Sercel GRC ESP Series User manual

!"#$#%&&

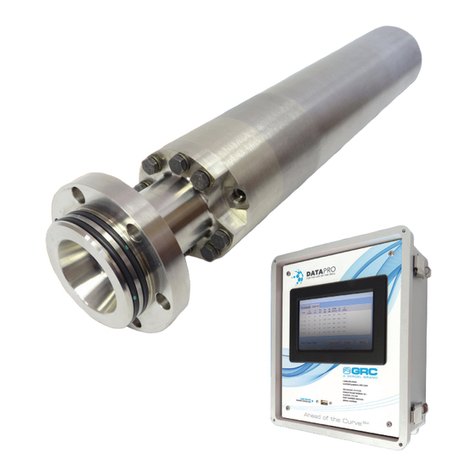

ESP Monitoring System

'()*+%#%,-'()$./%,-%0%#)$./%,

!.%12-.(&$'11'$."(-

/'(3'1

Document: 006-0211-00 Rev AD Page 2 of 62

NOTICE

This manual is intended for private information only, with the understanding that any

other use of the subject matter, in whole or in part, by reference or otherwise, shall be

only with the prior knowledge and approval of Sercel-GRC Corp, and with the further

understanding that this manual is for informational purposes only and that suggestions

and recommendations contained herein shall not be understood or construed as a

guarantee or warranty of any method, product or device.

Federal copyright law protects the publication. No part of this publication may be copied

or distributed, transmitted, transcribed, stored in a retrieval system, or translated into

any human or computer language, in any form or by any means, electronic, magnetic,

manual or otherwise, or disclosed to third parties without the express written permission

of Sercel GRC Corp.

Any questions concerning the content of this manual, equipment operation, field

maintenance, maintenance assistance and operation or maintenance training courses

should be directed to Sercel-GRC.

Copyright © 2014 by Sercel-GRC Corp.

All rights reserved worldwide.

Document Number: 006-0211-00

Sercel-GRC Corp.

6540 East Apache Street, Tulsa, Oklahoma 74115-3616 USA

P.O. Box 581570 Tulsa, Oklahoma 74158-1570 USA

Telephone: (1) 918-834-9600 / Fax: (1) 918-838-8846

Visit our web page at www.Sercel-GRC.com

Document: 006-0211-00 Rev AD Page 3 of 62

Table of Contents

INTRODUCTION.............................................................................................................5

Customer Service/Support...........................................................................................5

BENCH TESTING AND VERIFICIATION PROCEDURES.............................................6

Tools Required ............................................................................................................6

Process Steps for Bench Test and Verification............................................................6

INSTALLATION PROCEDURES FOR DOWNHOLE GAUGE.......................................8

Installing the ESP Sensor to the Motor........................................................................9

Installing the Sensor Discharge Pressure Base Adapter (For ESP& QESP-3500

Gauge Models Only)..................................................................................................11

Installing the Resistance Temperature Detector “RTD” (For Non-Factory Installed

RTDs, Probe Style)....................................................................................................13

Wye Point Replacement...................................................................................................15

INSTALLING THE SURFACE INTERFACE EQUIPMENT...........................................19

SCOUT-3000 Installation...........................................................................................19

SPS-3000 Installation................................................................................................19

SPS-1500 Installation................................................................................................21

SCOUT-2200 Installation...........................................................................................22

INSTALLING THE SURGE SUPPRESSOR AND SURFACE CHOKE ........................23

Surface Choke...........................................................................................................26

Surge Panel Protector/Suppressor............................................................................23

Surface Choke and Surge Protector Panel Assembly #90B2175..............................25

SCOUT-3000 RELAY ALARMS SETUP ......................................................................28

SOFTWARE AND FIRMWARE INSTALLATION AND UPDATES ..............................28

Scout-3000 (for Rev. A Only).....................................................................................30

Updating SPS Firmware Using Tera Term - TTermpro.....................................................30

Updating LCD Firmware............................................................................................32

Scout-3000 (for Rev. B and Later Versions)..............................................................40

Updating RCM Firmware with Memory Tools & USB Cable ..........................................40

SPS-1500..................................................................................................................40

Updating SPS-1500 Firmware Using Hyper-Terminal Utility.............................................41

Updating SPS-1500 Using Tera Term - TTermpro............................................................44

Procedure for Viewing USB Memory with Memory Tools Software...........................46

4-20 mA CARD INSTALLATION AND CONFIGURATION..........................................47

Installing 4-20mA optional cards into the Scout-3000................................................47

Scout-3000 4-20mA Port Setup.................................................................................50

TROUBLESHOOTING..................................................................................................51

Sensor To Surface Communication Troubleshooting ................................................51

Scout-3000 Troubleshooting......................................................................................52

SPS-1500 Troubleshooting........................................................................................55

SCOUT and SPS Error Codes and Corrective Actions..............................................56

Doc No. 006-0211-00 Rev AD Page 4 of 62

Table of Contents, cont.

APPENDIX....................................................................................................................57

Surface Readout Status Message Summary.............................................................57

Fortress ESP Monitoring System Field Checklist.......................................................58

ESP Gauge and Surface Control Interface Diagram..................................................59

Surface Readout Devices - Gauge Interface Specifications......................................60

SPS-3000.........................................................................................................................60

SPS-1500.........................................................................................................................60

Scout-3000.......................................................................................................................61

Datalogger-2000 ..............................................................................................................62

Document: 006-0211-00 Rev AD Page 5 of 62

INTRODUCTION

This field installation manual will detail and explain the operation and installation of the

Sercel-GRC FORTRESS ESP Monitoring System, including gauges:

ESP-1000

ESP-1500

ESP-1800

ESP-2500

ESP-3500

QESP-2500

QESP-3500

and surface readout equipment:

SCOUT-2200

SCOUT-3000

SPS-1500

SPS-3000

Surge Suppressor (Protector)

Surface Choke

In the Appendix of this manual is a copy of the FORTRESS ESP Monitoring System

Field Checklist. This checklist will provide the installer with the ability to follow and

record the installation of the monitoring system. Please follow this guide and use the

checklist provided when installing the Fortress ESP Gauge System.

Customer Service/Support

If any assistance is needed please contact any of our service centers listed below. The

engineers and technicians will be more than happy to provide you with any assistance

needed.

SITE

LOCATION

PHONE

CAPABILITIES

Tulsa, OK,

USA

6540 E. Apache Street

Tulsa, OK 74115 USA

+1.918.834.9600

Headquarters, Engineering,

Manufacturing, Sales,

Service for USA and

Canada

Villahermosa,

Mexico

Comalcalco Num. 111 Fracc, Prados

De Villahermosa, Villahermosa,

Tabasco, Mexico C.P. 86030

993-312-7234

Sales, Service for Mexico

Dubai, UAE

Sercel Dubai

Building ZC02/ZC03 - Blue Shed Area,

P.O. Box 17523,

Jebel Ali Free Zone

Dubai, UAE

+971 4 8832142

Sales, Service for Middle

East

Mumbai, India

SK Oilfield Equipment Co Pvt Ltd.

26,Tarun Bharat Chakala, Andheri

East, Mumbai, 400009 India

91 22 2837 7070

Sales and Service for India

Singapore

Sercel Singapore

68 Loyang Way

Singapore 508758

65 6417 7000

Sales and Service for South

East Asia/Australia

Doc No. 006-0211-00 Rev AD Page 6 of 62

BENCH TESTING AND VERIFICIATION PROCEDURES

Note: Bench test and verification procedures are applicable to all Fortress ESP gauges.

Tools Required

110V Power Source

Either a Sercel-GRC SCOUT-3000 (Surface Readout)

oPortable Scouts will include a twisted wire pair with alligator clips

Or a SERCEL-GRC SCOUT-2200

Bulkhead Cable Assembly

Process Steps for Bench Test and Verification

1. SECURE THE GAUGE to keep the gauge from rolling or moving during

testing.

2. Remove the top shipping cap from the Fortress ESP Sensor.

3. Inspect to make sure no liquid and/or debris is present. (If liquid or debris is

present, contact Sercel-GRC).

4. Connect the red wire (Gauge Signal Wire) from the SCOUT to one of the 3 pins

in the hockey puck as shown in Figure 1 “a”. See page 25 for Surge Panel

connections. See figure 1A and 1B for an illustration of connections from

Scout-3000 to Surge Panel to ESP Gauge.

5. Connect the white/black wire (Ground Wire) to the body of the sensor as

shown in Figure 1 “b”.

6. This next step is applicable to all FORTRESS ESP Sensors EXCEPT the

ESP-1800 and where the motor temperature sensor (Resistance Temperature

Detector, “RTD”.) is not factory installed.

7. Locate the RTD kit (Probe Style or Threaded Style).

8. Locate the two white wires exiting the top of gauge.

9. Temporarily connect the two RTD wires to the two white wires exiting the

gauge. (As there is no polarity, wires can be connected in any way).

NOTE: Installation Procedure for the RTD connection can be found in the

installation section.

10.Power up SCOUT (Red Switch to “On” position)

a. Red switch illuminates indicating SCOUT is powered up. If switch light

does not illuminate, check power connection and/or fuse.

11.SCOUT will begin auto-analyze steps (sync phase and analyze messages on

display).

12.SCOUT will begin displaying gauge data in approximately 2-5 minutes.

13.Record the parameter readings on the Fortress ESP Sensor Checklist in the

Appendix of this manual for test verification records.

a. Bench Test Validation Parameters:

i. Pressure: 0-40 psi

ii. Temperature: ±5º F of ambient

iii. Motor Temperature: ±7º F of ambient

iv. Vibration (If Available): 0-1.2g

Doc No. 006-0211-00 Rev AD Page 7 of 62

a

b

HOCKEY PUCK

Figure 1: Fortress ESP Wiring Configuration

Figure 1A Fortress ESP Wiring Configuration

Doc No. 006-0211-00 Rev AD Page 8 of 62

Figure 1B: Fortress ESP Wiring Configuration

The end of the 3-phase cable will come out somewhere in the center of the ESP

cable spool as shown in Figure 1 above. Follow the steps below to test the gauge

through the ESP cable spool once the cable has been connected to the motor.

Since the SCOUT is powered by 110 VAC, an external power supply will be

needed.

Do not set the SCOUT on the Spooling unit as shown on this trailer.

ONLY CONDUCT THIS CHECK WHILE THE SPOOL IS NOT MOVING.

NEVER AT ANY TIME STEP OVER THE 3 PHASE ESP CABLE.

1. Connect the red wire (gauge signal wire) to one of the 3 phase leads.

2. Connect the white or black wire (ground) to the shielding on the 3 phase cable.

3. Power on the SCOUT.

4. Record the parameter readings on the Fortress ESP Sensor Checklist given in

the Appendix of this Manual.

5. Repeat this for every 10 stands of completion tubing until the last tubing stand

has been assembled.

Doc No. 006-0211-00 Rev AD Page 9 of 62

INSTALLATION PROCEDURES FOR DOWNHOLE GAUGE

Installing the ESP Sensor to the Motor

This procedure outlines the best practices that should be taken in the field. The sensor

can be mounted to the motor before the motor is shipped to the field. In that case, the

procedure will be the same, but probably not done on the back of a flat bed trailer as

shown in these pictures.

1. Layout the sensor so that the three female connections on the Hockey puck

are aligned with the three pins coming out of the motor, and the holes on the

motor base are aligned with the holes on the motor head as shown in Figure 2.

Figure 2. Aligning the motor pins to the Hockey puck.

2. Carefully stab the sensor onto the motor watching closely that the three pins

mate up with the three female connections on the hockey puck. IT IS VERY

IMPORTANT DURING THIS STEP YOU DO NOT TWIST THE SENSOR

WHILE STABBING ONTO THE MOTOR BASE. DOING SO WILL RESULT

IN DAMAGING THE HOCKEY PUCK AND RUINING COMMUNICATION TO

THE SENSOR ONCE THE MOTOR IS STARTED.

Doc No. 006-0211-00 Rev AD Page 10 of 62

Figure 3. Gauge stabbed into motor base.

3. Once the sensor has been stabbed as far as shown in Figure 3, place one of

the motor base bolts through the bolt hole and into the sensor motor head to

make sure that the bolt holes are lined up. DO THIS BEFORE PROCEEDING

TO STAB THE SENSOR FULLY ONTO THE MOTOR BASE.

4. Use of the fill and plug valve to fill the gauge with oil from the gauge plug. Most

customers do not use the fill and plug valve on the gauge and use the one

located on the motor. Below is a description of the plug:

Item

#

Part Number

Description

1

089-0252-00

PLUG, VENT & DRAIN

2

089-0254-00

GASKET, VENT & DRAIN

LEAD SEAL

3

089-0251-00

VALVE, DRAIN & FILL

4

089-0253-00

GASKET, LEAD SEAL

Note: Both gaskets listed above are single-use components. Item 3 (valve) should be

torqued to 210 in-lbs and Item 1 (plug) should be torque to 100 in-lbs.

5. Connect the SCOUT to the motor and gauge assembly. Connect the red wire

(gauge signal) to one of the motor lead power connections and the white or

black wire to the motor housing.

6. Record the parameter readings on the Fortress ESP Sensor Checklist.

Doc No. 006-0211-00 Rev AD Page 11 of 62

Testing the ESP Sensor While Installing Tubing

Figure 4. Spooling Unit.

Installing the Sensor Discharge Pressure Base Adapter (For

ESP& QESP-3500 Gauge Models Only)

Discharge Port Connection

All Dual Pressure gauges are equipped with a Discharge Pressure Port. The

Discharge Pressure Port must be purged with motor oil, vent plugged, and connected to

the hydraulic tubing connecting to the pump discharge sub before being deployed.

Failure to install the Discharge Bleed Plug will result in failure to read the discharge

pressure. See Installation and Troubleshooting guide for instruction to purge discharge

pressure port connections.

Figure 5. Discharge tubing connection.

Compression Fitting

1/8” NPT to ¼” inch

capillary tubing

Discharge

Pressure Bleed

Port Plug

Must be

INSTALLED

before running

gauge into the

well.

Doc No. 006-0211-00 Rev AD Page 12 of 62

THIS OPERATION NEEDS TO BE COMPLETED IN ITS ENTIRETY BEFORE THE

MLE IS CONNECTED TO THE MOTOR.

1. Remove the fitting and ensure that the NPT threads have been Teflon taped.

2. Install the n fitting back into the base.

3. Remove the compression nut and ferrules.

4. Install compression nut and ferrules onto the capillary tubing ensuring the

correct ferrule orientation.

5. Place the capillary tubing with nut and ferrule into the fitting and tighten until one

thread only is visible on the fitting or until the fitting is hand tight using a 9/16”

end wrench.

6. Nipple up BHA and Discharge Sub.

7. Leave the fitting on the discharge sub hand tight so that it will leak fluid slightly.

8. Once the BHA and discharge sub is installed, POOH BHA and connect a

pressure test system to the Discharge pressure bleed port.

9. Remove pressure test system and install plug in port.

10.Fill the line with hydraulic fluid until fluid exits the pressure bleed port.

11.RIH BHA and tighten the pressure fitting on the discharge pressure port.

12.POOH BHA and remove plug from port.

13.Immediately install the pressure test system and pressure test to 5Kpsi for 10

min.

14.If the pressure remains constant +/- 20 psi, then the installation is complete, if

not, then repeats Steps 1-13.

Megger testing motor and cable

The motor and cable may be Megger tested if required using the following guidelines:

The output voltage of a Megger will exceed the breakdown voltage of the protective

MOV mounted on the fuse block. The MOV will conduct if a Megger is used, giving

incorrect readings. Disconnect the three-phase choke and fuse block from the motor

cable before testing. Do not Megger test the downhole equipment while any of the

surface components are connected to the motor power cable.

NOTE: MEGGER TEST THE SENSOR IN REVERSE POLARITY ONLY!!

Doc No. 006-0211-00 Rev AD Page 13 of 62

Installing the Resistance Temperature Detector “RTD” (For

Non-Factory Installed RTDs, Probe Style)

All ESP Gauges monitor Motor Temperature with a Platinum 1K RTD. There are

several RTD Motor Temperature Probe options including Probe, Threaded, and

customer supplied. Motor Temp probes are mounted inside the gauge assembly and

placed against the Motor Windings for maximum temperature transfer and fast

response. Motor Temperature Sensors can be ordered as an accessory or wired

permanently inside the gauge eliminating field connection concern.

The following procedure appears much more complex than it actually is and can be

performed in either the field or shop environment. Also included in this document is the

wye point solder procedure that Manufacturing uses.

Motor RTD Connection Instructions

a. The first step is to determine where the RTD is going to be placed. It can be

either inside the ESP motor oil passage or inside the Sercel-GRC gauge. Inside

the gauge is the safest and is the least likely to come in contact with rotating

motor components, but it will be slower in responding to temperature variations of

the ESP motor. Placing the RTD inside the motor oil passages provides faster

response times to temperature changes, but runs the risk of contacting rotating

parts.

b. Shorten the two wires coming from the gauge for the RTD to match where you

have determined to place the RTD. If it’s going inside the motor oil passage

secure the wiring and its excess to insure that the RTD is not drawn further into

the oil passage by the oil flowing through it. This prevents the RTD from coming

in contact with the rotating internal parts of the motor. Also insure that the wiring

will not come in contact with the end of the rotating motor shaft located where the

motor and ESP gauge are mated together. If the RTD is being placed inside the

gauge do not coil up the excess wire inside gauge but instead shorten the wires

and then insert the RTD and wiring back into the gauge. The reason for not

coiling the excess wire up and placing it inside the gauge is this can possibly

allow motor noise to show up on the motor temperature readings.

c. Strip 1/4” to 3/8” of insulation from the RTD and gauge wires.

d. Cut a piece of high temp heat shrink tubing, around 2.5”, and slide it over and

past both stripped gauge wires.

e. Using two more pieces of high temperature heat shrink tubing, around 1.5” long,

slide each piece over and past each individual gauge wire. The result should look

like the example in Figure 6.

Doc No. 006-0211-00 Rev AD Page 14 of 62

Figure 6. Three pieces of shrink tubing on gauge wires.

f. Twist one RTD wire and one RTD gauge wire together creating a splice so that it

appears as a straight wire and not two wires side by side. At this time solder the

two wires together using high temp solder. Do the same step for the other two

wires (one from the RTD and the other from the gauge).

g. Slide the heat shrink tubing down over each individual soldered bare wire and

heat shrink the two pieces of tubing using a hot air gun (heat gun). The solder

joint should be located in the center of the length of the tubing and the result

should appear as shown in Figure 7.

h. From step c, now slide the longer piece of heat shrink tubing over both wires so

that the solder joint is centrally located inside the tubing as shown in Figure 8.

Figure 7. Heat shrink tubing over solder joints.

Solder joint located

at the center of the

heat shrink tubing.

Doc No. 006-0211-00 Rev AD Page 15 of 62

Figure 8. Long piece of heat shrink tubing over both wires.

Finally, replace the wye point if you have removed it. Attach the Scout-3000 or portable

Scout to any of the motor terminals of the wye point or to the gauge wire if not using our

wye point. Turn on the Scout and check/record gauge readings.

Place the RTD in the position you had determined and reassemble the gauge and

motor. Re-check and record readings using the Scout attached to the top of the motor

on one motor lead.

Wye Point Replacement

If you do have to remove the wye point, below is the GRC procedure that is used when

Manufacturing is attaching the wye point.

Purpose

The purpose of this procedure is to give instructions on how to solder the

communication wire to the WYE terminal for ESP gauges.

Cautions and Warnings

Ensure there are no nicks on the conductor of the communication wire when stripping.

Ensure there are no sharp edges on solder joint of wire and terminal. Ensure shrunken

heat shrink does not back off from the terminal. Read entire procedure before initiating

procedure.

Equipment needed

2 Heat Shrink Wraps 1 ½ inches long, P/N: 133-0051-00

Needle nose pliers

Heat Gun

High Temperature Solder, P/N: 140-0001-00

Flux

Isopropyl Alcohol

WYE Adapter

Communication Wire (From Assembly 90C2025, not to be confuse with the RTD

white wire)

Terminal, P/N: 90B1863

Doc No. 006-0211-00 Rev AD Page 16 of 62

Procedure

Cut P/N 037-0050-04 off from the communication wire, refer to Appendix Fig. A1.

Thread the communication wire through the hole on the terminal.

Be sure not to use the RTD wires as all wiring from the choke is white.

Fold the excess wire back towards itself making a loop. Refer to Figure 52.

Figure 9. WYE Connector Shown with the

Communication Wire Prior to Crimping.

Any excess wire extending beyond the insulation of the wire should be removed.

Before soldering, gently crimp the wires with needle nose pliers to close the gap of the

wire loop. Refer to Figure 10.

Figure 10. WYE Terminal Shown with the

Communication Wire After Being Crimped.

Doc No. 006-0211-00 Rev AD Page 17 of 62

Now solder the wire to the terminal with the aid of flux making sure not to leave any

sharp edges. Refer to Fig. 11. After soldering, clean the solder with alcohol and slide

the clear plastic wire insulator to the solder joint. Refer to Fig. 11.

Figure 11. WYE Terminal Shown with the

Communication Wire Soldered.

Slide one piece of heat shrink tubing down to the hex base of the terminal. Apply heat

to shrink the first heat shrink tubing before applying second layer of heat shrink

tubing. Refer to Figure 12.

Figure 12. WYE Connector Shown with the

First Heat Shrink Tubing Un-Shrunk.

Doc No. 006-0211-00 Rev AD Page 18 of 62

Now slide the second piece of heat shrink tubing down to the base of the threaded pin.

This will go over the first heat shrink tubing. Refer to Fig. 13a.

Figure 13. WYE Connector Shown with the

Second Heat Shrink Tubing.

Apply heat to the heat shrink to complete the assembly. Refer to Fig.13b for final

assembly.

Figure 13b. WYE Connector Terminal Shown with

Both Heat Shrink Tubing Shrunk.

Doc No. 006-0211-00 Rev AD Page 19 of 62

! CAUTION ! Lethal Voltages Present Inside Enclosure.

Remove power anytime the front panel of the Scout-3000 is removed.

There are potentially dangerous voltages present!

INSTALLING THE SURFACE INTERFACE EQUIPMENT

SCOUT-3000 Installation

Figure 14 shows a typical wiring and installation schematic for the ESP surface

equipment. Figure 15 describes the specific connections of a Scout-3000 to a gauge.

Connections are also detailed for the 4-20mA Current Loop and Modbus.

Figure 14. SCOUT and Suface System Wiring Diagram

Doc No. 006-0211-00 Rev AD Page 20 of 62

Signal Name

Recommended Wire Colors

AC Power-In

Black-Live, White-Neutral, Green-Earth Gnd

Gauge

Red-Signal (+), Green-Return (-)

4-20mA #1

Orange/Gray

(Connections for Scout-3000 w/ Optional

4-20mA Current Loop)

4-20mA #2

Blue/Violet

(Connections for Scout-3000 w/ Optional

4-20mA Current Loop)

Modbus

Blue/Violet

(Connect to Pins 1 and 4)

Figure 15. Scout-3000 Wiring and Connections

SPS-3000 Installation

The connections for the SPS-3000 are shown in Figure 16 below.

Gauge: +Connection to ESP gauge signal. –Connection to dedicated wellhead

ground.

VDC: Connections to a +12 to 18VDC and Ground.

ModBus: TR- and TR+ Connections to ModBus master

Figure 16. SPS-3000 Connections

SPS-3000

Sig+ Grd- 12-18V Grd TR+ TR- TR+ TR-

Power

Supply

12-18 VDC

Surge Panel

(to Wellhead

Ground)

ModBus Master

or

485 Converter

ModBus

Slave

+

+

-

+

+

+

-

+

+

+

-

+

+

+

-

+

This manual suits for next models

11

Table of contents

Other Sercel Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Texas Instruments

Texas Instruments MSP-SA430-SUB1GHZ quick start guide

Dorrough Electronics

Dorrough Electronics 40-A instruction manual

PCB Piezotronics

PCB Piezotronics 422M136 Installation and operating manual

Sper scientific

Sper scientific 300001 instruction manual

inbody

inbody BSM270 user manual

GHM

GHM DeltaOHM LPUVA02 operating manual