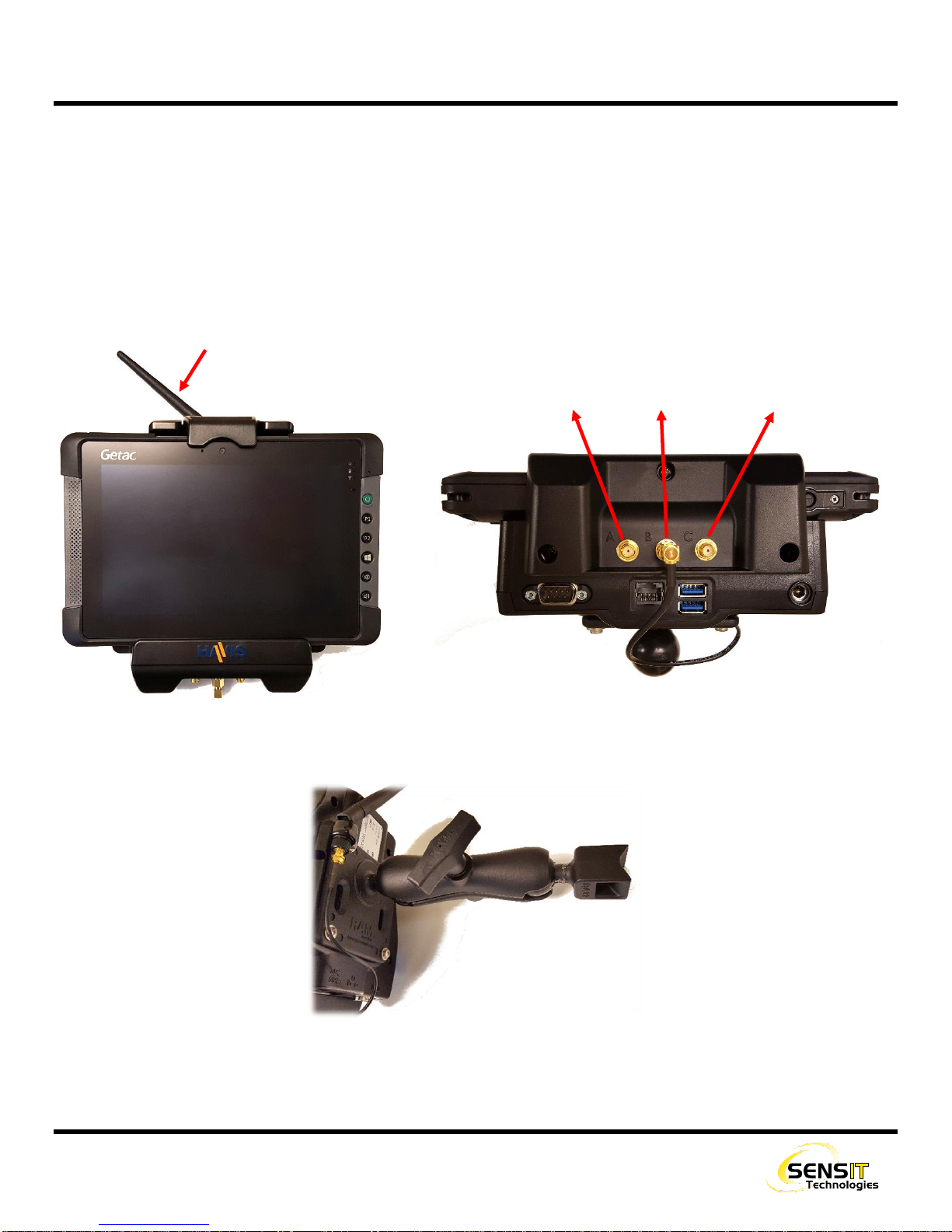

GETAC TABLET CONNECTIONS

The provided tablet for the SENSIT VMD is the Getac T800. Also provided is a dock for the tablet, which has pass-through

connections for the Bluetooth and GPS signals. The antennas for each is attached to SMA connectors on the bottom of the

dock. The Bluetooth antenna (8”) will most likely be pre-installed. The GPS antenna has a magnetic puck with 10 feet of

cable and will need to be installed by the user.

Refer to the picture below for a description of each connection. Also shown is the provided mounting arm.

A: GPS B: BLUETOOTH C: WIFI (NOT USED)

BLUETOOTH ANTENNA

12

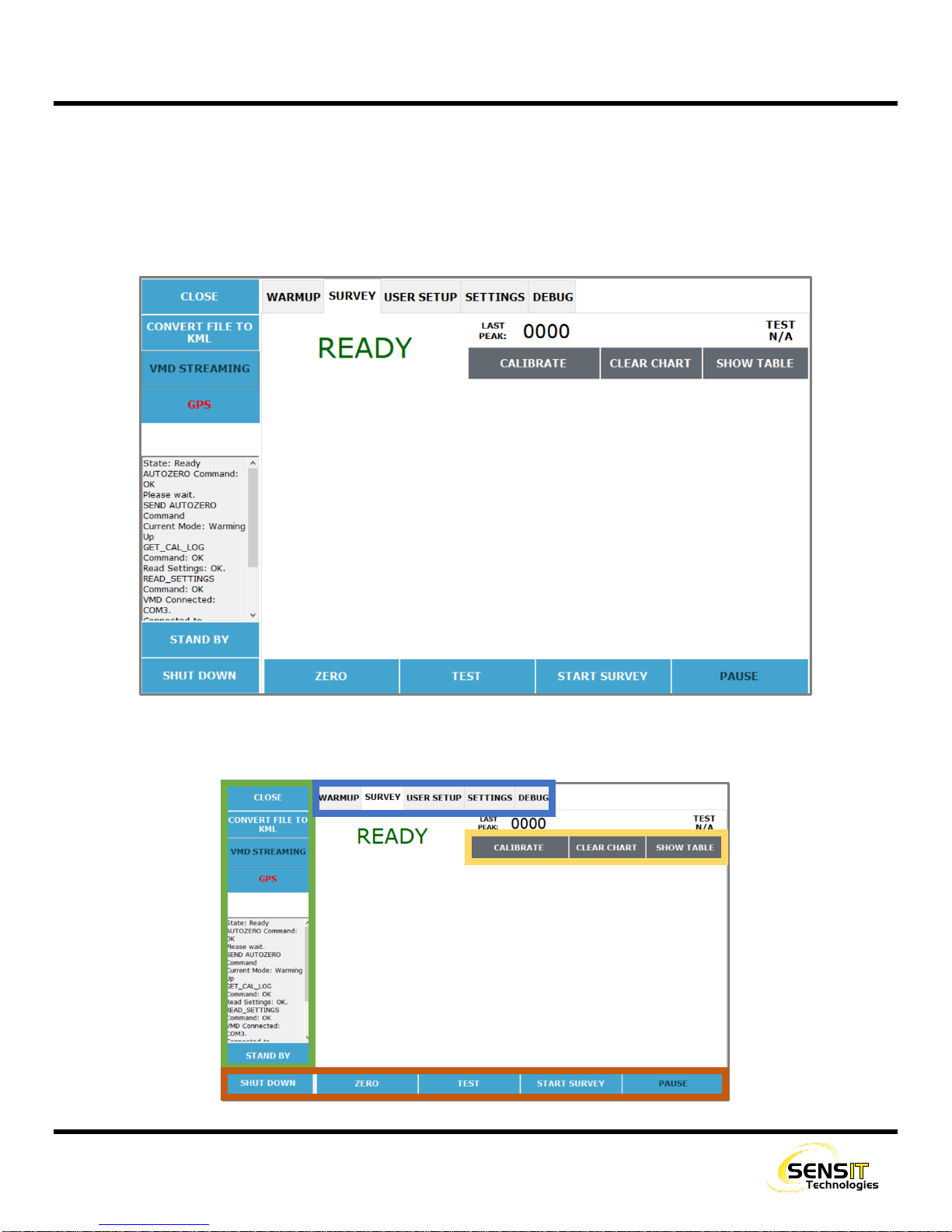

USER INTERFACE

The user interface of the SENSIT VMD is controlled by a tablet computer with a touch screen. The instrument streams all

data over Bluetooth to the tablet, where it is displayed in real time (200ms sample time).

The majority of the screen is reserved for survey data to be displayed. The bottom and left parts of the screen have

command buttons that can be used as needed. The top part of the screen has tabs for various display modes and menus.

Refer to the image below and descriptions on the next page for how each of these buttons are used.

13

USER INTERFACE

DESCRIPTION OF INTERFACE BUTTONS

Main Function buttons (bottom of screen):

1. POWER_ON_/_SHUT_DOWN

Shuts off the VMD. Does not close the application or

shut off the tablet.

2. ZERO

Sets a new zero baseline for the current survey (or

next survey). Does not alter the calibration or

sensitivity of the instrument.

3. TEST

Performs a self-test function of the instrument. A cell

with a known concentration of gas inside the

instrument is inserted into the detecting path. The

VMD detects this gas and shows the operator a

reading, as well as a test pass/fail indication.

4. START/STOP_SURVEY

Starts or stops a survey. No readings will be

displayed or recorded if a survey isn’t running. The

user will be prompted when starting a survey to either

save data to the previous log file or start a new one

(unless logging is disabled). Survey must be stopped

to calibrate the instrument.

5. PAUSE/RESUME

Pauses and resumes the survey instead of starting

and stopping. This will assume the user wants to

continue with the previous log file. Also used to

resume the survey if it gets interrupted due to low

light.

Function Buttons (left side of screen)

1. CLOSE

Closes the application but does not shut off the VMD.

This allows the user to bypass the warmup period if

the application is opened again. When used, a

timeout period of 10 minutes begins, after which the

VMD will be powered off. This is useful if the user

needs to access some other part of the operating

system, but wants to resume surveying afterwards.

2. CONVERT_FILE_TO_KML

Menu for converting a datalog file to ‘.kml’ file format

instead of ‘.csv’. ‘.kml’ files are used for viewing data

with a mapping/GIS application, such as Google

Earth. GPS data is required in order for a file to be

converted.

3. VMD/PMD_STREAMING

Status/indication icon for state of any streaming

options that are enabled.

4. GPS

Status/indication for GPS functionality. If no GPS

signal is available, the GPS text will be red and the

white box below it will be empty. If a GPS signal is

available, the GPS text will be green and the

coordinates will be displayed below.

5. STAND_BY

Puts the instrument in a low power state. User must

wait 120 seconds before use when it is woken up.

14

USER INTERFACE

Display modes / menu tabs (top of screen):

1. NORMAL/WARMUP

Initial startup and warmup screen. Only shown after

first power on and while the instrument is warming up.

Outputs basic sensor information. The user does not

need to interact with the instrument during this

process.

2. SURVEY

Main operation mode for use of the instrument. From

this mode the user can start and stop surveys, use

the self-test function, calibrate the instrument, etc.

For more information, see the sections on operation

and calibration.

3. USER_SETUP

Contains settings and configuration options that are

available to the user at any time. Alarm settings,

calibration logs, Bluetooth streaming, etc. For more

information, see the following section.

4. SETTINGS

Password protected settings menu that contains

factory level adjustments.

5. DEBUG

Password protected menu that outputs debug

information. Only used for troubleshooting purposes.

Other buttons (upper right of screen):

1. CALIBRATE

Starts the calibration process. The user will be

prompted to place the calibration cell on the

instrument. Calibration takes less than a minute. See

the calibration section for more information.

2. CLEAR_CHART

Clears the current information on the screen. This is

only visual and does not restart the survey or remove

any data from the log.

3. SHOW_TABLE/SHOW_GRAPH

Switches between displaying survey information with

a graph and with a table. The graph (default) has a

visual representation of the readings in the form of a

timeline, and is generally preferred.

15

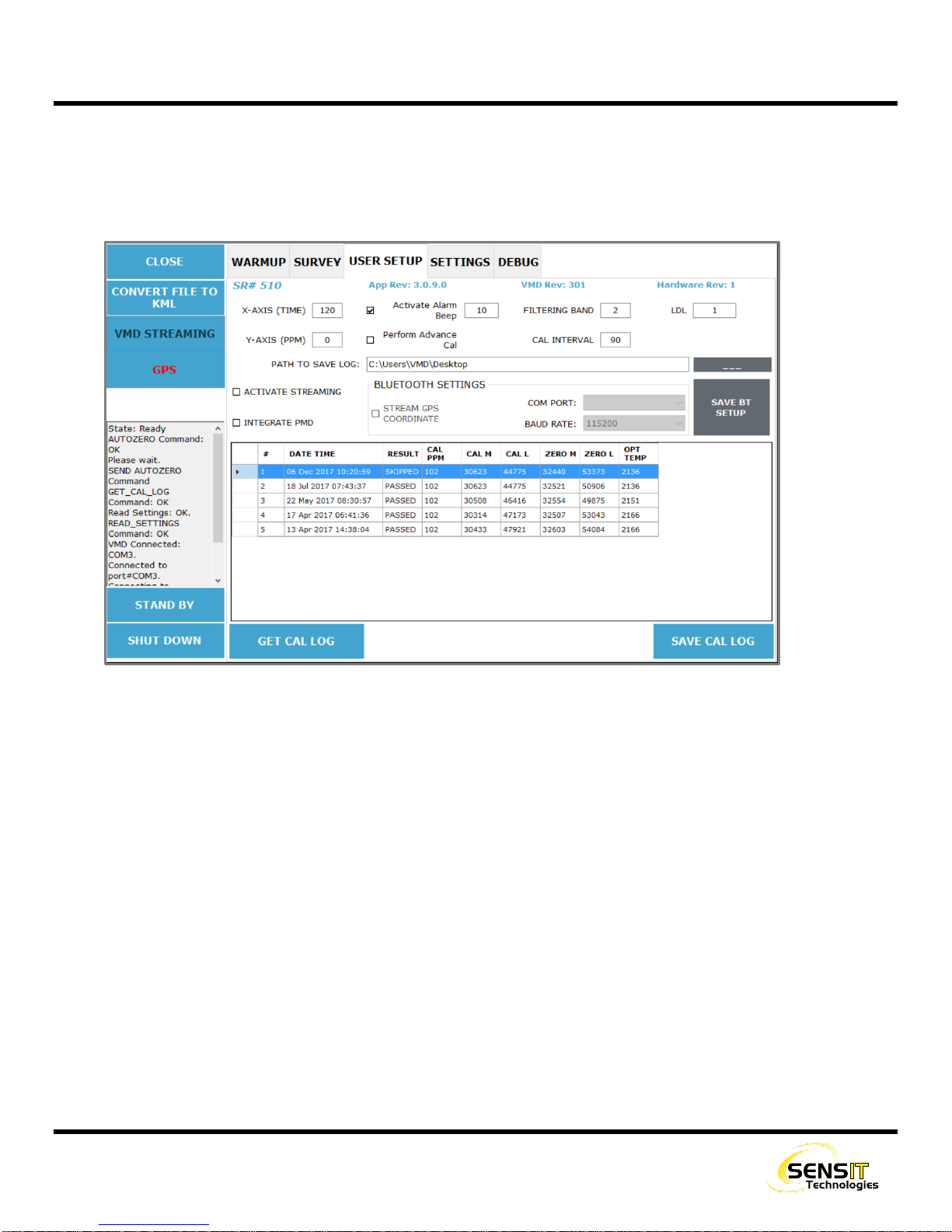

USER INTERFACE

USER SETUP TAB

The user setup tab contains settings and configuration options that are available to the user at anytime, as well as calibration

information. It is accessed by selecting the user setup tab from the top of the screen. The survey must be stopped in order

to access it.

From this menu, the user can:

Change the graph settings for time displayed on the X axis (default 120 seconds) and PPM range displayed on the Y

axis (default 0).

oFor the PPM setting, 0 means that there is no limit and the display will auto-range. Using another value will

fix the Y axis to that value and it will not adjust.

Change the alarm set point (default 10).

Change the Calibration Interval (default 90 days).

Setup Bluetooth streaming and/or PMD Bluetooth settings

View and export calibration data

16

OPERATION AND USE

WARNING: Always start any SENSIT VMD in a gas free environment to ensure a proper zero.

1. Activate the computer by pressing the button located on the lower right hand side of the housing. The system will boot

up.

a. If the VMD application does not automatically begin, double click the icon on the desktop screen.

2. Click power on to begin the warmup process, which will take approximately 8-12 minutes.

a. The graph and chart on the screen will show various diagnostic information during the warmup process, such as

the light level, sensor output, and internal temperature. This information is only pertinent for troubleshooting

purposes.

3. After the WARM UP and AUTOZERO complete, the display will show ready in the survey mode. READY should be

displayed in the upper left of the screen.

a. If the AUTOZERO failed, ZERO FAIL will be displayed. Please check that nothing is obstructing the light path and

that there is no dirt or other debris on the lenses. Try manually performing a zero by pressing the ZERO (F2)

BUTTON.

4. Travel to the area where the survey will begin.

5. If necessary, lower the VMD from the transport position (higher on the L-bracket) to the survey position (lower on the L-

bracket). The L-bracket allows for a broad range of height adjustment. Adjust as needed and tighten the jam bolt. In

general, the survey position should be as low as possible on the L-bracket without any potential of collision.

6. Use the TEST (F3) BUTTON to do a self-test of the instrument.

a. A test can be performed at any time during a survey as well. It will be logged along with your survey as test data

(appears differently than survey data).

b. A TEST PASS or TEST FAIL message will be displayed in the upper right of the display after the test has completed.

c. If the test fails, perform a calibration. A failed test pauses the survey. You can restart the survey by using the

RESTART (F5) BUTTON.

7. Press the start SURVEY (F4) BUTTON to begin the survey.

a. The user will be prompted to choose to add onto the previous log file or being a new log file. This is useful if one

survey or route has to be completed over multiple sessions.

b. Live readings will appear on the screen. By default this is shown as a graph, but can be displayed as a table if

desired.

c. If readings exceed the alarm point (10ppm/m default), an audible and visual alarm will be triggered.

d. If at any time the light path is obstructed, the survey will stop and low light will be displayed along with an audible

tone and warning message. Check for obstructions in the light path or any dirt or other debris on the lenses. Try

to manually zero the instrument by pressing the ZERO (F2) BUTTON.

8. Press the STOP (F4) or PAUSE (F5) buttons as necessary to stop or pause the survey.

17

CALIBRATION

WARNING: Calibration must be performed in a gas-free environment. Calibration cycles over 90 days are not

recommended. Using calibration kits other than recommended by SENSIT TECHNOLOGIES may cause inaccurate

readings. Repairs are required if the instrument fails to calibrate. Consult the factory for details.

The SENSIT VMD is calibrated with an external calibration cell assembly, which contains a known concentration of gas

trapped between two plates of glass. Unlike calibrating a conventional CGI, this calibration process does not use a

consumable. By default, the calibration cycle of the SENSIT VMD is 30 days, but can be increased or decreased to match

your company policies. There is no harm in performing a calibration process as often as desired (even daily).

1. Power on the instrument and wait for the warmup process to complete.

a. If the instrument is already powered on, calibration cannot be done while a survey is running. The survey must

be STOPPED and not PAUSED.

2. Hang the calibration cell on the bar of the VMD, so that the light will pass through it, up against the housing of either

module. Tighten the thumbscrew.

3. On the tablet, select the calibrate button. A dialog box will appear asking you to place the calibration cell on the bar.

Select OK. The calibration process will begin.

4. In the upper left of the screen, the current reading will be displayed as it is adjusted during calibration. This should be

very close to 100ppm/m. Once calibration is successful, READY will be displayed.

a. If calibration failed, CAL FAIL will be displayed. Attempt calibration again. If calibration continues to fail, contact

Sensit Technologies Service Department for assistance.

NOTE:In certain scenarios, if calibration fails, the instrument may need to have an advanced calibration

performed. In this case, the user will be prompted to do so with a dialog box after a failed calibration.

18

ADVANCED CALIBRATION

WARNING: Calibration must be performed in a gas-free environment. Calibration cycles over 90 days are not

recommended. Using calibration kits other than recommended by SENSIT TECHNOLOGIES may cause inaccurate

readings. Repairs are required if the instrument fails to calibrate. Consult the factory for details.

Beginning with software revision 3.10(app)/3.02(firmware), advanced calibration is automatically be performed instead of

the normal calibration on a 90 day cycle. This process is described below.

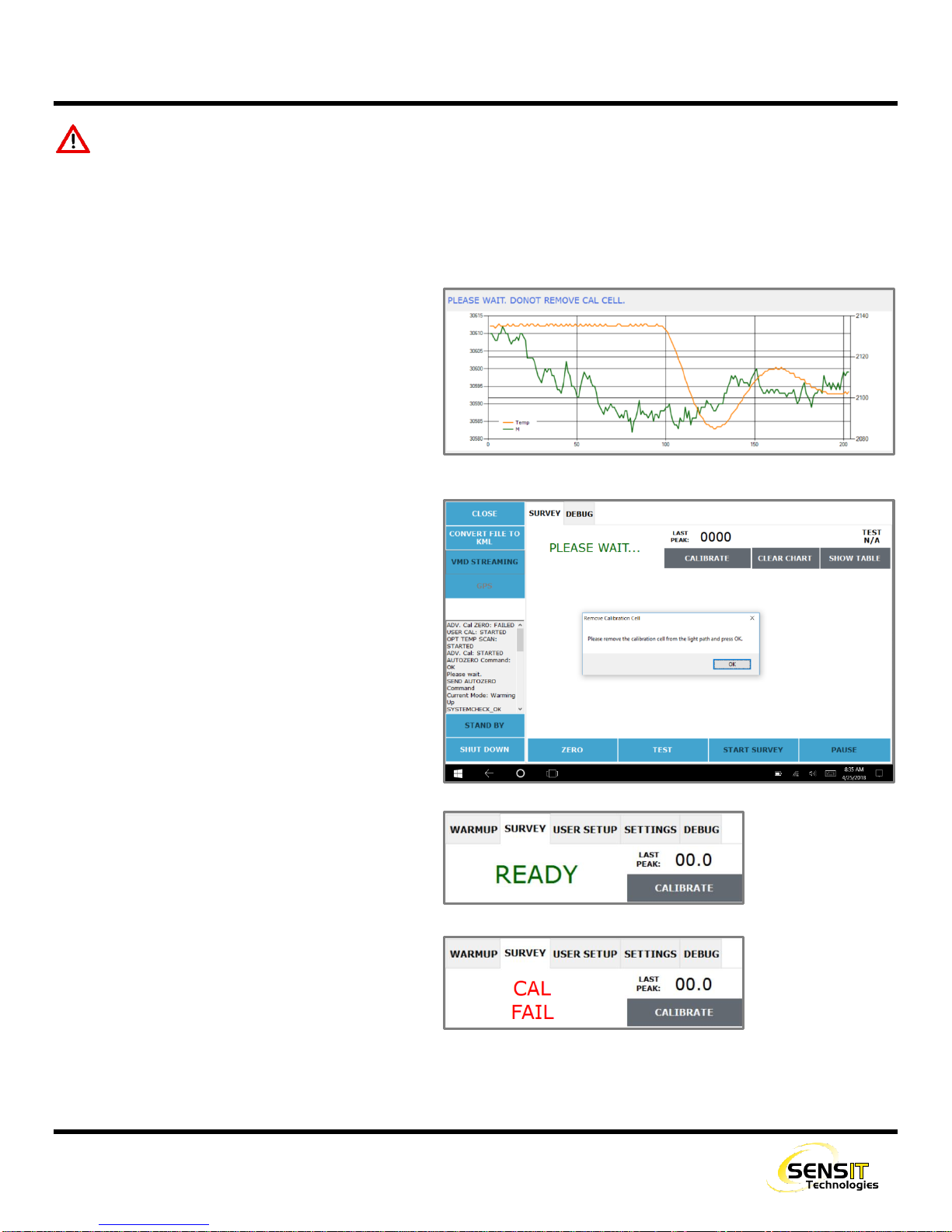

1. After the calibration has started, the display will

change to the Advanced Calibration screen. This

process will take between 2-5 minutes to

complete.

2. When the Advanced Calibration is done, the

display will return to the survey screen.

3. A “PLEASE WAIT…” message will be displayed.

The user will be asked to remove the calibration

cell so that a factory zero can be automatically

performed. Press “OK” after the cell has been

removed.

4. The “PLEASE WAIT…” message will continue to

display for a few seconds. Afterwards, the

calibration will be complete.

a. If calibration is successful, READY will be

displayed.

b. If calibration failed, CAL FAIL will be

displayed. Attempt calibration again. If

calibration continues to fail, contact Sensit

Technologies Service Department for

assistance.

19

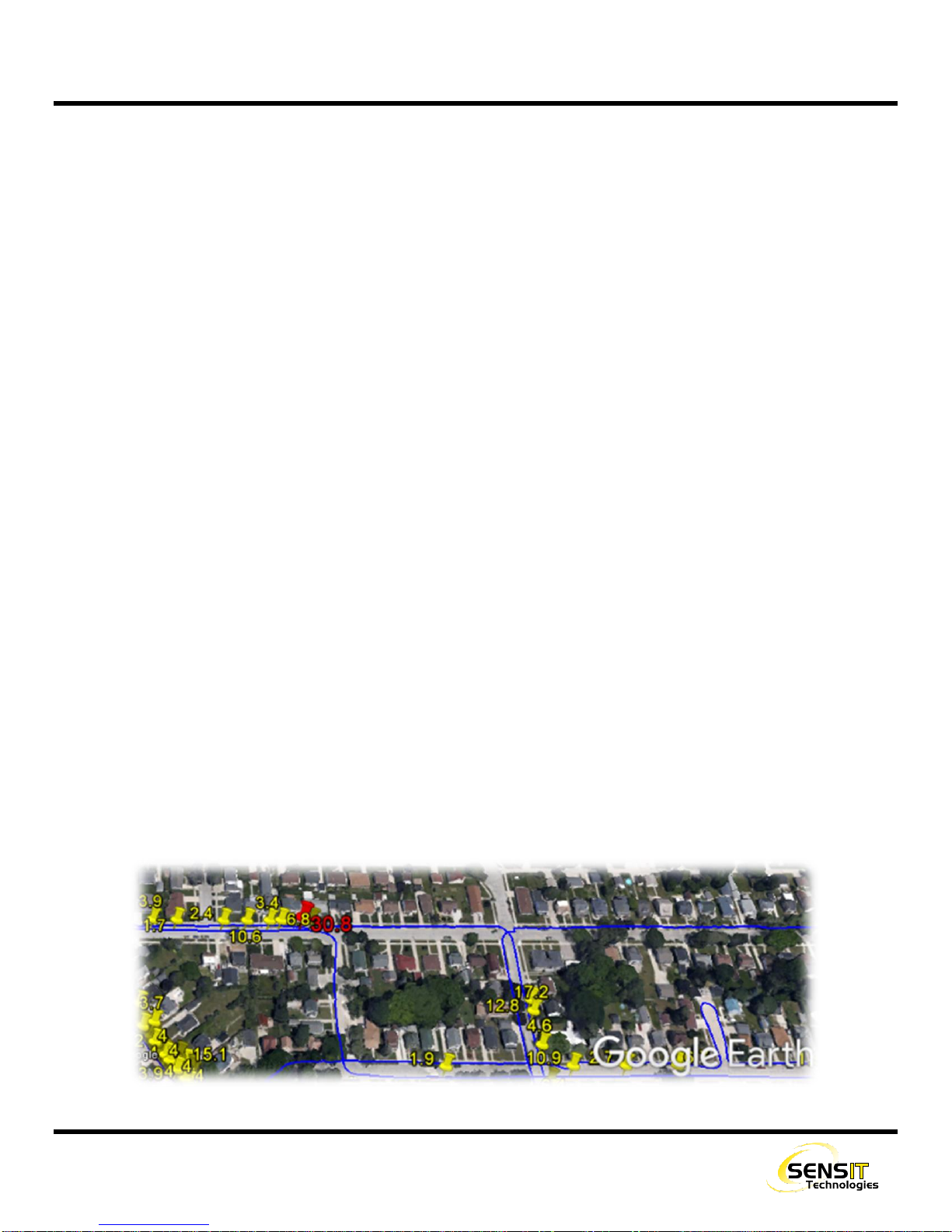

PLOTTING SURVEYS

The SENSIT VMD saves a data log file for every survey conducted. These files will contain the date, time, ppm/m reading,

and GPS coordinates if available. With valid GPS coordinates, these files can be converted to .kml format and viewed with

mapping software. This gives a breadcrumb trail for the route driven with the vehicle, including any readings found above

the chosen alarm points and any self-tests performed.

This section details how to convert these files, export them, and view them in Google Earth.

CONVERTING TO .KML AND EXPORTING

1. Power on the tablet computer. Allow it to fully boot and load the VMD application.

2. From the VMD application, select the CONVERT FILE TO KML from the upper left of the screen. The VMD does not have

to be powered on.

3. On the following screen, select SELECT FILE TO CONVERT. A file select window will appear.

4. Navigate to the location datalog file(s) that you want to convert. By default, the VMD will save log files to the desktop.

5. Select one or more files and hit OPEN. You will be returned to the previous screen.

6. Make any adjustments necessary to the pin assignments. Anything below the value chosen for the yellow pin will not

be shown on the map.

7. If you are planning to export right away to a flash drive, insert the drive now.

a. The USB port is on the right side of the tablet. Access it by pushing down the cover and lifting up.

8. Select CONVERT. A save window will appear.

a. If you get an error message, this means that one or more files you have chosen did not have valid GPS

coordinates. Any valid files in the selection can still be converted.

9. Navigate to the location that you would like to save the files to. If you are exporting to a flash drive, select the drive

from the list on the left.

10. Select save. A message will appear confirming that you have successfully created .kml file(s).

11. The .kml files can be opened directly into Google Earth to view the data.

20

PAIRING A PMD

The SENSIT VMD and PMD have the ability to be used as a paired system. In this case, the PMD will be used in conjunction

with a vacuum system, with cones on the front of the vehicle being drawn from with the aid of a powerful external pump.

Readings from the PMD can be streamed real time using Bluetooth to the VMD tablet, so that the user has information from

both instruments at the same time.

Additionally, this information can be logged, along with the GPS coordinates from both instruments, which can then be

mapped with Google Earth. This is especially advantageous for use cases where the vehicle will be stopped when a reading

is found, and the leak will be pinpointed using the PMD. That way, the path of the vehicle is shown as well as where the

walking survey was conducted to find the leak.

When ordered as a system, the SENSIT VMD and PMD will be shipped already paired from the factory. If for some reason

this needs to be done in the field, contact Sensit Technologies for assistance.

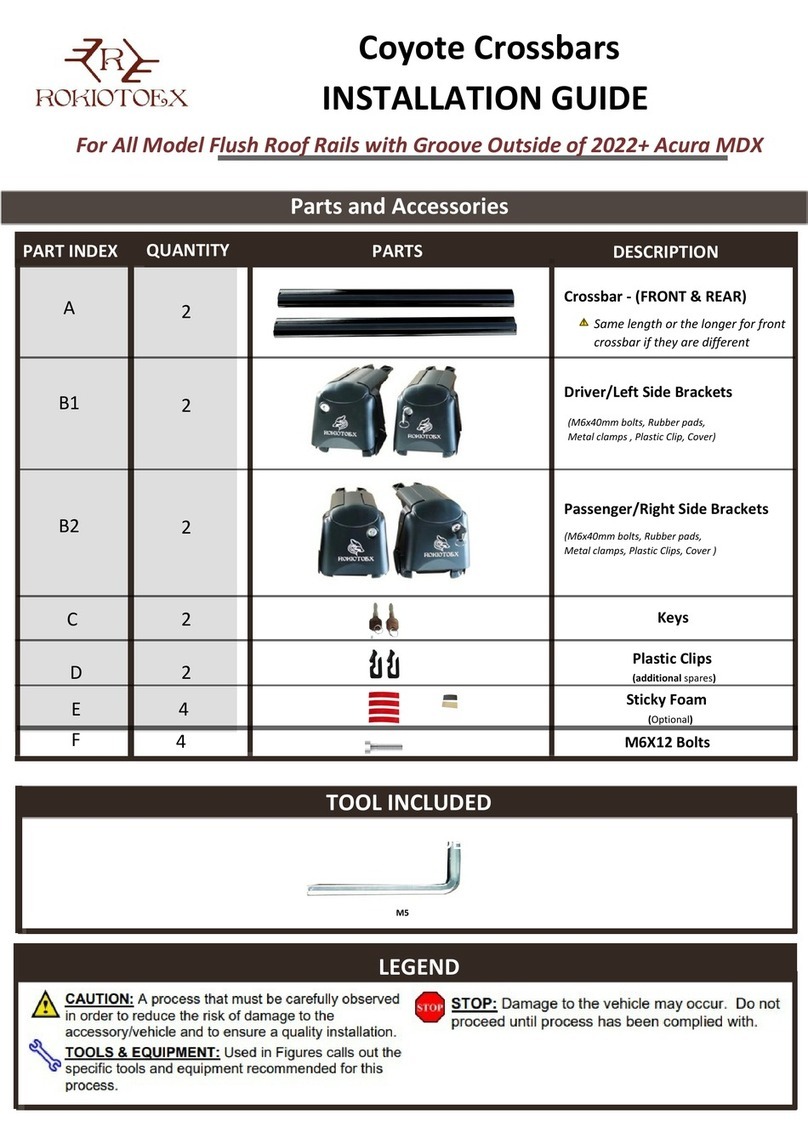

Other manuals for VMD

1

Table of contents

Popular Automobile Accessories manuals by other brands

ROKIOTOEX

ROKIOTOEX Coyote Crossbars installation guide

Carrier TRANSICOLD

Carrier TRANSICOLD Vector 8500 Operation & service manual

Bestop

Bestop HighRock 4x4 42950 installation instructions

Seat

Seat 5FJ.071.691 installation instructions

CAR-connect

CAR-connect VAS 671 001 operating manual

AMiO

AMiO BF Series user manual