SensorLink Varcorder 910 Series User manual

SensorLink®Corporation

Operators Manual

Varcorder

Amp & Power Factor Recorder

Unit and Accessory Part Numbers

Varcorder

Model 910

*Qty (1) sold in 6-910-1 Kit

*Qty (3) sold in 6-910-3 Kit

Universal Switch Stick Adapter

Model 7-053

*Qty (1) sold in 6-910-1 Kit

*Qty (1) sold in 6-910-3 Kit

Universal Switch Stick Receiver

Model 7-054

*Qty (1) sold in 6-910-1 Kit

*Qty (3) sold in 6-910-3 Kit

Carrying Case

Model 659

*Qty (1) sold in 6-910-1 Kit

*Qty (1) sold in 6-910-3 Kit

USB IrDA Dongle

Model 7-021B

*Qty (1) sold in 6-910-1 Kit

*Qty (1) sold in 6-910-3 Kit

Operators Manual

Varcorder

Amp & Power Factor Recorder

Table of Contents Page

Specifications 4

Safety Information 5

Theory of Operation 5

Preventative Maintenance 6

Cleaning 6

Low Temperature Applications 6

Powering the Unit 6

Sample and Log Intervals 6

Battery Replacement and Operation 7

Installing on a Line

Installing on a line with a Shotgun Hot Stick 8

Installing on a line with a Universal Switch Stick Hot Stick 9

Warranty 19

Quality Assurance Back Cover

Softlink Software

System Requirements 10

Installation of Software and USB IrDA 10

Communicating with Recorder 11

Discover Recorder 11

Configure Recorder 12

Entering Nominal Voltage 13

Download Recorder Data 13

Saving Recorder Data 14

Opening Recorder Data 15

Recorder Options 16

Graphing Recorder Data 17

Troubleshooting 18

Available Stock Codes:

910-50HZ 910-60HZ 910 EURO

Page 4

SPECIFICATIONS

Kit Number 6-910-3

Type Recording Varcorder Kit, three phase

Kit Includes 3 ea Varcorder

1 ea IrDA USB Cable

1 ea Universal Hot Stick Adapter

3 ea Universal Hot Stick Receivers

1 ea Soft Carrying Case

Range of Operation

Phase to Phase Voltage 69 kV, 600 V minimum for accurate Power Factor

Current 1 to 2000 A

Resolution

Amps 1 to 99.9 A 0.1 A

Amps 100 to 2000 A 1 A

Power Factor .01

Accuracy

Amps ± 1%, ± 2 Counts

Power Factor ± .01 (from .71 lead to .71 lag)

Frequency, 50 Hz 47 to 53 Hz

Frequency, 60 Hz 57 to 63 Hz

Mechanical

Weight 1.5 lbs, 0.68 kg

Dimensions 9.75 in x 4.75 in x 3 in (24.77 cm x 12.07 cm x 7.62 cm)

Sensor Opening Up to 1.5 in, Up to 3.3 cm

Operating Temperature -22 to +140˚ F, -30 to +60˚ C

Lithium battery required for temperatures below -4°F (-20°C).

Storage Temperature -40 to +158˚ F (-40 to +70˚ C)

Hotstick Mounting Shotgun & Switch Stick Style Hot Stick (Hot sticks not included)

Battery 9 Volt Alkaline or Lithium

Indoor/Outdoor Use

Relative Humidity 90% Non - Condensing

Altitude 9800 ft, 3000 m

Software Requirements Softlink by SensorLink, included in sales kit

Operating System Windows 7, 8, or 10

Data Collection Space 64,000 Log intervals

EC Standards Successfully passed international test standards indicated by CE

Page 5

Safety Information

Read all safety and instruction statements before using the product. Failing to

follow the safety guidelines can cause severe injury or death.

Varcorders are designed for use on live, overhead lines with 0 to 69KV. All

procedures appropriate for the line voltage are to be taken, including proper

work techniques, equipment, and Personal Protection Equipment.

The Varcorder should be deployed and retrieved only by certified personnel

who have been trained for live-line, high voltage work by their organization.

The Varcorder is to be installed and removed from the line with a suitable

shotgun or switch stick style hot stick. The hot stick is considered the sole

voltage isolation device.

The hot stick length must be correct for line voltage per minimum approach

distances stated in published OSHA regulations and/or provided by the utility.

The cover plate, chuck, and entire Varcorder are to be considered at the same

potential. Putting the cover plate, chuck, or other parts of the Varcorder

within the air gap of adjacent phases or ground could cause a phase to phase

or phase to ground fault.

Do not alter the product in any manner.

Theory of Operation

The Varcorder deploys on a line to measure and record True RMS Amps and Power

Factor on overhead lines. The Varcorder uses the same current sensor technology

as the original SensorLink®Ampstik®, which does not use magnetic materials and

has no moving parts. True Power Factor is calculated by measuring the electric field

in comparison with the current reported from the amp sensor. The electric field

waveform characteristics give accurate readings for Power Factor calculation.

Measurements are taken at user defined intervals. In Softlink software the user

selects how often to sample and log the data.

Remove the units from the line to download the data via IrDA. With the optional

Transcorder, data may be downloaded via radio with the unit deployed on the line.

SoftLink software will calculate the VARs after the user applies a nominal phase to

ground voltage constant in Softlink.

For accurate Power Factor, direct connection to the bare conductor is required.

Low Temperature Applications

The Alkaline Battery and the IrDA transceiver are two components that limit the

operation of the Recorder to down to -4F / -20C. By substituting a Lithium long-life

battery the Recorder can collect data down to -40. Because the IrDA transmitter

doesn't perform at these low temperatures, when collecting the data from the

Recorder the temperature needs to be above -4F/ -20C.

Powering the Unit

The Recorder powers on and begins taking recordings when the battery is properly

connected and placed into the battery compartment.

Preventative Maintenance

The Recorder should be visually inspected for cracks in urethane. Do not use if

cracks are present or the unit is damaged. Verify the air vent on the faceplate has

not been covered. The membrane on the inside of the faceplate is designed to allow

the unit to breath properly.

Cleaning

The Recorder should be cleaned by wiping with a silicone hot stick wipe to remove

dirt, sand, and salt that will degrade the urethane housing.

Page 6

Sample and Log Intervals

Sample and Log Interval: The Sample Interval is how often the Recorder reads

the current on the conductor. The Recorder will hold the sample current readings

until it reaches the Log Interval, at which time the Recorder will average the sample

measurements. This average becomes the logged data point. The Recorder begins

sampling and logging as soon as a battery is connected.

How many days will the Recorder Log Data? The length of the Log Interval

determines the length of time the Recorder will take to use all of the available logged

data points. See the below chart for the number of days it will take to fill a Recorder

with data, based on various Log Intervals. Note that in most cases the Recorder is

limited by battery life more than the recording capacity.

Log Interval

(seconds)

Days Recording Until Full

3600 1333*

1800 667*

900 333*

600 222*

300 111

60 22

30 11

*Exceeds expected battery life

Battery Replacement and Operation

Changing the Battery: The Varcorder requires one 9V battery. Remove the

screw at the base of the unit and remove the cover plate. Snap the battery to the

connector and insert into the battery slot. Replace the cover plate.

The Recorder should have a fresh 9-volt battery replaced each time it is setup and

deployed. A fresh battery has greater than 9.2 VDC. Alkaline batteries have a short

shelf life and care should be taken to make sure the battery is fresh.

Expected Battery Life: The expected life of the battery in a Recorder is varied

by how often the Recorder samples the line to collect data and the ambient

temperature. Fresh non-rechargeable batteries are required so the reliability and life

of the battery can be easily predicted. Predicting the life of rechargeable batteries

is uncertain, especially after several recharges. A new battery should be placed into

the Recorder before it deployed to ensure the reliability of the battery life.

The Recorder will stop operating when the battery fails to supply more than five

volts. All the logged data is safely stored in flash memory. When a fresh battery is

put into the Recorder, the user has five minutes to start downloading the data. The

data will have accurate date and time stamps. The old data will be cleared from

memory after five minutes.

NOTE: Once a fresh battery is inserted, the user has 5 minutes to start

downloading the data before the Varcorder resets itself. The Varcorder will only save

the logged data in its flash ram for 5 minutes. We recommend that you do not

remove the battery until you have downloaded all of the data. A new battery

should be placed into the Varcorder before it is deployed on the line to ensure the

reliability of the battery life.

Page 7

Expected battery life at 68° F or 20° C

Alkaline operating time reduced to 25% at -4° F or -20° C

Lithium operating time reduced to 75% at -4° F or -20° C

Lithium operating time reduced to 50% at -40° F or -40° C

Sample Interval

(Seconds)

Expected life of a

9V Alkaline battery

(Days)

Expected life of a

9V Lithium battery

(Days)

60 180 360

30 120 240

Page 8

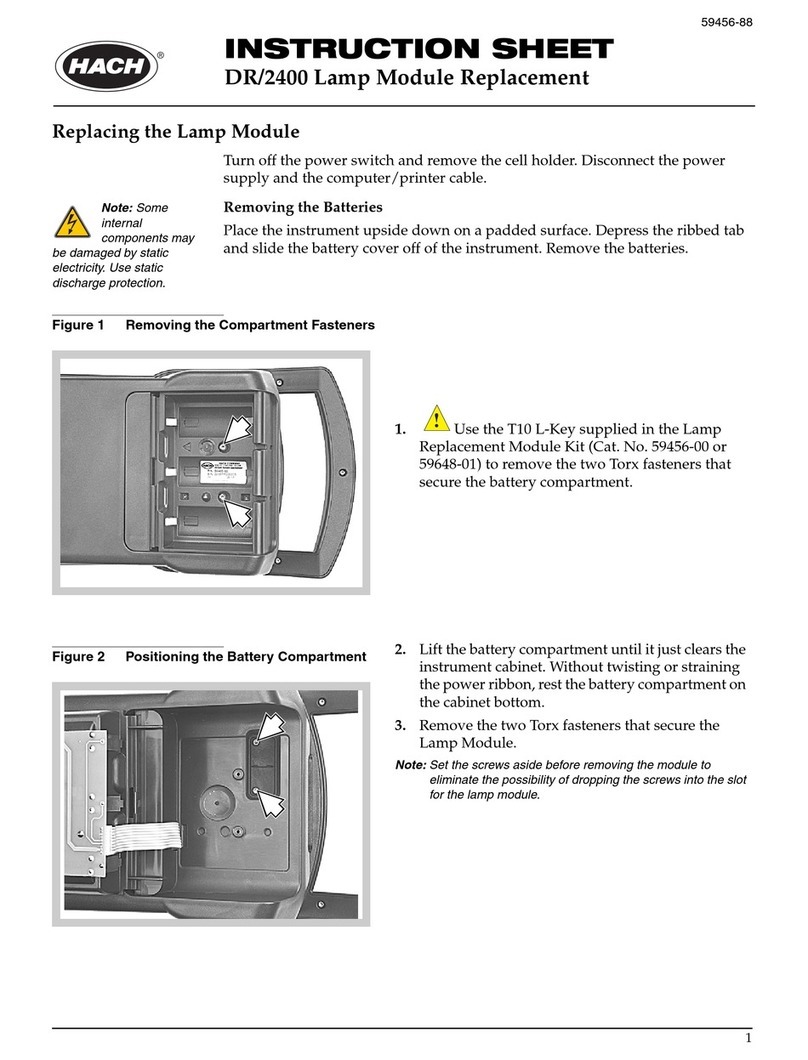

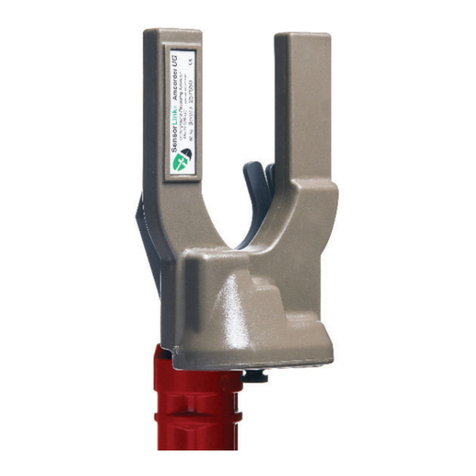

Installation: Shotgun Style

The metal contactor on the Varcorder must have a direct connection to the bare

conductor to accurately measure the power factor. The Varcorder will not take

accurate Power Factor measurements on covered wire.

Step 1: Attach the Shotgun adapter to the Varcorder

Step 2: Grasp the Varcorder with the hot stick

Step 3: Place the Varcorder on the conductor

Step 4: Pull down on the unit to ensure that the urethane spring is securely holding

the Varcorder on the conductor

Step 5: Release the hot stick

Removing the Varcorder from the line with a shotgun style hot stick:

Step 1: Attach the hot stick to the unit

Step 2: Disengage the urethane spring from the conductor

Step 3: Push against the urethane carabineer; it requires ~15lbs of pressure on the

carabineer to remove the Varcorder from the line

Shotgun

Adapter

Urethane

Spring

Urethane

Carabineer

Do not install on angled or vertical overhead lines. The clamping mechanism

is not designed for these lines and doing so will cause the unit to move with

the potential of damaging utility assets.

Line Installation

CORRECT INCORRECT

Page 9

Urethane

Spring

Urethane

Carabineer

Switch Stick

Receiver

Installation: Universal Switch Stick

The metal contactor on the Varcorder must have a direct connection to the bare

conductor to accurately measure the power factor. The Varcorder will not take

accurate Power Factor measurements on covered wire.

Step 1: Attach the Switch Stick receiver to the Varcorder

Step 2: Attach the Switch Stick adapter the switch stick

Step 3: Insert the adapter into the receiver and twist until firmly in the receiver

Step 4: Place the Varcorder on the conductor

Step 5: Pull down on the unit to ensure the urethane spring is securely holding the

Varcorder on the conductor

Step 6: Unscrew the switch stick to release the Varcorder

Switch Stick Adapter

Removing the Varcorder from the line with a switch stick style hot stick:

Step 1: Insert the adapter into the receiver and twist until firmly in the receiver

Step 2: Push against the urethane carabineer; it requires ~15lbs of pressure on the

carabineer to remove the Varcorder from the line

Do not install on angled or vertical overhead lines. The clamping mechanism

is not designed for these lines and doing so will cause the unit to move with

the potential of damaging utility assets.

Line Installation

CORRECT INCORRECT

Page 10

Softlink for Varcorder

Softlink is a software application that allows the user to download, view, graph and

import data from their Recorder. In order for a PC running Softlink to communicate,

the Recorder must be powered on, with the IR port on the unit in-line with the IrDA

USB that is connected to the PC.

Please see the Transcorder Manual for instructions with radio communication.

Softlink System Requirements

OPERATING SYSTEM: Softlink installs onto computers running Windows 7, 8, and

10. Softlink requires Microsoft .NET, which will install with Softlink if not already

installed.

NETWORK INSTALLATION: Softlink is a single user application and is not

supported when installed onto a server.

INSTALLATION AUTHORITY: Installation will require administration rights.

Computers managed by electric utility organizations often limit the programs that

can be installed. If the user does not have admin rights they will need the assistance

of the IT department to download the software.

USB PORT PERMISSIONS: The USB IrDA has an install program that runs the first

time it is connected. The user may have rights to install programs but may not

be aware that the USB ports are locked on the PC. Please contact your network

administrator for permission and instructions to complete the install if drivers are

not installing automatically.

Softlink Installation

Step 1: Softlink Installer is available at www.sensorlink.com/products/varcorder.

Save the file to the desired location. The Softlink .exe file will automatically begin

the download when clicked.

Step 2: You must agree to the licensing agreement to proceed with the download

Step 3: A dialog box will appear to let you know when the download is complete

Step 4: To open Softlink, click on the Start Menu. Under Programs, select Softlink.

Shortcut paths will automatically load during the install.

Manual IrDA Driver Installation

For information on this install, please reference the IrDA manufactures’

documentation available on their product CD. Additionally, if a digital download is

required, the driver is available online at www.sensorlink.com/products/varcorder.

[ACT-IR224UN-LN115GENERAL SETUP PROCEDURE]

1. Make sure IrDA USB is NOT plugged into the PC until the driver is installed.

2. Insert the installation CD and run the setup file.

3. Click "Next" to continue through the IrDA Driver Installer welcome screen.

4. When this Installation completes, click "Finish" to close the Wizard window.

5. Insert the IrDA cable into the USB port. A message will pop up stating: "Found

new Hardware", then replaced with "New hardware successfully installed and ready

to use."

Page 11

Discover

Configure

Download

Discover Recorder

Click the discover button to instruct the IrDA to immediately find and communicate

to the Recorder. The description and photo displayed will change from the

communication device to the unit when the Recorder has been discovered.

Communicating with Recorder

Softlink communicates with one Recorder at a time. To make sure only one Recorder

is communicating, stand any other Recorders on their base. To communicate with a

Recorder, follow these steps:

Step 1: Insert the USB IrDA cable into the PC's user port

Step 2: Position the Recorder so the IrDA Port, located at the bottom of the unit, is

facing the IrDA

Step 3: Open Softlink from either the Desktop or Start Menu.

Softlink will automatically discover the IrDA and display the communication device

in the upper left corner of the program.

Page 12

Configure Recorder

Select the Configure button to setup Recorder preferences.

Name: Identify the Recorder with up to 16 characters.

Description: Enter a description of up to 46 characters. For example, you may

want to note the Recorder's service location and the date range for the recordings.

Log Interval: Select how often to log data. The Recorder averages all samples

taken since the previous logging and records the result. Typical sample and log

synchronization intervals are one minute and 15 minutes, respectively. The log

interval must exceed the sample interval.

How many Log intervals are available in the Varcorder? 64,000

Sample Interval: Select how often the Recorder will sample current by sliding

the cursor on the scroll bar. Minimum sample interval is five seconds. Battery life

depends on this setting; see page four.

Synchronization: Selecting the “Clear all logged data from the Recorder… and

synchronize logging to the hour” box will allow the Recorder to synchronize itself

to the computer's clock. When multiple Recorders are setup and synchronized using

the same log interval and the same computer, they will all log at the same time.

Clock is Set: If the Recorder is not synchronized before hanging on the line, the log

time and date will be set, even though not evenly aligned to the hour.

Clock is Unset: If the Recorder’s battery fails prior to any Softlink communication.

Legacy: Older version Recorders cannot be synchronized. To achieve log-time

accuracy with these units, take them down before the battery fails, and download

all data before re-hanging the unit. All log times prior to the first download are

accurate to within a log interval, as long as the battery has not failed.

Page 13

Download Recorder Data

Click the Download button to begin downloading data from the Recorder. The user

is able to view the Recorder's configuration and progress as it is downloading in the

graph view.

The download can be stopped at any time by selecting the red X button.

Repeat these steps to download the data from any additional units. Each unit's data

will load into a new tab.

NOTE: Once a fresh battery is inserted, the user has 5 minutes to start downloading

the data before the Varcorder resets itself. The Varcorder will only save the logged

data in its flash ram for 5 minutes. We recommend that you do not remove the

battery until you have downloaded all of the data. A new battery should be

placed into the Varcorder before it is deployed on the line to ensure the reliability of

the battery life.

Entering the Nominal Voltage

It is necessary to set the nominal phase to ground voltage in Softlink before

downloading data. Nominal voltage can be set in options, or entered at the time of

download. It cannot be changed for the dataset after download.

The user will be prompted to enter nominal phase to ground voltage after selecting

"download". Any value already set will be default; it can be updated by selecting

the "change" button.

Page 14

Saving Recorder Data

Data files may be saved as a .csv or .xlsx file for future review in Softlink or another

data management program. The data from each recorder is saved into its own file.

Step 1: Select the data file by selecting the Recorder on the menu

Step 2: Select "save"

Step 3: Repeat this process for any other data files to be saved

Opening Recorder Data files in Softlink

Previously saved files from a Recorder may be opened in Softlink. Follow these steps

for opening saved files:

Step 1: Open Softlink

Step 2: Close the "Discovering ports and instruments" bar

Step 2: Select "Open File"

Step 3: Find and select the .csv or xlsx Softlink file

Page 15

Opening data files in other programs

Previously saved files from a Recorder may be opened in other data management

programs for analysis and review.

Page 16

Recorder Options

The options button on the Download Screen allows the user to change preferences.

Radio instruments remembered: For use with optional Radio Transcorders only.

Softlink remembers Radio Transcorders that were used in previous downloads. Select

"Clear all" for Softlink to forget the radios. See the Radio Transcorder User's Manual

for further details.

Chart line thickness: The thickness of the graph lines can be changed by the

user. Thickness is numbered 1 - 10, and defaults at three. The software will show a

preview to the user as the value is changed.

Chart spline tension: The chart spline tension is used to smooth graph lines. The

spline tension range is 0 - 1. Slide the scroll bar to change the spline tension. The

software will show a preview to the user as the value is changed.

Default nominal phase to ground voltage: Softlink will populate this voltage

value each time the nominal voltage window pops up at the beginning of a

download. To change the number, select the existing number and type the desired

value, or use the up/down arrow keys to update the value.

Page 17

Graphing

To graph the downloaded data, click the Graph Icon on the download screen.

A second screen will open and display the data in graphical format.

Report Options

Select the units and measurement parameters to graph by clicking in the selection

boxes. Only selected measurement parameters will display on the graph.

Hide and Show Report Options

Click the left arrow to hide Report Options. Click the right arrow to show the

hidden Report options.

Zoom Window

The bottom graph displays the entire time series. To view a section of time, adjust

the left and right sliders. The upper graph will display the values between the slides.

Cursor Tool

Placing the cursor over the graph will display the date and time values of the

measurements.

Unit Data Selection

All units downloaded in a session will show, even if the downloaded data has been

closed in the previous screen.

Graph

Page 18

Troubleshooting

The Recorder is not communicating

1) Position the IrDA no more than three feet away from the Recorder.

2) Examine the IrDA connection to the PC and reconnect if necessary.

3) Verify the battery has greater than 5 Volts with a Voltmeter. Replace if low.

4) IrDA USB cables are not universal; using an IrDA not supported by Softlink

may not work. The IrDA you received with your kit has been tested to work

with the Recorders.

5) The Serial Number of the IrDA must start with a "TA" if running Softlink on

WIN 10.

6) Try restarting Softlink by first exiting and then restarting.

7) Try restarting your computer and then re-open Softlink.

8) Do not use docking station USB ports. This will cause the program to hang

up or have no communication to the USB.

9) Use the same USB port that was unlocked by IT for the USB IrDA. Using a

different port will not work without security permissions from IT.

Power Factor measurements do not seem to be correct

Varcorder specification limitations:

1) Power Factor Range is .71 lead to .71 lag. Accuracy of Power Factor

measured outside this range is not guaranteed.

2) Voltage requirements: Minimum voltage required for accurate measurement

is 600 volts.

Varcorder's contact with the line:

1) The metal contactor has to have constant contact with the bare wire.

2) The unit will not take accurate Power Factor measurements on covered wire.

Source load effects:

1) Electric motors, equipment that is used above rated voltages, etc., will cause

poor power factor. It may be necessary to further investigate the customer's

usage to locate a problem source.

Power factor lead/lag

1) If the PF on the conductor is fluctuating close to unity, and has a mix of

sample lead and lag measurements, the unit will select lead or lag by the

hightest count.

Incorrect nominal Voltage was entered before downloading the data

1) Re-download the data if it hasn't been cleared from the Recorder

Page 19

SensorLink Corporation

Warranty

SensorLink Corporation warrants each instrument it manufactures to be free from

defects in materials and workmanship under normal use and service for the period of

one year after date of shipment. Within this period, SensorLink Corporation agrees

to repair or replace, at SensorLink Corporation’s option, any instrument that fails to

perform as specified. This Warranty shall not apply to any instrument that has been:

1 Repaired, worked on, or altered, including removal of the front panel, by persons

unauthorized by SensorLink Corporation in such a manner as to injure, in

SensorLink Corporation’s sole judgment, the performance, stability, or reliability

of the instrument;

2 Subjected to misuse, negligence, or accident; or

3 Connected, installed, adjusted, or used otherwise than in accordance with the

instructions furnished by SensorLink Corporation.

This Warranty is in lieu of any other warranty, expressed or implied. SensorLink

Corporation reserves the right to make any changes in the design or construction

of its instruments at any time, without incurring any obligation to make any change

whatever in units previously delivered.

If a failure occurs, contact the manufacturer for a Return Authorization and

instructions for return shipment. This warranty constitutes the full understanding of

the manufacturer and buyer, and no terms, conditions, understanding, or agreement

purporting to modify or vary the terms hereof shall be binding unless hereafter made

in writing and signed by an authorized official of SensorLink Corporation.

Quality Assurance Certification

Amp, Power Factor & VAR Recorder

Model 910

SensorLink Corporation certifies that its calibration measurements are

traceable to the National Institute of Standards and Technology (NIST),

to the extent allowed by the Institute's calibration facility, and to the

calibration facilities of other International Standards Organization members.

This document certifies the following Model 910 was tested at the

SensorLink Corporation High Voltage Laboratory, Ferndale, WA, USA to the

appropriate standard and comply with the requirements of that standard.

Serial Number: ____________________________________________

Model Number: ___________________________________________

I hereby certify that the Model 910 Varcorder has passed all tests defined

in the SensorLink Corporation standard. I also certify that I have reviewed

the standard and test procedure and that they are sufficient in determining

compliance with the standard.

Signed: ___________________________________________________

Date: _____________________________________________________

SensorLink®Corporation

1360 Stonegate Way

Ferndale, WA 98248 USA

phone: 360/595.1000

fax: 360/595.1001

www.sensorlink.com

Form No: SALE-Manual Template Varcorder-011 REV: V04

Date: 10/2019

Manual Stock Code No: M050-070-001

Information contained in this document is subject to change without notice. Product specification may change. Contact

your SensorLink representative for the most current product information. © 2005 by SensorLink. All rights reserved.

These products proudly made in the USA.

This manual suits for next models

3

Table of contents

Other SensorLink Measuring Instrument manuals

SensorLink

SensorLink 8-182 User manual

SensorLink

SensorLink Amcorder UG Series User manual

SensorLink

SensorLink 8-117 XT 50HZ User manual

SensorLink

SensorLink Ampstik+ User manual

SensorLink

SensorLink True RMS Ampstik 8-020 User manual

SensorLink

SensorLink Swarm S2 User manual

SensorLink

SensorLink TMS 950 User manual

SensorLink

SensorLink 6-120 User manual

SensorLink

SensorLink Radio Ohmstik User manual