SensorLink Radio Ohmstik User manual

Operators Manual

Radio Ohmstik

Radio Linked

Micro Ohmmeter

SensorLink®Corporation

Model 8-182

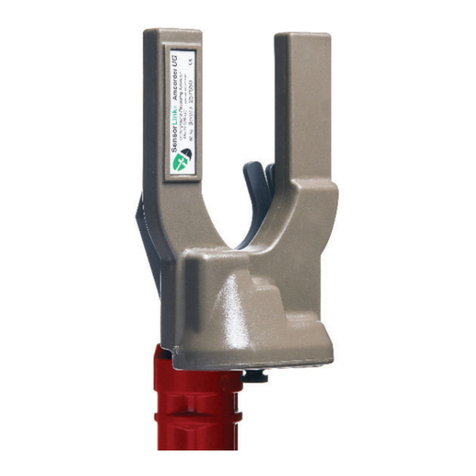

Radio Ohmstik Transmitter

Model 8-184 not pictured

Model 8-180

Radio Ohmstik Display Unit

Model 6-182

Radio Ohmstik Kit

and Accessories

OPERATORS MANUAL

Radio Ohmstik

Radio Linked Live-Line Micro Ohmmeter

Table of Contents Page

Specifications 4

Safety Information 5

Theory of Operation 6

FCC and Industry Canada Statements 7

Cleaning and Transporting 7

Calculating Connector Resistance Ratio 8

Ratio Conditions and Actions 9

Radio Ohmstik Communication 10

Software Requrements and Installation 10

Communication with Software 11

Communication with Display Unit 12

Taking a Measurement 13

Reviewing the Measurement 14

Powering Off 14

Troubleshooting 15-16

Probes & Accessories 17-18

Battery Replacement 16

Warranty 19

Quality Assurance Back Cover

Available Stock Codes:

8-182 50HZ 8-182 60HZ 8-182 EURO

8-180 8-180 EURO 8-184 50HZ

8-184 60HZ 8-184 EURO

Page 4

Specifications

Model Number & Type 8-182 8-184

Type Standard Wide Jaw

Sensor Opening 2.5 in, 6.35 cm 3.86 in, 9.8 cm

Weight 2.3 lbs, 1.05 kg 4.0 lbs, 1.81 kg

Measurements

Amps 1-1400 A

Microohms 5-2500 μΩ

Accuracy

Amps ±1% 1 A

Microhms Absolute ±2% 2

Microhms Repeatability ±1% 2

Accuracy is diminished if the current is less than 15 amps 0-35kV and when current is less than 50 A while on 36-500kV

Range of Operation

Voltage Rated 500kV

Resolution

Amps 1.9-99 A 0.1 A

Amps 100-1400 A 1.0 A

Microhms 0-999 μΩ 1 μΩ

Frequency Actual frequency indicated on the unit

50Hz Calibrated 47 to 53Hz

60Hz Calibrated 57 to 63Hz

Radio

Frequency ISM 2.4 GHz

Power 63 mW, 10 mW in Europe & Japan

Range 150', (46 meters) Line of Sight, 120' (36.5 meters) in Europe & Japan

Mechanical

Battery 9 Volt Alkaline, 1 each per unit

Battery Life 6-8 Hours at 68°F or 20°C, 3-4 Hours at 32°F or 0°C

Detachable Probes Fused Probe or Adjustable Probe

Ambient Temperature -4 to +140° F, -20 to +60° C

Display Graphics LCD

Software Requirements Radio Ohmstik Software

System Requirements Windows XP, Vista, WIN 7, WIN 8, WIN 10

Hardware Requirements Minimum of two USB ports

EEC Standards Successfully passed international test standards indicated by CE

Page 5

Safety Information

Read all safety and instruction statements before using the product. Failing to

follow the safety guidelines can cause severe injury or death.

Ohmstiks are designed for use on live, overhead lines with 0 to 500KV. All

procedures appropriate for the line voltage are to be taken, including proper

work techniques, equipment, and Personal Protection Equipment.

The Ohmstik should be used only by certified personnel who have been

trained for live-line, high voltage work by their organization.

Connecting the probes in a phase to phase, phase to ground, or any

application where the voltage potential between the probes is more than 2.5

volts will cause damage to the instrument and create a system fault.

The hot stick length must be the correct for line voltage per minimum

approach distances stated in published OSHA regulations and/or provided by

the utility.

The cover plate, chuck, and entire Ohmstik are to be considered at the same

potential. Putting the cover plate, chuck, or other parts of the Ohmstik within

the air gap of adjacent phases or ground could cause a phase to phase or

phase to ground fault.

Do not alter the product in any manner.

Theory of Operation

The Radio Ohmstik Live-Line Micro Ohmmeter measures micro-ohm resistance

on conductors, connectors, splices, and switching devices positioned directly on

energized, high voltage lines. Resistance is the electrical condition of the connection

and calculating the measurements into condition ratios provides definitive and

actionable early warnings of a deteriorating fitting. If the resistance of the fitting

is outside the normal range, the connection is deteriorating. A connection with

resistance above the normal range is in a failure process, where the time to failure

depends on how high the resistance is.

The Ohmstik is placed on a splice or connector so the connection under test is

between the two electrodes. Measurement data is communicated to both the

Remote Display and the Radio Ohmstik Software on the user's laptop. At the

same time, the GPS device sends location data to the Software. When a valid

measurement is received, the software writes the data to a comma separated (CSV)

file. This combined data allows the user to map the location of the connector as well

as the measurements to analyze its condition.

Page 6

FCC & Industry Canada Statements

United States of America and Canada

Contains FCC ID: OUR-XBEEPRO

Contains Model XBee-PRO Radio, IC: 4214A-XBEEPRO

The/XBee-PRO® RF Module has been certified by the FCC for use with other

products without any further certification (as per FCC section 2.1091). Modifications

not expressly approved by Digi could void the user's authority to operate the

equipment.

This equipment has been tested and found to comply with the limits for a Class

B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following

measures: Re-orient or relocate the receiving antenna, Increase the separation

between the equipment and receiver, Connect equipment and receiver to outlets

on different circuits, or Consult the dealer or an experienced radio/TV technician for

help.

Cleaning

The Radio Ohmstik should be cleaned by wiping with a silicone hot stick wipe to

remove dirt, sand, and salt that will degrade the urethane housing.

Transporting

There are no special considerations for transporting this device.

Page 7

Calculating Connector Resistance Ratio:

Resistance ratio is calculated by comparing the resistance of the fitting over the

resistance of the conductor. Factors effecting the readings may include line tension

and wire condition (heavily birdcaged or other).

Ratio = Connector / Conductor

All fittings or splices consist of two different connectors. All connectors consist of

three resistors in series: (1) resistance of the conductor, (2) the connector, and (3)

the interface between the conductor and the connector.

The interface is the only resistor of the three that changes over time. The object of

using the Ohmstik is to measure as little of the conductor & connector as possible,

and all of the section that surrounds the interface.

EXAMPLE: A splice connector has two interfaces.

Step 1: TAKE THE CONDUCTOR MEASUREMENT

Measure a portion of the conductor equal in length to the interface portion of the

connector. Various lengths can be configured with the probes sent with the unit.

Step 2: MEASURE THE INTERFACE OF CONNECTOR SIDE A

Measure the interface of the first connector.

One contactor should be placed in just past the compressed section. On an

automatic splice, place the contactor in the middle of the connector. The second

contactor should be placed on the conductor, as close to the connector as possible

without touching the connector.

Step 3: MEASURE THE INTERFACE OF CONNECTOR SIDE B

Measure the interface of the second connector.

One contactor should be placed in just past the compressed section. On an

automatic splice, place the contactor in the middle of the connector. The second

contactor should be placed on the conductor, as close to the connector as possible

without touching the connector.

Page 8

Ratio Conditions and Actions

Evaluating any necessary actions can be completed once the ratios for the

connector are calculated. The following table shows the suggested action based on

maintaining the present load rating of the asset.

Resistance Ratio Condition of fitting Action

0.3 to 1.0 Normal Connection: Serviceable

New connections are expected to be in

the 0.3 to 0.8 range

None

1.01 to 1.2 Serviceable; Poor

Shows deterioration; Overloads &

faults may deteriorate the connection

Re-inspect in one

year, or after next

fault

1.21 to 1.5 Serviceable; Poor

Shows deterioration; Overloads &

faults may deteriorate the connection

Re-inspect in six

months, or after

next fault

1.51 to 2.0 Serviceable; Very poor

High loads, overloads, or faults may

deteriorate the connection

Schedule asset

replacement in less

than three months

2.01 to 3.0 Bad; deterioration rate is

increasing

High loads, overloads, or faults may

fail the connection. High tensions from

cold weather or wind may initiate

failure under normal loading

Schedule asset

replacement very

soon

>3.0 Failing

Normal loads, overloads, or faults may

fail the connection; High tensions from

cold weather or wind are likely to

initiate failure under normal loading

Replace as soon as

possible

*Actions required based on resistance ratios (Rfitting / Rconductor)

*These ratio conditions and actions are developed from field measurements, manufacturer

data, lab tests, failure analysis and understanding of deterioration mechanisms. This

guideline may be modified as field and test data accumulates.

Calculating the Resistance of Power Tap

Connectors:

The Ohmstik will take resistance on other Full and Limited tension connectors.

It is always best practice to take all three readings of the series and evaluate the

condition with the above table. However, due to the build and size, it may not be

possible to take all three readings in series. If evaluating based on a benchmark

measurements, or comparison to a known good fitting, a reading across the

connector can be made.

Factors effecting the reading may include line tension and wire condition (heavily

birdcaged or other).

Page 9

Radio Ohmstik Communication

The user is able to view the measurement sets on both a Display Unit and on a

laptop running Radio Ohmstik software. These communications may be used singly,

or at the same time.

With Radio Ohmstik software and GPS, the following data may be written to the

data file: Amps, Micro-Ohms, Date, Time, Comments, Latitude, and Longitude (with

the GPS USB plugged into the laptop).

Communicating to the Display Unit: The Display Unit is designed to be attached

to a hot stick or held by hand. The sensor transmits the live readings to the Display

Unit via radio. This functionality allows the user to easily see readings were taken.

Readings are not saved on the Display unit.

Communicating to the Laptop: With the Radio Ohmstik software loaded, and

the radio adapter plugged in, the Sensor will transmit the data and readings to the

laptop. The measurement set will automatically be saved as a .csv file for future

review.

Radio Ohmstik System Requirements

OPERATING SYSTEM: Radio Ohmstik Software installs onto computers running

Windows XP, VISTA, 7, 8, and 10. USB ports are needed for both GPS and Radio

communication.

NETWORK INSTALLATION: This is a single user application and is not supported

when installed onto a server.

INSTALLATION AUTHORITY: Installation will require administration rights.

Computers managed by electric utility organizations often limit the programs that

can be installed. If the user does not have admin rights they will need the assistance

of the IT department to download the software.

USB PORT PERMISSIONS: The USB GPS and USB Radio have install programs that

run the first time connected. The user may have rights to install programs but may

not be aware that the USB ports are locked on the PC. Please contact your network

administrator for permission and instructions to complete the install if drivers are

not installing automatically and need to be installed manually.

Softlink Installation

Step 1: Softlink Installer is available at www.sensorlink.com/products/ohmstik. Save

the file to the desired location. The Radio Ohmstik .exe file will automatically begin

the download when clicked.

Step 2: You must agree to the licensing agreement to proceed with the download.

Step 3: A dialog box will appear to let you know when the download is complete.

Shortcut paths will automatically load during the install.

Page 10

Setup: Communication with Software

Step 1: Plug the 7-024 USB Radio and the 7-025 USB GPS devices into the laptop's

USB ports. It will take several seconds for the computer to discover the devices

Step 2: Open the Radio Ohmstik Software

Step 3: The program starts by asking the user to select a file name and location to

write the data.

Note: The default File Name is a date and time code for the date and

time the application is opened.

Step 4: Select Save; the Radio Ohmstik Dashboard will load and is ready for

measurments

Page 11

Copyright 2011

SensorLink

F574 8XP 300

Firmware XXX No Signal

Display Software Dashboard

Setup: Communication with Radio Display

Step 1: If securing to a hot stick, place the Display Unit with the Velcro strap so the

LCD display is visible while taking measurements.

Step 2: Press the function button on the Display Unit. The display will run through

a startup sequence, ending with No Signal.

Setup: Radio Ohmstik Sensor

Step 1: Attach the Probe to the back of the Radio Ohmstik.

7-081 XT Standard Probe, for 8-182 Transmitter

7-081 Standard Probe, for 8-184 Transmitter

The probe is designed for use in close proximity to adjacent phases or ground

structures. See Safety Information on page

five. In the event of making a phase

to phase or phase to ground connection, the Probe will break the connection.

Step 2: Press the function button on the Radio Ohmstik sensor. The LED will flash

green when powered on.

Step 3: Both the Display and Software will indicate the Radio Ohmstik is ready to

take measurements

Page 12

Taking a Measurement:

Step 1: Place the Radio Ohmstik on a conductor as depicted below. It is essential to

make contact between the conductor and the voltage sensor, which is the V-shaped

plate between the jaws, as well as the voltage probe.

Step 2: Measurement begins as soon as the Ohmstik is in position and stable on the

conductor.

Step 3: While the Radio Ohmstik is taking the measurement, the screens will

display:

Step 4: The display screens will show the current in the conductor as well as the

Micro-Ohm resistance of whatever is between the two voltage probe.

Step 5: Remove the Ohmstik from the conductor. It holds the reading and displays

it as follows:

Step 6: Remove the Radio Ohmstik from the conductor or splice.

Step 7: The measurements are now written to the Radio Ohmstik software. The

displays will continue to show readings until the Radio Ohmstik is placed on a new

current carrying conductor, or until the units are powered off.

Step 8: Continue to take measurements for ratio analysis. See pages 8-9 for

measurement sequence and resistance ratio calculations.

Page 13

Page 14

Power Off the Radio Ohmstik

Press and hold the Function Button on the Display Unit until the LCD goes blank

or Press and hold the Function Button on the Radio Ohmstik until the LED goes off.

Either of these actions will power off itself and the accompanied device. The Radio

Ohmstik will power off by itself if left inactive for 20 minutes.

Collecting Measurements in Software

Step 1: The Radio Ohmstik software will display the completed measurement and

GPS location on the Dashboard.

Step 2: The data will automatically be written to a comma-separated values (CSV)

file when the Radio Ohmstik is removed from the conductor.

Step 3: A comment may be added before the reading is taken. Any comment

written will be a part of the record for the next reading and will save for future

lines. If the comment is not needed delete it on the record before taking the next

measurement.

Step 4: To review the data, open the saved CSV file in any spreadsheet or word

processing application.

Note: Opening the CSV file while the dashboard is open, will stop the recording

of readings. The number of readings will be recorded on the dashboard

but the readings will not be stored.

Troubleshooting and Error Messages:

“No Contact”

The Radio Ohmstik reads current but not micro-ohms:

This indicates one of the two voltage sensors is not making contact. Use the

rough edges of the probe to clean corrosion from the conductor and re-take the

measurement. Make certain both voltage sensors are making contact. The fitting

cannot be covered. See page 13 for instructions on Taking a Measurement.

“Poor Contact”

The Radio Ohmstik reads current but not micro-ohms:

There is poor contact on the conductor with one of the voltage contacts.Provide

five seconds to measure, while the Radio Ohmstik is held stationary with both

voltage probes securely on the line.

“Reading Ohms”

The following message indicates the current measurement was completed before

the resistance measurement could be completed:

Provide five seconds to measure, while the Radio Ohmstik is held stationary with

both voltage probes securely on the line.

“Unable To Measure”

The Radio Ohmstik uses logic to know when it is on a conductor by looking for a

stable load:

Hold the Radio Ohmstik firmly on the line for at least five seconds. The Ohmstik

samples the line three times every 100 milliseconds. If it cannot find three

consecutive reads that are within tolerance it will display “Unable To Measure”.

Page 15

“Exceeds 1400 Amps”

The Radio Ohmstik limits the maximum current to 1400 Amps:

The Radio Ohmstik is not specified to measure above 1400A.

Battery Replacement

The Radio Ohmstik system is powered by two 9V batteries, one in the Radio

Ohmstik and one in the Display. The expected battery life for both units is 6 to 8

hours at 68° F or 20° C. The expected life declines in colder environments. At 32°F

or 0°C it is reduced 3 to 4 hours.

Note: It is recommended fresh batteries be installed prior to operation each day.

Always replace both batteries.

To replace the battery, remove the four screws on the battery cover at the rear of

the unit. Carefully insert a screwdriver blade in the notch and pry the cover out,

being careful not to damage the cover seal. Pull the battery out of the compartment

and separate the battery from the battery connector. To avoid breaking the battery

leads do not pull on the battery only. Install a fresh battery and reinsert the battery

in its compartment. Do not pinch the wires between the battery and compartment;

put wires in slot above the battery. Reinstall the cover by gently pressing it into

place while pulling out on the edges of the compartment, and reinstall the four

cover screws. Take care to avoid over tightening the screws. Always reuse the screws

provided and do not damage or lose the O-ring seal on each screw.

Page 16

Standard Probe Configuration with Contactor Attachment

Standard Probes and Accessories

7-081 and 7-081XT Accessory Kits Include:

(1) Standard Probe (1) Contactor Attachment

(1) Wire Brush Contactor (1) Probe Hook

(1) 4" Rod, Straight (1) 4" Rod, Bent

(1) Philips Head Screw (1) Coupling Nut

(4) Lock Washers (6) Hexnuts

Standard Probe Configuration with a Straight Rod and Contactor Attachment

Standard Probe Configuration a Bent Rod and Curved Rod

Page 17

Wire Brush Contactor

7-081 ADJ Adjustable Probe Accessory Kit Includes:

The Adjustable probe is designed for any measurement where the distance to be

measured is less than 12 inches. This probe will adjust from 4 to 13 inches.

Adjustable Probe Kit includes:

(1) Adjustable Probe (1) Wire Brush Contactor

(1) Contactor Attachment (2) Hex Nuts

Other Replacement Accessories

The Universal Adapter allows the user to adjust the Ohmstik Transmitter at compound

angles. This is a useful adapter when working from the ground on complex apparatus.

7-050 Universal Adapter

Page 18

Adjustable Probe with Contactor Attachment

7-025 USB GPS Adapter 7-051 Carrying Case 7-024 USB Radio Adpater

Page 19

SensorLink Corporation

Warranty

SensorLink Corporation warrants each instrument it manufactures to be free from

defects in materials and workmanship under normal use and service for the period of

one year after date of shipment. Within this period, SensorLink Corporation agrees

to repair or replace, at SensorLink Corporation’s option, any instrument that fails to

perform as specified. This Warranty shall not apply to any instrument that has been:

1 Repaired, worked on, or altered, including removal of the front panel, by persons

unauthorized by SensorLink Corporation in such a manner as to injure, in

SensorLink Corporation’s sole judgment, the performance, stability, or reliability

of the instrument;

2 Subjected to misuse, negligence, or accident; or

3 Connected, installed, adjusted, or used otherwise than in accordance with the

instructions furnished by SensorLink Corporation.

This Warranty is in lieu of any other warranty, expressed or implied. SensorLink Cor-

poration reserves the right to make any changes in the design or construction of its

instruments at any time, without incurring any obligation to make any change whatever

in units previously delivered.

If a failure occurs, contact the manufacturer for a Return Authorization and instructions

for return shipment. This warranty constitutes the full understanding of the manufac-

turer and buyer, and no terms, conditions, understanding, or agreement purporting

to modify or vary the terms hereof shall be binding unless hereafter made in writing

and signed by an authorized official of SensorLink Corporation.

Quality Assurance Certification

Radio Ohmstik

Transmitter Models 8-182 and 8-184

Display Unit Model 8-180

SensorLink Corporation certifies that its calibration measurements are traceable to

the National Institute of Standards and Technology (NIST), to the extent allowed

by the Institute's calibration facility, and to the calibration facilities of other

International Standards Organization members.

This document certifies the following Radio Ohmstik was tested at the SensorLink

Corporation High Voltage Laboratory, Ferndale, WA, USA to the appropriate

standard and comply with the requirements of that standard.

Sensor; Model Number: ______________________________________

Serial Number: _______________________________________________

Display Unit; Model Number: __________________________________

Serial Number: _______________________________________________

I hereby certify that the Radio Ohmstik listed above has passed all tests defined

in the Sensorlink Corporation standard. I also certify that I have reviewed the

standard and test procedure and that they are sufficient in determining compliance

with the standard.

Signed: _____________________________________________________

Date: _______________________________________________________

1360 Stonegate Way

Ferndale, WA 98248 USA

phone: 360/595.1000

fax: 360/595.1001

www.sensorlink.com

Form No: SALE-Manual Template OHMSTIK-008 REV: V04

Date: 01/2020

Manual Stock Code No: DOPM-818-200

Information contained in this document is subject to change without notice. Product specification may change. Contact

your SensorLink representative for the most current product information. © 2019 by SensorLink. All rights reserved.

Made in the USA.

SensorLink®Corporation

This manual suits for next models

4

Table of contents

Other SensorLink Measuring Instrument manuals

SensorLink

SensorLink Varcorder 910 Series User manual

SensorLink

SensorLink 6-120 User manual

SensorLink

SensorLink Amcorder UG Series User manual

SensorLink

SensorLink True RMS Ampstik 8-020 User manual

SensorLink

SensorLink TMS 950 User manual

SensorLink

SensorLink 8-182 User manual

SensorLink

SensorLink 8-117 XT 50HZ User manual

SensorLink

SensorLink Swarm S2 User manual

SensorLink

SensorLink Ampstik+ User manual