FTN02 manual v1717 10/49

1Theory

1.1 General Non-Steady-State Probe Theory

For determining the thermal conductivity of materials various types of measurement

equipment can be used. In general one can make a distinction between steady-state

techniques in which the investigated sample is supposed to reach a perfect thermal

equilibrium, and non-steady-state techniques. In non-steady-state techniques the

material properties are determined while the sample temperature still changes.

The main advantage of steady-state techniques is the simplicity of the analysis of

stabilised constant sensor signals. The main advantages of non-steady-state techniques

are the short measurement time and the fact that the sample dimensions do not

necessarily enter the equation.

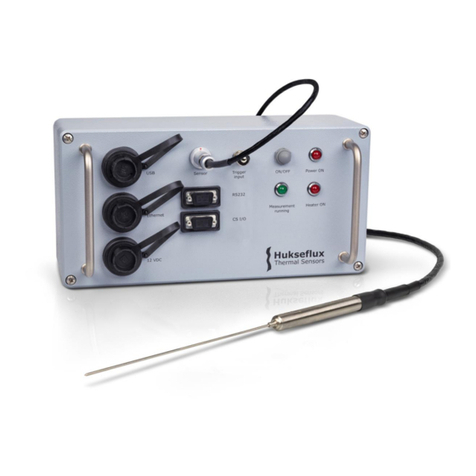

The only Non-Steady-State technique that has been standardised is the one using a

single needle probe (Non-Steady-State Probe or NSSP) like TP09.

ASTM D5334-14 and IEEE Std 442-1981(03) “Standard Test Methods" specify the use of

the NSSP in soil and soft rock. More information about these standards can be found in

the appendices.

In general a NSSP consists of a heating wire, representing a perfect line source and a

temperature sensor capable of measuring the temperature at this source. The probe is

inserted into the soil that is investigated. The NSSP principle relies on a unique property

of a line source: after a short transient period the temperature rise, ∆T, only depends on

heater power, Q, and medium thermal conductivity, λ:

∆T = (Q / 4 πλ) (ln t + B) Formula 1.1.1

With ∆T in K, Q in W/m, λin W/(m·K), t the time in s and B a constant.

The thermal conductivity can be calculated from two measurements at t1and t2. For TP09

(6.35 mm diameter) both t1and t2are higher than 100 s, and typically 150 s apart. ∆T is

the temperature difference between the measurements at time t1and t2, taking t = 0 at

the moment that the heating starts.

λ= (Q / 4 π∆T) ln(t2/ t1) Formula 1.1.2

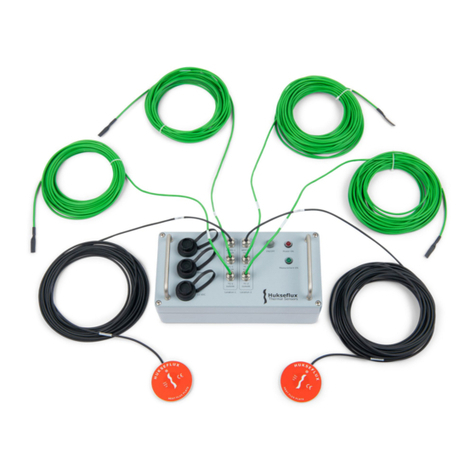

The sample size is not critical, as long as a radius around needle is covered that is

roughly 50 times the needle radius, in case of TP09 (the needle of FTN02), which has a

3.175 mm radius: 160 mm. (please note that with low conductivity media like dry sand,

glycerol and Perspex, the sample diameter can be reduced to 100 mm)