Sensorex TCSMA User manual

O & M Manual 1

REV G, 7/2009

Model TCSMA

Conductivity Measurement

System

(Toroid Sensor, Blind, 2-Wire 4-20mA Transmitter)

Operation and Maintenance

Manual

11751 Markon Dr.

Garden Grove, CA 92841 USA

Tel: 714-895-4344

Fax: 714-894-4839

www.sensorex.com

O & M Manual 2

REV G, 7/2009

PRODUCT WARRANTY

SENSOREX warrants all products to be free of defects in materials and

workmanship for 1 year from date marked on the product. However, SENSOREX

offers no warranty, either expressed or implied, as to the useful life of these

products. There are no implied warranties of merchantability or fitness for a

particular purpose given in connection with the sale of any goods. In no event

shall SENSOREX be liable for consequential, incidental or special damages.

The buyer’s sole and exclusive remedy and the limit of SENSOREX’s liability for

any loss whatsoever shall not exceed the purchase price paid by the purchaser

for the product to which claim is made.

O & M Manual 3

REV G, 7/2009

Table of Contents

Part 1 Introduction

1.1 General 5

1.2 Features 5

1.3 TCSMA System Specifications 6

1.4 TCSMA Performance Specifications 8

Part 2 Transmitter Mounting

2.1 General 9

2.2 Wall Mount 9

2.3 Pipe Mount 9

2.4 Panel Mount 9

Part 3 Sensor Mounting

3.1 General 13

Part 4 Transmitter Electrical Installation

4.1 General 14

4.2 Power 14

4.3 Load Drive 15

Part 5 Sensor Electrical Connection

5.1 General 17

5.2 Direct Sensor Connection 17

5.3 Junction Box Connection 18

Part 6 Calibration

6.1 General 19

6.2 User Interface 19

6.21 Offset Adjustment 19

6.22 Coarse Span Adjustment 19

6.23 Fine Span Adjustment 19

6.24 Range Selection 19

6.25 Temp Comp Adjustment 20

6.26 REV/DIR Switch 20

6.27 Loop Current 20

6.28 Cell Drive 20

6.3 Conductivity Calibration 21

6.4 Reverse Operation 23

Table of Contents (continued)

O & M Manual 4

REV G, 7/2009

Part 7 System Maintenance

7.1 General 24

7.2 Transmitter Maintenance 24

7.3 Sensor Maintenance 24

Part 8 Service

8.1 General 25

8.2 External Sources of Problems 25

8.3 Transmitter Tests 26

8.4 Sensor Tests 26

8.5 Spare Parts List 27

Diagrams and Illustrations

Figure 1-1 Specifications - Views 7

Figure 2-1 TCSMA Mounting Details 10

Figure 2-2 Panel Mount and Cut-Out 13

Figure 4-1 Loop Power Connection 15

Figure 5-1 Bulkhead Connection 17

Figure 8-1 Pt1000 RTD Table 27

O & M Manual 5

REV D, 2/2007

Part 1 - Introduction

1.1 General The Model TCSMA is a blind, loop-powered monitoring

system, designed for the continuous measurement of

solution conductivity. The full scale operating range of the

transmitter may be user adjusted to any value between 500

uS and 1,000,000 uS using the same sensor. The sensing

system will operate on water streams with temperatures from

-5°C to 110C.

1.2 Features - Special toroidal sensor design greatly minimizes sensor

fouling and, therefore, reduces maintenance requirements.

- Standard main module is designed to be a fully isolated, loop

powered instrument for 2-wire DC applications.

- Can be user-adjusted for specific application span from 500

uS to 1,000,000 uS using the same sensor.

- Direct/Reverse operation allows 4-20 mA output direction to

be flipped.

- Adjustable temperature compensation from 0% to 4% per °C

to match solution requirements.

- Loop indicator LED glows to indicate loop current level.

- Instrument supplied in rugged NEMA 4X enclosure with

multi-purpose mounting bracket.

TCSMA Conductivity System Part 1 - Introduction

O & M Manual 6

REV G, 7/2009

1.3 TCSMA System Specifications

Measuring Range Manual selection of one of the following ranges,

500 to 2,500 uS/cm

2,500 to 15,000 uS/cm

15,000 to 100,000 uS/cm

100,000 to 1,000,000 uS/cm

Enclosure NEMA 4X, IP66, polycarbonate, stainless steel

hardware, weatherproof and corrosion resistant,

HWD: 4.4" (112 mm) x 4.4" (112 mm) x 3.5" (89

mm)

Mounting Options Wall, panel, pipe, DIN rail, or integral-sensor.

Conduit Openings Standard: 1 - PG-9 opening, 1 - 1" NPT center

opening, cordgrips and PG-11 adapter included.

Weight 1 lb. (0.45 kg)

Ambient Temperature Transmitter Service, -20 to 60 °C (-4 to 140 ºF)

Sensor Service, -5 to 110°C (23 to 230 °F)**

Storage, -30 to 70 °C (-22 to 158 ºF)

Ambient Humidity 0 to 95%, non-condensing

Location Designed for hazardous and non-hazardous areas

EMI/RFI Influence Designed to EN 61326-1

Output Isolation Inherently isolated by sensor design

Temperature Input Pt1000 RTD with automatic compensation,

compensation adjustable from 0.0 to 4.0%/°C.

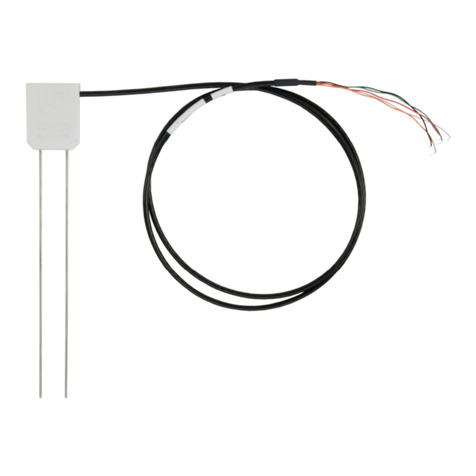

Sensor Noryl body toroidal, 150 psig max, ¾” NPT rear

process connection, P1000 RTD, CPVC 20 ft

length integral cable.

Max. Sensor-to-Transmitter

Distance 200 feet (61 meters)

Power 16-35 VDC (2-wire device)

DC Cable Type Belden twisted-pair, shielded,

Maximum length 3000 ft (914 meters)

Insertion Loss 16 VDC

** Note – sensor cable limited to 105°C max temperature when dry and 70°C max temperature if

submerged.

TCSMA Conductivity System Part 1 - Introduction

O & M Manual 7

REV G, 7/2009

Figure 1-1 Specifications - Views

Inches

(

mm

)

1” NPT

WITH PG-11

ADAPTER

AND PG-11

CORD GRIP

TCSMA Conductivity System Part 1 - Introduction

O & M Manual 8

REV G, 7/2009

1.4 TCSMA Performance Specifications

Repeatability 0.2% of selected range

Sensitivity 0.1% of selected range

Non-linearity 0.5% of selected range

Stability 0.2% of range per 24 hours, non-cumulative

Temperature Drift 0.06% of range/°C, span or zero

Response Time 2 seconds to 90% of full-scale step input

O & M Manual 9

REV D, 2/2007

Part 2 – Transmitter Mounting

2.1 General A bracket is included with each unit that allows mounting to

walls, pipes and DIN rail. In all cases, choose a location that

is readily accessible for calibrations. Also consider that it

may be necessary to utilize a location where solutions can

be used during the calibration process.

Locate the instrument in close proximity to the point of

sensor installation - this will allow easy access during

calibration. The sensor-to-instrument distance should not

exceed 200 feet. To maximize signal-to-noise ratio however,

work with the shortest sensor cable possible. The standard

cable length of the sensor is 20 feet (6.1 meters).

2.2 Wall Mount The instrument may be easily wall mounted (see Figure 2-1

details). The multi-purpose bracket is attached to the rear of

the enclosure using the four provided pan head screws. The

protrusion side of the multi-purpose bracket should face into

the depression on the rear of the instrument enclosure. The

instrument is then attached to the wall using the four outer

mounting holes in the bracket.

2.3 Pipe Mount For the pipe-mounting configuration, the multipurpose

bracket is attached to the rear of the enclosure with the four

provided screws. The protrusion on the bracket must face

outward. The bracket may be rotated for proper alignment

prior to mounting (see Figure 2-1 for details).

Once the bracket is fastened to the rear of the enclosure, the

provided pipe clamp must be completely opened and slipped

through the two slots in the multi-purpose mounting bracket.

The clamp is then looped around the pipe, re-attached, and

tightened.

TCSMA Conductivity System Part 2 – Transmitter Mounting

O & M Manual 10

REV G, 7/2009

Figure 2-1 Mounting Bracket Details

Inches

(

mm

)

TCSMA Conductivity System Part 2 – Transmitter Mounting

O & M Manual 11

REV G, 7/2009

2.4 Panel Mount In the panel mount configuration, the entire enclosure is

panel-mounted using a special optional sealing flange – as

shown in Figure 2-2. The panel mount kit, part number

07-0204, must be ordered separately.

The sealing flange must first be attached to the enclosure.

Fasten the flange to the rear half of the enclosure using the

four hex retainers. The flange gasket material must face

towards the rear of the enclosure. The flange is now

installed. Seal up the finished enclosure by tightening down

the four enclosure screws prior to mounting.

A special cut-out is required for this configuration, as shown

in Figure 2-2. Once the cut-out has been completed, insert

the flanged enclosure through the cut-out. The mounting

bracket is then attached to the rear of the enclosure as

shown. Install the four tension screws through the four

mounting holes in the bracket, and place the no-slip rubber

boots on each screw. Tighten all screws down to seal the

enclosure flange onto the panel.

TCSMA Conductivity System Part 2 – Transmitter Mounting

O & M Manual 12

REV G, 7/2009

Figure 2-3 Panel Mount and Cut-out

Inches

(

mm

)

O & M Manual 13

REV D, 2/2007

Part 3 – Sensor Mounting

3.1 General Select a location within the maximum sensor cable length for

mounting of the sensor flow cell. Locate sensor away from

pumps, adjustable frequency drive systems, or other sources

of high frequency EMI if possible. Once submerged, verify

that the sensor has the proper minimum 2” clearance to tank

walls or other objects nearby the sensor mounting. Close

proximity to objects can cause the sensor to read falsely

high or low. If in-line mounted, as in a tee application, the

sensor will stay cleaner if it is faced up or down stream so

that the line flow goes directly through the sensor bore.

Contact the factory for information on submersion hardware

mounts and tee mounts.

O & M Manual 14

REV D, 2/2007

Part 4 – Transmitter Electrical Installation

4.1 General The TCSMA loop-powered instrument is a 16-35 VDC

powered transmitter.

WARNING: Do not connect AC line power to the 2-wire

module. Severe damage will result.

Important Notes:

1. Use wiring practices that conform to all national, state

and local electrical codes.

2. Do NOT run sensor cables or instrument 4-20 mA output

wiring in the same conduit that contains AC power wiring.

AC power wiring should be run in a dedicated conduit to

prevent electrical noise from coupling with the

instrumentation signals.

4.2 Power A separate DC power supply must be used to power the

instrument. The exact connection of this power supply is

dependent on the control system into which the instrument

will connect. See Figure 4-1 for further details. Any general

twisted pair shielded cable can be used for connection of the

instrument to the power supply. Route signal cable away

from AC power lines, adjustable frequency drives, motors, or

other noisy electrical signal lines. Do not run sensor or

signal cables in conduit that contains AC power lines or

motor leads.

.

TCSMA Conductivity System Part 4 – Transmitter Electrical Installation

O & M Manual 15

REV G, 7/2009

Figure 4-1 Loop-Power Connection

4.3 Load Drive The two-wire instrument can operate on a power supply

voltage of between 16 and 35 VDC. The available load drive

capability can be calculated by applying the formula V/I=R,

where V=load drive voltage, I=maximum loop current (in

Amperes), and R=maximum resistance load (in Ohms).

To find the load drive voltage of the two-wire TCSMA,

subtract 16 VDC from the actual power supply voltage being

used (the 16 VDC represents insertion loss). For example, if

a 24 VDC power supply is being used, the load drive voltage

is 8 VDC.

The maximum loop current of the two-wire TCSMA is always

20.00 mA, or .02 A. Therefore,

TRANSMITTER

POWER SUPPLY

24 VDC

LOAD

(+)

(-)

(+)

(-)

(+) (-)

(Power Supply Voltage - 16)

.02 = RMAX

TCSMA Conductivity System Part 4 – Transmitter Electrical Installation

O & M Manual 16

REV G, 7/2009

For example, if the power supply voltage is 24 VDC, first

subtract 16 VDC, then divide the remainder by .02. 8/.02 =

400; therefore, a 400 Ohm maximum load can be inserted

into the loop with a 24 VDC power supply.

Similarly, the following values can be calculated:

Power Supply Voltage (VDC) Total Load (Ohms)

16.0 0

20.0 200

24.0 400

30.0 700

35.0 950

O & M Manual 17

REV D, 2/2007

Part 5 – Sensor Electrical Connection

5.1 General The sensor cable can be quickly connected to the TCSMA

terminal strip by matching the wire colors on the cable

conductors. A junction box is suggested to provide a quick-

disconnect point for the sensor, or a break point for very long

sensor cable runs. Route signal cable away from AC power

lines, adjustable frequency drives, motors, or other noisy

electrical signal lines. Do not run sensor or signal cables in

conduit that contains AC power lines or motor leads.

5.2 Direct

Sensor

Connection Route the sensor cable into the enclosure through the center

PG-11 cord grip only. If the cord-grip devices are used for

sealing the cable, make sure the cord-grips are snugly

tightened after electrical connections have been made to

prevent moisture incursion. When stripping cables, leave

adequate length for connections in the transmitter enclosure,

as shown below.

Figure 5-1 Bulkhead Connection

TCSMA Conductivity System Part 5 – Sensor Electrical Connection

O & M Manual 18

REV G, 7/2009

Once inside the enclosure, the individual colored sensor

sensor cable leads can be connected directly to the

SENSOR connection terminals by matching the wire colors.

5.3 J-Box

Connection For installations where the sensor is to be located more than

20 feet from the transmitter, a customer supplied junction

box should be used.

O & M Manual 19

REV D, 2/2007

Part 6 – Calibration

6.1 General The transmitter is factory calibrated in a default range of 0-

10,000 uS/cm. The transmitter must be re-calibrated with

the actual sensor for optimum accuracy using the following

procedure.

6.2 User

Interface The user interface controls for the transmitter are quite

simple, and they are described below.

6.21 Offset

AdjustmentThe offset adjustment sets the 4 mA output current

point for the system. This adjustment is made after

the proper range has been selected, and the sensor is

held in air. Offset adjustments can only be made to

zero-signal conductivity.

6.22 Coarse Span

AdjustmentThe coarse span adjustment sets the initial 20 mA

output current point for the system. This adjustment

is used to make the initial rough adjustment on the

sensor span.

6.23 Fine Span

AdjustmentThe fine span adjustment sets the final 20 mA output

current point for the system. This adjustment is used

to make the final, precise, adjustment on the sensor

span.

6.24 Range

Selection This dipswitch selects the general range of operation

for the transmitter. Pick the range to be larger than

the maximum operating conductivity value of the

transmitter.

RANGE CELL DRV

500 uS – 2,500 uS 1-ON, 2-ON 1-ON, 2-OFF

2,500 uS – 15,000 uS 1-ON, 2-OFF 1-ON, 2-OFF

15,000 uS – 100,000 uS 1-OFF, 2-OFF 1-ON, 2-OFF

100,000 uS – 1,000,000 uS 1-OFF, 2-OFF 1-OFF, 2-ON

TCSMA Conductivity System Part 6 - Calibration

O & M Manual 20

REV G, 7/2009

Due to the nature of the sensor design, it is

recommended to use the largest range possible for

the application. The higher instrument ranges are

easier to user calibrate, as they require less back-

and-forth zero/span adjustments.

6.25 Temperature

Compensation

AdjustmentThe TC % PER C adjustment sets the specific linear

temperature compensation factor for the measured

solution. The range of adjustment is from 0-4%/C.

Since the majority of aqueous solutions are

compensated at approximately 2%/C, leave this

setting at the default 2%/C setting if the exact

compensation requirement is not known. The

following list contains some common factor settings:

1.9 Sodium Hydroxide

1.5 Hydrochloric Acid

1.5 Sulfuric Acid

1.5 Nitric Acid

1.1 Phosphoric Acid

2.1 Sodium Chloride

2.4 Sodium Sulfate

2.2 Sodium Nitrate

2.0 Potassium Chloride

6.26 REV/DIR

Switch This switch sets the direction of output change for the

system. In the direct mode (DIR), the output current

will increase to 20 mA as the conductivity increases.

In the reverse mode (REV), the output current will

decrease to 4 mA as conductivity increases.

6.27 Loop

Current This indicator glows when the transmitter is powered

and operating correctly. The intensity of the light will

increase with increasing output current.

6.28 Cell

Drive This switch sets the sensor drive potential and is used

to set the instrument range of operation (see section

6.24.)

Table of contents

Other Sensorex Measuring Instrument manuals