Senso AK30 User manual

Instructions Manual

PROCESS INDICATORS

Manual ver 2.0 2

Manual ver 2.0 3

CONTENTS

1. INTRODUCTION 4

1.1 General specifications 4

1.2 Form of order 5

2. INSTALLATION 6

2.1 Preliminary aspects 6

2.2 Input and output configuration 7

2.3. Panel assembly 7

3. INPUTS / OUTPUTS 8

3.1 Signal input options. Examples. 8

3.2 Configuration of the different inputs 10

3.3 Alarms. 11

3.4 Serial Communications ( Optional ) 13

3.5 Auxiliary analogue output( Optional ) 14

4. OPERATION 16

4.1 Introduction 16

4.2 Description of the front 17

4.3 Starting 17

4.4 Loss of power supply 17

4.5 Automatic calibration of the pressure transducer 17

4.6 Tare function 18

4.7 Pressure transducer type 18

4.8 Display filtering function on presure measurement 18

4.9 Limits of the configurable parameters 19

4.10 Parameter configurable values and initial value 22

4.11 General menu diagram 25

4.12 Parameter protection 28

5 TECHNICAL SPECIFICATIONS 29

6 SPECIAL MESSAGES 31

Manual ver 2.0 4

1. INTRODUCTION

This instructions manual describes the installation and operation

of the universal process indicators AK30 and AK32 models.

Read the instructions manual before starting the

unit.

1.1. General specifications

The AK30 is a universal indicator with a configurable input. The

AK32 is a universal indicator with two inputs for the simultaneous

measurement of 2 variables, one configurable and the other for pressure

transducer reading.

Standard:

Totally configurable input for thermocouple, thermoresistance,

voltage, current loop, pressure reading or extensiometric gauge (only

AK30)

5 digit display (AK30) or double 5-digit display(AK32).

2 fully configurable alarms.

Optional:

Modbus RS-485 communications module.

Analogue output proportional to the reading on the indicator

24 V DC power supply for transmitter

Other:

Format: 1/8 DIN43700 (96 x 48 mm, horizontal). Extractable from the

front.

Power supply. 85..265 V AC 50/60 Hz (optionally 21..53 V AC / V DC)

Dimensions: 96 x 48 x 98 mm

Panel drill holes: 91,5 x 45,5 ( ±0,5 )

Display:

AK30:

5 digits 13 mm for the process variable.

Manual ver 2.0 5

2 alarm warning lights

AK32:

Double display 5 digits 10 mm, one for each process.

2 alarm warning lights

Alarms: 2 fully configurable alarms. SPST output( 1A@250 V AC )

Weight:

AK30: 220 g.

AK32: 240 g.

Inputs:

User-configurable as:

L : 0..600°C (Fe-CuNi, DIN43710)

J : 0..600°C (Fe-CuNi, IEC584)

K: 0..1200°C (NiCr-NiAl, IEC584)

N: 0..1200°C (NiCrSi-NiSi, IEC584)

T: 0..400°C (Cu-CuNi, IEC584)

R: 0..1600°C (Pt/13%Rh-Pt, IEC584)

S: 0..1600°C (Pt/10%Rh-Pt, IEC584)

RTD, Pt100: -200..600°C (IEC751)

RTD, Pt100: -99,9..200,0°C (IEC751)

Current loop 0..20 , 4..20 mA (load 150 ohm)

Voltage V DC 0..5 , 0..10 V (Impedance >1 Mohm)

Pressure transducer

Extensiometric gauge 350 ohm( only AK30 )

1.2. Form of order

Model Options Power supply Language

0: No options

1: Analogue output with

AK35

2: Standard

communications

Modbus/RS-485 with

AK36

3: 24 V DC power supply for

transmitter with AK37

1: 85..265 V AC, 50/60 Hz

2: 21..53 V AC / V DC

AK30 1 1

AK32 1 1

Manual ver 2.0 6

2. INSTALLATION

2.1. Preliminary aspects

The unit is connected with the instrument installed in its final

place of use. To avoid electrical discharges while connecting, connect

the instrument to the power supply in the last wiring operation. The

installation must include at least one 1ª, 250 V bipolar switch, which must

be close to the instrument and easily accessible for the operator. It must

be marked as an instrument switch. Likewise, a 200 mA, 250 V fuse must

be installed in the power supply wiring (isolation cable of at least 1000 V).

The following recommendations should be followed as far as

possible:

-The instrument must be connected in the absence of power supply.

-Do not install the instrument close to moving parts, contacts or

motor starters.

-Try to avoid mechanical vibrations.

-For the signal lines, it is recommendable to use a screened cable

with a ground connection at a single point.

-It is important to check the configuration of the instrument if any

problem appears in the starting.

Any installation or use of the instrument other than that specified

in this manual may affect the protection levels of the unit.

Power supply

Manual ver 2.0 7

2.2. Input and output configuration

The instruments of the are entirely configurable, so it is necessary

to make sure before starting that the configuration of the instrument

corresponds to the application for which it is intended.

Follow the steps in chapter 3 to change the configuration of the

input or sensor signal.

2.3. Panel assembly

The instrument must be installed in a panel with a maximum

thickness of 8 mm. Its location must be subject to as little vibration as

possible and it must be ensured that the ambient temperature remains

between 0 and 50ºC.

Insert the instrument in the panel hole and hold it firm while, with

a screwdriver, you tighten the fixing clips on the interior wall of the panel.

To install more than one instrument, a minimum separation must be left

between instruments of 10 mm vertically and 20 mm horizontally.

Manual ver 2.0 8

3. INPUTS / OUTPUTS

3.1. Signal input options.Examples.

This chapter diagrammatically describes the connection of the

different options for the input signal.

Thermocouple input connections

Thermosresistance input connections

Manual ver 2.0 9

Connection for the linear voltage input

Connection for the linear current input

Connection for the pressure transducer

input

Manual ver 2.0 10

Connection for the extensiometric

gauge input

3.2 Configuration of the different inputs

Each instrument is default configured for a type J input (Fe-

CuNi). It is possible to change the set-up of the type of input simply with

the INP parameter from the menu. In the AK32, the second channel

always shows the reading of the pressure transducer.

INP

Value

Meaning

0 J : 0..600°C (Fe-CuNi, IEC584)

1 L : 0..600°C (Fe-CuNi, DIN43710)

2 K: 0..1200°C (NiCr-NiAl, IEC584)

3 N: 0..1200°C (NiCrSi-NiSi, IEC584)

4 T: 0..400°C (Cu-CuNi, IEC584)

5 R: 0..1600°C (Pt/13%Rh-Pt, IEC584)

6 S: 0..1600°C (Pt/10%Rh-Pt, IEC584)

7 RTD, Pt100: -200..600°C (IEC751)

8 RTD, Pt100: -99,9..200,0°C (IEC751)

9 Voltage V DC 0..5 V (Impedance >1 Mohm)

10 Voltage V DC 0..10 V (Impedance >1 Mohm)

11 Current loop 0..20 mA (load 150 ohm)

12 Current loop 4..20 mA (load 150 ohm)

13 Pressure transducer ( only AK30 )

14 Extensiometric gauge 350 ohm( only AK30 )

Manual ver 2.0 11

3.3 Alarms.

The AK30 and AK32 include 2 alarms. In the case of the AK32,

these alarms may be associated independently with the required

channel using the Ch.A1 and Ch.A2 parameters. Channel 1 corresponds to

the configurable input and channel 2 to the pressure input. The alarm

output is by relay with SPST contacts (one voltage-free contact). The

alarm outputs are as follows:

The working configuration of the alarms is performed by means

of the C.A1 and C.A2 parameters.

1) Type of activation.

High Alarm: The alarm is activated when the process variable is

equal to or higher than the consignment point of the alarm. For

instance, if the consignment point of the alarm is at 450°C, the alarm

will remain on as long as the temperature is greater than or equal to

450ºC.

Low Alarm: The alarm is activated when the process variable is equal

to or lower than the consignment point of the alarm. For instance, if

the consignment point of the alarm is at 450°C, the alarm will remain

on as long as the temperature is lower than or equal to 450ºC.

2) Type of action.

Direct Action: The output relay is usually off and is activated when

the alarm activation condition is caused.

Manual ver 2.0 12

Inverse Action: The output relay is usually on and is deactivated

when the alarm activation condition is caused.

By combining the type of activation and the type of action, it is

possible to configure the following alarm operation modes:

Configuration C.A1/2Working mode

0 Alarm disabled

1 High alarm, direct action

2 High alarm, inverse action

3 Low alarm, direct action

4 Low alarm, inverse action

The alarm hysteresis can be set up using the HY.A1 or HY.A2 parameter. This

hysteresis is used so that an activated alarm is not deactivated until the margin

indicated from the consignment point has been exceeded. The following graphs

show the behaviour of a high and low alarm with hysteresis.

Hysteresis

with high

alarm

Alarm

deactivated

Alarm activated Alarm

deactivated

Hysteresis

with low

alarm

The activation of each alarm may be set up so that it is only

activated once the activation condition has been fulfilled for a period of

Manual ver 2.0 13

time of up to 20 seconds. This is achieved using the dLy.A1 and DLY.A2

parameters. If these parameters are 0, the activation is instantaneous.

Also included is a working mode where the alarm is kept off

while the alarm condition is not fulfilled (masked alarm). Once the alarm

condition is not fulfilled for the first time, the alarm works as normal. This is

useful when a low alarm is configured and we do not want it to be

activated until a working area has been entered. This working mode is

activated with the NAs.A1 and NAs.A2 parameters. Once activated, this

mode is entered without the instrument having to be turned on once

more. When the instrument is turned on again, this mode will be started.

The alarm deactivation may be set up as manual or automatic.

If an alarm is triggered with manual deactivation, it will not be

deactivated until the instrument is told explicitly. This configuration is

performed with the Lch.A1 and Lch.A2 parameters. To activate the alarm

manually, the and keys must be pressed simultaneously.

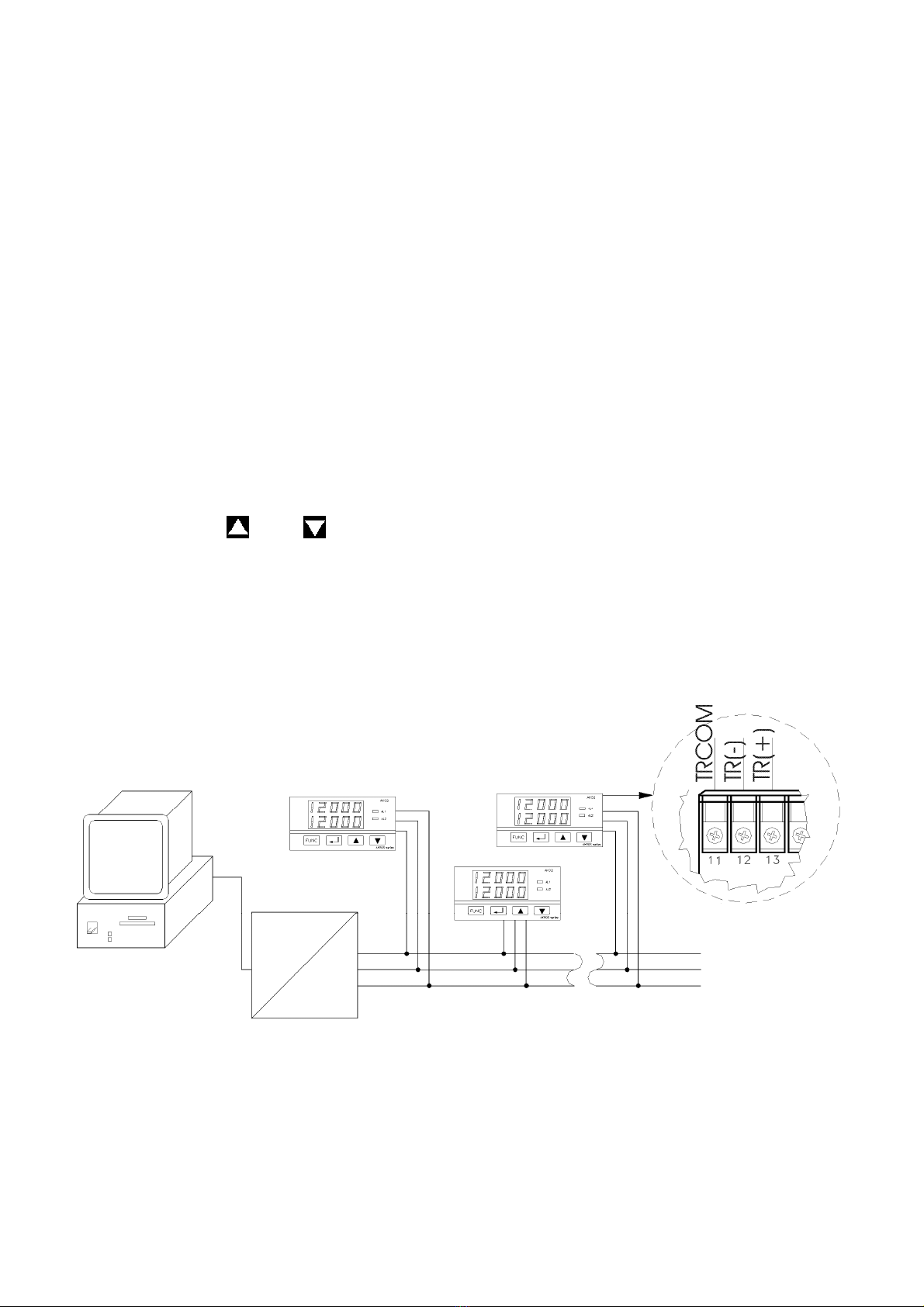

3.4 Serial Communications ( Optional )

The serial communications interface is RS485, 2 starnds + ground,

half duplex.Once installed, this interface is activated on assigning the Opt

parameter to 1.

There is a specific instructions manual for the interface and

communications protocol.

Manual ver 2.0 14

3.5 Auxiliary analogue output( Optional )

The auxiliary analogue output may be 0..20 mA, 4..20 mA, 0..5 V

or 0..10 V and the option must be configured both in the module

provided and in the indicator. Once installed, this interface is activated

on assigning the value 2( 0..20 mA ), 3( 4..20 mA ), 4( 0..5 V ) or 5( 0..10 V )

to the Opt parameter.

Once activated, the analogue output may be set up as direct

or inverse and the variation margin of the signal may also be set up by

the user.

Direct Output ( AOut.S = 1 )means that the value of the output signal

increases along with the process variable.

Inverse Output ( AOut.S = 0 )means that the value of the output signal

falls as the process variable increases.

Likewise, it is possible to set up the minimum ( AOut.L ) and

maximum ( AOut.H ) value of the process variable between which the

analogue output will vary between its minimum and maximum.

For example, an instrument with a type J thermocouple input

has a scale of 0..600°C. If this instrument has an analogue output of 4..20

mA, it is possible to set up AOut.L = 100°C and AOut.H = 500°C with which

the analogue output will take the following values:

Process (°C) Direct

Analogue

Output (mA)

Inverse

Analogue

Output (mA)

0 4,0 20,0

100 4,0 20,0

200 8,0 16,0

300 12,0 12,0

400 16,0 8,0

500 20,0 4,0

600 20,0 4,0

Manual ver 2.0 15

In the Ak32, it is possible to set the channel associated to the

digital output by means of the Set.Ch parameter. Channel 1 corresponds

to the configurable input and channel 2 corresponds to the pressure

input.

Manual ver 2.0 16

4. OPERATION

4.1 Introduction

The indicators may be completely set up by means of a series of

parameters accessible from a menu. The availability of some parameters

depends on the current set-up of the instrument and the model. Point 4.7

describes all the configurable parameters and point 4.9 graphically

displays the route necessary to access each of the parameters.

The operation of the menus is controlled by means of 4 keys with

the following function:

: Function key. It is used to enter the menu or to pass to the

following parameter if we are already in this menu.

: It serves to increase the value of a parameter. If it is held

down, every 10 increments the speed of the increase rises. In the

case of an AK30 set up as an extensiometric reader, if it is held

down for 3 seconds from outside the menu, the value of the

current reading is taken as a Tare. When the instrument is

applying a tare, this is indicated by means of a point that flashes

on the last digit.

: It serves to decrease the value of a parameter. If it is held

down, every 10 decreases the speed of the decrease rises. In

the case of an AK30 set up as an extensiometric reader, if it is

held down for 3 seconds from outside the menu, the value of the

Tare is eliminated.

: Confirmation key. This must be pressed each time a change

made to a parameter is to be confirmed. The instrument will

flash to indicate that the parameter has been saved. All of the

parameters that depend on the modified parameter are

updated in order to be consistent. If it is held down in an AK30

set up as a pressure transducer reader or in an AK32, we enter

the automatic transducer calibration mode. At the end of this

mode, confirmation is requested of the new calibration.

Manual ver 2.0 17

4.2 Description of the front

In addition to the front keys described in the previous aside,

there are 2 alarm warning lights labelled as AL1 and AL2.

4.3 Starting

On connecting the power supply, the instrument shows the

message tESt moving through the displays while all the internal

parameters are started.

4.4 Loss of power supply

All of the working parameters of the instrument are stored in an

internal memory. When the power supply returns, it will return to the

operating mode in which it was before.

4.5 Automatic calibration of the pressure transducer

This indicator has an automatic self-calibration function for

pressure transducers that enable this. In the AK-32, this function is always

available, whereas in the AK-30 it is only available when the input probe

is set up as a pressure transducer InP = 13 ).

To activate the self-calibration, the must be held down for 3

seconds. Firstly, the zero value of the transducer is calibrated, and then

the value of 80% of the scale base. If the transducer is subject to pressure

when the zero value is calibrated, the calibration will not be correct.

At the end of the self-calibration, the message SAUE appears if

the measurements taken are correct. By pressing the new calibration

is confirmed, whereas by pressing , it is discarded. If the

measurement taken in the zero and that taken at 80% of the scale base

are not correct, the FAiL message appears.

Manual ver 2.0 18

4.6 Tare function (only available in AK-30 using an

extensiometric gauge)

This indicator allows a tare to be added to the measurement

when it is set up with a gauge input. To activate a new tare, hold down

the key. Once activated, the tAr.On message appears and the

decimal point of the last digit flashes, indicating that the indicator is

adjusted. To deactivate the tare, press the key for 3 seconds. On

deactivating it, the tAr.Of message appears.

4.7 Pressure transducer type

The tyPE parameter let you cose between 3 different pressure

transducer types with different input margins and auto-calibration

options. The following table shows the meaning of the different values

from tyPE.

tyPE Meaning

0 Pressure transducer with

input margin from -3 mV to

37 mV and auto-calibration

of 0 and 80%

1 Pressure transducer with

input margin from 0 mV to

100 mV and auto-

calibration of 0 and 80%

2 Pressure transducer with

input margin from 0 mV to

100 mV and auto-

calibration of 0%

4.8 Display filtering function on presure measurement

Setting the Filtr parameter to 1 activates filtering the value

shown in the display when measuring pressure. The objective of this filter

is to make the displayed measure more stable when working on fast

changing enviroments. The filter only affects to the displayed

measurement, that is, other functions still use the real measured

signal(alarm activation, analog output,…).

Manual ver 2.0 19

4.9 Límites de los parámetros configurables

SP.A1 Alarm consignment point 1

Minimum value:

Probe selected Value

Thermocouple Minimum probe value

Thermoresistance Minimum probe value

Linear input( V o mA ) in.L parameter

Pressure transducer -10% scale base

Extensiometric gauge (AK30) 0

Maximum value:

Probe selected Valor

Thermocouple Maximum probe value

Thermoresistance Maximum probe value

Linear input( V o mA ) in.H parameter

Pressure transducer FSV

Extensiometric gauge(AK30) FSV

SP.A2 Alarm consignment point 2

Minimum value:

Probe selected Value

Thermocouple Minimum probe value

Thermorresistance Minimum probe value

Linear input( V o mA ) in.L parameter

Pressure transducer -10% scale base

Extensiometric gauge(AK30) 0

Maximum value:

Probe selected Value

Thermocouple Maximum probe value

Thermorresistance Maximum probe value

Linear input( V o mA ) in.H parameter

Pressure transducer FSV

Extensiometric gauge(AK30) FSV

C.A1 Alarm configuration 1

Minimum value: 0

Maximum value: 4

C.A2 Alarm configuration 2

Minimum value: 0

Maximum value: 4

Hy.A1 Alarm hysteresis 1(only visible if C.A1 ≠0 )

Minimum value: 0

Maximum

value:

If alarm configured low SP.A1 – Probe Low Limit

If alarm configured high Probe High Limit – SP.A1

Hy.A2

Alarm hysteresis 1(only visible if C.A2 ≠0 )

Minimum value: 0

Maximum

value:

If alarm configured low SP.A1 – Probe Low Limit

If alarm configured high Probe High Limit – SP.A1

Manual ver 2.0 20

Ch.A1 Alarm channel 1 ( only visible in AK32 if C.A1 ≠0 )

Minimum value: 1

Maximum value: 2

Ch.A2 Alarm channel 2 ( only visible in AK32 if C.A2 ≠0 )

Minimum value: 1

Maximum value: 2

Mas.A1 Alarm mask 1 ( only visible if C.A1 ≠0 )

Minimum value: 0

Maximum value: 1

Mas.A2 Alarm mask 2 ( only visible if C.A2 ≠0 )

Minimum value: 0

Maximum value: 1

dLy.A1 Alarm wait 1 ( only visible if C.A1 ≠0 )

Minimum value: 0

Maximum value: 300

dLy.A2 Alarm wait 2 ( only visible if C.A2 ≠0 )

Minimum value: 0

Maximum value: 300

Lch.A1 Alarm manual deactivation 1 ( only visible if C.A1 ≠0 )

Minimum value: 0

Maximum value: 1

Lch.A2 Alarm manual deactivation 2 ( only visible if C.A2 ≠0 )

Minimum value: 0

Maximum value: 1

Bias1 Channel bias 1

Minimum value: -9999

Maximum value: 99999

Bias2 Channel bias 2(only visible in AK32)

Minimum value: -9999

Maximum value: 99999

INP Channel input probe 1

Minimum value: 0

Maximum value:

14 in AK30

12 in AK32

Unit Unit ( only visible if INP <= 8 )

Minimum value: 0

Maximum value: 1

Dp Position of the decimal point ( only visible if INP >= 9 )

Minimum value: 0

Maximum value: 3

in.L A lower value for the scale of linear signal inputs ( only visible

if INP = 9, 10, 11, 12 )

Minimum value: -9999

Maximum value: In.H -1

in.H

A higher value for the scale of linear signal inputs ( only visible

if INP = 9, 10, 11, 12 )

Minimum value: in.L + 1

Maximum value: 99999

This manual suits for next models

1

Table of contents

Other Senso Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Anritsu

Anritsu 11 Series Operating and maintenance manual

az-instrument

az-instrument AZ8903 Operation manual

Masibus

Masibus PM2160-A user manual

KROHNE

KROHNE GA24 Supplementary instructions

Endress+Hauser

Endress+Hauser Waterpilot FMX11 operating instructions

Burster

Burster RESISTOMAT 2329 Operation manual