10 Jetflush Rapid V1-02-1 5

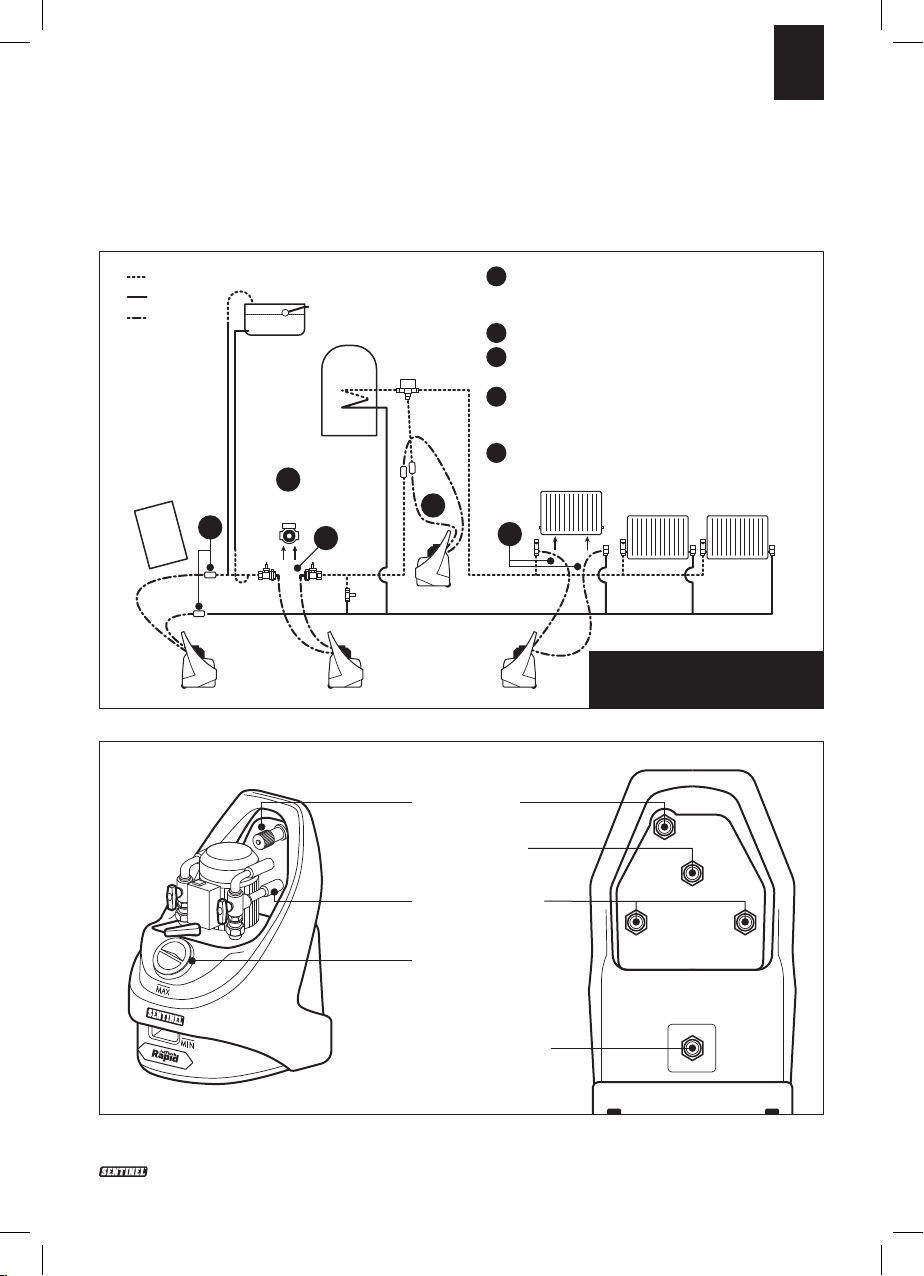

Section B – Using the Jetflush Rapid pump for power flushing

LOCATION AND CONNECTION

OF THE FLUSHING PUMP

(CONTINUED)

The connection point for the flushing

pump may vary depending on the

system to be cleaned, and the

availability of suitable connection

points.

However the optimum location is via

the central heating circulation pump,

using the special hoses supplied to

connect across the pump unions.

Generally the unit should be located

in a room with a suitable drain point,

and near to a convenient mains

water supply, such as a bathroom or

kitchen. The cold water supply for

a washing machine or dish-washing

machine is a convenient source

when a mixer tap makes connection

of a hose difficult. The normal

precautions during work on any

heating system should be taken, and

it is prudent to place the pump on a

waterproof groundsheet or drip tray.

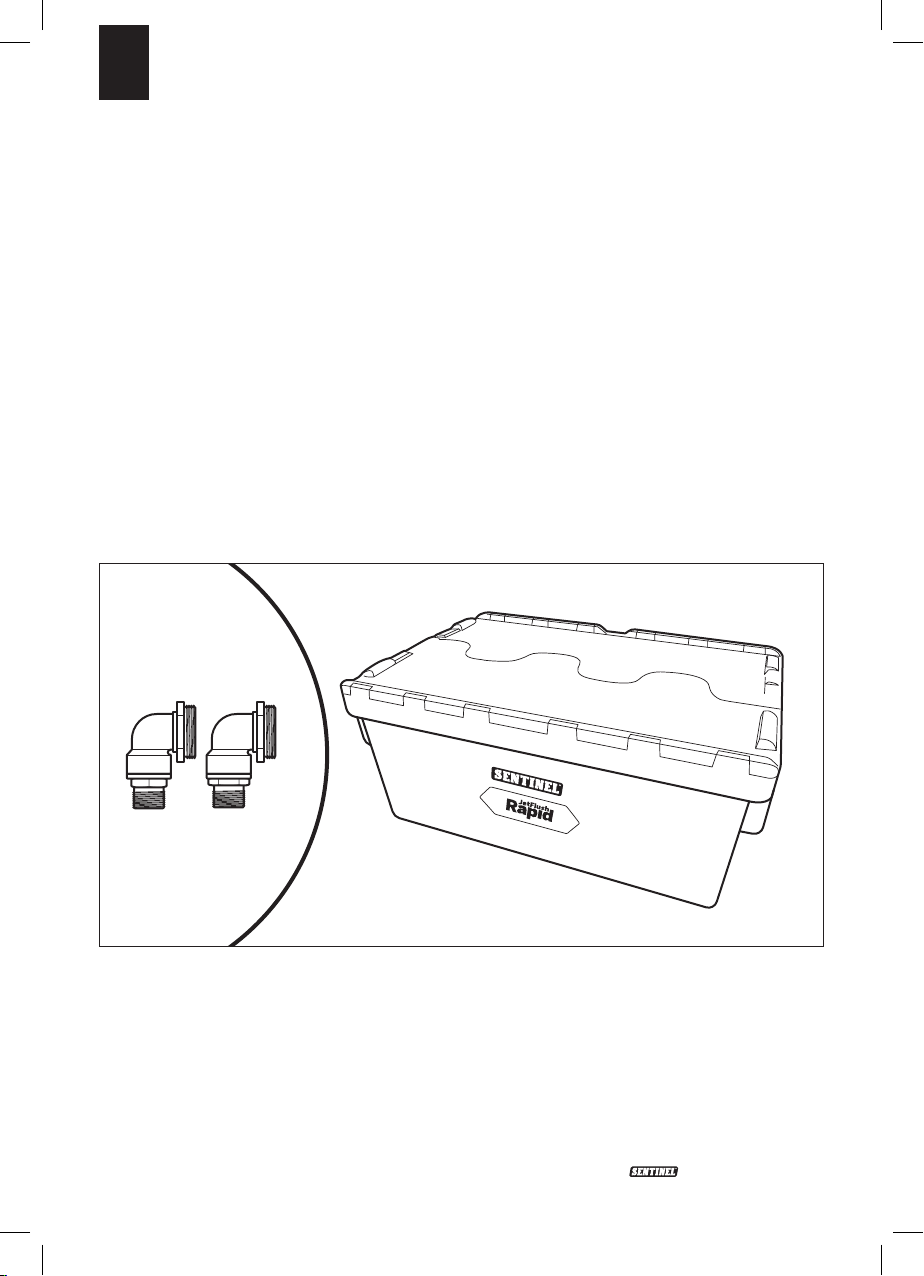

1. Hose connections to the

flushing pump

1a. Ensure that both valves are in

the closed position (i.e. the valve

handles are horizontal).

1b. The pump has two 5 metre flow

and return hoses, fitted with ¾"

female brass hose connectors on

either end of each hose.

One end of both flow and return

hoses should be screwed onto

the corresponding ¾" brass

nipples on rear of the hose

support plate. The other ends of

these hoses will be connected

into the heating system.

1c. Connect the overflow hose

connector to the ¾" BSP male

overflow fitting on the rear of the

pump tank, and lead to a suitable

drain point.

1d. Connect the 8meter dump hose

to the brass nipple on the reverse

of the hose support plate, and

lead the hose to a toilet pan or

Jetflush Rapid Guidelines (19-02-15).indd 10 19/02/2015 12:13