Sentec tcPCO2 User manual

Instruction Manual

For the Digital Monitoring System

(Software version SMB SW-V08.02; MPB SW-V06.02)

SenTec Digital Monitoring System

Noninvasive Ventilation and Oxygenation Monitoring

[John Smith]

[Sarah Miller]

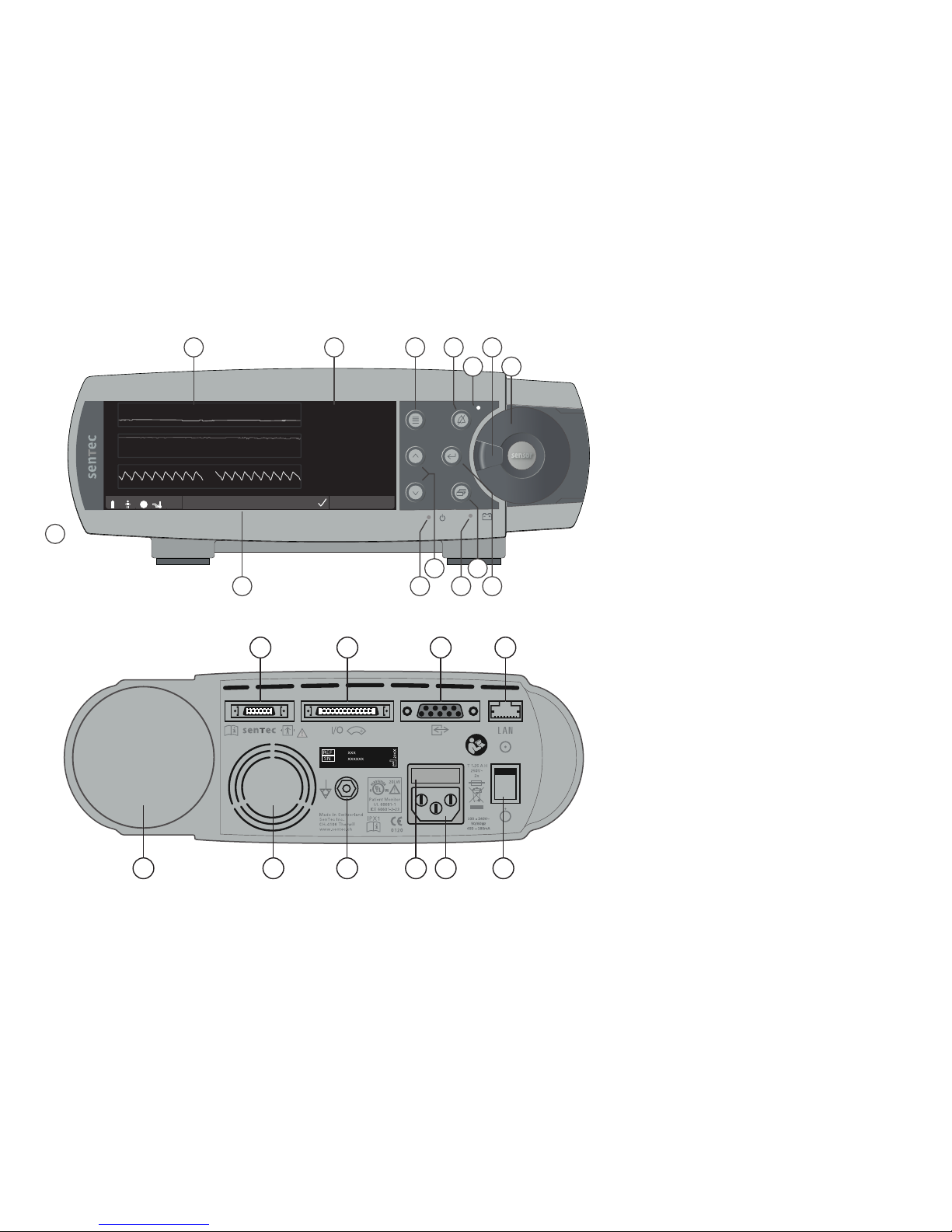

19 20 21 22 23 24

15 16 17 18

12 sec

100

70

75

25

- 15 min 0 min

- 15 min 0 min

0 min

39.4

50

30 PCO2

mmHg

84140

50 PR

bpm

96

100

85 %SpO2

2.0 PI

100%

+

-

7.7h

AD

°C

42.0

RHP

0

[John Smith] 2014-04-28 15:28:31

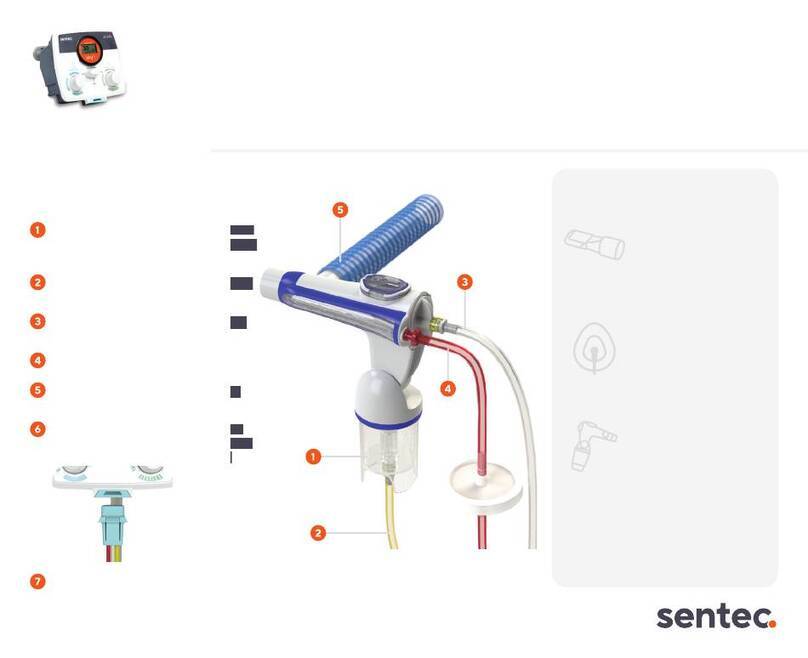

1 2 3 4

5

6

7

8101213

14

11 9

1Trend Display Area

2Numerical Display Area

3Menu/Previous Level Button

4AUDIO PAUSED/OFF Button

5AUDIO PAUSED/OFF Indicator (yellow LED)

6Door Handle

7Docking Station Door (colored dot in center

of door indicates the SDM’s PO2activation

status: blue if activated, orange otherwise)

8Enter Button

9Display Button

10 AC Power/Battery Indicator

(green/yellow LED)

11 UP/DOWN Buttons

12 ON/OFF Indicator (green LED)

13 Status Bar

14 Speaker (on the side)

15 Sensor Connection Port

16 Multipurpose l/O-Port

(Nurse Call & Analog Output)

17 Serial Data Port (RS-232)

18 Network Port (LAN)

19 Gas Bottle Slot

20 Fan

21 Equipotential Terminal Connector (ground)

22 Fuse Holder

23 AC Power Connector

24 ON/OFF Switch

C

L

A

S

S

I

F

I

E

D

UL

C U

S

R

Warranty

The manufacturer warrants to the initial purchaser that each new component of the SenTec Digital Monitoring System will be free from defects in

workmanship and materials. The manufacturer’s sole obligation under this warranty is to at its own choice repair or replace any component – for

which the manufacturer acknowledges the warranty cover – with a replacement component.

Warranty Exclusions and System Performance

SenTec AG can neither guarantee or verify instrument performance characteristics nor accept warranty claims or product liability claims if the

recommended procedures are not carried out, if the product has been subject to misuse, neglect or accident, if the product has been damaged

by extraneous causes, if accessories other than those recommended by SenTec AG are used, if the warranty seal on the lower side of the monitor

is broken, or if instrument repairs are not carried out by SenTec authorized service personnel.

CAUTION: Federal law (U.S.) restricts this device to sale by or on the order of a physician.

Patents/Trademarks/Copyright

International Industrial Design No. DM/054179, Japanese Design No. 1137696, U.S. Design Patent No. D483488. Canadian Patent No. 2466105,

European Patent No. 1335666, German Patent No. 50111822.5-08, Spanish Patent No. 2278818, Hongkong Patent No. HK1059553, U.S. Patent

No. 6760610. Chinese Patent No. ZL02829715.6, European Patent No. 1535055, German Patent No. 50213115.2, Spanish Patent No. 2316584,

Indian Patent No. 201300, Japanese Patent No. 4344691, U.S. Patent No. 7862698. SenTec™, V-Sign™, OxiVenTTM, V-STATS™, V-CareNeT™,

V-Check™, Staysite™, Illuminate Ventilation™ and Advancing Noninvasive Patient Monitoring™ are trademarks of SenTec AG / © 2018 SenTec AG.

All rights reserved. The contents of this document may not be reproduced in any form or communicated to any third party without the prior

written consent of SenTec AG. While every effort is made to ensure the correctness of the information provided in this document, SenTec AG

assumes no responsibility for errors or omissions. This document is subject to change without notice.

Patient Monitor

IN ACCORDANCE WITH IEC 60601-1; ANSI/AAMI ES60601-1; CAN/CSA C22.2 No. 60601-1,

IEC 60601-1-2, IEC 60601-2-23, ISO 80601-2-61

Manufacturer: SenTec AG, Ringstrasse 39, CH-4106 Therwil, Switzerland,

www.sentec.com

Page 3.Contents

Contents

Intended Use, Principles of Operation and Limitations .............................................................. 5

Intended Use of the SenTec Digital Monitoring System (SDMS) ...................................................................................... 5

Transcutaneous PCO2and PO2..........................................................................................................................................5

Pulse Oximetry .................................................................................................................................................................7

SenTec TC Sensors ...........................................................................................................................................................9

The SenTec Digital Monitoring System (SDMS) ........................................................................ 10

Setting up the SDMS ................................................................................................................. 12

Connect SDM to AC Power ............................................................................................................................................. 12

Battery Operation of the SDM ........................................................................................................................................ 12

Turning on the SDM........................................................................................................................................................ 12

Installation of the Gas Bottle (Service Gas-0812) .......................................................................................................... 13

Connection/Disconnection of Digital Sensor Adapter Cable ........................................................................................... 13

Connection of a SenTec TC Sensor................................................................................................................................. 14

Sensor Check, Sensor Calibration/Storage and Membrane Change ......................................... 15

Checking a SenTec TC Sensor ........................................................................................................................................ 15

Sensor Calibration and Storage ...................................................................................................................................... 16

Changing the Sensor Membrane .................................................................................................................................... 17

Patient Monitoring with the SDMS............................................................................................ 20

Selection of Patient Type, Measurement Site, and Sensor Attachment Accessory ........................................................ 20

Check SDM Settings and System Readiness................................................................................................................... 22

Sensor Application Using a Multi-Site Attachment Ring/Easy......................................................................................... 24

Sensor Application Using an Ear Clip.............................................................................................................................. 27

Patient Monitoring .......................................................................................................................................................... 29

Sensor Removal with Multi-Site Attachment Ring/Easy.................................................................................................. 38

Sensor Removal with Ear Clip......................................................................................................................................... 40

Controls, Indicators and Alarms................................................................................................ 42

Controls (Buttons) .......................................................................................................................................................... 42

LED Indicators ................................................................................................................................................................ 45

Auditory Indicators/Signals............................................................................................................................................. 45

Alarms ............................................................................................................................................................................ 46

Status Bar with Status Icons and Status Messages........................................................................................................ 48

Maintenance of the SDMS ......................................................................................................... 50

Routine Checks............................................................................................................................................................... 50

Service............................................................................................................................................................................ 51

Specifications of tcPCO2, tcPO2and Pulse Oximetry ................................................................ 52

Specifications of tcPCO2and tcPO2................................................................................................................................. 52

Specifications of Pulse Oximetry..................................................................................................................................... 53

Glossary of Symbols .................................................................................................................. 54

Page 5.Intended Use, Principles of Operation and Limitations

Intended Use of the SenTec Digital

Monitoring System (SDMS)

The SenTec Digital Monitoring System (SDMS) – consisting

of the SenTec Digital Monitor (SDM), sensors and accessories

(p. 10) – is indicated for continuous, noninvasive monitoring

of carbon dioxide tension and oxygen tension as well as oxygen

saturation and pulse rate in adult and pediatric patients. In

neonatal patients the SDMS is indicated for carbon dioxide and

oxygen tension monitoring only. Oxygen tension monitoring is

contraindicated for patients under gas anesthesia.

The SDMS is indicated for use in clinical and non-clinical

settings such as hospitals, hospital-type facilities, intra-hospital

transport environments, clinics, physician offices, ambulatory

surgery centers and – if under clinical supervision – home

environments. The SDMS is for prescription use only.

Note: The above phrasing corresponds to an abbreviated

version of the SDMS’ Intended Use. Please refer to the current

issue of the Technical Manual for the SDM (HB-005752) for the

full phrasing of the SDMS’ Intended Use.

Intended Use, Principles of Operation and Limitations

Transcutaneous PCO2and PO2

Principles of Operations of tcPCO2and tcPO2

Carbon dioxide (CO2) and Oxygen (O2) are gases that readily

diffuse through body and skin tissue and, therefore, can be

measured by an adequate noninvasive sensor being applied at

the skin surface. If the skin tissue beneath the sensor site is

warmed up to a constant temperature local capillary blood flow

increases, metabolism stabilizes, gas diffusion improves and,

hence, reproducibility and accuracy of CO2/O2measurements

at the skin surface improves.

CO2tensions measured at the skin surface (PcCO2) are usually

consistently higher than arterial PCO2 values (PaCO2) in patients

of all ages. It is therefore possible to estimate PaCO2from

the measured PcCO2using an adequate algorithm. TcPCO2

designates an estimate of PaCO2calculated from the measured

PcCO2with an algorithm developed by J.W. Severinghaus.

The ‘Severinghaus Equation’ first corrects PcCO2measured at

the sensor temperature (T) to 37 °C by using an anaerobic

temperature factor (A) and then subtracts an estimate of the

local ‘Metabolic Offset’ (M).

Note: Hence, the tcPCO2values displayed by the SDM are

corrected/normalized to 37 °C and provide an estimate of

PaCO2at 37 °C. On the SDM and throughout this manual

(unless explicitly stated otherwise) ‘tcPCO2’ is displayed/

labeled as ‘PCO2’.

In newborns PO2measured at the skin surface (PcO2) correlates

with arterial PO2(PaO2) almost in a one to one relationship at

a sensor temperature of 43 to 44 °C, whereby the accuracy

of PcO2compared to PaO2is best up to PaO2of 80 mmHg

(10.67 kPa), above which it increasingly tends to read lower

than PaO2(especially in adults). As target PaO2levels in

newborns are usually below 90 mmHg (12 kPa), a correction

of PcO2values measured at a sensor temperature of 43 to

44 °C is normally not necessary. TcPO2designates an estimate

of PaO2and corresponds to the measured PcO2.

Note: On the SDM and throughout this manual (unless

explicitly stated otherwise) ‘tcPO2’ is displayed/labeled as ‘PO2’.

Good to know!

Warming the skin tissue beneath the sensor to a constant

temperature improves accuracy as it a) increases capillary

blood flow/induces local arterialization, b) stabilizes

metabolism, and c) improves gas diffusion through skin

tissue. With increasing sensor temperature the application

duration (‘Site Time’) must be evaluated carefully and

adjusted accordingly to reduce the risk of burns. Special

attention must be given to patients with sensitive skin

at the sensor site (e.g. preterm or geriatric patients, burn

victims, patients with skin diseases) and/or very low skin

tissue perfusion beneath the sensor site (e.g. hypothermic

patients, patients with vasoconstrictions, low blood pressure,

or circulatory centralization (shock)).

Please refer to Technical Manual for the SDM (HB-005752)

and the references cited therein for additional information on

transcutaneous blood gas monitoring.

Limitations of tcPCO2and tcPO2

The following clinical situations or factors may limit the

correlation between transcutaneous and arterial blood gas

tensions:

• Hypo-perfused skin tissue beneath the sensor site due

to low cardiac index, circulatory centralization (shock),

hypothermia (e.g. during surgery), use of vasoactive drugs,

arterial occlusive diseases, mechanical pressure exercised

on measurement site, or inadequate (too low) sensor

temperature.

• Arterio-venous shunts, e.g. ductus arteriosus (PO2specific).

• Hyperoxemia (PaO2> 100 mmHg (13.3 kPa)) (PO2specific).

• Inadequate measurement site (placement over large

superficial veins, on areas with skin edema (e.g. oedema

neonatorum), skin breakdown, and other skin anomalies).

• Improper sensor application resulting in an inadequate, not

hermetically sealed contact between the sensor surface and

the patient’s skin causing the CO2and O2gases diffusing out

of the skin to intermix with ambient air.

• Exposure of the sensor to high ambient light levels (PO2

specific).

CAUTION: Compared to the corresponding arterial blood

gases PCO2readings are typically too high and PO2readings

typically too low if the measurement site is hypo-perfused.

CAUTION: The SDMS is not a blood gas device. Keep

the above mentioned limitations in mind when interpreting

PCO2and PO2values displayed by the SDM.

Page 7.Intended Use, Principles of Operation and Limitations

When comparing PCO2/PO2values displayed by the SDM with

PaCO2/PaO2values obtained from arterial blood gas (ABG)

analysis, pay attention to the following points:

• Carefully draw and handle blood samples.

• Blood sampling should be performed in steady state

conditions.

• The PaCO2/PaO2value obtained from ABG analysis should be

compared to the SDM’s PCO2/PO2reading at the time of blood

sampling.

• In patients with functional shunts, the sensor application site

and the arterial sampling site should be on the same side of

the shunt.

• If the menu-parameter ‘Severinghaus Correction Mode’

is set to ‘Auto’, the PCO2values displayed by the SDM are

automatically corrected to 37 °C (regardless of the patient’s

core temperature). When performing the ABG analysis, be

sure to properly enter the patient’s core temperature into the

blood gas analyzer. Use the blood gas analyzer’s ‘37 °C-PaCO2’

value to compare with the SDM’s PCO2value.

• Verify proper operation of the blood gas analyzer. Periodically

compare the blood gas analyzer’s barometric pressure against

a known calibrated reference barometer.

Pulse Oximetry

Principles of Operations of Pulse Oximetry

The SDMS uses pulse oximetry to measure functional oxygen

saturation (SpO2) and pulse rate (PR). Pulse oximetry

is based on two principles: firstly, oxyhemoglobin and

deoxyhemoglobin differ in their absorption of red and infrared

light (spectrophotometry) and secondly, the volume of arterial

blood in tissue (and hence, light absorption by that blood)

changes during the pulse (plethysmography).

Pulse oximeter sensors pass red and infrared light into a

pulsating arteriolar vascular bed and measure changes in light

absorption during the pulsatile cycle. Red and infrared low-

voltage light-emitting diodes (LED) serve as light sources and

a photodiode serves as photodetector. The software of a pulse

oximeter uses the ratio of absorbed red to infrared light to

calculate SpO2.

Pulse oximeters use the pulsatile nature of arterial blood flow

to differentiate the oxygen saturation of hemoglobin in arterial

blood from the one in venous blood or tissue. During systole,

a new pulse of arterial blood enters the vascular bed: blood

volume and light absorption increase. During diastole, blood

volume and light absorption decrease. By focusing on the

pulsatile light signals, effects of nonpulsatile absorbers such as

tissue, bone and venous blood are eliminated.

Note: The SDMS measures and displays functional oxygen

saturation: the amount of oxygenated hemoglobin expressed

as a percentage of the hemoglobin that can transport oxygen.

The SDMS does not measure fractional saturation: oxygenated

hemoglobin expressed as a percentage of all hemoglobin, in-

cluding dysfunctional hemoglobin such as carboxyhemoglobin

or methemoglobin.

Good to know!

Oxygen saturation measurement techniques – including pulse

oximetry – are not able to detect hyperoxemia.

Due to the S-shape of the oxyhemoglobin dissociation curve

(ODC) SpO2alone cannot reliably detect hypoventilation in

patients being administered with supplemental oxygen.

Limitations of Pulse Oximetry

The following clinical situations or factors may limit the

correlation between functional oxygen saturation (SpO2) and

arterial oxygen saturation (SaO2) and may cause the loss of

the pulse signal:

• dysfunctional hemoglobins (COHb, MetHb)

• anemia

• intravascular dyes, such as indocyanine green or methylene

blue

• low perfusion at the measurement site (e.g. caused by inflated

blood pressure cuff, severe hypotension, vasoconstriction in

response to hypothermia, medication, or a spell of Rynaud’s

syndrome)

• venous pulsations (e.g. due to use of the forehead, cheek

or earlobe as a measurement site on a patient in steep

Trendelenburg position)

• certain cardiovascular pathologies

• skin pigmentation

• externally applied coloring agents

(e.g. nail polish, dye, pigmented cream)

• prolonged and/or excessive patient movement

• exposure of the sensor to high ambient light levels

• defibrillation

Page 9.Intended Use, Principles of Operation and Limitations

SenTec TC Sensors

SenTec TC Sensors provide superior performance, are robust,

reliable and require comparatively low maintenance. They

combine within a patented digital sensor design the optical

components needed for 2-wavelength, reflectance pulse

oximetry with the components needed to measure PCO2and –

in case of the OxiVenT™ Sensor only – PO2.

PO2(OxiVenT™ Sensor) is measured with dynamic fluorescence

quenching, an oxygen sensing technology measuring the

oxygen molecules present in the vicinity of a fluorescent dye

being immobilized in a thin carrying layer incorporated within

the sensor surface.

The PCO2measurement of SenTec TC Sensors (V-Sign™

Sensor 2, OxiVenT™ Sensor) is based on a Stow-Severinghaus

type PCO2sensor, i.e. a thin electrolyte layer is confined to

the sensor surface with a hydrophobic, CO2and O2permeable

membrane. Membrane and electrolyte must be exchanged

every 28 to 42 days. With SenTec’s patented Membrane

Changer the membrane and electrolyte can be changed

with the ease of 4 identical Press-and-Turn steps in a highly

reproducible manner (p. 17).

Calibration of the PCO2segment of SenTec TC Sensors is

recommended every 6 to 12 hours and mandatory every 12 to

16 hours (p. 16). The PO2measurement of the OxiVenT™

Sensor is virtually drift free and, hence, calibration free.

Nevertheless, the SDM, as a precaution, calibrates PO2during

each mandatory calibration and subsequently approximately

once every 24 hours during one of the anyways ongoing PCO2

calibrations.

To achieve local arterialization of the skin tissue at the

measurement site, SenTec TC Sensors are operated at a

constant sensor temperature of typically 41 °C in neonatal and

42 °C in adult/pediatric patients if PO2is disabled and – if PO2

is enabled – of typically 43 °C in neonatal and 44 °C in adult/

pediatric patients, respectively. Controls of sensor temperature

and application duration are designed to meet all applicable

standards. To guarantee safe operation, SenTec TC Sensors

reliably supervise the sensor temperature with two independent

circuits. Additionally, the SDM firmware redundantly controls

the temperature of the connected sensor.

The SenTec Digital Monitoring System (SDMS)

The SenTec Digital Monitoring System (SDMS) comprises the

following main components:

SenTec Digital Monitor (SDM)

Note: SDMs with firmware version SMB SW-V08.00/MPB SW-

V06.00 or newer are available in a software-configuration

without activated PO2-option (SDM) and in a configuration with

activated PO2-option (SDM-PO2). The respective configuration

is indicated on the SDM’s ‘Power On Self Test’ Screen and

on the second page of the menu ‘System Information’.

Furthermore, the colored dot in the center of a SDM’s Docking

Station Door 7is orange, if PO2is not activated, and blue, if

PO2is activated.

V-Sign™ Sensor 2 (for PCO2, SpO2/PR monitoring) or

OxiVenT™ Sensor (for PCO2, PO2, SpO2/PR monitoring)

Note: Throughout this manual the notion ‘SenTec TC Sensor’

refers to SenTec sensors providing transcutaneous blood gas

measurements (i.e. to the V-Sign™ Sensor 2 and the OxiVenT™

Sensor).

Digital Sensor Adapter Cable (to connect a SenTec TC Sensor

to SDM)

Ear Clip and Multi-Site Attachment Rings (to attach SenTec

TC Sensors to patients)

Staysite™ Adhesive (to improve attachment of Multi-Site

Attachment Rings, e.g. in high humidity environments, for patients

who perspire profusely and/or in challenging patient motion

conditions).

Contact Gel (contact liquid for the application of SenTec TC

Sensors)

Service Gas (to calibrate SenTec TC Sensors)

Membrane Changer (to change membrane and electrolyte

of SenTec TC Sensors)

V-STATS™ (PC based Trend Data Download/Analysis, Remote

Monitoring, and Configuration Software for SenTec Digital

Monitors)

SDMS Quick Reference Guide and SDMS Instruction

Manual (the present document)

SDMS Manual CD (with the exception of the ‘Service and

Repair Manual for the SDMS’ all manuals and Directions for

Use being related to the SDMS are provided on the Manual CD)

Note: The components listed above do not necessarily

correspond to the scope of delivery. A complete list of available

products including disposables and accessories is provided at

www.sentec.com/products.

Page 11 .The SenTec Digital Monitoring System (SDMS)

Additional information on SenTec TC Sensors, the Ear Clip,

the Multi-Site Attachment Rings, the Staysite™ Adhesive,

the Membrane Changer, and the Membrane Changer Inserts

is provided in the respective Directions for Use. Detailed

information on the SenTec Digital Monitor is provided in the

Technical Manual for the SDM (HB-005752). Information on

maintenance, service and repair procedures that do not require

opening the cover of the SDM as well as on maintenance and

service procedures for SenTec TC Sensors are provided in the

SDMS Service Manual (HB-005615).

To ensure proper operation of the SDMS, precisely follow the

instructions provided in this Instruction Manual step by step.

WARNING: The instructions given in the SDMS Quick

Reference Guide, the SDMS Instruction Manual, the Technical

Manual for the SDM, and on the SDMS Manual CD must be

followed in order to ensure proper instrument performance

and to avoid electrical hazards.

Note: Statements in this manual are only applicable for SDMs

with the software version indicated on the cover page.

Note: The SDMS Quick Reference Guide, the SDMS

Instruction Manual and various other manuals are

available for online viewing at www.sentec.com/ifu.

Note: SDMS related tutorials are available for online

viewing at www.sentec.com/tv.

Setting up the SDMS

Connect SDM to AC Power

Plug the female connector of the power

cord into the AC power connector on the

rear of the monitor 23 .

Plug the male connector of the power

cord into a properly grounded AC

power outlet.

Note: The SDM will automatically

adapt to the applicable local voltage:

100 - 240V~ (50/60Hz).

Verify that the AC power/battery indicator 10 is lit. If the AC

power/battery indicator is not lit, check the power cord, fuses,

and the AC power outlet.

Battery Operation of the SDM

The SDM is equipped with a rechargeable internal Li-Ion

battery that can be used to power the monitor during transport

or when AC power is not available. The Status Icon ‘Battery’

(p. 48) indicates the remaining battery charge (%).

Good to know!

When using an SDM with a LED backlight display, a new, fully

charged battery will provide up to 10 hours of monitoring

time if Sleep Mode=OFF or Auto, and up to 12 hours of

monitoring time if Sleep Mode=ON. It takes approximately

7 hours to fully charge a drained battery.

The AC Power/Battery Indicator 10 provides information on

the charging status of the battery:

Green: SDM connected to AC power, battery fully charged

Yellow: SDM connected to AC power, battery charging

LED OFF: SDM not connected to AC power (i.e. powered by

internal battery)

Turning on the SDM

Turn on the SDM by pushing the ON/OFF Switch on the rear

panel 24 . The SDM will automatically perform a ‘Power On

Self Test’ (POST). Check the date/time settings of the SDM and

adjust if necessary.

Note: If the POST fails, discontinue use of the SDM and contact

qualified service personnel or your local SenTec representative.

Refer to the Technical Manual for the SDM (HB-005752) for a

detailed description of the POST.

ON/OFF

switch

Page 13 .Setting up the SDMS

Installation of the Gas Bottle

(Service Gas-0812)

The gas bottle slot is located on the rear of the SDM 19 .

Remove the old gas bottle by turning

it counter-clockwise.

Insert the new gas bottle by turning

it clockwise approx. 4.5 turns and

thoroughly tighten it (without applying

undue force).

CAUTION: Failure to properly insert the gas bottle

may result in incorrect sensor calibrations and may cause

increased gas consumption.

The Status Icon ‘Gas’ (p. 48) indicates the remaining capacity

of the gas bottle in %. It is only displayed if a SenTec TC

Sensor is connected to the SDM and is in the Docking Station.

WARNING: The Service Gas bottle is a pressurized

container. Protect from sunlight and do not expose to

temperatures exceeding 50 °C (122 °F). Do not pierce or

burn, even after use. Do not spray on a naked flame or any

incandescent material.

WARNING: Do not use expired gas bottles or gas

bottles from manufacturers other than SenTec. The use of

non-SenTec gas bottles may damage the Docking Station.

Improper calibration gas mixtures will result in incorrect

sensor calibrations and subsequently result in inaccurate

PCO2and/or PO2data.

Dispose of empty gas bottles according to local waste disposal

regulations for aluminium containers.

Connection/Disconnection of Digital

Sensor Adapter Cable

Connect the Digital Sensor Adapter Cable to the SDM. The con-

nection is properly established when both clamps of the plug

snap into place in the sensor connection port 15 .

Disconnect the cable from the SDM

by pressing the two latches on the

black plug to release the clamps (see

picture) and pull to remove the cable.

Press

Connection of a SenTec TC Sensor

Take a SenTec TC Sensor (V-Sign™ Sensor 2 or OxiVenT™

Sensor).

Important: For PO2monitoring you must use an OxiVenT™

Sensor and an SDM with activated PO2-option.

Check the condition of the sensor membrane and the integrity

of the sensor (p. 15). Change the membrane if necessary

(p. 17). Do not use the sensor if any problems are noted.

Once sensor check/inspection of its membrane are completed

successfully, connect the SenTec TC Sensor to the Digital

Sensor Adapter Cable.

Thereafter, the SDM usually will display the message ‘Calibrate

sensor’ (for exceptions see description of the feature SMART

CALMEM, p. 17).

Insert the sensor into the Docking Station for sensor calibration

(p. 16).

If the sensor’s ‘Membrane Change Interval’ has elapsed

(this usually applies to new sensors), the SDM will trigger

the message ‘Change sensor membrane’ upon insertion of

the sensor into the Docking Station. In this case, you must

change the sensor membrane (p. 17) before the SDM starts

calibrating the sensor.

Note: If you have changed the sensor membrane just before

connecting the sensor to the SDM, it won’t be necessary

to change it once again. In this case, simply confirm the

membrane change on the monitor (menu ‘Membrane Change’ -

only accessible if the sensor is outside the Docking Station).

Checking a SenTec TC Sensor

Check the condition of the sensor membrane and the integrity

of the sensor before and after each use and after changing the

membrane (p. 17)!

Ensure that the sensor is clean before visually checking it. If

necessary, carefully wipe off any residue from the sensor’s

surface (including membrane, housing and cable) with 70%

isopropanol or another approved cleaning agent (refer to

sensor’s Directions for Use).

a) Change the sensor membrane if it is damaged or missing,

has a loose fit, or if there is trapped air or dry electrolyte under

the membrane.

Page 15 .Sensor Check, Sensor Calibration/Storage and Membrane Change

CAUTION: Do not touch the delicate optical/glass

components embedded in the sensor’s surface should the

membrane be missing.

b) Do not use the sensor if there is any visible damage to

the sensor housing or cable, if the color of the ring around the

glass electrode has a metallic luster (should be brown), or if the

sensor’s red LED does not light when the sensor is connected

to the SDM. Instead, contact qualified service personnel or

your local SenTec representative regarding continued use or

replacement of the sensor.

c) When operating with an OxiVenT™

Sensor, do not use the sensor if

the off-centered, white, round spot

on the sensor surface is missing

or is not illuminated in green-cyan

color when the OxiVenT™ Sensor is

connected to the SDM with enabled

PO2measurement function.

Sensor Check, Sensor Calibration/Storage and Membrane

Change

CAUTION: Always clean the sensor before placing it in

the Docking Station.

3. Hang the sensor into the holder in

the inside of the door. Ensure that the

sensor’s red light is visible.

CAUTION: Incorrect orientation

of the sensor in the Docking Station

may cause damage to the sensor, the

Docking Station, or parts thereof when

closing the Docking Station door.

4. Close the Docking Station Door. The SDM will check the

sensor and – if necessary – start the sensor calibration

(message ‘Calibration in progress’). The message ‘Ready for

use’ will display once calibration is finished.

WARNING: Correct calibration requires the sensor to

be properly positioned in the Docking Station Door and the

Docking Station Door to be closed.

Note: If the sensor is stored in the Docking Station, additional

sensor calibrations can be activated via a ‘Quick Access Menu’

(p. 42). If enabled, PO2is also calibrated during calibrations

that are activated with the menu-function ‘Calibrate sensor’.

Sensor Calibration and Storage

If a sensor calibration is mandatory, the SDM displays the

message ‘Calibrate sensor’, a low priority alarm sounds and

PCO2and PO2are marked as ‘invalid’ (values replaced by ‘---’).

Good to know!

‘Calibration Intervals’ for SenTec TC Sensors can last up to

12 hours. Once the ‘Calibration Interval’ has elapsed, sensor

calibration is recommended (message ‘Sensor calibration

recommended’) and monitoring is possible for another 4

to 6 hours with PCO2marked as ‘questionable’ (p. 32).

Thereafter, sensor calibration is mandatory.

The SDM, as a precaution, calibrates PO2during each

mandatory calibration and subsequently approximately once

every 24 hours during one of the default PCO2calibrations.

To calibrate the sensor:

1. Open the Docking Station Door 7by pulling the door

handle.

2. Check the gasket (arrow) in the

Docking Station. If necessary, clean

the Docking Station and gasket by

using a cotton swab moistened with

70% isopropanol (for other approved

cleaning agents refer to the Technical

Manual for the SDM).

Page 17 .Sensor Check, Sensor Calibration/Storage and Membrane Change

Note: After switching on the SDM or after a membrane

change (p. 17), it is recommended to store the sensor

in the Docking Station at least for the duration indicated

by the yellow information message ‘Recommended Sensor

Stabilization [min]:’ on the ‘Ready for use’ screen and on the

‘Calibration’ screen.

Note: To maintain monitor readiness in-between monitoring,

always keep the monitor switched on and always store the

sensor in the Docking Station.

Good to know!

SMART CALMEM is a feature of SenTec TC Sensors permit-

ting disconnection of the sensor from the SDM for up to

30 minutes without losing the calibration status. Thus,

monitoring can temporarily be interrupted without the need

to remove the sensor from the patient, e.g. to untangle

cables, to turn or move the patient, or if the patient needs

to go to the restroom. Furthermore, SMART CALMEM

reduces the number of required calibrations and, hence, the

consumption of calibration gas.

Changing the Sensor Membrane

The membrane of a SenTec TC Sensor must be changed if the

‘Membrane Change Interval’ has elapsed. In this case, the SDM

displays the message ‘Change sensor membrane’, triggers a

low priority alarm, marks PCO2/PO2as invalid and activates

the menu ‘Membrane Change’ - provided the sensor is in the

Docking Station.

Good to know!

The ‘Membrane Change Interval’ is set to 28 days by

default. Depending on the specific requirements of various

clinical settings, the interval can be customized ranging from

1 to 42 days.

CAUTION: Without being requested by the SDM, the

sensor membrane must additionally be changed if any of the

conditions described in the section ‘Checking a SenTec TC

Sensor’ (p. 15) apply.

CAUTION: Use Membrane Changers with a green center

dot only for V-Sign™ Sensors. Membrane Changers with a

blue center dot can be used for all SenTec TC Sensors.

CAUTION: The Contact Gel is not needed in any of the

membrane change steps. The Contact Gel is only used for

sensor application.

i

s

o

p

r

o

p

a

n

o

l

7

0

%

1

Note: A Membrane Change Tutorial is available for

online viewing at www.sentec.com/tv/v0.

Note: The Membrane Changer can be reused

by replacing its insert. To prepare the Membrane

Changer for reuse, refer to the Directions for Use

of the Membrane Changer Inserts or see tutorial at

www.sentec.com/tv/v1.

Inserting Sensor into Membrane Changer

1. Verify that the sensor is clean before

changing its membrane. If necessary,

carefully wipe off any residue from

the sensor’s surface (including

membrane, housing and cable) with

70% isopropanol (for other approved

cleaning agents refer to the sensor’s

Directions for Use).

2. Place the Membrane Changer on

a horizontal, dry surface with the

colored dot facing up.

3. Insert the sensor into the Membrane

Changer with the sensor side facing up.

The insert receiver 1is designed so

that improper alignment of the sensor

is difficult if not impossible.

Note: Neither touch nor hold the sensor cable while the sensor

is inside in the Membrane Changer nor pick up the Membrane

Changer as this may lead to dislodging the sensor from the

Membrane Changer.

Four Press-and-Turn Steps

to Change the Membrane

The membrane change procedure consists of four identical

press-and-turn steps. To provide better guidance, these steps

are marked with the corresponding numbers on the Membrane

Changer.

Step 1 removes the old sensor membrane: Press down slowly

but firmly with palm of hand and hold for 3 seconds. Release

the top Carry out a visual check to ensure that the membrane

is removed. Turn the top portion one click clockwise to the next

step. Keep the Membrane Changer horizontal.

Step 2 cleans the sensor surface from old electrolyte: As in

step 1, press the membrane changer slowly but firmly, release

the top and turn clockwise to the next step.

Step 3 applies new electrolyte on the sensor surface: Press

the membrane changer slowly but firmly for 3 seconds, release

the top and turn clockwise to the next step.

Step 4 places a new membrane on the sensor: Press the

membrane changer top down slowly but firmly for 3 seconds,

release the top and turn clockwise to the √ symbol.

This manual suits for next models

2

Table of contents

Other Sentec Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Vitalograph

Vitalograph 2120 User instructions

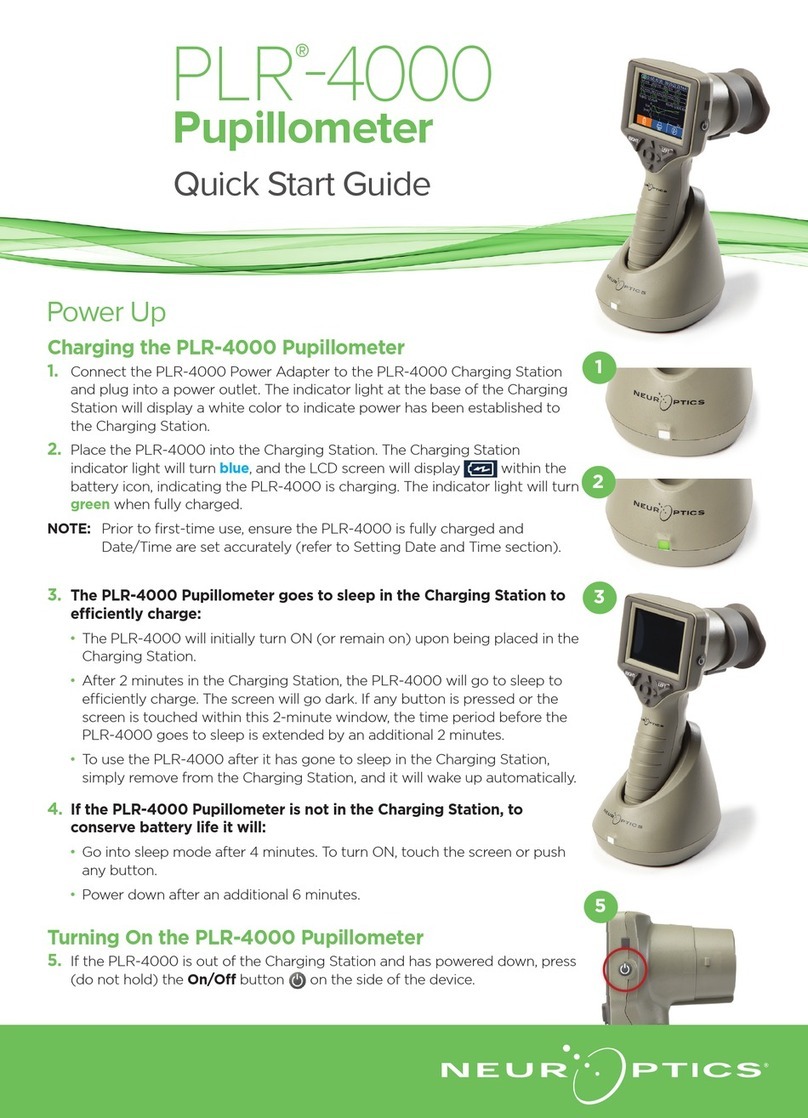

NeurOptics

NeurOptics PLR-4000 quick start guide

MHC Medical Products

MHC Medical Products SureLife Clearwave user manual

Cardinal Health

Cardinal Health Kangaroo Quick reference guide

Mediana

Mediana RESCATE PERU Heart On AED A10 quick start guide

Intelect

Intelect Legend 2 user manual