senva AQD Duct Series User manual

INSTALLATION INSTRUCTIONS

senvainc.com 1-866-660-8864 (F)1-503-296-2529 9290 SW Nimbus Ave. Beaverton Oregon 97008

AQD Duct Series

AQO Outdoor Series

Analog and BACnet versions

CO2/RH/T Combination Sensor

IMPORTANT WARNINGS

• Only qualied trade installers should install this product

• This product is not intended for life-safety applications

• Do not install in hazardous or classied locations

• The installer is responsible for all applicable codes

• De-energize power supply prior to installation or service

PRODUCT APPLICATION LIMITATION:

Senva products are not designed for life or safety applications.

Senva products are not intended for use in critical applications

such as nuclear facilities, human implantable device or life sup-

PRODUCT IDENTIFICATION

OPERATION

The AQ series design allows customization for a sensor that

meets project requirements for monitoring temperature, CO

and relative humidity. The product can be ordered for outdoor

or duct mount and with a 0-5/10V analog or BACnet RS485

output.

To verify the features see the ‘Product Identication’ section of

the installation manual.

RTD/Thermistor*

A = None

C = 100Pt (385) RTD

D = 1000Pt (385) RTD

E = 10k type 2

F = 10k type 3

Output

CO2 Sensor

A = None

B = CO Sensor

D = Dual Channel CO2

RH Sensor

A = None

B = 2% RH Sensor

Output Type

A = Analog (0-5/10V)

B = BACnet

CO RH RTD/TH

D

*Add-on RTD/Thermistor is not readable via BACnet.;

Temperature output is standard on AQ devices.

AQ -

Package

D = Duct

O = Outdoor

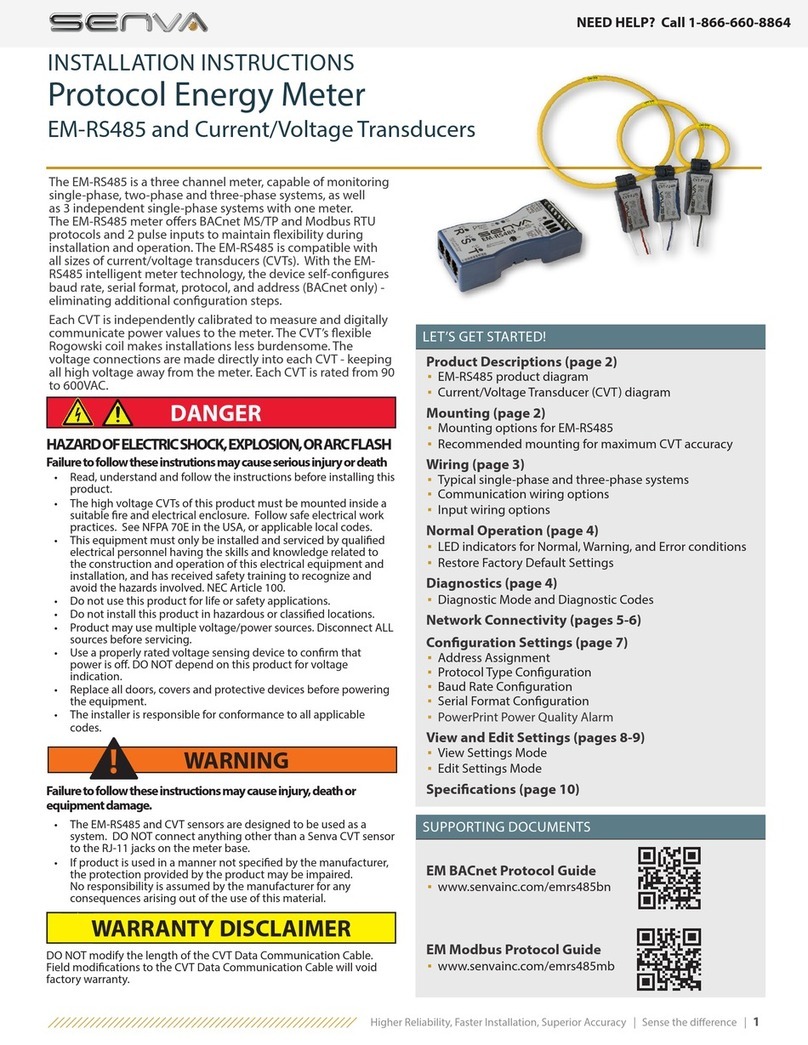

INSTALLATION

AQD (Duct) Installation

1. Drill a 3/4” hole in duct. Install sensor using gasket and

screws provided. The pickup tube will ensure adequate air ow

regardless of air ow direction.

2. Mount unit to duct with supplied screws. Continue to step 3

under general installation.

AQO (Outdoor) Installation

1. Select an outdoor location under an eave on north side of

building away from direct sunlight and rain exposure.

2. Mount product to building with supplied screws. Continue

to step 3 under general installation.

General (both) Installation

3. If installing with a conduit adapter, remove and replace the

factory-installed cable gland.

4. Wire analog (or RS485 for BACnet version) outputs as needed.

5. Apply power to sensor.

6. Tighten cable gland rmly around wires. If installing with a

conduit adapter, seal wire entry to prevent conduit air from

aecting sensor readings or operation.

7. Close lid and tighten screw. Cover must be securely installed

to prevent moisture from entering enclosure.

AQD (Duct) AQO (Outdoor)

G = 10k w/11k

H = 3k

I = 2k2

J = 1k8

K = 20k

WIRING

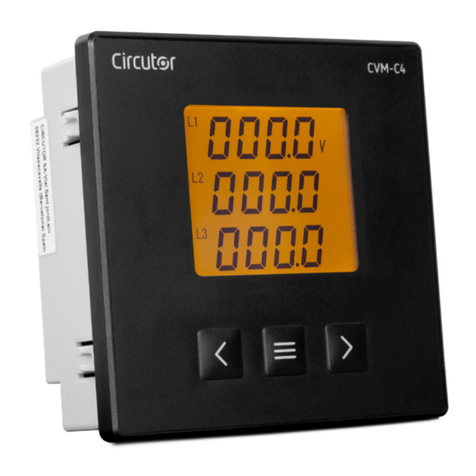

QUICK START MENU

1. Press and hold qand u(left and middle) buttons for 1

second to enter the Quick Start Menu that is adjustable using

the LCD. Screen will display SPt when the menu has been

activated.

2. Navigation and parameters:

• Pressing uadvances to the next menu item.

• If a menu item is visible, pressing either qor pdisplays the

current value.

• If a value is visible, pressing either qor pchanges the value.

Holding qor pfor a time accelerates the value change.

• If a value is visible, pressing qand ptogether sets the value

to the default.

• If a value is visible, pressing ureturns to the menu item list.

SPt Sets the relay turn-on threshold (Closed

above this level); Default: 800

SPhSets the relay turn-o hysteresis (Open below

this level); Default: 100

SCLSets the CO2 concentration scaling (2=

2000ppm (default); 5= 5000ppm, 10 = 10000ppm)

ADjSets the CO2 concentration calibration oset up to +/-

250ppm; Default: 0ppm

CALSets the CO2 auto calibration period

OFF Auto calibration disabled*, 7d 7 days,14d 14 days

(default), 30d 30 days, 60d 60 days

°FCSelects the unit system for displayed temperature

measurements UsRUser dened (default), °FDegrees

Fahrenheit, °CDegrees Celsius

LvLOutput Scaling (analog version only): 5v5.0V full

scale, 10v 10.0V full scale (default)

RUNClose this menu with changes saved and display

parameters.

3. When setup is complete, select RUN or wait for setup mode

to time out.

*If auto calibration is disabled, sensor may experience drift. Use

in areas that are continuously occupied or with concentrated

levels of CO such as greenhouses should consider dual-

channel sensor options. Consult factory for more information.

POWER VIN

GND/COMMON

N.O. RELAY

N.O. RELAY

T

C

H

ALL MODELS:

OUT CO

OUT RH

OUT TEMP

RS485 -

AGND

RS485 +

THERMISTOR

RESISTANCE

OUTPUT

1TERMINALS - ALL MODELS

2TERMINALS - ANALOG ONLY

3TERMINALS - BACNET ONLY

1PARTS LIST:

(-)

(+) -

+

0-5/10VDC CO2 ANALOG

OUTPUT TO CONTROLLER

1EXAMPLE ANALOG OUTPUT:

BACNET ONLY:

ANALOG ONLY:

OPTIONAL:

SPARE

C

T

H

(-)

(+)

5

4

9

678

1

10

2 3

4DISPLAY

5THERMISTOR OUTPUT (OPTION)

6DOWN BUTTON

7MENU BUTTON

8UP BUTTON

9REPLACEABLE CO SENSOR

10 TEMP/RH SENSOR

3

2

1

C

QUICK START MENU - BACNET

IMPORTANT: The device will not activate the BACnet interface

until the baud rate and the MS/TP MAC address are congured.

If an active RS485 network is not available, congure the device

using the Setup Menu (documented in the ‘AQ Series User’s

Guide’).

Access the auto conguration wizard by removing the front

cover and pressing the q, u, and p(all three) buttons for one

second. After the wizard activates, the display will show CFG.

The wizard automatically advances between each step after a

few seconds. Pressing the ubutton also advances the wizard.

bR The baud rate value can usually be detected from

existing network activity. If no baud rate could be

detected, the display will show ??. If necessary, use q

and pto change the baud rate before advancing.

AdR The device detects the smallest free MAC address on

the local MS/TP subnet from existing network activity.

If the installation requires a specic MAC address,

use qand pto override the detected address. If the

wizard detects that the selected MAC address

conicts with another device, it automatically

advances to the next smallest free MAC address.

After the wizard completes, the device saves the baud rate and

MS/TP MAC address. Additionally, the device adds 665000 to

the selected MAC address and saves the resulting sum as the

device object ID. If the object ID conicts with another device,

use id.1,id.2, and id.3 in the Setup Menu to set a unique

object ID.

The BACnet interface becomes active immediately after the

wizard completes. To recongure the baud rate and MAC

address, use the Setup Menu or run the wizard again.

VISUAL INDICATORS

Each measurement should display in turn.

If a measurement does not appear, the respective sensor

damaged, has been removed from the device, or has been

selected not to appear through the User’s Menu (See ‘AQ Series

User’s Guide’).

BACnet Only:

The baud rate and MAC address must be congured before the

device begins transmitting.

The RX light (receiving indicator) will ash while data is being

received. If the RX light is not blinking, verify the wiring

conguration and wiring connections.

The TX light (transmitting indicator) will ash while data is

being transmitted.

HOME SCREEN

By default, the device displays one measurement at a time,

rotating between measurements every 10 seconds if multiple

sensor options are installed.

If the installer wants to change which values are displayed on

the LCD, access the User’s Menu (See ‘AQ Series User’s Guide’).

TROUBLESHOOTING

Symptom Solution

No output Check wiring. Ensure power supply

meets requirements.

Reading error

Verify unit is located away from

hot/cold sources.

Verify control panel software is

congured correctly.

Verify accuracy of test instrument.

Install insulation behind sensor to

prevent air ow from inside wall.

MENU OPTIONS

To access the full menu options use the ‘AQ Series User’s Guide’

manual online at www.senvainc.com/download_center.asp

The ‘AQ Series User’s Guide’includes:

-User’s Menu

-Setup Menu

-Quick Start Menu

-Diagnostics

SENVA TECHNICAL SUPPORT

Need futher assistance? Call our toll-free number for live

technical support: (866) 660-8864 or feel free to email us at

DIMENSIONS

AQD Dimensions

AQO Dimensions

OBJECT LIST MANUAL

For further reading access the object list and conformance

statement‘AQ Series BACnet Protocol Guide’ found online at

www.senvainc.com/download_center.asp

The ‘AQ Series BACnet Protocol Guide’ includes:

-Protocol Implementation Conformance Statement

-Supported Objects

-Supported Properties

SPECIFICATIONS

Power Supply 12-30VDC/24VAC(1), 100mA max.

Analog Outputs

(Analog Version Only)

Temperature 0-5/10V standard; Scaling 50°F to 95°F (10°C to 35°C); Thermistor/RTD values optional

CO2 and RH 0-5/10V

Update Rate Continuous

Programmable Relay Solid-state output, 1A @ 30VAC/DC, N.O.

Protocol Output (BACnet

Version Only)

Protocol BACnet

Conection 3-wire RS-485, with isolated ground

Data Rate Locally set baud rate up to 115200 (9600, 19200, 28800, 38400, 57600, 76800, 115200)

Address Range 0-127

Bus Load 1/8th unit (256 nodes maximum on bus)

Programmable Relay Solid-state output, 1A @30VAC/DC, N.O. Source Selectable: CO, RH, Temperature

CO

Type Non-dispersive Infrared (NDIR)

Accuracy (Standard)

±(30ppm +3% of reading) (400-2000ppm), @-10-50°C

±(50ppm +5% of reading) (2000-5000ppm), @-10-50°C

±(100ppm+10% of reading) (5000-10000ppm), @ 0-50C

Accuracy (Dual-Channel option)

±(30ppm+3% of reading) (0-2000ppm), @ 0-50C

±(50ppm+3% of reading) (2000-5000ppm), @ -10-50C

±(100ppm+10% of reading) (5000-10000ppm), @ 0-50C

Drift with ABC disabled (Standard) < 35ppm/month

Drift with ABC disabled (Dual Channel) < 5ppm/month

Pressure Dependence +1% reading per 1kPa (0.146PSI) deviation from nominal pressure (101kPa, 14.7PSI)

Range 0-2000/5000/10000ppm (2000ppm default); Programmable up to 10,000ppm

Response time 30s

Sample rate 1s

Relative Humidity

Type Digital CMOS

Accuracy 2% models, +/-2% over 10 to 90%RH range

Resolution 0.05%RH

Hysteresis +/-1%RH

Temperature coecient Compensated on-board

Response time (2) 30s

Sample rate 3s

Operating range/Output Scale 0 to 100%RH (non-condensing)

Long term drift <0.5%RH per year

Operating conditions (4) -20° C to 60° C @ RH>90%

-20° C to 80° C @ RH=50%

Type Silicon Bandgap

Temperature

(with RH element)

Nominal Accuracy +/-0.3° C (operating range)

Maximal Accuracy +/-0.5° C (at 25° C), +/-1.0° C (operating range)

Resolution 0.01° C

Repeatability +/-0.1° C

Response time 30s

Sample rate 3s

Type NTC Thermistor

Nominal Accuracy +/-0.5° C (operating range)

Temperature Maximal Accuracy +/-1.0° C (at 25° C), +/-2.0° C (operating range)

(without RH element) Resolution 0.05° C

Repeatability +/-0.2° C

Sample Rate 100 milliseconds

Operating Environment Temperature -4 to 122F (-20 to 50° C)

Humidity 0-95% non-condensing

Enclosure Material ABS/Polycarbonate

Dimensions 4.0”h x 4.4”w x 2.1”d (AQD: +6.8”probe) (AQO: +2.8”solar shield)

Revised 04/29/2020 Document #152-0376-0B

This manual suits for next models

1

Other senva Measuring Instrument manuals