senva EM-RS485 User manual

Modbus Protocol Guide

EM-RS485

Senva Sensors

9290 SW Nimbus Ave

Beaverton, OR 97008

154-0023-0B

Rev.

Release Date

By

Description of Change

ECR

0A

11/22/2016

DLE

Initial Release

---

0B 4/10/2017 DLE Updated for firmware v1.1.2 ---

Copyright ©2017. All rights reserved. This document contains Senva Sensors proprietary

information, and may not be reproduced or distributed without written permission.

EM-RS485 Modbus Protocol Guide Page 2 of 52 154-0023-0B

Table of Contents

Readable ..................................................................................................................................R

Access Writable....................................................................................................................................W

Legend Writable with 0 only (statistics reset, see System Readings) ...............................W0

Saved in non-volatile configuration memory ...........................................................NV

Configuration................................................................................................................................................ 6

Holding Registers ......................................................................................................................................... 8

System Configuration.......................................................................................................................................................................8

R102 Reset Reason ......................................................................................UINT16 ...................R .............................8

R103 Reset Count ........................................................................................UINT16 ...................R/NV......................8

R104/05 Up Time ................................................................................................UINT32 ...................R .............................8

R111 Identify Meter ....................................................................................BOOL.......................R/W........................8

R112 Auto Protocol .....................................................................................BOOL.......................R/W/NV ................9

R114 Auto Baud Rate .................................................................................BOOL.......................R/W/NV................9

R116 Auto Parity ..........................................................................................BOOL.......................R/W/NV................9

R117 Auto Data Bits ....................................................................................BOOL.......................R/W/NV................9

R118 Auto Stop Bits ....................................................................................BOOL.......................R/W/NV ............. 10

R122 RS485 Protocol ..................................................................................UINT16 ...................R/W/NV ............. 10

R123 Slave Address .....................................................................................UINT16 ...................R/W/NV............. 10

R124/25 RS485 Baud Rate ...............................................................................UINT32 ...................R/W/NV ............. 10

R126 RS485 Parity ........................................................................................UINT16 ...................R/W/NV ............. 11

R127 RS485 Data Bits .................................................................................UINT16 ...................R/W/NV ............. 11

R128 RS485 Stop Bits ..................................................................................UINT16 ...................R/W/NV............. 11

R133 Temperature Units ...........................................................................UINT16 ...................R/W/NV............. 11

R134 Smoothed Temperature Response Time ................................UINT16 ...................R/W/NV............. 12

R142 Smoothed Frequency Response Time .....................................UINT16 ...................R/W/NV ............. 12

R144 Smoothed Voltage Response Time ...........................................UINT16 ...................R/W/NV............. 12

R152 System Current Sensor Technology ..........................................UINT16 ...................R .......................... 12

R153 Angle Units .........................................................................................UINT16 ...................R/W/NV ............. 13

R154 Smoothed Current Response Time ...........................................UINT16 ...................R/W/NV ............. 13

R161 System Phase Selection .................................................................UINT16 ...................R/W/NV............. 13

R162 Power Spectrum ...............................................................................UINT16 ...................R/W/NV............. 13

R163 Power Units ........................................................................................UINT16 ...................R/W/NV ............. 14

R164 Smoothed Power Response Time ..............................................UINT16 ...................R/W/NV ............. 14

R170 Energy Data Type .............................................................................BOOL.......................R/W/NV ............. 14

R173 Energy Units .......................................................................................UINT16 ...................R/W/NV............. 15

R174/75 Energy Timestamp ...........................................................................FLOAT.....................R .......................... 15

R181 Demand Synchronization Mode .................................................UINT16 ...................R/W/NV............. 15

R183 Demand Window Time ..................................................................UINT16 ...................R/W/NV ............. 16

EM-RS485 Modbus Protocol Guide Page 3 of 52 154-0023-0B

R184/85 Elapsed Demand Window ............................................................UINT32 ...................R/W0 .................. 16

R186/87 Demand Window Count ................................................................UINT32 ...................R/NV................... 16

R190/91 Reset Meter Configuration ...........................................................UINT32 ...................W......................... 17

R192/93 Reset Meter Statistics ......................................................................UINT32 ...................W......................... 17

R194 Energy Reset Count .........................................................................UINT16 ...................R/NV................... 17

R195 Auto Reset Statistics ........................................................................BOOL.......................R/W/NV............. 17

Binary Inputs .....................................................................................................................................................................................18

R200 Setup Button ......................................................................................BOOL.......................R .......................... 18

R201 Binary Input 1 .....................................................................................BOOL.......................R .......................... 18

R202 Binary Input 2 .....................................................................................BOOL.......................R .......................... 18

Pulse Inputs .......................................................................................................................................................................................18

R208 Pulse Input Debounce Time .........................................................UINT16 ...................R/W/NV............. 18

R210/11 Pulse Input 1 Count .........................................................................UINT32 ...................R/W/NV............. 19

R212/13 Pulse Input 1 Active Elapsed Time .............................................UINT32 ...................R/W0 .................. 19

R214/15 Pulse Input 1 Maximum .................................................................UINT32 ...................R/W/NV............. 19

R216/17 Pulse Input 1 Preset .........................................................................UINT32 ...................R/W/NV............. 19

R218/19 Pulse Input 1 Count Before Preset .............................................UINT32 ...................R/NV................... 19

R220/21 Pulse Input 2 Count .........................................................................UINT32 ...................R/W/NV............. 19

R222/23 Pulse Input 2 Active Elapsed Time .............................................UINT32 ...................R/W0 .................. 19

R224/25 Pulse Input 2 Maximum .................................................................UINT32 ...................R/W/NV............. 19

R226/27 Pulse Input 2 Preset .........................................................................UINT32 ...................R/W/NV............. 19

R228/29 Pulse Input 2 Count Before Preset .............................................UINT32 ...................R/NV................... 19

PowerPrint .........................................................................................................................................................................................20

R240 PowerPrint Alarm .............................................................................BOOL.......................R .......................... 20

R241 PowerPrint Active .............................................................................BOOL.......................R/W/NV............. 20

R242/43 PowerPrint Frequency ....................................................................FLOAT.....................R/W/NV............. 20

R244/45 PowerPrint Frequency Tolerance ...............................................FLOAT.....................R/W/NV............. 21

R246/47 PowerPrint Voltage Tolerance .....................................................FLOAT.....................R/W/NV ............. 21

R248/49 PowerPrint Voltage Angle Tolerance .......................................FLOAT.....................R/W/NV............. 21

Miscellaneous ...................................................................................................................................................................................21

R276-91 Location String ..................................................................................ASCII........................R/W/NV ............. 21

R292-99 User Data .............................................................................................UINT16 ...................R/W/NV ............. 21

System Readings .............................................................................................................................................................................22

R310/11 Temperature .......................................................................................FLOAT.....................R/W0 .................. 22

R380/81 Power Supply Voltage ....................................................................FLOAT.....................R/W0 .................. 22

R400 Active Conditions .............................................................................UINT16 ...................R .......................... 23

R401 Previous Conditions ........................................................................UINT16 ...................R/W0 .................. 23

R410/11 Line Frequency ..................................................................................FLOAT.....................R/W0 .................. 23

R420/21 Phase Average RMS Voltage ........................................................FLOAT.....................R/W0 .................. 23

R450/51 Phase to Phase Average RMS Voltage ......................................FLOAT.....................R/W0 .................. 24

R520/21 Phase Average RMS Current ........................................................FLOAT.....................R/W0 .................. 24

R540/41 Phase Average Current Angle .....................................................FLOAT.....................R/W0 .................. 24

EM-RS485 Modbus Protocol Guide Page 4 of 52 154-0023-0B

R550/51 System Power Factor ......................................................................FLOAT.....................R/W0 .................. 25

R600/09 Total Real Power ...............................................................................FLOAT.....................R/W0 .................. 25

R610/11 Phase Average Real Power ...........................................................FLOAT.....................R/W0 .................. 25

R620/21 Net Real Power ..................................................................................FLOAT.....................R/W0 .................. 25

R640/41 Total Reactive Power .......................................................................FLOAT.....................R/W0 .................. 25

R650/51 Phase Average Reactive Power ...................................................FLOAT.....................R/W0 .................. 26

R660/61 Total Apparent Power ....................................................................FLOAT.....................R/W0 .................. 26

R670/71 Phase Average Apparent Power .................................................FLOAT.....................R/W0 .................. 26

R700/01 Total Real Energy ..............................................................................FLOAT*...................R/NV................... 26

R720/21 System Real Energy .........................................................................FLOAT*...................R/NV................... 26

R740/41 Total Reactive Energy .....................................................................FLOAT*...................R/NV................... 27

R760/61 Total Apparent Energy ...................................................................FLOAT*...................R/NV................... 27

R800/01 Demand Real Power ........................................................................FLOAT.....................R/W0 .................. 27

R820/21 Demand System Real Power ........................................................FLOAT.....................R/W0 .................. 28

R840/41 Demand Reactive Power ...............................................................FLOAT.....................R/W0 .................. 28

R860/61 Demand Apparent Power .............................................................FLOAT.....................R/W0 .................. 28

R Phase Configuration...................................................................................................................................................................28

R1010-19 CVT Serial Number ...........................................................................ASCII........................R .......................... 28

R1020-29 CVT Model ...........................................................................................ASCII........................R .......................... 28

R1102 CVT Present .........................................................................................BOOL.......................R .......................... 28

R1103 CVT Status ...........................................................................................UINT16 ...................R .......................... 28

R1104 PowerPrint Identity Status ............................................................UINT16 ...................R .......................... 29

R1140/41 Voltage Rating ...................................................................................FLOAT.....................R .......................... 29

R1142/43 Voltage Multiplier .............................................................................FLOAT.....................R/W/NV............. 29

R1144/45 PowerPrint Voltage ..........................................................................FLOAT.....................R/W/NV............. 29

R1146/47 PowerPrint Voltage Angle ............................................................FLOAT.....................R/W/NV............. 30

R1150/51 Current Rating ...................................................................................FLOAT.....................R .......................... 30

R1152/53 Current Multiplier .............................................................................FLOAT.....................R/W/NV............. 30

R1154 Current Sensor Technology ..........................................................UINT16 ...................R .......................... 30

R1161 Power Multiplier Override .............................................................BOOL.......................R/W..................... 31

R1162/63 Power Multiplier ...............................................................................FLOAT.....................R/W/NV............. 31

R1192/93 Statistics Reset ...................................................................................UINT32 ...................R/W..................... 31

R Phase Measurements.................................................................................................................................................................32

R1400 Active Conditions .............................................................................UINT16 ...................R .......................... 32

R1401 Previous Conditions ........................................................................UINT16 ...................R/W0 .................. 32

R1420/21 Phase RMS Voltage ..........................................................................FLOAT.....................R/W0 .................. 32

R1440/41 Phase to Phase Voltage Angle .....................................................FLOAT.....................R/W0 .................. 33

R1450/51 Phase to Phase RMS Voltage ........................................................FLOAT.....................R/W0 .................. 33

R1520/21 Phase RMS Current ..........................................................................FLOAT.....................R/W0 .................. 34

R1540/41 Phase Current Angle .......................................................................FLOAT.....................R/W0 .................. 34

R1550/51 Phase Power Factor .........................................................................FLOAT.....................R/W0 .................. 35

R1600/01 Phase Real Power .............................................................................FLOAT.....................R/W0 .................. 35

EM-RS485 Modbus Protocol Guide Page 5 of 52 154-0023-0B

R1640/41 Phase Reactive Power .....................................................................FLOAT.....................R/W0 .................. 35

R1660/61 Phase Apparent Power ...................................................................FLOAT.....................R/W0 .................. 36

R1700/01 Total Phase Real Energy .................................................................FLOAT*...................R/NV................... 36

R1740/41 Total Phase Reactive Energy ........................................................FLOAT*...................R/NV................... 36

R1760/61 Total Phase Apparent Energy ......................................................FLOAT*...................R/NV................... 37

R1800/01 Demand Real Power ........................................................................FLOAT.....................R/W0 .................. 37

R1840/41 Demand Reactive Power ...............................................................FLOAT.....................R/W0 .................. 38

R1860/61 Demand Apparent Power .............................................................FLOAT.....................R/W0 .................. 38

S Phase.................................................................................................................................................................................................38

R2000 – 2999...............................................................................................................................................................................38

T Phase ................................................................................................................................................................................................38

R3000 – 3999...............................................................................................................................................................................38

Functions.....................................................................................................................................................39

Data Types .........................................................................................................................................................................................39

0x03 Read Holding Registers......................................................................................................................................................40

0x06 Write Single Register...........................................................................................................................................................41

0x08 Diagnostics .............................................................................................................................................................................42

0x00 | Return Query Data .......................................................................................................................................................42

0x01 | Restart Communications...........................................................................................................................................42

0x03 | Change ASCII Input Delimiter .................................................................................................................................43

0x04 | Force Listen Only Mode.............................................................................................................................................43

0x0A | Clear Counters and Diagnostic Register.............................................................................................................44

0x0B – 0x12 | Return Diagnostic Counters ......................................................................................................................44

0x10 Write Multiple Registers.....................................................................................................................................................46

0x11 Report Server ID....................................................................................................................................................................47

0x17 Read/Write Multiple Registers.........................................................................................................................................48

Appendix A: Common Registers ................................................................................................................49

Appendix B: Condition Flags Decoding.....................................................................................................51

Appendix C: Hex Conversions....................................................................................................................52

See Also:

152-0291 EM-RS485 Installation Instructions

154-0022 EM-RS485 BACnet Protocol Guide

EM-RS485 Modbus Protocol Guide Page 6 of 52 154-0023-0B

Configuration

EM-RS485

POWER

GND

A (+)

COM

B (–)

To CVTs

R S T

Device

Status

Line

Status

RS485

Status

CVT

Status

Setup

Button

✓Get In ✓Get Out Get Data

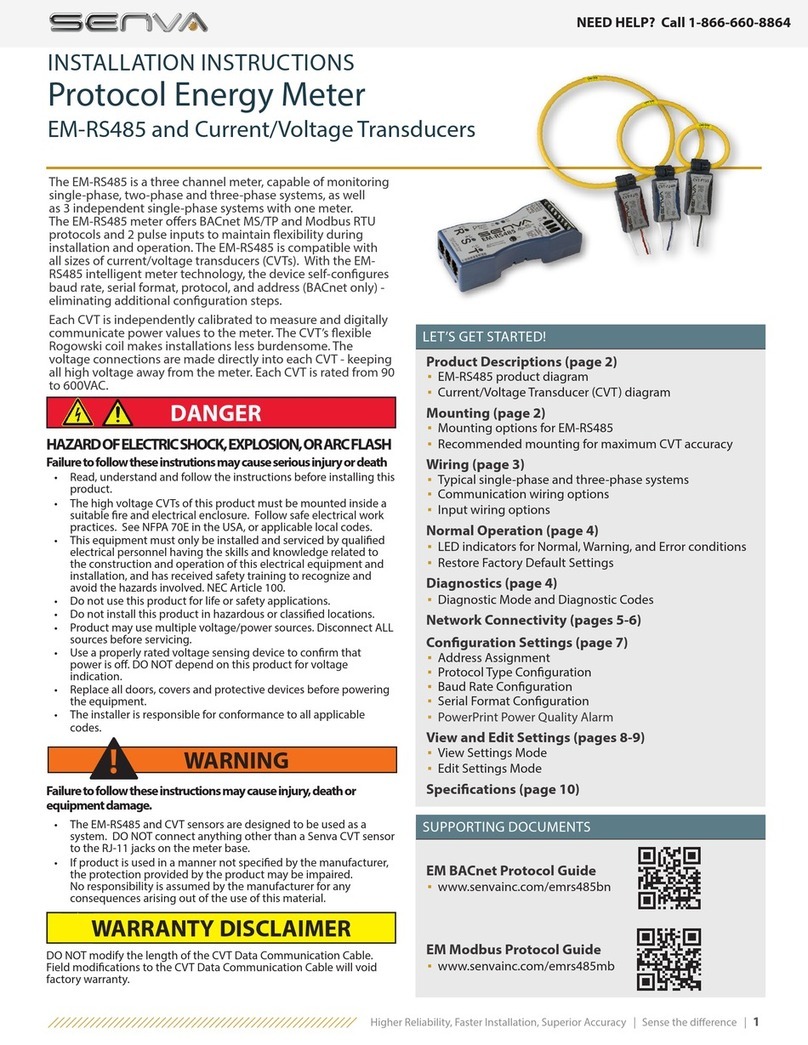

Congratulations on installing your new Senva EM-RS485 energy meter!This Modbus Protocol Guide assumes

the first stage of installation is complete, with the meter and any CVTs connected and powered. A green

Device Status indicates the meter is powered and ready. If not, refer to the separate Installation Instructions

before continuing. Now, only the network configuration remains between you and the data.

Each meter ships with a default Slave Address. To identify this address, add “100” to the last two digits of the

unique serial number printed on the label. When installing a meter on a dedicated Modbus network with no

other slave devices, the global address 255 (0xFF) may also be used (see R123).

SN 123456

56

+100

156

3456

Figure 1: Example Default Address

WARNING:Before connecting a meter to an existing network, ensure the default Slave Address will not

conflict! If necessary, select an alternate seed address with the Setup Button interface (see Installation

Instructions). Regardless of whether the default Slave Address, the global address, or an alternate seed

address is used, the meter may be programmed with any supported address after an initial connection is

established (see R123).

Leave the meter in the default factory mode for automatic network configuration:

•Automatic Baud Rate detection (see R114, R124): 9600 – 115200 baud

•Automatic Parity detection (see R116, R126): Even, Odd, No Parity

•Automatic Data Bits detection (see R117, R127): 7, 8 Bits

•Automatic Protocol detection (see R112, R122): Modbus RTU, ASCII

EM-RS485 Modbus Protocol Guide Page 7 of 52 154-0023-0B

To begin automatic configuration, simply connect the RS485 terminals to an active Modbus network. An

active Modbus network consists of a Modbus master device that regularly polls at least one Modbus slave

(whether the slave replies or not).

IMPORANT: If a Modbus network has devices communicating with multiple baud rates and/or formats,

the automatic configuration result is unpredictable. Set the configuration manually with the Setup Button

interface (see Installation Instructions) before connecting the meter in such an environment.

Once connected, the meter observes RS485 activity to learn baud rate, serial format, and protocol. Without

activity, the meter cannot learn! The meter will not interfere with existing network traffic during the

observation phase. As configuration proceeds, the RS485 Status LED indicates progress with a combination

of color and blinking activity patterns. Diagnostic mode conditions can help identify the current auto

configuration step (see Figure 2, and also the Installation Instructions).

Waiting For

Activity

Detecting

Baud Rate

Detecting

Protocol Re ady

Figure 2: Automatic Configuration Conditions

The RS485 Status LED turns green after at least one full frame successfully passes a CRC* integrity test.

Assuming no conflicts, the master can then use Modbus functions to query or configure registers.

The meter stores any discovered automatic configuration result in non-volatile memory and reloads them

whenever the meter resets (e.g. after power loss). The automatic configuration can be cleared by holding

down the Setup Button while resetting the meter (e.g. removing and reapplying power). User-configured

parameters will not be affected, but the meter must redetect any missing parameters before reestablishing

communication.

For permanent installations, the protocol configuration parameters (see R122 – R128) may be set to lock the

baud rate, format, and protocol. However, this will prevent the meter from adapting to future changes in

the network environment.

The EM-RS485 supports the following Modbus device functions:

•0x08 Diagnostics

•0x11 Report Server ID

*Cyclical Redundancy Check

EM-RS485 Modbus Protocol Guide Page 8 of 52 154-0023-0B

Holding Registers

The EM-RS485 supports the following Modbus functions:

•0x03Read Holding Registers

•0x06 Write Single Register

•0x10 Write Multiple Registers

In this document, Modbus addresses (beginning with “R”) represent raw protocol addresses. Some Modbus

conventions offset protocol addresses to form a register ID (e.g. 40001, Modicon notation). Refer to the

relevant controller documentation to determine any required programming offset for each installation.

Constructed registers (see Data Types) span multiple Modbus address. The notation RXX/YY specifies a pair

of aligned registers. The notation RXX-YY specifies a range of consecutive registers, inclusive.

Unless otherwise specified, changes to RS485 parameters are effective after the response (i.e. a client must

maintain the original parameters for the remainder of the current transaction).

System Configuration

R102 Reset Reason UINT16 R

Returns a reason determined at the time of the last reset:

1. Configuration Reset (see R190)

2. (reserved)

3. Power Loss

4. (reserved)

5. Hardware Watchdog

R103 Reset Count UINT16 R/NV

Returns a lifetime count of firmware resets for any reason. The meter maintains this count in a

protected section of non-volatile memory unaffected by Configuration Reset (see R190).

At each reset, the meter restores accumulated energy, demand statistics, and pulse input counts

from non-volatile memory. However, all the analog statistics reset, plus the Up Time (see R104),

Energy Timestamp (see R174), and pulse input Elapsed Active Time (see R212).

R104/05 Up Time UINT32 R

Returns the time since the last meter reset, in seconds. To determine the cause, read R102.

R111 Identify Meter BOOL R/W

Sets the LED status interface into a visually identifiable mode:

0. Inactive

1. Active

When set to Active, all status LEDs (see Installation Guide) begin slowly blinking green together.

This pattern is distinct from any other interface pattern the meter may display during normal

operation. The LEDs will remain in identify mode until the reset to Inactive or the Setup Button is

pressed.

This feature may be useful if several meters are connected on a single network and the association

between discovered device IDs and physical meters is uncertain.

Default: Inactive (normal LEDs)

EM-RS485 Modbus Protocol Guide Page 9 of 52 154-0023-0B

R112 Auto Protocol BOOL R/W/NV

Sets the state of automatic protocol detection:

0. Inactive

1. Active

When Active, the RS485 receiver initially allows frames of any supported protocol. On establishing

confidence in a particular protocol (about 10 consecutive frames of the same type), this becomes

the preferred RS485 Protocol (see R122).

Generally, having a preferred protocol disallows other protocols. This reduces uncertainty in the

unlikely event that a particular frame or sequence could be interpreted as more than one protocol.

However, should the protocol really change (e.g. by moving the meter to a different network), the

meter will eventually lose confidence in the preferred protocol. After temporarily allowing all

protocols, automatic protocol detection will establish a new preference. To avoid the delays

associated with changing protocol, set the RS485 Protocol to some option that permanently allows

multiple protocols.

When changing this value, the meter keeps the current RS485 Protocol to avoid communication

loss. Setting Inactive disables further automatic protocol changes and only allows the protocol(s)

specifically set in RS485 Protocol.

Default: Active

R114 Auto Baud Rate BOOL R/W/NV

Sets the state of automatic baud rate detection:

0. Inactive

1. Active

When Active, the meter may automatically change the Baud Rate (see R124) in response to RS485

communication errors. When changing this value, the meter always keeps the current Baud Rate to

avoid communication loss.

Default: Active

R116 Auto Parity BOOL R/W/NV

Sets the state of automatic parity detection:

0. Inactive

1. Active

When Active, the meter may automatically change the Parity (see R126) in response to RS485

communication errors. When changing this value, the meter always keeps the current Parity to

avoid communication loss.

Default: Active

R117 Auto Data Bits BOOL R/W/NV

Sets the state of automatic data bits detection:

0. Inactive

1. Active

When Active, the meter may automatically change the Data Bits (see R127) in response to RS485

communication errors. When changing this value, the meter always keeps the current Data Bits to

avoid communication loss.

Default: Active

EM-RS485 Modbus Protocol Guide Page 10 of 52 154-0023-0B

R118 Auto Stop Bits BOOL R/W/NV

Sets the state of automatic stop bits:

0. Inactive

1. Active

Returns Active when Stop Bits is Auto (see R128).

Default: Active

R122 RS485 Protocol UINT16 R/W/NV

Sets the communication protocol(s):

1. Auto

2. BACnet

3. Modbus RTU

4. Modbus ASCII

5. BACnet and Modbus RTU

6. BACnet and Modbus ASCII

7. Modbus RTU and ASCII

8. Any Protocol

If Auto Protocol is Active (see R112), returns the auto-detected protocol (typically Modbus RTU or

Modbus ASCII). Otherwise, returns the user-configured protocol option.

Setting any value other than Auto also sets Auto Protocol to Inactive. Setting Auto copies any

previously set protocol option to the automatic protocol detector, and sets Auto Protocol to Active.

Setting an option with multiple protocols (5 – 8) reduces the Auto Protocol re-detection delay.

Default: Auto

R123 Slave Address UINT16 R/W/NV

Sets the Modbus slave address, 1 – 254.

Assign unique addresses to each Modbus slave device on a network. The Modbus specification

only allows slave addresses 1 – 247. Although the meter supports the assignment of reserved

addresses 248 – 254, undefined network behavior may result.

In the default configuration, returns the factory default slave address (see Configuration).

Otherwise, returns the user-configured slave address. Before setting the address, ensure that the

new address will not conflict with any other slave devices on the Modbus network.

In addition to the assigned slave address, the meter will respond to Modbus commands addressed

to the global address 255 (0xFF). Only use this address if the meter is installed on a dedicated

Modbus network with no other slave devices.

Default: Varies

R124/25 RS485 Baud Rate UINT32 R/W/NV

Sets the communication baud rate, 1200 – 460800.

When Auto Baud Rate is Active (see R114), returns the auto-detected baud rate (see Configuration).

Otherwise, returns the user-configured baud rate.

Almost by definition, successfully reading baud rate implies a correct value, with no further action

required. However, when transitioning a Modbus network to a new baud rate, it may be useful to

remotely configure the new baud rate before transitioning the gateway/controller. Setting any

user-configured baud rate also sets Auto Baud Rate to Inactive.

WARNING: The meter provides no facility to revert the baud rate remotely. Once written, the

meter will lose communication until the client baud rate matches the new configuration.

Default: Varies

EM-RS485 Modbus Protocol Guide Page 11 of 52 154-0023-0B

R126 RS485 Parity UINT16 R/W/NV

Sets the communication parity:

1. Auto

2. No Parity

3. Odd Parity

4. Even Parity

If Auto Parity is Active (see R116), returns the auto-detected parity (typically Even Parity for Modbus).

Otherwise, returns the user-configured parity option.

Setting any value other than Auto sets Auto Parity to Inactive. Setting Auto sets Auto Parity to Active,

but keeps the current parity option to avoid loss of communication.

Setting Auto copies any previously set parity option to the automatic parity detector and sets Auto

Parity to Active.

Default: Auto

R127 RS485 Data Bits UINT16 R/W/NV

Sets the communication data bits:

1. Auto

2. 7 Bits

3. 8 Bits

If Auto Data Bits is Active (see R117), returns the automatically detected number of data bits

(typically 8 Bits for Modbus RTU, 7 Bits for Modbus ASCII). Otherwise, returns the user-configured

data bits option.

Setting any value other than Auto sets Auto Data Bits to Inactive. Setting Auto sets Auto Data Bits to

Active, but keeps the current data bits option to avoid loss of communication.

Default: Auto

R128 RS485 Stop Bits UINT16 R/W/NV

Sets the communication stop bits:

1. Auto

2. 1 Bit

3. 1.5 Bits

4. 2 Bits

Always returns the user-configured stop bits option.When set to Auto, Modbus dynamically

provides the most compatible configuration:1 Bit for data receive and 2 Bits for data transmit.

The Auto Stop Bits(see R118) value follows this value. Setting any value other than Auto sets Auto

Stop Bits to Inactive. Setting Auto sets Auto Stop Bits to Active.

Default: Auto

R133 Temperature Units UINT16 R/W/NV

Sets the preferred units for temperature values:

1. Degrees Fahrenheit (°F)

2. Degrees Celsius (°C)

Saved statistical values automatically convert when the selected unit changes.

Default: Degrees Fahrenheit

EM-RS485 Modbus Protocol Guide Page 12 of 52 154-0023-0B

R134 Smoothed Temperature Response Time UINT16 R/W/NV

Sets the step response time for smoothed temperature (see R312), in seconds.

Across all groups, the various Smoothed values track the instantaneous measurement after the

application of a first-order exponential function. This low pass filter attenuates fast changes, such

as the inrush current of a large industrial motor. Smoothed values may provide a stable baseline

measurement but will always lag the instantaneous measurement (see Figure 3A).

Formally, response time sets the time required for a Smoothed value to complete 90% of the

transition after an ideal step between two stable values (see Figure 3B).

90%

τ

A: General Smoothing B: Ideal Step Response

instantaneous

sm oo thed

Figure 3: Smoothed Response Time

During periods of invalid measurement, Smoothed values return 0 (undefined). The resumption of

valid measurements momentarily suppresses the smoothing function while the value stabilizes.

Default: 30 seconds

R142 Smoothed Frequency Response Time UINT16 R/W/NV

Sets the step response time (see R134) for smoothed Frequency (see R412) and Voltage Angle

(e.g. R1442), in seconds.

Default: 60 seconds

R144 Smoothed Voltage Response Time UINT16 R/W/NV

Sets the step response time (see R134) for smoothed RMS Voltage (e.g. R1422), in seconds.

Default: 10 seconds

R152 System Current Sensor Technology UINT16 R

Returns the overall current sensor technology of the CVT(s) installed with a meter. This value is

provided in anticipation of future CVT technology upgrades:

1. Unknown Technology

2. Conflicted Technology

3. Multiple Technology

4. Rogowski Coil

5. Current Transformer

This value derives from the combination of the Current Sensor Technology (see R1154) of each CVT.

All CVTs installed with a single meter must be compatible for proper operation.

Read only. At EM-RS485 launch, all Senva CVTs are based on Rogowski Coil technology. If no CVTs

are installed, returns Unknown Technology.

EM-RS485 Modbus Protocol Guide Page 13 of 52 154-0023-0B

R153 Angle Units UINT16 R/W/NV

Sets the preferred units for angle values:

1. Degrees

2. Radians

Saved statistical values automatically convert when the selected unit changes.

Default: Degrees

R154 Smoothed Current Response Time UINT16 R/W/NV

Sets the step response time (see R134) for smoothed RMS Current (e.g. R1522), Current Angle

(e.g. R1542), and Power Factor (e.g. R1552), in seconds.

Default: 2 seconds

R161 System Phase Selection UINT16 R/W/NV

Sets the phase selection mask for system measurements:

1. 3 Phase

2. R Phase and S Phase

3. S Phase and T Phase

4. R Phase and T Phase

System measurements, including phase averages (e.g. R420) and accumulations (e.g. R700), are

based on the selected phases only. Set this value in case of a split system (e.g. 2 CVTs measuring a

2-phase system input with a third CVT measuring a separate branch load). There are no equivalent

options for single phase, as individual phase measurements are always accessible.

For consistency, consider resetting the system statistics (see R192) after changing this setting.

Default: 3 Phase

R162 Power Spectrum UINT16 R/W/NV

Sets the bandwidth of real and reactive power and energy measurements:

1. Wideband

2. Fundamental

Generally, harmonic components are the result of non-linear distortions in the generator or the

load. In Wideband mode, measurements include power of all harmonic components (e.g. 3rd, 5th),

up to the cutoff frequency (see Installation Instructions). In Fundamental mode, measurements

include only power in the fundamental Frequency (see R410).

NOTE: Harmonic power requires matched frequency components in the spectrum of both voltage

and current. For example, given a 5th harmonic of current, there must be a corresponding 5th

harmonic of voltage. Otherwise, even though distortion power increases, the real and reactive

components of power cancel leaving only the power in the fundamental.

For consistency, consider resetting accumulated energy (see R192) after changing this setting.

Default: Wideband

EM-RS485 Modbus Protocol Guide Page 14 of 52 154-0023-0B

R163 Power Units UINT16 R/W/NV

Sets the preferred units for power and demand power values:

1. Kilowatts

2. Watts

3. Megawatts

Saved statistical values, included maximum demand power, automatically convert when the

selected unit changes.

The options specify real power units only. Reactive and apparent power always follow the real

power scale, as shown in each column:

Relative Scale = 1.0 1,000 1,000,000

Real Power W (Watts) kW MW

Reactive Power VAR (Volt-Amps Reactive) kVAR MVAR

Apparent Power VA (Volt-Amps) kVA MVA

Default: Kilowatts

R164 Smoothed Power Response Time UINT16 R/W/NV

Sets the step response time (see R134) for smoothed Power (e.g. R1602), in seconds.

Default: 2 seconds

R170 Energy Data Type BOOL R/W/NV

Sets the data type when reading energy accumulators (e.g. R700):

0. Floating Point

1. Unsigned Integer

Both modes read from the same internal register, with a fixed capacity of ±1.0 TWh. Changing the

mode does not affect the accumulated energy in any way. Reading a register in either mode always

returns a value scaled to the system Energy Units (see R173).

In Floating Point mode, energy registers return a floating point value that does not overflow (unless

the internal 1.0 TWh register itself overflows). However, the resolution will gradually degrade as

energy accumulates, making it harder to observe small changes in energy over short intervals.

In Unsigned Integer mode, energy registers return an unsigned integer, 0 – 999999. When the

energy exceeds the upper bound, the value wraps to 0 (modulo arithmetic). This view most closely

corresponds to traditional analog meters, with the primary

advantage that the energy resolution is fixed at 1 Energy Unit.

If energy overflows, the overflow energy may still be read by

setting the next larger Energy Unit. Negative power causes net

accumulators (e.g. R1706) to run backwards; underflow causes

the value to wrap from 0 backwards to 999999.

Default: Floating Point

EM-RS485 Modbus Protocol Guide Page 15 of 52 154-0023-0B

R173 Energy Units UINT16 R/W/NV

Sets the preferred units for accumulated energy values:

1. Kilowatt Hours

2. Watt Hours

3. Megawatt Hours

Accumulated energy automatically converts with no loss when the selected unit changes.

The options specify real energy units only. Reactive and apparent energy always follow the real

energy scale, as shown in each column:

Relative Scale = 1.0 1,000 1,000,000

Real Energy Wh (Watt hours) kWh MWh

Reactive Energy VARh (Volt-Amp Reactive hours) kVARh MVARh

Apparent Energy VAh (Volt-Amp hours) kVAh MVAh

Default: Kilowatt Hours

R174/75 Energy Timestamp FLOAT R

Returns a high resolution timestamp, 0 – 4194304 milliseconds (222 – 1, about 1 hour).

The timestamp value updates atomically with the various energy accumulators. If read just before

or after a block of one or more energy measurements, this timestamp may be useful for calculating

accurate average power from differential energy:

=

=

R181 Demand Synchronization Mode UINT16 R/W/NV

Sets the synchronization mode for the demand window:

1. No Synchronization

2. Setup Button

3. Binary Input 1 (falling)

4. Binary Input 1 (rising)

5. Binary Input 2 (falling)

6. Binary Input 2 (rising)

Selecting any of the synchronization sources allows the internal window to be aligned to some

external reference (Figure 4B). When a synchronization event is detected, the current window ends

immediately and a new window begins. Synchronization events occur exactly once when the

selected condition is detected. Synchronization cannot re-occur until the condition is removed and

redetected, no matter how long it may be maintained.

In No Synchronization mode, the Elapsed Demand Window (see R184) counts time continuously, only

restarting if the meter itself restarts (Figure 4A). When the counter reaches the full Demand Window

Time (see R183), the current demand window ends and a new window begins.

In Setup Button (see R200) mode, synchronization occurs as soon as the button is pressed. The

Setup Button always performs its normal function. If there are any active diagnostic conditions, it

may be necessary to exit diagnostic mode after pressing the button (see Installation Instructions).

To avoid a second synchronization, wait for diagnostic mode to time out (about 60 seconds).

In Binary Input (see R201, R202) mode, Falling Edge synchronization occurs when an external contact

pulls the pulse input to GND (active low, see Figure 5). Rising Edge synchronization occurs in the

opposite condition, when an external contact opens. The Debounce Time (see R208) may delay the

EM-RS485 Modbus Protocol Guide Page 16 of 52 154-0023-0B

synchronization up to 250 milliseconds after the transition. This mode may be useful to align

demand windows with a utility meter that provides a regular synchronization pulse.

For Full Synchronization, relying exclusively on an external trigger, disable the internal window time

by setting the Demand Window Time to 0 minutes (Figure 4C).

A: No Synchronization B: Basic Synchronization C: Full Synchronization

S

T

W W W W W

S S S S

Figure 4: Synchronization Modes

NOTE: Consider synchronizing when the average power is typically light. When a synchronization

event is detected, it makes no difference how much or little time has elapsed in the current

window. Average power may be more volatile if the window has only just started, being measured

over a shorter period of time.

Default: No Synchronization

R183 Demand Window Time UINT16 R/W/NV

Sets the maximum demand window time, 0 – 1440 minutes.

The demand measurements (see R1800) measure average power within a windowed period.

Every time the Elapsed Demand Window time (see R184) reaches this limit, the current window ends

and a new window starts.

If set to 0 minutes, the window time is unlimited. In this case, new windows are only started by

external synchronization (see R181) or software synchronization (see R184).

Default: 15 minutes

R184/85 Elapsed Demand Window UINT32 R/W0

Returns the time since the beginning of the current demand window, in minutes.

The demand measurements (see R1800) measure average power within a windowed period.

This value resets to 0 at the beginning of each new demand window. Writing 0 at any time

automatically starts a new window (software synchronization).

R186/87 Demand Window Count UINT32 R/NV

Returns the number of completed demand windows. Any demand window at least 1 second long

counts, regardless of whether the window was defined by external synchronization (see R181),

software synchronization (see R184), or elapsed time (see R183). Resetting all or a portion of the

demand statistics (see R192, R1192) does not automatically start a new demand window.

The system and all phase demand values update together (e.g. R1800), so this count can serve as a

unique key to identify each new batch of demand statistics (e.g. for logging).

Resets to 0 only when the system and all phase demand statistics are reset together (see R192).

EM-RS485 Modbus Protocol Guide Page 17 of 52 154-0023-0B

R190/91 Reset Meter Configuration UINT32 W

Always returns 0. Write the reset key to reset the meter to factory defaults.

WARNING: The entire non-volatile configuration will be permanently lost; previous configurations

cannot be recovered. This includes accumulated energy, demand statistics, and pulse input counts.

This also includes the current RS485 serial format and Slave Address. The only parameters not

affected are the Reset Count (see R103) and the Energy Reset Count (see R194).

After a configuration reset, the meter itself will reset and re-learn the current baud rate, serial

format, and protocol (see Configuration).

Write 9699690 to reset the meter to factory defaults.

R192/93 Reset Meter Statistics UINT32 W

Always returns 0. Write one of the following keys to reset some or all of the phase statistics. Writing

any other value results in an error response.

WARNING: Selected statistics will be permanently lost; previous records cannot be recovered.

System statistics ONLY:

•Write 4765089 to reset analog statistics (R410 – R678: Minimum, Maximum, Average)

•Write 5338209 to reset demand statistics (R800 – R866: Minimum, Maximum)

•Write 6647201 to clear accumulated energy (R700 – R766: All Registers)

•Write 5811297 to reset all system statistics

System and all phases R/S/T:

•Write 7648701 to reset all analog statistics

•Write 7566461 to reset all demand statistics

•Write 6909373 to clear all accumulated energy

•Write 4762749 to reset all statistics

Phase R/S/T statistics may also be reset individually (see R1192). Analog statistics automatically

reset whenever the meter itself resets (see R103). Individual analog and demand statistics may also

be automatically reset when Auto Reset Statistics is Active (see R195).

Resetting any subset of accumulated energy increments the Energy Reset Count (see R194).

R194 Energy Reset Count UINT16 R/NV

Returns the number of times accumulated energy has been reset. Counts “1” for every full or partial

energy reset key written (see R192, R1192), regardless of the actual energy accumulation.

This value may be useful for auditing, since the meter maintains this count in a protected section of

non-volatile memory unaffected by Configuration Reset (see R190)

R195 Auto Reset Statistics BOOL R/W/NV

Setting “1” activates Reset After Read mode, where reading an individual statistical measurement

also resets it, as if it had been followed by a write of 0 (see System Readings).

Auto reset mode may be useful in some low-overhead remote logging installations.

WARNING: When using Auto Reset Statistics as part of a periodic process, ensure there are no extra

reads generated between logging intervals. Otherwise, the resulting records may reflect only a

portion of the intended interval.

Default: Inactive

EM-RS485 Modbus Protocol Guide Page 18 of 52 154-0023-0B

Binary Inputs

R200 Setup Button BOOL R

Returns “1” when the Setup Button (see Installation Instructions) is pressed.

This value may be useful for protocol testing. Regardless of the value returned, the Setup Button

always performs its normal function for diagnostics and configuration.

R201 Binary Input 1 BOOL R

R202 Binary Input 2 BOOL R

Returns the current stable state of the corresponding

pulse input (active low; see Installation Instructions). The

Pulse Input Debounce Time (see R208) sets the minimum

stability requirement for each transition.

This value may be useful if the pulse input is connected to

a discrete contact, such as an alarm, to trigger additional

controller actions. If so, the corresponding Pulse Input

count (see R210, R220) may be ignored.

One of the binary inputs may be selected as the source for

Demand Window Synchronization (see R181).

Pulse Inputs

R208 Pulse Input Debounce Time UINT16 R/W/NV

Sets the delay time for each input transition before registering a new state, 0 – 255 milliseconds.

This suppresses glitches in the input, such as might be generated by a mechanical relay or electrical

interference (see Figure 6). Affects both the Pulse Inputs (see R210, R220) and corresponding Binary

Inputs (see R201, R202).

Raw Input

Debounced

Figure 6: Debouncing Delay

If possible, set the debounce time to 50% of the expected minimum pulse time. Setting 0 disables

debouncing: new input states register immediately, but the count may be noisy.

IMPORTANT: Because each pulse must have both a high and low interval, the maximum pulse rate

will be 1/2 the equivalent rate of a single debounce time. For example, a 1 millisecond debounce

time permits a maximum pulse rate of 500 Hz. Reduce the maximum pulse rate further when the

duty cycle of the input is not 50%.

Default: 10 milliseconds (50 Hz)

Remote

Contact

GND

Pulse

Input

Figure 5: Binary Input Wiring

EM-RS485 Modbus Protocol Guide Page 19 of 52 154-0023-0B

R210/11 Pulse Input 1 Count UINT32 R/W/NV

Returns the count of pulses received at the respective pulse terminal (see Installation Instructions).

NOTE: The corresponding Binary Inputs (R201/R202) track the instantaneous state of the terminal.

Each count represents a pair of input edges (active low), registered on the leading (falling) edge.

At each transition, the input delays by the Debounce Time (see R208).

1 2 3 4

Figure 7: Pulse Input Counting

R212/13 Pulse Input 1 Active Elapsed Time UINT32 R/W0

Returns the total time, in seconds, that the pulse input has been active (active low) since the last

meter reset. Write 0 to reset the count.

R214/15 Pulse Input 1 Maximum UINT32 R/W/NV

Sets the upper limit of the Pulse Input Count (see R210). After counting up to this limit, the next

pulse will cause the Count to reset to 0. If setting the Maximum smaller than the Count, the Count

does not update until the next pulse input event.

Default: 4294967295 (232 – 1)

R216/17 Pulse Input 1 Preset UINT32 R/W/NV

Write this register to initialize the pulse input counter. This may be useful for continuity when the

EM-RS485 replaces an existing meter.

When written, the meter first copies the original Pulse Input Count (see R210) to Count Before Preset

(see R218). Then, the meter sets both Pulse Count and Preset (this register) to the new value. These

steps are performed atomically, which allows the Pulse Count to be modified while accurately

accounting for every input pulse.

Default: 0

R218/19 Pulse Input 1 Count Before Preset UINT32 R/NV

Returns the Pulse Count (see R200) saved during the last write to Pulse Input Preset (see R216).

Default: 0

R220/21 Pulse Input 2 Count UINT32 R/W/NV

R222/23 Pulse Input 2 Active Elapsed Time UINT32 R/W0

R224/25 Pulse Input 2 Maximum UINT32 R/W/NV

R226/27 Pulse Input 2 Preset UINT32 R/W/NV

R228/29 Pulse Input 2 Count Before Preset UINT32 R/NV

Pulse Input 2 holding register functions match Pulse Input 1.

EM-RS485 Modbus Protocol Guide Page 20 of 52 154-0023-0B

PowerPrint

R240 PowerPrint Alarm BOOL R

Returns “1” when any of the PowerPrint conditions are active:

•Frequency Drift (see R242, R400)

•Phase Angle Drift (see R1146, R400)

•Brown Out Voltage (see R1144, R1400)

•Surge Voltage (see R1144, R1400)

•Unexpected Sensor (see R1104, R400)

Review associated conditions and measurements to determine the source of any anomaly and

appropriate actions. Once triggered, the Alarm remains Active for as long as any PowerPrint

condition remains active, plus an additional 10 seconds.

R241 PowerPrint Active BOOL R/W/NV

Sets the overall state of the PowerPrint feature:

0. Inactive

1. Active

Returns Active if at least one of the PowerPrint reference parameters has been set.

•Frequency (see R242)

•Voltage (see R1144)

•Voltage Angle (see R1146)

•Identity (see R1104)

Setting Inactive clears all of the reference parameters at once. Setting Active while Inactive

initializes PowerPrint (if already Active, setting Active has no effect). When activated this way,

PowerPrint initializes all of the reference parameters at once:

•Sets the expected frequency to exactly 50 Hz or 60 Hz if the measured Frequency (see R410) is

within the Frequency Tolerance (see R244); otherwise leaves expected frequency undefined.

•Sets the expected voltage for each phase equal to the measured RMS Voltage (see R1420) if the

measured voltage is not detecting the Phase Loss condition.

•Sets the expected voltage angle between each phase and the next equal to the measured

angle (see R1440) if neither phase is detecting the Phase Loss condition.

•Sets the reference identity for each phase CVT if the Status (see R1103) is No Fault Detected.

May return a BACnet Internal Error if no PowerPrint parameters could be set (e.g. no CVTs installed).

Default: Inactive

R242/43 PowerPrint Frequency FLOAT R/W/NV

Sets the expected PowerPrint frequency. If set to any non-zero value, and the Frequency (see R410)

differs from expected by more than the Frequency Tolerance (see R244), then the Frequency Drift

condition (see R400) will be set.

Set the expected frequency by writing this value directly, or by initializing PowerPrint (see R241).

Default: 0 Hz (undefined)

Other manuals for EM-RS485

1

Table of contents

Other senva Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

forlong

forlong DRT-301M user manual

Ascon tecnologic

Ascon tecnologic TRH200 user manual

AEMC instruments

AEMC instruments Clamp-On 3705 user manual

MKS

MKS Ophir Centauri quick reference

Precision Digital Corporation

Precision Digital Corporation Loop Leader PD6600 Series instruction manual

YOKOGAWA

YOKOGAWA WT310E user manual