Sentec LuMon User manual

Service Manual for the LuMon™ System

2ST200-199 Rev002 │04 2021

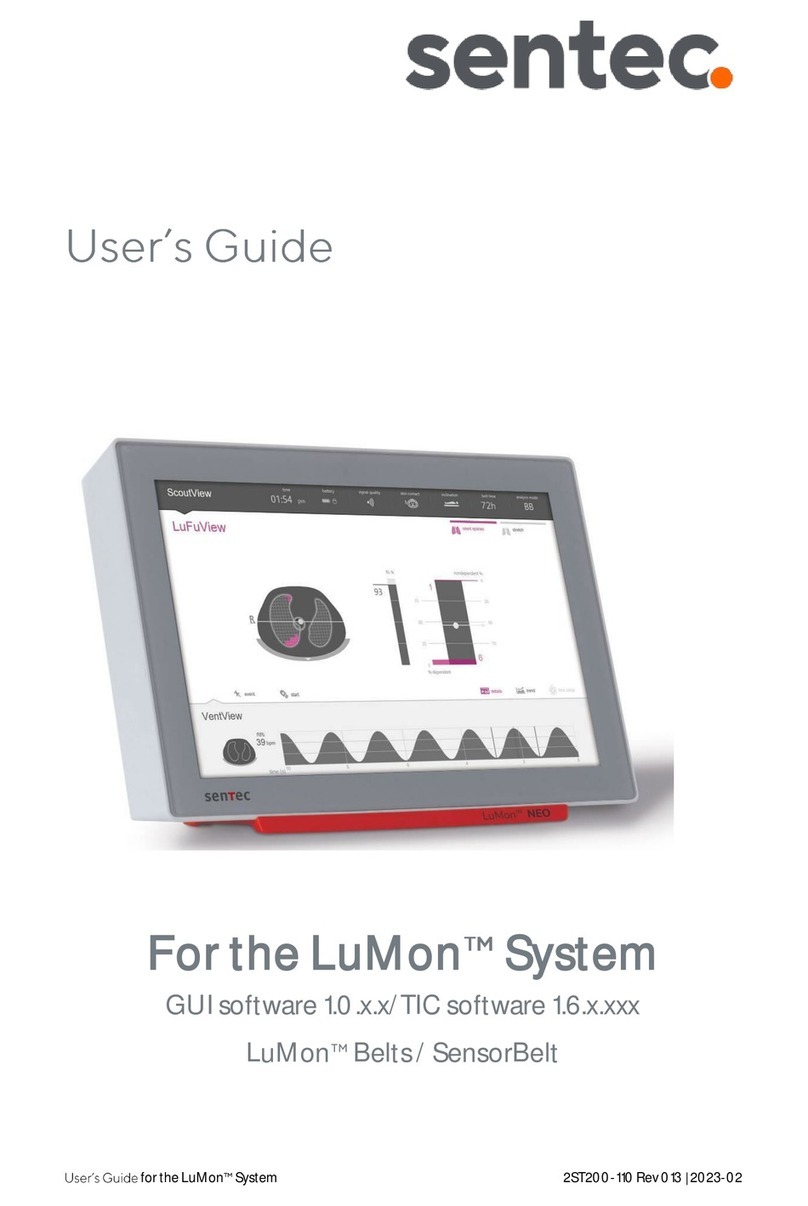

Service Manual

For the LuMon™ System

GUI software 1.0.x.x/TIC software 1.6.x.xxx

LuMon™ Belts sizes 47 and smaller / SensorBelts

2 of 33

Service Manual for the LuMon™ System

Warranty

The manufacturer warrants to the initial purchaser that each new component of the LuMon™ System will be

free from defects in workmanship and materials. The manufacturer’s sole obligation under this warranty is to at

its own choice repair or replace any component – for which the manufacturer acknowledges the warranty cover

– with a replacement component.

Warranty exclusions and system performance

SenTec AG can neither guarantee or verify instrument performance characteristics nor accept warranty claims

or product liability claims if the recommended procedures are not carried out, if the product has been subject

to misuse, neglect or accident, if the product has been damaged by extraneous causes, if accessories other than

those recommended by SenTec AG are used, if the warranty seal on the lower side of the monitor is broken, or if

instrument repairs are not carried out by

SenTec Authorized LuMon™ Technicians

.

Design/patents related to the LuMon™ System:Please refer to the specification sheets for the LuMon™

System: www.sentec.com/education/eit/plpm-eit

Trademarks: SenTec™, Advancing Noninvasive Patient Monitoring™, LuMon™ and sentec eit™ are trademarks

of SenTec AG.

Terms of use of software components: SenTec devices that use software may use SenTec, third party and/or

open-source software, depending on their setup. SenTec, third party and/or open-source software may be

subject to different terms of license. Respective information regarding SenTec, third party and/or open-source

software used in the LuMon™ System is available at the following web page: https://www.sentec.com/licenses

©2020 SenTec AG:The contents of this Service Manual may not be reproduced in any form or communicated

to any third party without the prior written consent of SenTec AG.

While every effort is made to ensure the correctness of the information provided in this Service Manual, SenTec

AG assumes no responsibility for errors or omissions. This Service Manual is subject to change without notice.

LuMon™ Monitor

SensorBeltConnector

LuMon™ Connector

SensorBelt

LuMon™ Belt

ContactAgent

NeoContactAgent

Manufacturer:

SenTec AG | Kantonsstrasse 14 | 7302 Landquart | Switzerland | www.sentec.com

EU Representative:

SenTec GmbH | Carl-Hopp-Straße 19A | 18069 Rostock | Germany

Introduction

Service Manual for the LuMon™ System

3 of 33

CONTENT

1INTRODUCTION ....................................................................................................................................4

1.1 ABOUT THIS SERVICE MANUAL.............................................................................................................................................4

1.2 RELATED DOCUMENTS/FORMS ............................................................................................................................................4

1.3 TERMINOLOGY ..........................................................................................................................................................................5

1.4 SAFETY INFORMATION ............................................................................................................................................................5

2SYSTEM OVERVIEW ............................................................................................................................6

2.1 LUMON™SYSTEM ....................................................................................................................................................................6

2.2 LUMON™MONITOR ................................................................................................................................................................ 7

2.3 BELT CONNECTORS .................................................................................................................................................................8

2.4 EIT ADVANCED INTERFACE SET...........................................................................................................................................9

3MAINTENANCE/SAFETY AND FUNCTIONALITY TESTS ..................................................10

3.1 BELT CONNECTOR .................................................................................................................................................................10

3.2 LUMON™MONITOR .............................................................................................................................................................. 13

4TROUBLESHOOTING ........................................................................................................................18

4.1 HOW TO USE THE TROUBLESHOOTING LIST ..................................................................................................................... 18

4.2 TROUBLESHOOTING LIST ...................................................................................................................................................... 19

5REPAIRS OF THE LUMON™ MONITOR .................................................................................... 24

5.1 PRIOR TO REPAIR ................................................................................................................................................................... 24

5.2 REPLACEMENT –SUPPORT FOOT ...................................................................................................................................... 24

5.3 REPLACEMENT –MAIN FUSES ............................................................................................................................................ 25

6SOFTWARE UPDATES/UPGRADES .......................................................................................... 26

7DISPOSAL ...............................................................................................................................................27

7.1 LUMON™MONITOR ..............................................................................................................................................................27

7.2 BELT CONNECTORS ...............................................................................................................................................................27

7.3 BELTS .........................................................................................................................................................................................27

7.4 CONTACT MEDIUM.................................................................................................................................................................27

8APPENDIX I ........................................................................................................................................... 28

8.1 SPARE PARTS AND MAINTENANCE TOOLS ....................................................................................................................... 28

8.2 INTERFACES -PIN ASSIGNMENT ........................................................................................................................................ 28

8.3 TECHNICAL SPECIFICATION................................................................................................................................................30

8.4 CONTACT.................................................................................................................................................................................30

9APPENDIX II - PROTOCOL FOR SAFETY & FUNCTIONALITY TEST ............................ 31

TEST SUMMARY: ................................................................................................................................................................................. 32

BELT CONNECTOR ............................................................................................................................................................................ 33

LUMON™MONITOR ......................................................................................................................................................................... 33

Introduction

4 of 33

Service Manual for the LuMon™ System

1INTRODUCTION

1.1 About this Service Manual

This Service Manual contains information and instructions on servicing the LuMon™ System – i.e. maintenance,

safety, functionality tests, troubleshooting and repairs. Procedures that do not require opening the housing

of the device.

•Maintenance/safety and functionality tests for the LuMon™ System (LMS) intended for qualified

technicians only (3).

•Troubleshooting for the LuMon™ System (4). The troubleshooting list covers three levels of

recommended troubleshooting procedures: Afor the operator, Bfor qualified technicians, and Cfor

SenTec Authorized LuMon™ Technicians

only.

•Repair procedures that do not require opening the cover of the LMS intended for

SenTec Authorized

LuMon™ Technicians

only (5).

NOTE

Statements and instructions in this Service Manual are only applicable for LuMon™ Monitors with the software

versions indicated on the cover page, where “x” can be any number. The software versions of the LuMon™

Monitor – GUI and TIC – are displayed in the ‘system settings’ area of ScoutView [1]. If your LuMon™ Monitor has

other software versions than those indicated on the cover page, please refer to the corresponding version of

the Service Manual.

NOTE

This manual is intended for qualified technicians and

SenTec Authorized LuMon™ Technicians

and must be

read carefully prior performing service and repair. Section ‘safety information’ of the User’s Guide for the

LuMon™ System [1] must be read and understood.

NOTE

Repairs that require opening the LuMon™ Monitor cover are described within the Repair Manual for the

LuMon™ Monitor [3] (which is distributed to

SenTec Authorized LuMon™ Technicians

only).

1.2 Related documents/forms

To perform service you must know how to operate the LuMon™ System (2.1). Refer to the following manuals and

directions for use:

[1] The User’s Guide for the LuMon™ System provides detailed information on the LuMon™ System for

health care practitioners. It is available in several languages and can be downloaded from SenTec’s

webpage: www.sentec.com/education/eit/plpm-eit

[2] The Service Manual for the LuMon™ System (1.1) is available in English and can be downloaded from

SenTec’s webpage: www.sentec.com/education/eit/plpm-eit

[3] The Repair Manual for the LuMon™ Monitor describes repair procedures that require opening the

housing of the monitor for

SenTec Authorized LuMon™ Technicians

. This manual is distributed to

SenTec

Authorized LuMon™ Technicians

only.

[4] The Product Catalogue for the LuMon™ System provides information related to Product Numbers and

purchase of LMS related accessories, key spare parts and documents. It is available in English and can be

downloaded from SenTec’s webpage: www.sentec.com/education/eit/plpm-eit

[5] The Protocol for Safety and Functionality Test – LuMon™ Monitor is a checklist for guiding qualified

service personnel through the complete safety and functionality tests and documenting its results (9).

[6] The Certificate of Disinfection is a form serving as proof of disinfection before shipment. It must be

completed and provided to SenTec AG and must accompany the shipment (outside the package box). A

PDF-copy of this form and the RGA – Return Good Authorization – number are available from SenTec AG

upon request (info-eit@sentec.com).

[7] The Repair or Investigation Request Form – LuMon™ System is a form used to return material to SenTec

AG for service, investigation or repair. A PDF-copy of this form and the RGA – Return Good Authorization –

number are available from SenTec AG upon request (info-eit@sentec.com).

[8] The Technical Service Report Form – LuMon™ System is a form that must be completed and provided to

SenTec AG after software updates and after repairs performed by a

SenTec Authorized LuMon™

Technician.

A PDF-copy of this form is available from SenTec AG upon request (info-eit@sentec.com).

[9] The LuMon™ System – Price List for Special Services is a complete list of services and spare parts that is

Introduction

Service Manual for the LuMon™ System

5 of 33

[10] The Instruction to update the LuMon™ Monitor software provides instruction how to update the

software. A PDF-copy of this document and instruction to download the software PDF-copy of this form is

1.3 Terminology

For symbols used on devices labels and packaging, terminology and abbreviations used in this Service Manual

refer to the User’s Guide for the LuMon™ System [1].

SenTec EIT related terms are described in the User’s Guide [1].Notice that those terms being italicized and/or

capitalized in section ‘terminology’ of the User’s Guide [1] are italicized and/or Capitalized throughout the

entire Service Manual.

1.4 Safety information

A comprehensive list of warnings and cautions is provided in the User’s Guide [1] section ‘safety information’.

Notes are provided in sections where applicable. Carefully read all safety information in the User’s Guide [1]

before operating the device or performing service/repairs.

System overview

6 of 33

Service Manual for the LuMon™ System

2SYSTEM OVERVIEW

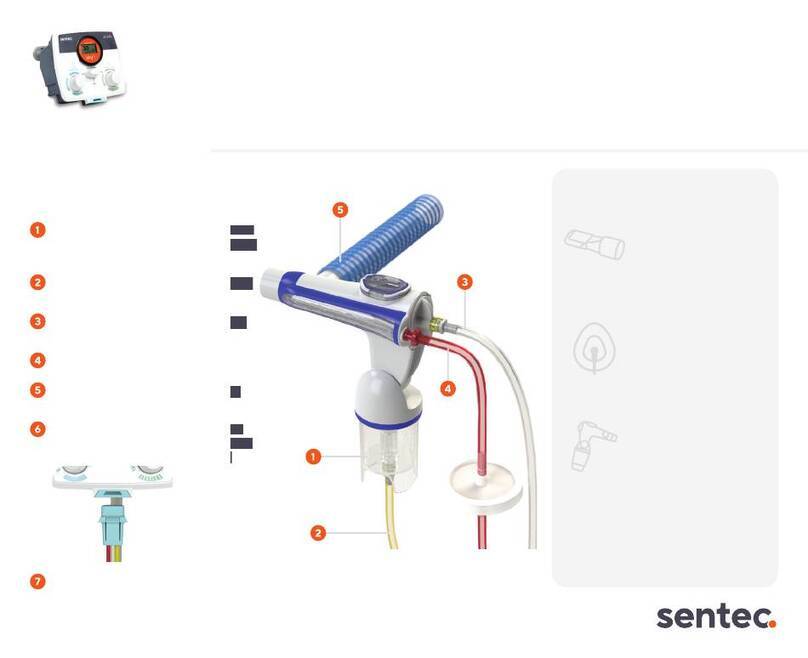

2.1 LuMon™ System

The LuMon™ System comprises LuMon™ Monitors (2.1), belt connectors (2.3) to link SenTec’s textile EIT belts

being available in various sizes to the LuMon™ Monitor, as well as SenTec’s contact agents serving as a medium

for impedance coupling between a belt and the patient’s skin. Measuring tapes permit the user to determine

the recommended belt size, i.e. the size of the belt best fitting the respective patient.

The LuMon™ System is available in two configurations

•() for adults and children illustrated in Table 2-1 with a family of belts supporting an underbust girth

range of approximately 76 to 128 cm (abbreviated as LMS-A).

•() for neonates and infants illustrated in Table 2-2 with a family of belts supporting an underbust

girth range of approximately 17 to 52 cm (abbreviated as LMS-N).

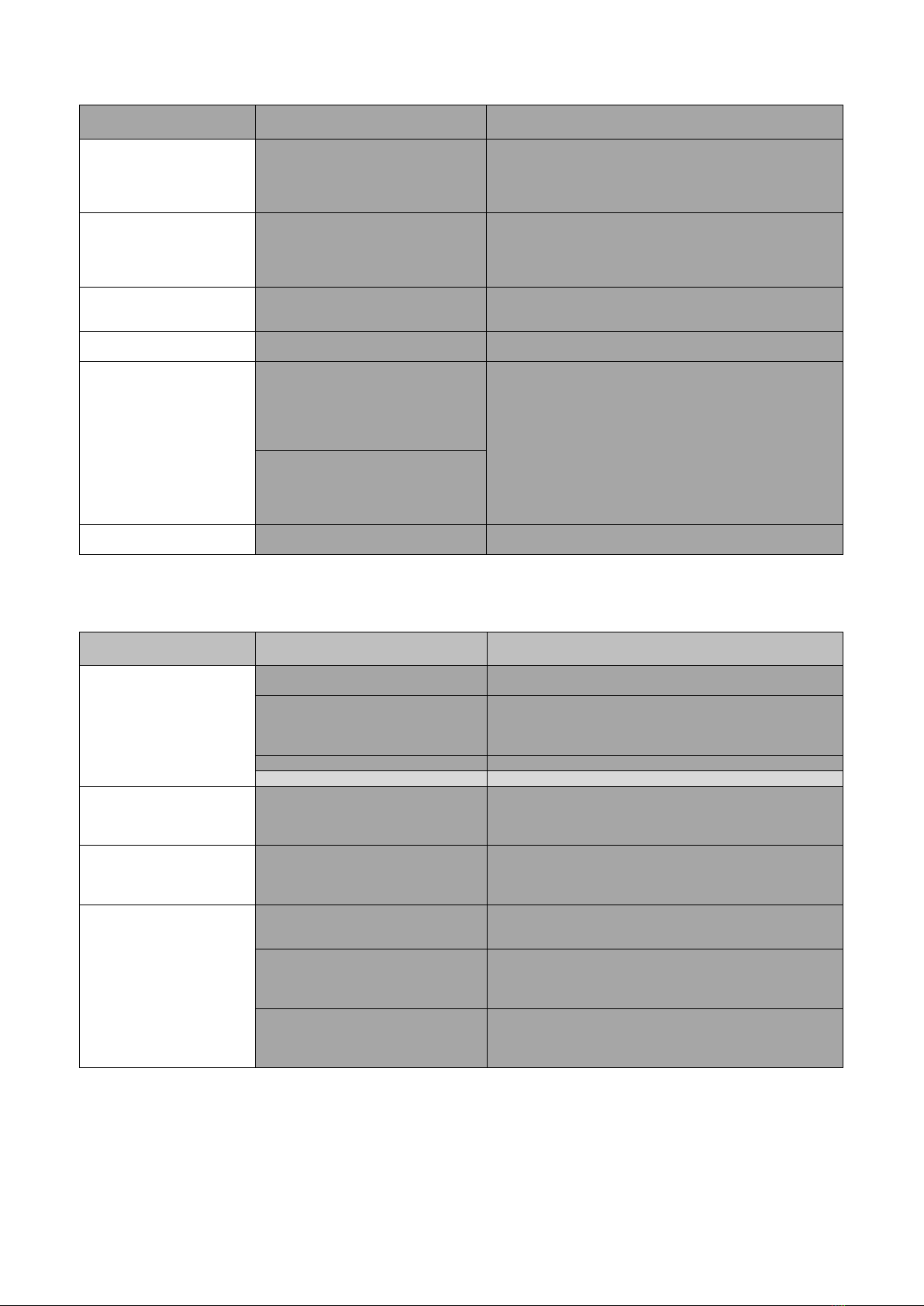

Table 2-1: LuMon™ System — Adults/Children configuration ( )

LuMon™ Monitor – Adult SensorBeltConnector SensorBelt ContactAgent

Table 2-2: LuMon™ System — Neonates/Infants configuration ( )

LuMon™ Monitor – Neo LuMon™ Connector LuMon™ Belt NeoContactAgent

System overview

Service Manual for the LuMon™ System

7 of 33

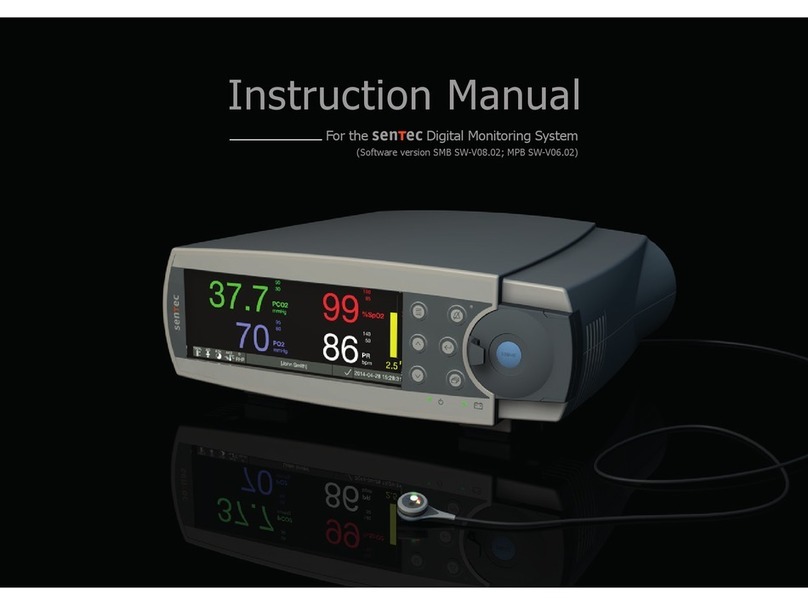

2.2 LuMon™ Monitor

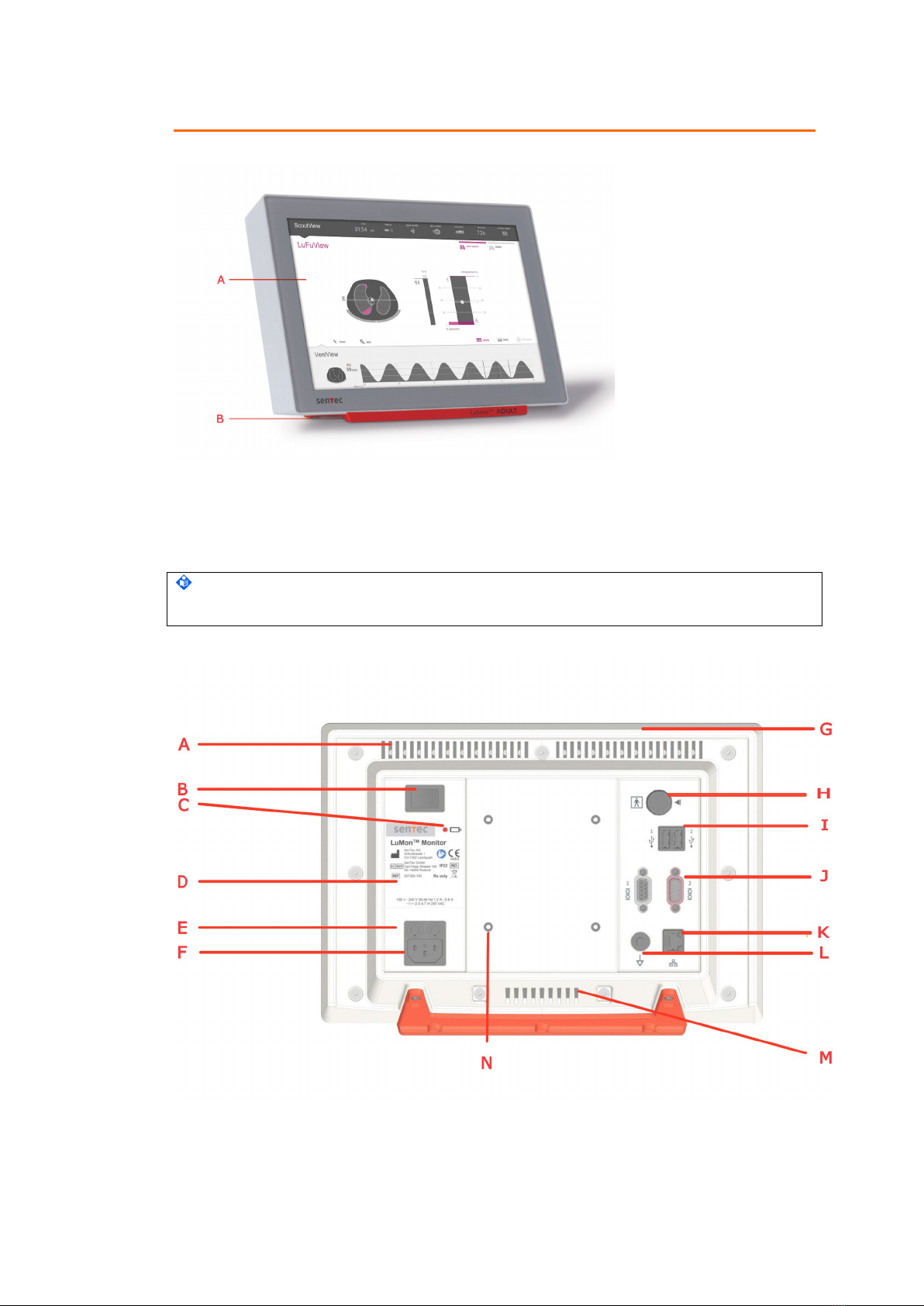

Figure 2-1: LuMon™ Monitor – front panel (here a LuMon™ Monitor – Adult)

A. Touch screen based Graphical User Interface – GUI

B. Support foot indicating the LuMon™ Monitor’s configuration:

LuMon™ ADULT identifies the LuMon™ Monitor – Adult;

LuMon™ NEO identifies the LuMon™ Monitor – Neo.

NOTE

The LuMon™ Monitor performs a calibration of its touch screen after it is switched on. To not disturb the

calibration of the touch screen, do not touch the screen the first few seconds after startup.

Figure 2-2: LuMon™ Monitor — rear panel

8 of 33

Service Manual for the LuMon™ System

A. Ventilation slot

B. ON/OFF switch

C. AC Power/Battery indicator

D. Type label

E. Fuse holders (2x)

F. AC power inlet

G. Integrated carrying handle

H. Belt connector socket

I. USB ports (2x) – only for use with

memory devices without external power

supply

J. Serial ports (2x) – factory use only

K. Ethernet port – factory use only

L. Equipotentiality terminal connector

M. Ventilation slot

N. VESA 75 compatible mounting holes (4x)

2.3 Belt connectors

The belt connectors are designed to link belts to LuMon™ Monitors. Belt connectors control the injection of

very weak alternating currents into the patient’s thorax and the measurement of the voltages (electrical

potentials) resulting at the skin of the patient’s thorax.

2.3.1 SensorBeltConnector

The SensorBeltConnector (Figure 2-3) links a SensorBelt to a LuMon™ Monitor – Adult. The position sensor

embedded in its MatchBox permits the LuMon™ System to measure and display the patient’s position (

rotation

and

inclination

). If the SensorBeltConnector is properly connected to a LuMon™ Monitor in on-state, the status

indicator LED of its MatchBox continuously lights green if a SensorBelt is connected.

Figure 2-3: SensorBeltConnector

A. MatchBox (includes a position sensor

and a status indicator LED) – connects

to SensorBelts

B. ControlBox (with integrated electronics

and status indicator LED)

C. Monitor plug – connects to the belt

connector socket on the LuMon™

Monitor

2.3.2 LuMon™ Connector

The LuMon™ Connector (Figure 2-4) links a LuMon™ Belt to a LuMon™ Monitor – Neo.

In contrast to the MatchBox of the SensorBeltConnector (2.3.1) the MatchBox of the LuMon™ Connector

contains neither a position sensor nor a status indicator LED.

Figure 2-4: LuMon™ Connector

A. LuMon™ MatchBox – connects to

LuMon™ Belts

B. ControlBox (with integrated electronics

and status indicator LED)

C. Monitor plug – connects to the belt

connector socket on the LuMon™

Monitor

System overview

Service Manual for the LuMon™ System

9 of 33

2.4 EIT Advanced Interface Set

Several tests require an EIT Advanced Interface Set.

Figure 2-5: EIT Advanced Interface Set

A. HR control (HR – Heart Rate)

B. HA control (HA – Heart Amplitude)

C. BR control (BR – Breath Rate)

D. BA control (BA – Breath Amplitude)

E. Voltage in: Connection for external AC/DC Power Supply

F. EIT 1 Fault

G. EIT 7 Fault

H. Too many failing electrodes – SensorBeltConnector only

I. Modes Switch

J. Manual breathing control (RL – Right lung / LL – Left lung)

K. Matchbox for SensorBeltConnector

Use with LuMon™ Connector only:

L. LuMon™ EIT Advanced

Interface Adapter

M. Ribbon Cable Medium (10

cm)

AC-Adapter 12V (for EIT Advanced

Interface)

M

A

J

B

C

D

L

E

F

G

H

I

K

Maintenance/Safety and Functionality Tests

10 of 33

Service Manual for the LuMon™ System

3MAINTENANCE/SAFETY AND FUNCTIONALITY TESTS

At normal use there is no internal adjustment or calibration of the LuMon™ System required. However, to

guarantee continuous performance, reliability and safety of the LuMon™ System, routine checks and

maintenance procedures (including cleaning/disinfection) as well as safety checks should be performed

regularly.

Routine checks and maintenance procedures that can be performed by the operator and instructions for

cleaning and/or disinfecting the LuMon™ Monitor and the belt connectors, are provided in the User’s Guide for

the LuMon™ System [1].

It is recommended that qualified service personnel performs the maintenance and a complete safety and

functionality tests as specified in this manual at regular intervals (recommended every 12 months but at least

every 24 months). Use the Protocol for Safety and Functionality Test (9) to guide you through the complete

safety and functionality tests and to document your test results. To perform a complete safety and functionality

test all tests described in this chapter MUST be performed.

NOTE

If safety or functionality test fail, the respective problem must be fixed before the equipment is returned to the

user.

NOTE

Prior to maintenance, service or repair all components of the LuMon™ System must be cleaned and disinfected.

More details can be found in section ‘cleaning and disinfection’ of the User’s Guide for the LuMon™ System [1].

NOTE

If equipment is send to a

SenTec Authorized LuMon™ Technician

, local SenTec representative or SenTec AG

please refer to section ‘instructions for repackaging and shipping’ of the User’s Guide [1].

A complete ‘Certificate of Disinfection’ [6] and, if applicable, the ‘Repair or Investigation Request Form’ [7] must

be provided.

3.1 Belt connector

3.1.1 Cleaning and Disinfection

For cleaning and disinfection procedures for the SensorBeltConnector and the LuMon™ Connector refer to

section ‘cleaning and disinfection’ of the User’s Guide [1].

3.1.2 Visual Inspection

Visually inspect the belt connector body, cable and plug for damage.

NOTE

If any of the components of the belt connector is damaged, replace the belt connector with a new LuMon™

Connector or SensorBeltConnector (8.1).

Maintenance/Safety and Functionality Tests

Service Manual for the LuMon™ System

11 of 33

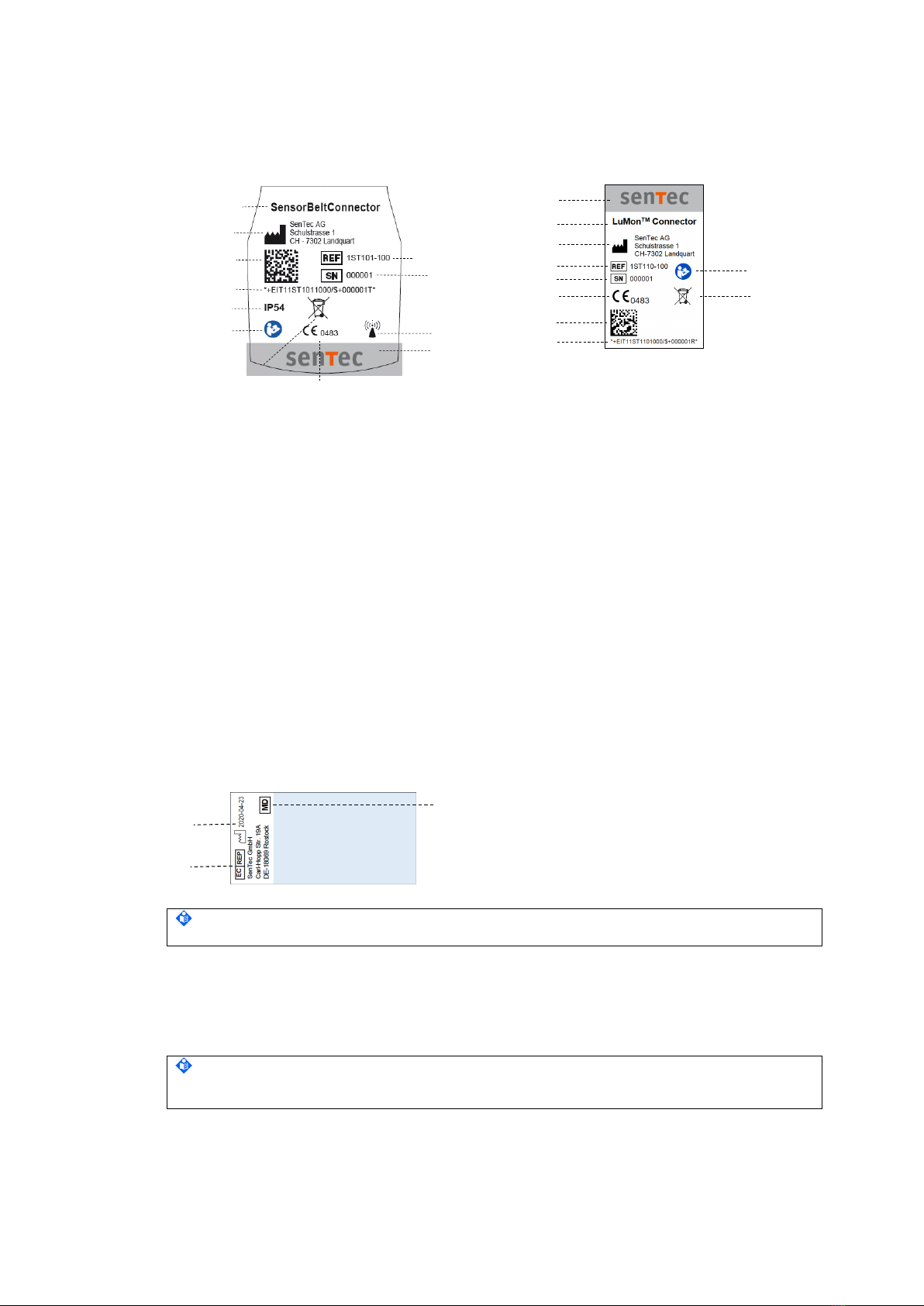

3.1.3 Labeling

Check presence/legibility of the label on the belt connectors.

The type label can be found on the MatchBox part of the belt connectors (2.3). Example labels are shown below.

A

C

D

E

J

H

G

B

F

L

M

I

A

C

D

E

F

G

H

I

K

B

A. Product name

B. Manufacturer symbol and address

C. UDI data matrix code

D. UDI human readable

E. IP (ingress protection class) code

F. Follow instruction for use

G. Dispose of according to Council Directive

2012/19/EU symbol

H. CE (‘Conformité Européene’) label and

notified body number

I. SenTec logo

J. Radio frequency symbol

K. –

L. Serial number symbol and number

M. Reference symbol and number

A. SenTec logo

B. Product name

C. Manufacturer symbol and address

D. Reference symbol and number

E. Serial number symbol and number

F. CE (‘Conformité Européene’) label and

notified body number

G. UDI data matrix code

H. UDI human readable

I. Follow instruction for use

J. -

K. Dispose of according to Council Directive

2012/19/EU symbol

The EU Authorized Representative (EC REP) label can be found on the cable close to the Redel connector

(Figure 2-2

Figure 2-2)

A

B

C

A. Symbol for manufacturing date and

manufacturing date

B. Symbol for EC Representative and the

address

C. Medical device symbol

NOTE:

If the label is not present/legible then contact

SenTec Authorized LuMon™ Technicians.

3.1.4 Status indicator LEDs - SensorBeltConnector

Connect the SensorBeltConnector to the LuMon™ Monitor and switch on the monitor. During the power-up

verify, that the Status LEDs in the ControlBox and MatchBox show the following sequence: MatchBox (Figure

2-3) LED blue ControlBox LED green MatchBox LED red flashing all LEDs off.

NOTE

Any deviation from this sequence – e.g. ControlBox LED lighting up blue or flashing red or MatchBox LED

flashing blue – indicates that the SensorBeltConnector is defective and must be replaced (8.1).

Maintenance/Safety and Functionality Tests

12 of 33

Service Manual for the LuMon™ System

3.1.5 Status indicator LEDs – LuMon™ Connector

Connect the LuMon™ Connector to the LuMon™ Monitor and switch on the monitor. During the power-up

verify that the Status LED in the ControlBox lights up green LED off.

NOTE

Any deviation from this sequence – e.g. ControlBox LED lighting up blue or flashing red – indicates that the

LuMon™ Connector is defective and must be replaced (8.1).

3.1.6 Function Test – SensorBeltConnector

1. Connect the SensorBeltConnector to the LuMon™ Monitor and verify that the hardware and software

version of the belt connector (A/ Figure 3-1) is displayed correctly in the ‘system settings’ area of

ScoutView [1]: 02.01.07-r288 4 1.02-r63 6. The numbers may vary but all numbers shall be present.

2. Connect the SensorBeltConnector to the EIT Advanced Interface (2.4). The indicator LED in the

MatchBox shall light up green indicating that the belt detection works properly. Verify that the ‘serial /

lot no.’ (B/ Figure 3-1) on ‘patient & belt’ area on ScoutView [1] is displayed: e.g. ‘ETAV50200311-

000129’, numbers may vary.

3. Rotate the EIT Advanced Interface left or right and verify on ScoutView that the displayed rotation

changes accordingly.

Figure 3-1: Function Test - Belt connector

3.1.7 Function Test – LuMon™ Connector

1. Connect the LuMon™ Connector to the LuMon™ Monitor and verify that the hardware and software

version of the belt connector (A/ Figure 3-1) is displayed correctly in the ‘system settings’ area of

ScoutView [1]: 02.03.03-r335 4 3.15-r83 13. The numbers may vary but all numbers shall be

present.

2. Connect the LuMon™ Connector to the EIT Advanced Interface using the LuMon™ Advanced

Interface Adapter, the ribbon cable and the AC-Adapter (2.4). Verify that the ‘serial / lot no.’ (B/

Figure 3-1) on ‘patient & belt’ area on ScoutView [1] is displayed: e.g. ‘ETAV50200311-000129’,

numbers may vary).

3. Rotate the MatchBox part of the belt connector – LuMon™ Advanced Interface Adapter – left or right

and verify on ScoutView that the displayed rotation changes accordingly.

Maintenance/Safety and Functionality Tests

Service Manual for the LuMon™ System

13 of 33

3.2 LuMon™ Monitor

3.2.1 Cleaning and Disinfection

For cleaning and disinfection procedures for the LuMon™ Monitor refer to section ‘cleaning and disinfection’ of

the User’s Guide [1].

3.2.2 Visual Inspection

Visually check the entire LuMon™ Monitor for possible damages.

NOTE

If you detect damage, the LuMon™ Monitor needs to be repaired. Contact

SenTec Authorized LuMon™

Technicians.

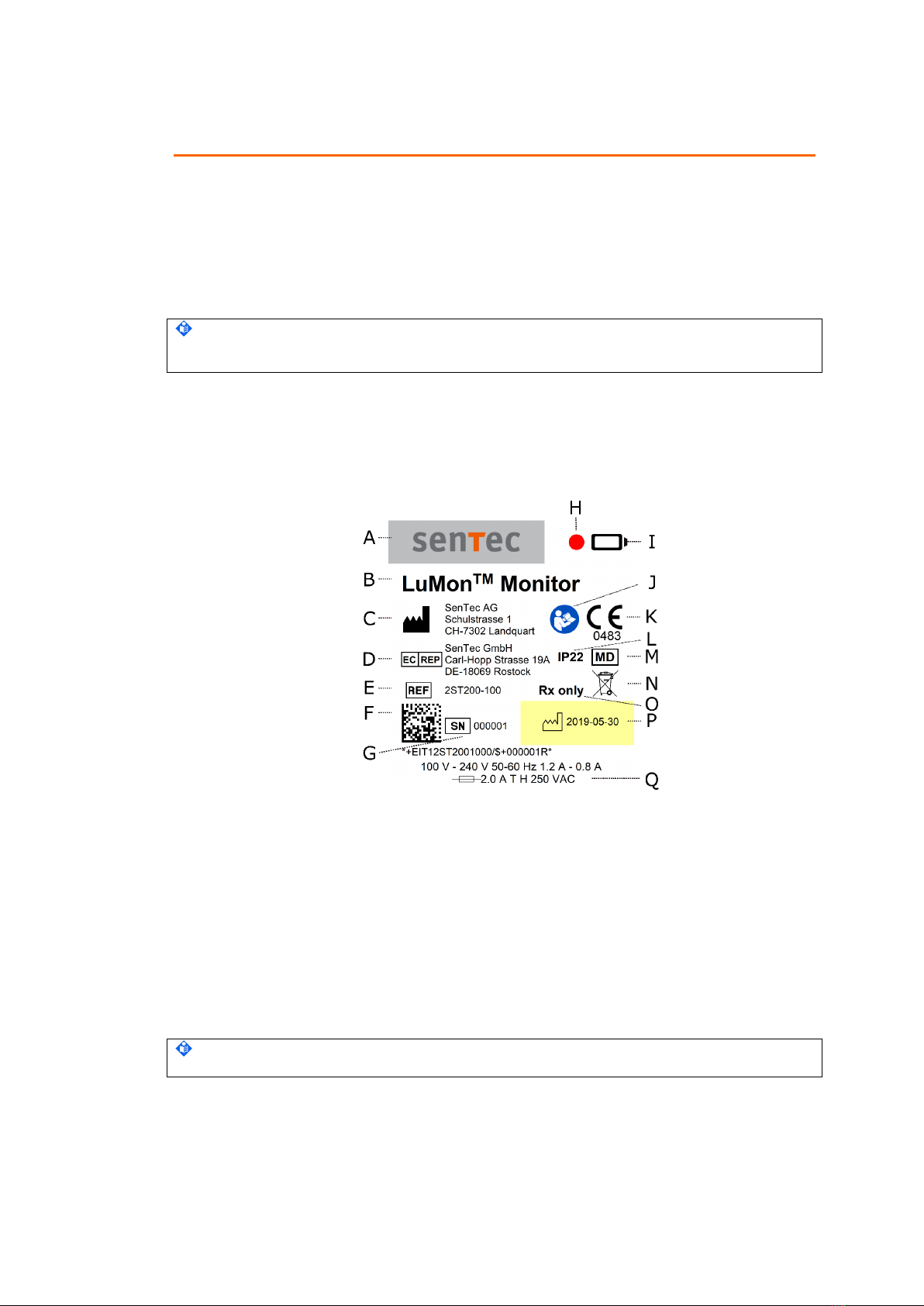

3.2.3 Labeling

Check presence/legibility of the label on the rear panel (Figure 2-2): Labels of all ports, connectors and

ON/OFF switch and the marking plate. Example labels are shown below.

Figure 3-2: Labeling – LuMon™ Monitor

A. SenTec logo

B. Product name

C. Manufacturer symbol and address

D. EU Authorized Representative

E. Reference symbol and number

F. UDI data matrix code and human

readable

G. Serial number symbol and number

H. Cut out (window for battery status LED)

I. Battery symbol

J. Follow instructions for use

K. CE (‘Conformité Européene’) label and

notified body number

L. IP (ingress protection class) code

M. Dispose of according to Council

Directive 2012/19/EU

N. Medical Device symbol

O. Prescription Device

P. Date of manufacture symbol and

manufacturing date

Q. Power inlet information

NOTE

If the label is not present/legible then contact

SenTec Authorized LuMon™ Technicians.

Maintenance/Safety and Functionality Tests

14 of 33

Service Manual for the LuMon™ System

3.2.4 Electrical Safety Check

The LuMon™ System has been designed to comply with the IEC 60601-1 standard:

•Safety approvals and applied part BF: IEC 60601-1 (3rd edition)

•Electromagnetic compatibility (EMC): IEC 60601-1-2 (4rd edition)

To ensure electrical safety of the equipment it is recommended that qualified service personnel performs the

electrical safety check once a year (but every two years the latest) and after repair.

The electrical safety check for the LuMon™ System must be performed in accordance with the IEC

62353:2014 standards for medical electrical equipment classified as Class 1 and Applied Part Type BF.

Technicians must be familiar with these standards applicable to the institution and the country. Test equipment

and its application must comply with the applicable standard.

NOTE

Safety test according to IEC 62353 may be performed if the following criteria are met:

•The LuMon™ Monitor has not been opened.

•No changes have been made to the mains power connections and none of the protective earth

connections (PE) have been disconnected.

Tools: Electrical safety analyzer for tests according to IEC 62353 (e.g. Rigel 288, Fluke ESA615 or Gossen

Metrawatt Secutest)

NOTE

If the required equipment is not available, send the LuMon™ Monitor to a

SenTec Authorized LuMon™

Technician,

your local SenTec representative or SenTec AG for testing.

NOTE

If equipment is send to a

SenTec Authorized LuMon™ Technician,

your local SenTec representative or SenTec

AG please refer to section ‘instructions for repackaging and shipping’ of the User’s Guide for the LuMon™

System [1].

A complete ‘Certificate of Disinfection’ [6] and, if applicable, the ‘Repair or Investigation Request Form’ [7] must

be provided.

NOTE

Prior to maintenance, service or repair, all components of the LuMon™ System must be cleaned and

disinfected. More details can be found in section ‘cleaning and disinfection’ of the User’s Guide for the LuMon™

System [1].

NOTE

Before performing the safety test, read the operating instructions of your safety analyzer.

NOTE

Make sure that all connecting cables are plugged in correctly. Poor or missing connections may lead to false

positive test results.

NOTE

If safety or functionality test fails, the respective problem must be fixed before the equipment is returned to the

user.

The belt and the belt connector are an applied part of Type BF. The interface ports of the LuMon™ Monitor are

isolated with 2 MOPP to the belt connector socket and 1 MOPP to the mains input. There is no isolation

between the individual interface ports.

The electrical safety check is performed according to IEC 62353. The following connections must be tested:

•Protective Earth Resistance Test: Earth wire of the AC power cord, Equipotentiality terminal

connector (ground). The resistance between two of these must be less than 0.3 Ω.

•Earth Leakage Current: The current must be below 5’000 µA (normal condition) / 10’000 µA

(single fault condition) see IEC 60601-1 Figure 13 and chapter 8.7.3 d).

•Patient Leakage Current from patient connection to earth. The current must be below 100 µA

(normal condition) / 500 µA (single fault condition) see IEC 60601-1 Figure 15.

Maintenance/Safety and Functionality Tests

Service Manual for the LuMon™ System

15 of 33

•Patient Leakage Current caused by an external voltage on the Patient Connection (Type BF). The

current must be below 5000µAsee IEC 60601-1 Figure 16.

•Insulation Resistance Test: L, N of AC power inlet – housing (equipotentiality terminal). The resistance

must be more than 2 MΩ@500V DC.

•Patient Insulation Resistance: Belt connector socket (insulation test cable) – housing (equipotentiality

terminal). The resistance must be more than 2 MΩ@500V DC.

Figure 3-3: Connections for safety test, protective earth resistance and leakage current

Figure 3-4: Connections for safety tests, insulation resistance

NOTE

If the above described tests do not met the corresponding acceptance criteria, the LuMon™ Monitor needs to

be repaired. Refer to section 4.2.4 to further evaluate the problem.

Check the AC power cord for damages of the isolation. Check the belt connectors for damages.

The AC power cord must be tested when connected to the AC power outlet. Thereby the cable must be

swayed to detect potential cable breaks or loose contacts. The AC power cord must be tested together with the

Ground Integrity.

NOTE

If the above specifications are not met, then the AC power cord needs to be replaced by a new AC power cord

from SenTec AG (8.1).

3.2.5 Touchscreen

Switch on the LuMon™ Monitor and wait until the default ScoutView is displayed.

1. Press the button ‘system settings’ to enter ‘system settings’ area and press it again to return to ‘patient

& belt’ area.

2. In ‘patient & belt’ area press ‘weight’ and select a different setting and press ‘OK’.

3. Enter LuFuView, press ‘trend’ and move the ‘T1’ and ‘T2’ flags to different positions.

4. Enter VentView ‘trend’ and check if ‘T1’ and ‘T2’ flags are as set in LuFuView.

Maintenance/Safety and Functionality Tests

16 of 33

Service Manual for the LuMon™ System

NOTE

The LuMon™ Monitor performs a calibration of its touch screen after it is switched on. To not disturb the

calibration of the touch screen, do not touch the screen the first few seconds after startup.

NOTE

If the above described functions do not operate properly contact a

SenTec Authorized LuMon™ Technician,

your local SenTec EIT representative or SenTec AG.

NOTE

If you need to return devices for service or repair follow the shipment instructions in the User’s Guide [1] section

‘instructions for shipment’.

NOTE

Send defective parts together with the completed "Repair or Investigation Request Form" [7] to a

SenTec

Authorized LuMon™ Technician,

your local SenTec EIT representative or SenTec AG.

3.2.6 Clock settings

Verify that the clock settings are correct. If necessary, adjust date and time in the ‘system settings’ area of

ScoutView. Refer to User’s Guide [1] section ‘ScoutView’. Power cycle the LuMon™ Monitor and check date and

time.

NOTE

If the above described functions do not operate properly refer to section 4.2.4 to further evaluate the problem.

3.2.7 Display and AC Power/Battery indicator

Check LED of ‘AC Power/Battery indicator’ (Figure 2-2) and the display for defects:

1. Connect the LuMon™ Monitor to AC power. Switch the LuMon™ Monitor OFF and ON again: The ‘AC

Power/Battery indicator’ LED lights up yellow (battery charging) or green (battery full).

2. Enter VentView and check the readability of the following critical areas: ‘AC Power/Battery’ icon on

status bar,

Plethysmogram

and

Global Dynamic Image

, RRi numerical display.

NOTE

If the above described functions do not operate properly, the LuMon™ Monitor needs to be repaired. Refer to

section 4.2.4 to further evaluate the problem.

3.2.8 Fan

The fan should briefly activate during Power-on Self-test. The fan should rotate freely and without causing

unusual noises.

NOTE

If the above described functions do not operate properly, the LuMon™ Monitor needs to be repaired. Refer to

section 4.2.4 to further evaluate the problem.

3.2.9 Capacity of rechargeable Lithium Ion battery

1. Connect the LuMon™ Monitor to AC power and wait until the battery is completely charged. Verify:

‘AC Power/Battery indicator’ on the rear panel of the LuMon™ Monitor (Figure 2-2) lights up green.

2. Connect the EIT Advanced Interface to the LuMon™ Monitor via a belt connector (2.4).

3. Disconnect the LuMon™ Monitor from AC power and press the ’event’ button [1].

4. Wait until the LuMon™ Monitor fully depletes its battery and shuts down automatically.

5. Connect the LuMon™ Monitor to AC power and wait until it starts up automatically again.

6. Connect a USB memory device to the LuMon™ Monitor, wait for a couple of seconds and then

disconnect it.

7. Connect the USB memory device to a PC. Locate and extract the contents of the file

‘eitMonitorLog.zip’

8. Open the ‘eitMonitor.log’ file with a tex+t viewer (e.g. notepad.exe).

9. Locate the last entry corresponding to the ‘event’: “[StorageMediator] User pressed Event” and

note down the corresponding time stamp of this event as Time1.

Maintenance/Safety and Functionality Tests

Service Manual for the LuMon™ System

17 of 33

10. Scroll to the end of the file, and locate the following entry: “[App] ********** EIT MONITOR

STARTING UP... ****************”

11. Scroll up to locate the last entry of the log file and note down the corresponding time stamp of this

entry as Time2.

12. Scroll further up and locate the following entry: “[HardwareMediator] ++ Hardware Info. Battery %:

100.00 Battery QCount: 16235 …” and note down the value for QCount.

Time1 corresponds to the time when the battery was full and Time2 corresponds to the time when the battery

was empty leading to the shutdown. The run-time of the battery can be computed as the difference between

Time2 - Time1.

The quality of the rechargeable Lithium Ion battery is still acceptable if the LuMon™ Monitor runs for at least

1 hour before the battery management switches off the monitor automatically or the last entry of the QCount

value is less than 26000 or the built in battery not older than 5 years (see the manufacturing date on the rear

panel of the LuMon™ Monitor (Figure 2-2, 3.2.3).

NOTE

If the above described requirements are not met, the LuMon™ Monitor needs to be repaired. Refer to section

4.2.4 to further evaluate the problem.

Troubleshooting

18 of 33

Service Manual for the LuMon™ System

4TROUBLESHOOTING

This section describes problems, possible causes and recommended corrective actions. Repairs (without

having to open the housing of the LuMon™ Monitor) are described in section 5. Repairs that require opening

the housing of the LuMon™ Monitor are to be performed by

SenTec Authorized LuMon™ Technicians

only and

are described in details within the Repair Manual for the LuMon™ Monitor [3].

NOTE

Prior to maintenance, service or repairs all components of the LuMon™ System must be cleaned and

disinfected. If equipment is send to a

SenTec Authorized LuMon™ Technician,

your local SenTec EIT

representative or SenTec AG a completed ‘Certificate for Disinfection’ [6] must be attached.

NOTE

If you need to return devices for service or repair follow the shipment instructions in the User’s Guide [1] section

‘instructions for shipment’. RGA – Return Good Authorization – number is available from SenTec AG upon

request.

NOTE

Send defective parts together with the completed ‘Repair or Investigation Request Form’ [7] to a

SenTec

Authorized LuMon™ Technician,

your local SenTec EIT representative or SenTec AG.

4.1 How to use the troubleshooting list

The troubleshooting list describes problems, possible causes and recommended actions for troubleshooting of

the system. The problems are numbered (EITXXXX) unambiguously. Please reference the respective EITXXXX

code whenever applicable.

This section describes problems, possible causes and recommended actions for troubleshooting.

4.1.1 Levels of recommended actions

The troubleshooting list comprises up to three levels of recommended actions to be performed

A. by the operator (shaded in dark grey) and, if the problem persists,

B. by a qualified technician (shaded in light grey), i.e. troubleshooting at service level (according to this

manual) and, if the problem persists,

C. by

SenTec Authorized LuMon™ Technicians

only (no shading), i.e. troubleshooting at repair level

(according to the Repair Manual [3]).

4.1.2 Abbreviations used in this section

In this sub-section the abbreviations used in this section are described. For a detailed list of abbreviations refer

to the User’s Guide for the LuMon™ System [1].

SB

SensorBelt

Belts

LMB

LuMon™ Belt

SBC

SensorBeltConnector

Belt connectors

LMC

LuMon™ Connector

LMM

LuMon™ Monitor

Monitor

Troubleshooting

Service Manual for the LuMon™ System

19 of 33

4.2 Troubleshooting list

This section describes problems, possible causes and recommended actions for troubleshooting.

NOTE

Concerning equipment, accessories, disposable and parts refer to section ‘warnings and cautions’ of the User’s Guide for the

LuMon™ System [1].

NOTE

Shadings in the troubleshooting table reflect different levels of recommended actions, i.e. for the operator (dark grey), qualified

technicians (light grey) and

SenTec Authorized LuMon™ Technicians

(no shading), see 4.1 for details.

4.2.1 Troubleshooting EIT monitoring

If you suspect a problem with any individual measurement, read the User’s Guide for the LuMon™ System [1] and double-check

that you or the operator have set up the system correctly. In particular, verify proper setup and adequacy of the selected

Analysis

Mode

. To resolve the problem(s) that may be associated with a displayed status message, refer to section ‘status messages’ of the

User’s Guide for the LuMon™ System [1].

Table 4-1: Troubleshooting EIT monitoring

Problem Possible cause(s) Recommended action(s)

EIT0100

Inclination displayed on

GUI— inclination status icon

AND inclination image —

does not suit patient’s

inclination

DockingStation of SB not parallel to

sternum of the patient.

Position sensor is placed in the

Matchbox of the SBC.

Verify belt positioning and a snug fit of the belt on the skin [1]

section ‘checking the proper setup’.

Consider to adjust the routing of the SBC-cable or the

DockingStation.

Position sensor placed behind the

‘bear’ in the LMB not parallel to

sternum of the patient.

Verify belt positioning and a snug fit of the belt on the skin [1]

section ‘checking the proper setup’.

Consider to adjust the LuMon™ Belt to align the ‘bear’ with the

sternum of the patient. In such case the belt displacement

needs to be measured and entered to patient data on monitor,

again.

EIT0101

Rotation displayed on GUI —

Belt-connection/ Skin-

contact/ Rotation status icon

AND all images — does not

suit patient’s rotation.

DockingStation of SB not parallel to

sternum of the patient.

Position sensor placed in the Matchbox

of the SBC.

Verify belt positioning and a snug fit of the belt on the skin [1]

section ‘checking the proper setup’.

Consider to adjust the routing of the SBC-cable or the

DockingStation.

Position sensor placed behind the

‘bear’ in the LMB not placed close to

the midline of the patient.

Verify belt positioning and a snug fit of the belt on the skin [1]

section ‘checking the proper setup’.

Consider to adjust the LuMon™ Belt, positioning the ‘bear’ on

the sternum. In such case the belt displacement needs to be

measured and entered to patient data on monitor, again.

EIT0102

Status icon ‘Belt Time’

displays ‘belt time elapsed’

SB/LMB has been used for longer than

the factory-preset duration a belt can

be used.

Remove and dispose of the old belt and obtain a new belt of

the same size to continue monitoring for the same patient.

EIT0103

Global Dynamic Image and

Plethysmogram fluttering

(Plethysmogram full of

irregular spikes).

Interference from other devices (e.g.

patient monitors, high-frequency

surgical equipment or devices emitting

strong electromagnetic fields).

In case of interferences from other devices – e.g. respiratory

rate measurement through ECG electrodes – try to place the

electrodes of the device as far from the belt as possible.

Note: Concerning interferences with or from other

devices refer to section ‘warnings and cautions’ of the

User’s Guide for the LuMon™ System [1].

If the interference cannot be eliminated Contact

a

SenTec

Authorized LuMon™ Technician,

your local SenTec EIT

representative or SenTec AG.

EIT0104

Indices not reflecting patient

situation - over or

underestimated

Belt applied too far caudally. If applied

too far caudally the measurements may

be influenced by the diaphragm.

Verify belt positioning and a snug fit of the belt on the skin [1]

section ‘checking the proper setup’.

Consider to adjust the belt.

Belt applied too far cranially.

EIT0105

Global Dynamic image is not

inside the Lung ROIs.

Patient and/or belt parameter not set

properly.

Thorax and Lung ROIs models do not

correspond to the patient constitution

and consequently causing either over-

or underestimated measurements.

If necessary, adjust the respective entries in the ‘patient & belt’

area of ScoutView. Enter actual (not lean or ideal) body weight

[1] section ‘belt application and initiating monitoring’.

EIT0106

LuFuView’s indices and

images not visible

BB

Analysis Mode

selected and breaths

not detected.

Black vertical lines displaying the end of

expiration and the end of inspiration

are not visible on

Plethysmogram

.

Verify the adequacy of the selected

Analysis Mode

[1] section

‘checking the adequacy of the selected Analysis Mode’.

Consider to change

Analysis Mode

.

Troubleshooting

20 of 33

Service Manual for the LuMon™ System

Problem Possible cause(s) Recommended action(s)

Impedance change is too small.

Black vertical lines displaying the

Analysis Interval

are not visible on

Plethysmogram

.

EIT0107

LuFuView’s ‘silent spaces’

and ‘stretch’ areas not

accessible

TB-II

Analysis Mode

selected.

LuFuView’s ‘silent spaces’ and ‘stretch’

areas not accessible when TB-II

Analysis Mode

is selected.

Verify the adequacy of the selected

Analysis Mode

[1] section

‘checking the adequacy of the selected Analysis Mode’.

Consider to change

Analysis Mode

.

EIT0108

LuFuView’s indices and

images are not stable

Patient is breathing irregularly.

Verify the adequacy of the selected

Analysis Mode

[1] section

‘checking the adequacy of the selected Analysis Mode’.

Consider to change

Analysis Mode

.

EIT0109

Respiratory Rate not visible

Patient is breathing irregularly or the

breath amplitude is too small.

-

EIT0110

EELi/ EILI trend not visible or

only partly visible

BB

Analysis Mode

selected and breaths

not detected.

Black vertical lines displaying the end of

expiration and the end of inspiration

are not visible on

Plethysmogram

.

Verify the adequacy of the selected

Analysis Mode

[1] section

‘checking the adequacy of the selected Analysis Mode’.

Consider to change

Analysis Mode

.

Impedance change is too small.

Black vertical lines displaying the

Analysis Interval

are not visible on

Plethysmogram

.

EIT0111

Aeration not visible

Aeration is visible in TB-II

Analysis

Mode

only.

Enter ScoutView and select TB-II

Analysis Mode

[1] section

‘ScoutView’.

4.2.2 Belt-specific troubleshooting

Table 4-2: Belt-specific troubleshooting

Problem Possible cause(s) Recommended action(s)

EIT0200

Despite a belt is connected

to SBC/LMC and LMM the

status message ‘connect

belt’ is displayed.

Bad contact (SBC/LMC not properly

connected)

Verify connections (disconnect and reconnect belt connector)

and – if necessary – power cycle the monitor.

SB/LMB defective

To identify the defective part, exchange the belt connector

and try again – if necessary, permute and try on a different

monitor.

In case of damage of the belt replace it (8).

SBC/LMC defective

In case of damage of the belt connector replace it.

LMM defective

Refer to 4.2.3 to further evaluate the problem.

EIT0201

MatchBox part of the SBC

cannot be inserted into the

DockingStation of the SB.

SB defective

In case of damage of the belt replace it (8).

EIT0202

Status message ‘belt fault’

SB/LMB defective

To identify the defective part, exchange the belt connector

and try again – if necessary, permute and try on a different

monitor.

In case of damage of the belt replace it (8).

EIT0203

Status message ‘insufficient

skin contact’

Incorrect positioning of the SB/LMB on

the skin

If necessary, adjust the belt and tighten it fit. If tightening the fit

of the belt, ensure not to restrict breathing. See User’s Guide

[1] section ‘Belt application and initiating monitoring’.

Contact medium is not applied or

incorrectly applied

Apply contact medium to the belt striped fabric on the

patient-facing side. Repeat the spraying until the striped fabric

is wetted evenly and entirely. See User’s Guide [1] section ‘Belt

application and initiating monitoring’.

SB/LMB defective

To identify the defective part, exchange the belt connector

and try again – if necessary, permute and try on a different

monitor.

In case of damage of the belt replace it (8).

Other manuals for LuMon

1

Table of contents

Other Sentec Medical Equipment manuals

Popular Medical Equipment manuals by other brands

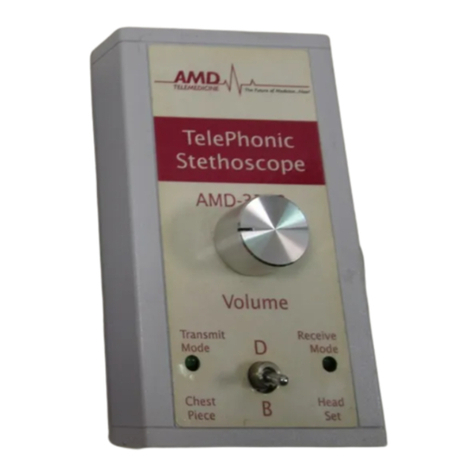

AMD

AMD AMD-3700 Installation and operation manual

Hologic

Hologic SUPERSONIC IMAGINE AIXPLORER MultiWave Cleaning Instruction Guide

Aivia

Aivia 200 Installation and operating manual

SALUDA MEDICAL

SALUDA MEDICAL Evoke SCS System Surgical Guide

Aivia

Aivia A-MIP 200 Installation and user guide

Steeper

Steeper Espire Pro Elbow Quick setup guide

natus

natus Nicolet SCU user guide

Aircraft Medical

Aircraft Medical McGRATH MAC EMS Operator's manual

ABTECH SAFETY

ABTECH SAFETY SLIXRR Instruction & Maintenance Manua

Fresenius Medical Care

Fresenius Medical Care DIASAFE 2008 K Operator's manual

Globus

Globus Magnum XL operating manual

ZOLL

ZOLL CPR-D-padz quick start guide