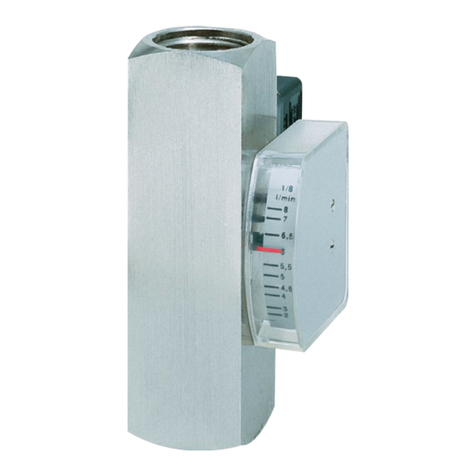

Models:

Nominal size: housing diameter 160 or 250 mm

Materials:

PMR06.x.M: stainless steel housing 1.4301,

brass of copper alloy,

from 100 bar st. steel, brass

connection

PMR06.x.E: stainless steel housing 1.4301,

stainless steel measuring element

and connection 1.4571

Process connection: G 1/2 or 1/2" NPT bottom or back

Vibration damping: optional glycerine filling

Measuring Ranges:

Measuring

range

bar]

Order code

For all nominal sizes not for

NG 250

-1200...0

mbar A17 B17 C17 D17 E17 F17

-1...0 A16 B16 C16 D16 E16 F16

-0,6...+1,0 A18 B18 C18 D18 E18 F18

-1...+0,6 A42 B42 C42 D42 E42 F42

-1...+1,5 A43 B43 C43 D43 E43 F43

-1...+3 A44 B44 C44 D44 E44 F44

-1...+5 A45 B45 C45 D45 E45 F45

-1...+9 A46 B46 C46 D46 E46 F46

-1...+15 A49 B49 C49 D49 E49 F49

0,2...1 A50 B50 C50 D50 E50 F50

0...0,6 A67 B67 C67 D67 E67 F67

0...1 A69 B69 C69 D69 E69 F69

0...1,6 A70 B70 C70 D70 E70 F70

0...2,5 A72 B72 C72 D72 E72 F72

0...4 A73 B73 C73 D73 E73 F73

0...6 A74 B74 C74 D74 E74 F74

0...10 A75 B75 C75 D75 E75 F75

0...16 A76 B76 C76 D76 E76 F76

0...25 A78 B78 C78 D78 E78 F78

0...40 A79 B79 C79 D79 E79 F79

0...60 A80 B80 C80 D80 E80 F80

0...100 A81 B81 C81 D81 E81 F81

0...160 A82 B82 C82 D82 E82 F82

0...250 A84 B84 C84 D84 E84 F84

0...400 A86 B86 C86 D86 E86 F86

0...600 A87 B87 C87 D87 E87 F87

0...1000 A88 B88 C88 D88 E88 F88

0...1600 A89 B89 C89 D89 E89 F89

Order Code:

Order number: PMR06.

Precision bourdon tube pressure

gauge

16. M. 1. 0. A75. 0. 0

Models:

16 = 160 mm

25 = 250 mm

Materials:

M = housing stainless steel,

connection brass

E = housing stainless steel,

connection stainless steel

S = special material

(please specify in plain text)

Process connection:

1 = G 1/2 bottom

2 = G 1/2 eccentric back

3 = 1/2" NPT bottom

4 = 1/2" NPT eccentric back

9 = special connection

Vibration damping:

0 = without

1 = with glycerine filling

Design and measuring ranges:

A17…F89 = see table “Measuring Ranges”

Additional electrical equipment:

0 = without

Options and accessories (multiple selection possible)

0 = without

xx = see table „Options and Accessories"

Technical Data:

Housing: round stainless steel housing,

d = 160 or 250 mm

protection class IP45

Liquid-filled version: glycerine filling with pressure relief

opening and internal pressure

e ualization, protection class IP65

Stainless steel

version:

with pressure relief opening (optional

for increased safety with break-proof

partition wall and blow-out rear wall)

Measuring element:

PMR06.xx.M: bourdon tube, up to 60 bar copper

alloy, soft-soldered, from 100 bar

stainless steel 1.4571, hard soldered

PMR06.xx.E: stainless steel bourdon tube 1.4571

Pointer mechanism:

PMR06.xx,M: brass, barrel nickel silver

PMR06.xx.E: stainless steel 1.4571/1.4301

Dial: aluminium, white, black font

acc. to EN 837-1

Viewing class:

PMR06.xx.M: instrument glass

PMR06.xx.E: laminated safety glass

Accuracy: class 0,6

Max. media

temperature: 60 °C for PMR06.xx.M to 60 bar,

100 °C for all other devices

Overload safety: short-term 1,3-times

PKP Prozessmesstechnik GmbH

Borsigstr. 24 • D-65205 Wiesbaden

S +49 (0) 6122-7055-0 • T +49 (0) 6122 7055-50

Pressure