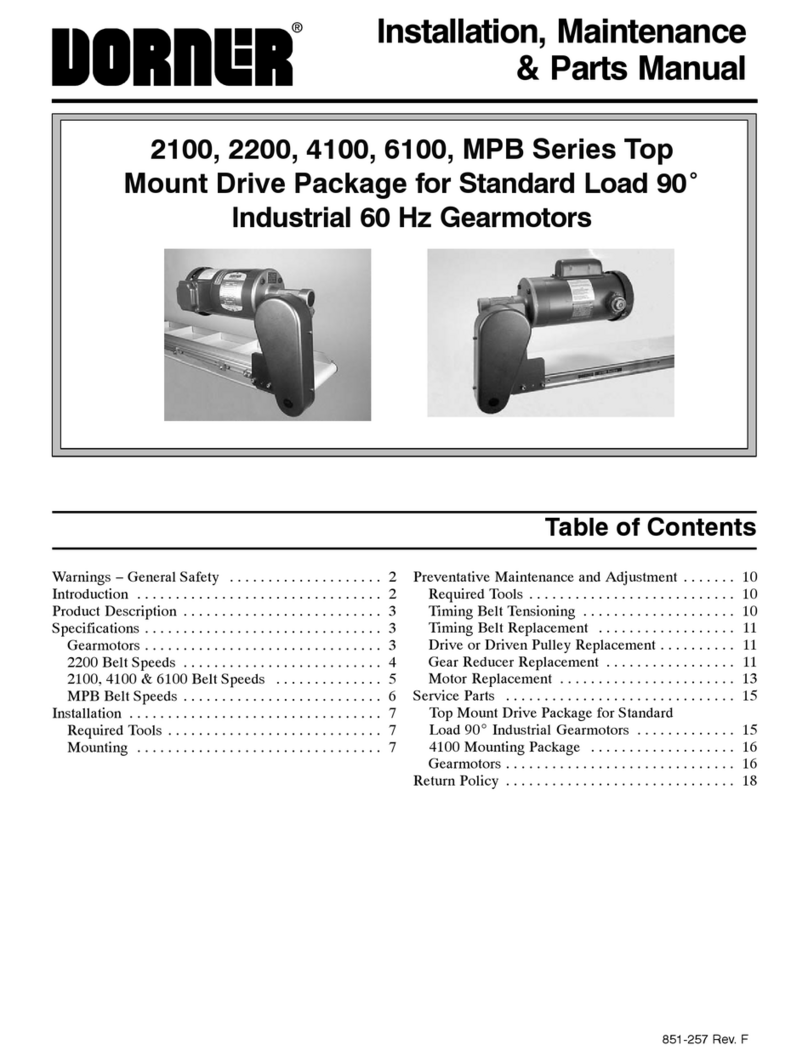

2100, 4100, 6100 Series Top Mount Drive Package for Standard Load 50 Hz Gearmotors SOMM

Dorner Mfg. Corp. 7851-295 Rev. A

Required Tools

DHex key wrenches

–2 mm, 2.5 mm, 3 mm & 5 mm

DAdjustable wrench (for hexagon head screws)

DStraight edge

DExternal snap ring pliers

DTorque wrench

Timing Belt Tensioning

Exposed moving parts can

cause severe injury.

LOCK OUT POWER before

removing guards or

performing maintenance.

WARNING

1.Remove four (4) screws (L of Figure 10) and remove

cover (K).

2.Loosen tensioner (V of Figure 11).

Figure 11

V

3.Depending on conveyor belt travel (direction 1 or 2),

locate timing belt tensioner (V of Figure 9) as shown.

Tension timing belt to obtain 3 mm deflection for

456 grams of force at timing belt mid-point (W).

Tighten tensioner screw to 12 Nm.

4.Install cover (K of Figure 10) with four (4) screws

(L). Tighten screws to 4 Nm.

Timing Belt Replacement

Exposed moving parts can

cause severe injury.

LOCK OUT POWER before

removing guards or

performing maintenance.

WARNING

1.Remove four (4) screws (L of Figure 10) and remove

cover (K).

2.Loosen tensioner (V of Figure 11).

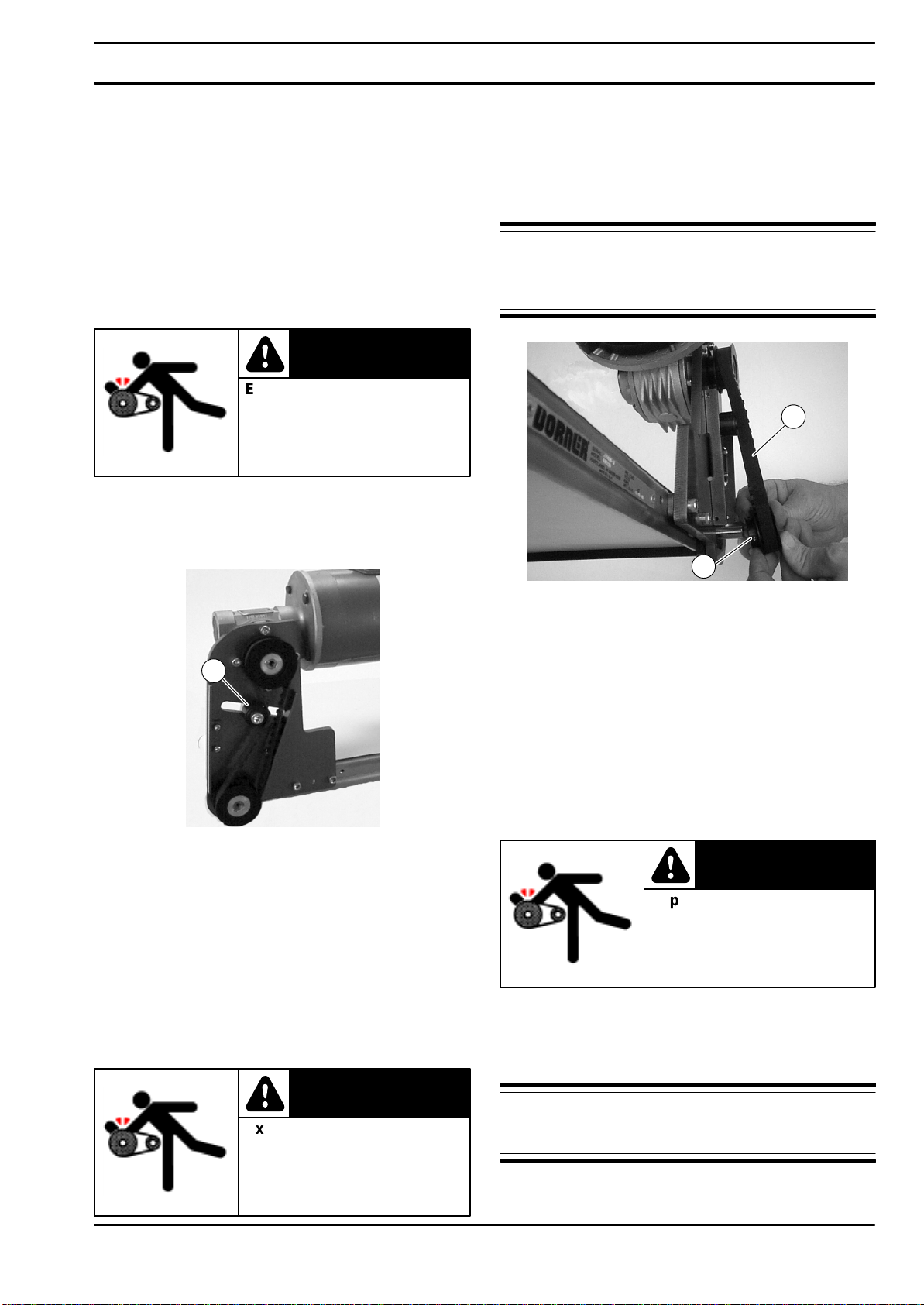

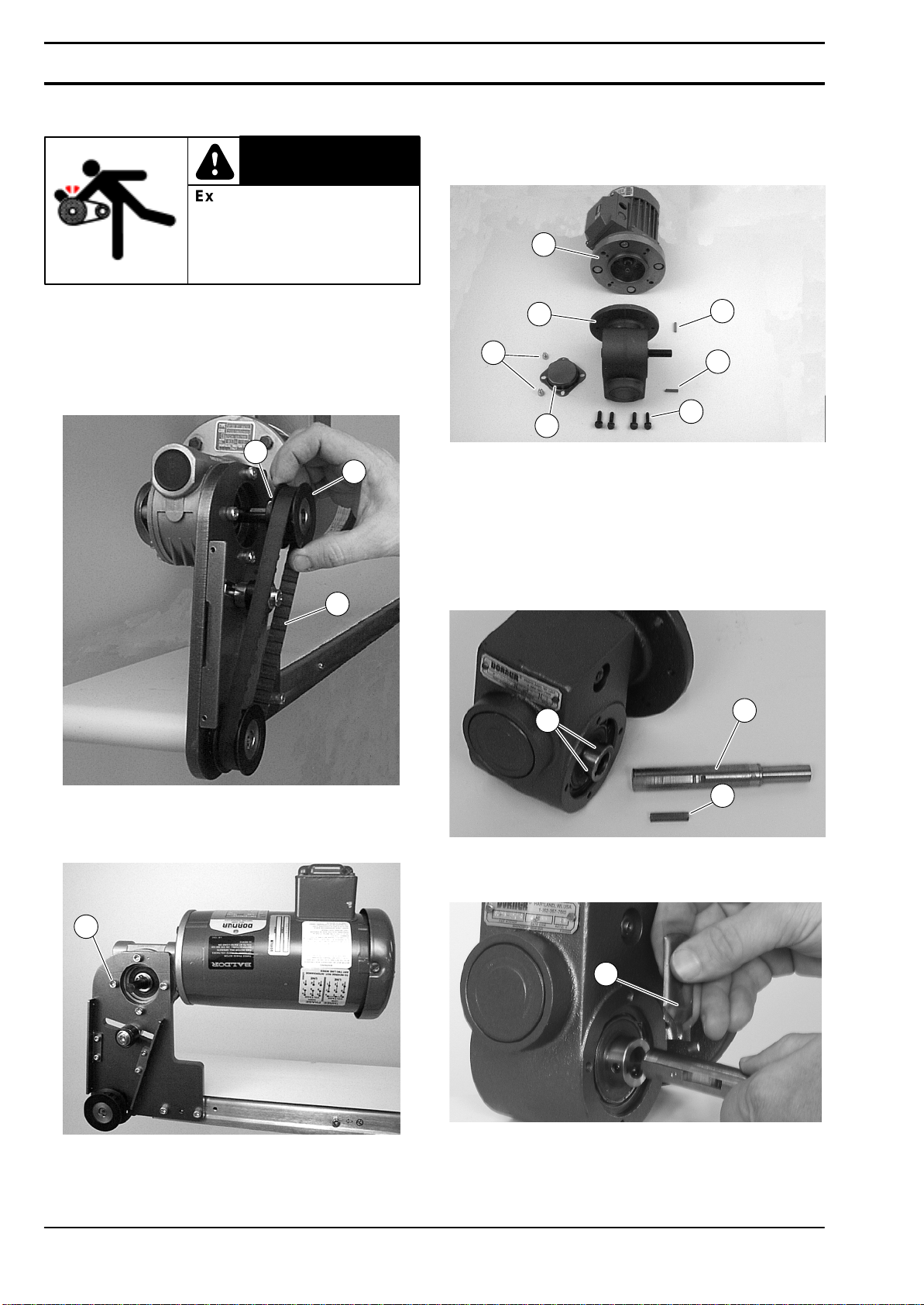

3.Remove timing belt (P of Figure 12).

NOTE: If timing belt does not slide over pulley

flange, loosen driven pulley set screws (U of Figure

12) and remove pulley with belt (P). For

re-installation, see steps 6 and 7 on page 6.

Figure 12

U

P

4.Install new timing belt.

5.Depending on conveyor belt travel (direction 1 or 2),

locate timing belt tensioner (V of Figure 9) as shown.

Tension timing belt to obtain 3 mm deflection for

456 grams of force at timing belt mid-point (W).

Tighten tensioner screw to 12 Nm.

6.Install cover (K of Figure 10) with four (4) screws

(L). Tighten screws to 4 Nm.

Drive or Driven Pulley Replacement

Exposed moving parts can

cause severe injury.

LOCK OUT POWER before

removing guards or

performing maintenance.

WARNING

1.Complete steps 1 through 3 of “Timing Belt

Replacement”section on this page.

2.Loosen set screws and remove drive or driven pulley.

NOTE: If drive pulley (J of Figure 13) is replaced,

wrap timing belt around drive pulley and complete

step 3.

3.Completesteps6through9of“Installation”section

on page 6.

Preventive Maintenance and Adjustment