Thiele TWN 0835/1 User manual

MOUNTING INSTRUCTIONS

HOOKS

GRADES 8 AND 10

THIELE GmbH & Co. KG # identifies revisions

www.thiele.de | info@thiele.de B08 6-B replaces B08 6-A

© All rights reserved EN 02.2022 1 |

Original in compliance with 2006/ 2/EC

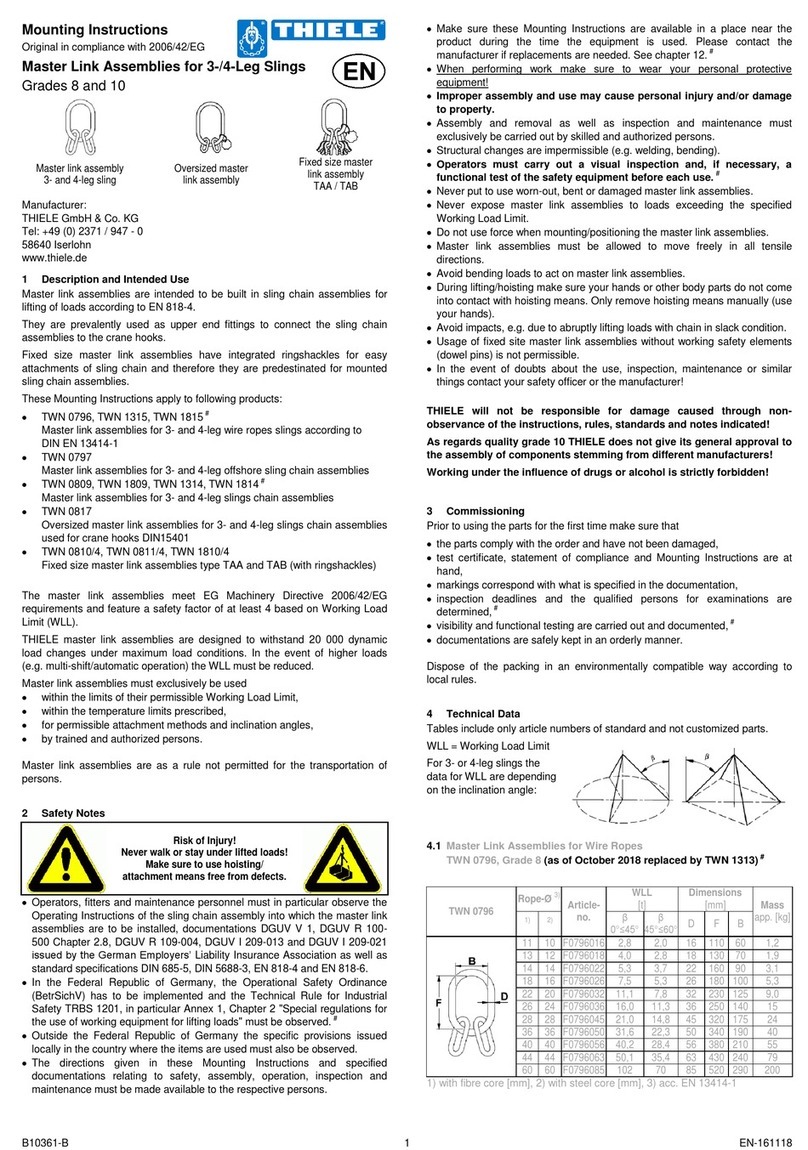

Sling

h

ooks

with clevis

Sling

h

ooks

with eye

Foundry

hooks

Swivel

hooks

Lifting

h

ook

for engines

TWN 0835/1

TWN 13 0/1

TWN 18 0/1

TWN 0855/1

TWN 0858/1

TWN 18 1/1

TWN 0859

TWN 0856

TWN 1856

TWN 085

TWN 0887

TWN 0889

1DESCRIPTION AND INTENDED USE

THIELE hooks are intended for the usage in chain sling assemblies according to EN 818-

or in lashing chain assemblies according to EN 12195-3.

The connection to the chain is made directly by the clevis or indirectly by using

connecting links which are assembled to the eye.

Hooks with eye can also be used within welded chain sling assemblies.

Hooks must exclusively be used:

•within the limits of their permissible Working Load Limits,

•within the temperature limits prescribed,

•for permissible attachment methods and inclination angles,

•by trained and authorized personnel.

THIELE hooks meet EG Machinery Directive 2006/ 2/EG requirements and feature a

safety factor of at least based on the working load limit (WLL). They are usually

certified by the German Employers' Liability Insurance Association and carry the

H -stamp.

They are signed with the corresponding chain size, grade, manufacturers mark and

traceability code.

#

THIELE hooks are designed to withstand 20 000 dynamic load changes under maximum

load conditions. In the event of higher loads (e.g. multi-shift/ automatic operation) the

working load limit must be reduced.

As a rule, hooks are not permitted for the transportation of persons!

An alternating use for lifting and lashing is not allowed!

2SAFETY NOTES

Risk of Injury

!

Never walk or stay under lifted loads!

Make sure to use hoisting/attachment

means free from defects!

•Operators, fitters, and maintenance personnel must in particular observe the

operating instructions of the used chain sling assembly, documentations DGUV V 1,

DGUV R 109-017

#

, DGUV I 209-013 and DGUV I 209-021 issued by the German

Employers’ Liability Insurance Association, as well as standard specifications

DIN 685-5 and EN 818-6.

•In the Federal Republic of Germany, the operational safety ordinance (BetrSichV) has

to be implemented and the technical rule for industrial safety TRBS 1201, in

particular Annex 1, Chapter 2 "Special regulations for the use of working equipment

for lifting loads" must be observed.

#

•Outside the Federal Republic of Germany the specific provisions issued locally in the

country where the items are used must also be observed.

•The directions given in these mounting instructions and specified documentations

relating to safety, assembly, operation, inspection, and maintenance must be made

available to the respective persons.

•Make sure these mounting instructions are available in a place near the product

during the time the equipment is used. Please contact the manufacturer if

replacements are needed. See also chapter 7.

#

•When performing work make sure to wear your personal protective equipment!

•Improper assem ly and use may cause personal injury and/or damage to property.

•Assembly and removal as well as inspection and maintenance must exclusively be

carried out by skilled and authorized persons.

•Structural changes are impermissible (e.g. welding, bending).

•Operators must carry out a visual inspection and, if necessary, a functional test of

the safety equipment efore each use.

#

•Never put to use worn-out, bent or damaged hooks.

•Do not overload hooks.

•Do not use force when mounting/positioning the hooks.

•Do not tip-load a hook.

•Hooks shall have well-functioning safety latches.

•Avoid bending loads to act on hooks.

•When using hooks without safety latch special care must be taken and a special risk

assessment should be done.

•Usage without working safety devices is not permissible.

•Safety elements must not be excessively stressed or strained operationally.

•Avoid sharp edges. Use edge protectors or reduce the WLL by 20 %.

#

•Do not start lifting before you have made sure the load has been correctly attached.

•During lifting/hoisting make sure your hands or other body parts do not come into

contact with hoisting means. Only remove hoisting means manually (use your

hands).

•Avoid impacts, e.g. due to abruptly lifting loads with chain in slack condition.

•Avoid hooks to get caught under the load.

•In the event of doubts about the use, inspection, maintenance or similar things

contact your safety officer or the manufacturer.

#

THIELE will not e responsi le for damage caused through non-o servance of the

instructions, rules, standards and notes indicated!

As regards grade 10 THIELE does not give its general approval to the assem ly of

components stemming from different manufacturers!

Working under influence of drugs, alcohol (even remaining alcohol) or interfering

medications is strictly for idden!

#

3COMMISSIONING

Prior to using the components for the first time make sure that

•the components comply with the order and have not been damaged,

•test certificate, statement of compliance, and operating instructions are at hand,

•markings correspond with what is specified in the documentation,

•inspection deadlines and the qualified persons for examinations are determined,

•visibility and functional testing are carried out and documented,

•the documentation is safely kept in an orderly manner.

Dispose of the packing in an environmentally compatible way according to local rules.

MOUNTING INSTRUCTIONS

HOOKS

GRADES 8 AND 10

THIELE GmbH & Co. KG # identifies revisions

www.thiele.de | info@thiele.de B08 6-B replaces B08 6-A

© All rights reserved EN 02.2022 2 |

TECHNICAL DATA

Table includes article numbers of basic versions but no customized editions.

WLL = Working load limit

#

Sling hooks wi h clevis TWN 0835/1, grade 8

Versions according to TWN 0835 without safety latch

Nominal

size

Article

no.

WLL

[t]

Dimensions [mm] Mass

[kg]

E G H C

18-8 F33651 10 195 60 52 50 7,6

20-8 F33656 12,5 220 65 58 55 9,7

22-8 F33661 15 2 75 6 61 10,6

Sling hooks wi h clevis TWN 1340/1, grade 8

Version TWN 13 0 without safety latch

Nominal

size

Article

no.

WLL

[t]

Dimensions [mm] Mass

[kg]

E G H C

6-8 F336010 1,12 75 2 20 17 0,36

8-8 F336110 2,0 92 30 25 22 0,75

10-8 F336210 3,15 113 37 32 28 1,

13-8 F336310 5,3 133 2 1 35 2,5

16-8 F336 10 8,0 162 51 50 1 ,

Sling hooks wi h clevis TWN 1840/1, grade 10

Version TWN 18 0 without safety latch

Nominal

size

Article

no.

WLL

[t]

Dimensions [mm] Mass

[kg]

E G H C

6-10 F336050 1, 75 2 20 17 0,36

8-10 F336150 2,5 92 30 25 22 0,75

10-10 F336250 ,0 113 37 32 28 1,

13-10 F336350 6,7 133 2 1 35 2,5

16-10 F336 50 10 162 51 50 1 ,

Sling hooks wi h eye TWN 0858/1, grade 8

Version TWN 0858 without safety latch

Nominal

size

Article

no.

WLL

[t]

Dimensions [mm] Mass

[kg]

E D

1

D

2

G H C

6-8 F32901 1,12 91 21 11 23 17 16 0,3

8-8 F32911 2,0 120 28 1 30 2 22 0,8

10-8 F32921 3,15 152 36 18 38 29 28 1,7

13-8 F32931 5,3 180 2 21 2 1 36 2,8

16-8 F329 1 8,0 221 5 27 52 5 3 5,1

18/20-8 F32951 12,5 270 62 30 65 58 55 8,7

22-8

1)

F329710 15 271 65 30 70 62 5 9,7

26-8

1)

F329810 21,2 302 70 33 75 71 59 1

32-8

1)

F329910 31,5 352 80 38 90 86 67 25

1) New design

Sling hooks wi h eye TWN 0855/1, grade 8

Version TWN 0855 without safety latch

Nominal

size

Article

no.

WLL

[t]

Dimensions [mm] Mass

[kg]

E D G H C

36-8 Z0 079 0 388 72 109 103 78 32

0-8 Z0 083 50 2 8 12 116 89 6

5-8 Z0 080 63 9 90 138 130 99 63

50-8 Z0 081 80 610 102 155 1 5 110 80

Sling hooks wi h eye TWN 1841/1, grade 10

Version TWN 18 1 without safety latch

Nominal

size

Article

no.

WLL

[t]

Dimensions [mm] Mass

[kg]

E D D

1

G H C

6-10 F32905 1, 91 21 11 2 20 17 0,36

8-10 F32915 2,5 118 28 1 30 25 22 0,78

10-10 F32925 ,0 1 5 36 18 37 32 28 1,5

13-10 F32935 6,7 168 2 21 2 1 35 2,6

16-10 F329 5 10 210 5 25 51 50 1 ,7

22-10 F32975 15 271 65 30 70 62 5 9,7

MOUNTING INSTRUCTIONS

HOOKS

GRADES 8 AND 10

THIELE GmbH & Co. KG # identifies revisions

www.thiele.de | info@thiele.de B08 6-B replaces B08 6-A

© All rights reserved EN 02.2022 3 |

Foundry hooks wi h clevis TWN 0859, grade 8

Nominal

size

Article

no.

WLL

[t]

Dimensions [mm] Mass

[kg]

E G H C

8-8 F33310 2,0 110 66 33 27 1,0

10-8 F33320 3,15 133 76 35 32 1,6

13-8 F33330 5,3 159 89 1 38 3,

16-8 F333 0 8,0 189 102 8 5 5,5

Lif ing hook for engines TWN 0889, grade 8

Size Article

no.

Chain size

[mm] WLL [t] Dimensions [mm] Mass

[kg]

E G H C

0,50 F33 39 6 0,50 137 19 13 12 0,55

Foundry hooks wi h eye TWN 0856, grade 8

Nominal

size

Article

no.

WLL

[t]

Dimensions [mm] Mass

[kg]

E D G H C

6-8 Z00 56 1,12 95 13 50 2 20 0,53

8-8 F32360 2,0 125 18 66 33 27 0,93

10-8 F32370 3,15 1 6 20 76 35 32 1,7

13-8 F32380 5,3 175 26 89 1 38 3,2

16-8 F32390 8,0 205 32 102 8 5 5,

18/20-8 F32 00 12,5 235 0 11 5 51 7,5

22-8

2)

Z00 57 15 265 7 127 70 65 11,

26-8

2)

Z00 58 21,2 305 52 136 80 72 1

32-8

2)

Z00 59 31,5 327 60 152 93 83 28

2) Hand forged

Foundry hooks wi h eye TWN 1856, grade 10

Nominal

size

Article

no.

WLL

[t]

Dimensions [mm] Mass

[kg]

E D G H C

8-10 F32365 2,5 13 18 66 33 26 0,92

10-10 F32375 ,0 156 20 76 35 32 1,5

13-10 F32385 6,7 188 26 89 2 38 2,75

Swivel hooks TWN 0854, grade 8

Nominal

size

Article

no.

WLL

[t]

Dimensions [mm] Mass

[kg]

E G H C F B D

0,75-8M F32103 0,75 113,5 19 1 13 25 30 10 0,36

6-8 F32100 1,12 113 18 20 1 25 30 10 0,38

8-8 F32110 2,0 155 21 25 19 2 16 1,0

10-8 F32120 3,15 162 23 30 21 2 16 1,2

13-8 F32130 5,3 190 32 33 28 3 51 19 2,1

16-8 F321 0 8,0 2 7 0 3 35 61 6 25 ,5

Swivel hooks TWN 0887, grade 8

Nominal

size

Article

no.

WLL

[t]

Dimensions [mm] Mass

[kg]

E G H C D F B

0,35 F32160 0,35 98,5 1 1 1 9 20 16 0,2

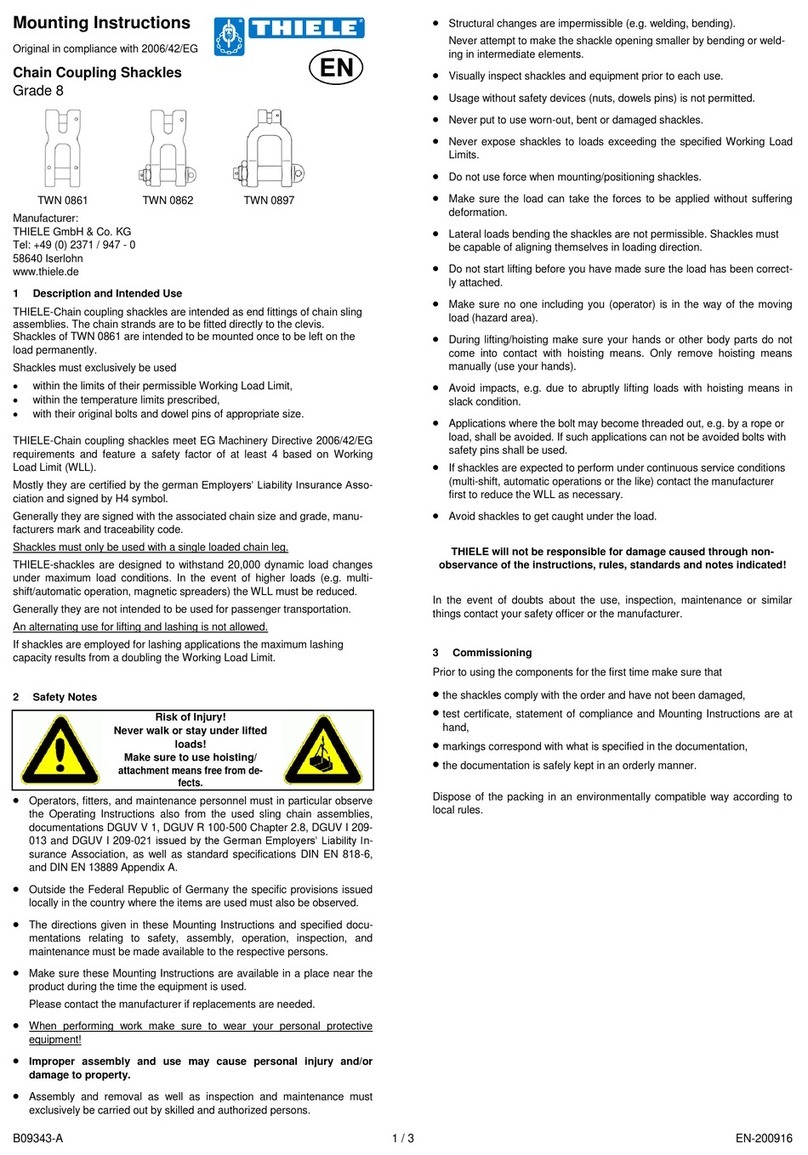

5ASSEMBLY AND REMOVAL

Assembly of clevis- ype fas ening sys em

•If necessary, remove dowel pin and pin.

•(A) Place end of chain leg between the lateral clevis

elements.

•(B) Push pin from the side fully into the clevis and

through the last chain link of the leg.

•(C) Drive dowel pin fully in (must not project) to

secure the pin.

The slot must face away from the pin.

•Check the chain runs smoothly!

The dowel pins must only be installed once.

Disassembly of clevis- ype fas ening sys em

•Slacken the respective chain leg.

•(A) Drive dowel pin out using hammer and drift

punch.

•(B) Push pin out.

•(C) Remove the chain.

Suitable drift punches are available by article no. Z03303.

MOUNTING INSTRUCTIONS

HOOKS

GRADES 8 AND 10

THIELE GmbH & Co. KG # identifies revisions

www.thiele.de | info@thiele.de B08 6-B replaces B08 6-A

© All rights reserved EN 02.2022 |

Safe y la ch

Disassembly by driving the dowel pins out.

Assembling by correct positioning of safety latch together with spring and driving in the

thicker dowel pin by a hammer. Afterwards the thinner dowel pin has to be driven in,

taking care that the slots positioned adverse.

Check the correct operability of the safety latch.

6OPERATION

Normal use

Hooks must always be freely movable when attached to the load.

Hooks must not rest on or be supported by other structural parts.

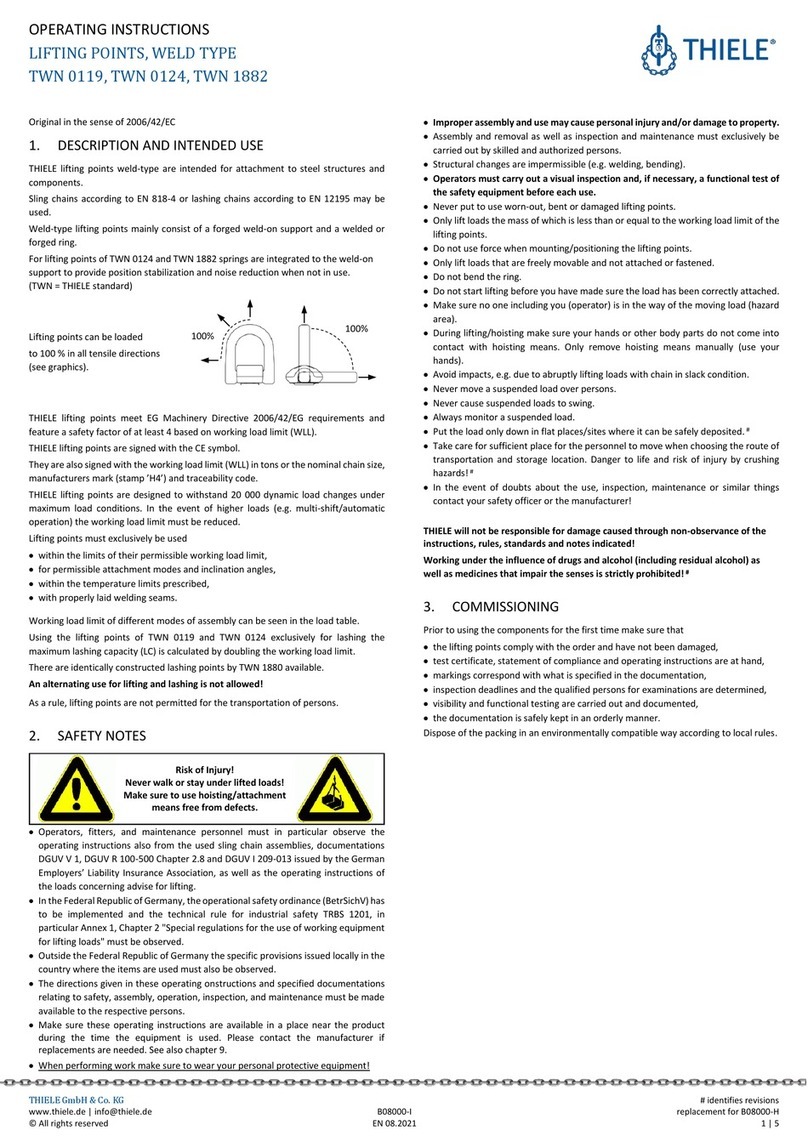

Influence of empera ure

Using hooks at elevated temperatures will cause the Working Load Limit to be reduced

as indicated below.

Grade Temperature range Remaining working load limit

8

- 0 °C ≤ t ≤ 200 °C 100 %

200 °C < t ≤ 300 °C 90 %

300 °C < t ≤ 00 °C 75 %

10

-30 °C ≤ t ≤ 200 °C 100 %

200 °C < t ≤ 300 °C 90 %

300 °C < t ≤ 380 °C 60 %

If hooks have been exposed to temperatures exceeding the maximum values specified

they must no longer be used.

Environmen al influence

Hooks must not be used in environments where acids, aggressive or corrosive

chemicals or their fumes are present.

Hot-dip galvanizing or a galvanic treatment is prohibited as well.

7 THIELE OPERATING AND MOUNTING INSTRUCTIONS

#

Current operating and installation instructions are available as

a PDF download on the homepage.

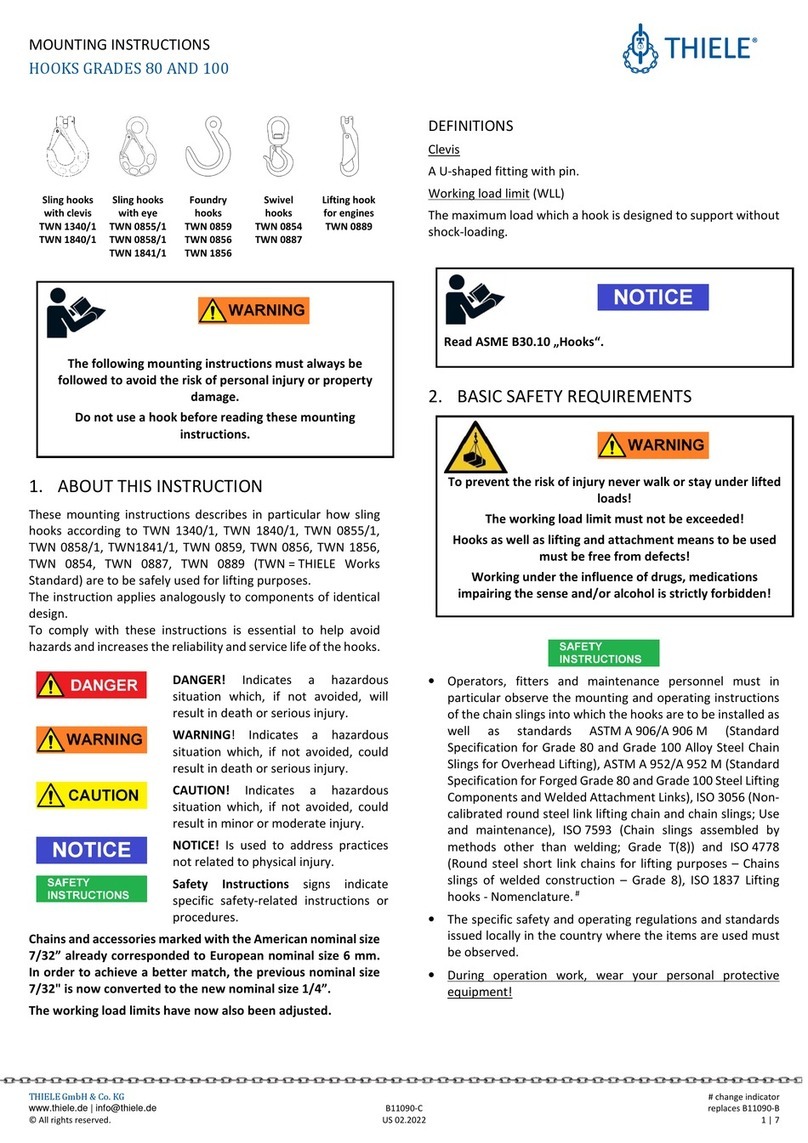

8SPARE PARTS

Use only original spare parts.

Spare par se s for safe y la ches

A set consists of safety latch, spring und dowel pins.

f

o

r

TWN 0835/1,

TWN 0858/1,

TWN 1340/1

f

o

r

TWN 1835/1,

TWN 1840/1

TWN 1841/1

Nominal

size Article no.

Nominal

size Article no.

6-8 F 8730 6-10 F 8731

8-8 F 8732 8-10 F 8733

10-8 F 873 10-10 F 8735

13-8 F 8736 13-10 F 8737

16-8 F 8738 16-10 F 8739

18-8 F 8585 22-10 F 87 5

20-8 F 87 2

22-8 F 87

26-8 F 87 6

32-8 F 87 7

Spare par se s for clevis- ype fas ening sys em

A set consists of pin and dowel pin.

Nominal

size Article no.

Nominal

size Article no.

6-8 F 869 6-10 F 8686

8-8 F 8352 8-10 F 8687

10-8 F 8355 10-10 F 8688

13-8 F 8358 13-10 F 8689

16-8 F 8361 16-10 F 8690

18-8 F 836

20-8 F 8369

22-8 F 8367

9INSPECTIONS, MAINTENANCE, DISPOSAL

Inspec ions

Inspections and maintenance must be arranged for by the owner!

Inspection intervals shall be determined by the owner!

Inspections must be carried out and documented by competent persons regularly but

at least once a year, or more frequently if hooks are in heavy-duty service. After three

years at the latest they must additionally be examined for cracks. A load test shall never

be considered a substitute for this examination.

The results of the inspection shall be entered into a register (DGUV I 209-062 or

DGUV I 209-063) to be prepared at first use. The register will show characteristic data

of the hooks and other components as well as identity details.

Immediately stop using hooks that show the following defects:

•missing or illegible identification/marking,

•deformation, elongation or fractures,

•cuts, notches, cracks, incipient cracks, pinching,

•heating beyond permissible limits,

•severe corrosion,

•broken springs,

•not sufficient workíng safety devices,

•wear in excess of 10 %, e.g. in the receiving area of the pin diameter,

•missing or damaged pin locks or removal preventing guards.

Inspec ion service

THIELE offers inspection, maintenance and repair services performed by trained and

competent personnel.

Main enance

Maintenance and repair work must only be performed by competent persons.

Minor notches and cracks at the rings may be eliminated by careful grinding observing

the maximum cross section reduction requirement of 10 % and avoid making more

severe cuts or scores.

All maintenance and repair activities are to be documented.

Disposal

All components and accessories of steel taken out of service are to be scrapped in line

with local regulations and provisions.

10 STORAGE

Hooks to be stored in dry locations at temperatures ranging between 0 °C and + 0 °C.

11 IMPRINT

THIELE GmbH & Co. KG

Werkstrasse 3

586 0 Iserlohn, Germany

Tel.: + 9(0)2371/9 7-0

This manual suits for next models

11

Other Thiele Industrial Equipment manuals

Thiele

Thiele Streamfeeder Reliant 3700 User manual

Thiele

Thiele TWN 0861 User manual

Thiele

Thiele TWN 1450 User manual

Thiele

Thiele Streamfeeder Value Series User manual

Thiele

Thiele TWN 1472 User manual

Thiele

Thiele TWN 0812 User manual

Thiele

Thiele TWN 0119 User manual

Thiele

Thiele TWN 1340/1 User manual

Thiele

Thiele Streamfeeder Reliant 3700 User manual

Thiele

Thiele TWN 0850/1 User manual