Sercel GRC Fortress SPS-1500 User manual

Doc. No. 006-0202-00 Rev AH 2

NOTICE

This manual is intended for private information only, with the understanding that any

other use of the subject matter, in whole or in part, by reference or otherwise, shall be

only with the prior knowledge and approval of Sercel-GRC Corp., and with the further

understanding that this manual is for informational purposes only and that suggestions

and recommendations contained herein shall not be understood or construed as a

guarantee or warranty of any method, product or device.

Federal copyright law protects the publication. No part of this publication may be copied

or distributed, transmitted, transcribed, stored in a retrieval system, or translated into

any human or computer language, in any form or by any means, electronic, magnetic,

manual or otherwise, or disclosed to third parties without the express written permission

of Sercel-GRC Corp.

Any questions concerning the content of this manual, equipment operation, field

maintenance, maintenance assistance and operation or maintenance training courses

should be directed to:

MODEL:

SPS-1500/SPS-1501 Operations Manual

V4.2 Update

Copyright © 2015 by Sercel-GRC Corp.

All rights reserved worldwide.

Document Number: 006-0202-00 Rev AH

Sercel-GRC Corp.

13914 E. Admiral Place, Ste. B

Tulsa, OK 74116-2107

Telephone: (1) 918-834-9600 / Fax: (1) 918-838-8846

Doc. No. 006-0202-00 Rev AH 3

TABLE OF CONTENTS

1.0 SPS-1500/SPS-1501 Board Overview......................................................................4

1.1 SPS-1500 Specifications.......................................................................................4

1.2 SPS-1501 Specifications.......................................................................................4

1.3 Default/Factory Settings SPS-1500 & SPS-1501..................................................4

1.4 DC Power Supply (Optional).................................................................................4

2.0 SPS-1500/SPS-1501 Connections............................................................................5

3.0 SPS-1500/SPS-1501 LCD ........................................................................................6

3.1 Status & Diagnostic Screens.................................................................................6

3.2 Status & Error Message........................................................................................7

4.0 SPS-1500/SPS-1501 DataWorks Software Configuration.........................................8

4.1 DataWorks 1.04 Configuration Menu....................................................................8

4.2 Modbus Communication Map Settings................................................................11

4.3 Modbus Slave ID & Baud Rate Settings .............................................................13

4.4 SPS Configuration Settings.................................................................................14

4.5 SPS Manual Operation .......................................................................................14

4.6 Firmware Update ................................................................................................15

5.0 ESP ‘E’ Series Sensor Configuration ......................................................................16

6.0 High Speed Operation.............................................................................................19

Appendix.......................................................................................................................21

1 SPS-1500/SPS-1501 Troubleshooting.......................................................................21

2 SPS-1500/SPS-1501 Modbus Map............................................................................23

3 CE Compliance Certifications.....................................................................................25

4 SPS-1500 Synchronization and Startup.....................................................................26

Doc. No. 006-0202-00 Rev AH 4

1.0 SPS-1500/SPS-1501 Board Overview

1.1 SPS-1500 Specifications

GRC P/N: 90B3125

Certifications: CE Compliance Tested (see Appendix)

Dimensions: 3.47”W, 3.68”L, 2.30”H

Voltage Input: 12 to 28 VDC, 0.5 Amp Max

Polling Interface: RS-485/RS-422 Isolated Modbus

PC Interface: Isolated USB COM Port for Modbus/Firmware Update

Supported Baud Rates: 1200, 2400, 4800, 9600, and 19200 bps

Display: 16x2 Backlit LCD

Gauge Power Out: 40 to 80 VDC Out (~80mA Current Limited)

Gauge Power Fuse: 100mA, GRC P/N 043-0047-00

1.2 SPS-1501 Specifications

GRC P/N: 10029745

Certifications: CE Compliance Tested (see Appendix)

Dimensions: 3.47”W, 3.68”L, 2.30”H

Voltage Input: 12 to 16 VDC, 0.5 Amp Max

Polling Interface: RS-485/RS-422 Isolated Modbus

PC Interface: Isolated USB COM Port for Modbus/Firmware Update

Supported Baud Rates: 1200, 2400, 4800, 9600, and 19200 bps

Display: 16x2 Backlit LCD

Gauge Power Out: 16 to 32 VDC Out (~80mA Current Limited)

1.3 Default/Factory Settings SPS-1500 & SPS-1501

Polling Interface RS-485

Baud Rate 9600 bps

Modbus ID 1

1.4 DC Power Supply (Optional)

GRC P/N: 062-0049-00 (Din Rail Power Supply, 12VDC, 3.0A,

Mfg. PN#STEP-PS/1AC/12DC/3)

Doc. No. 006-0202-00 Rev AH 5

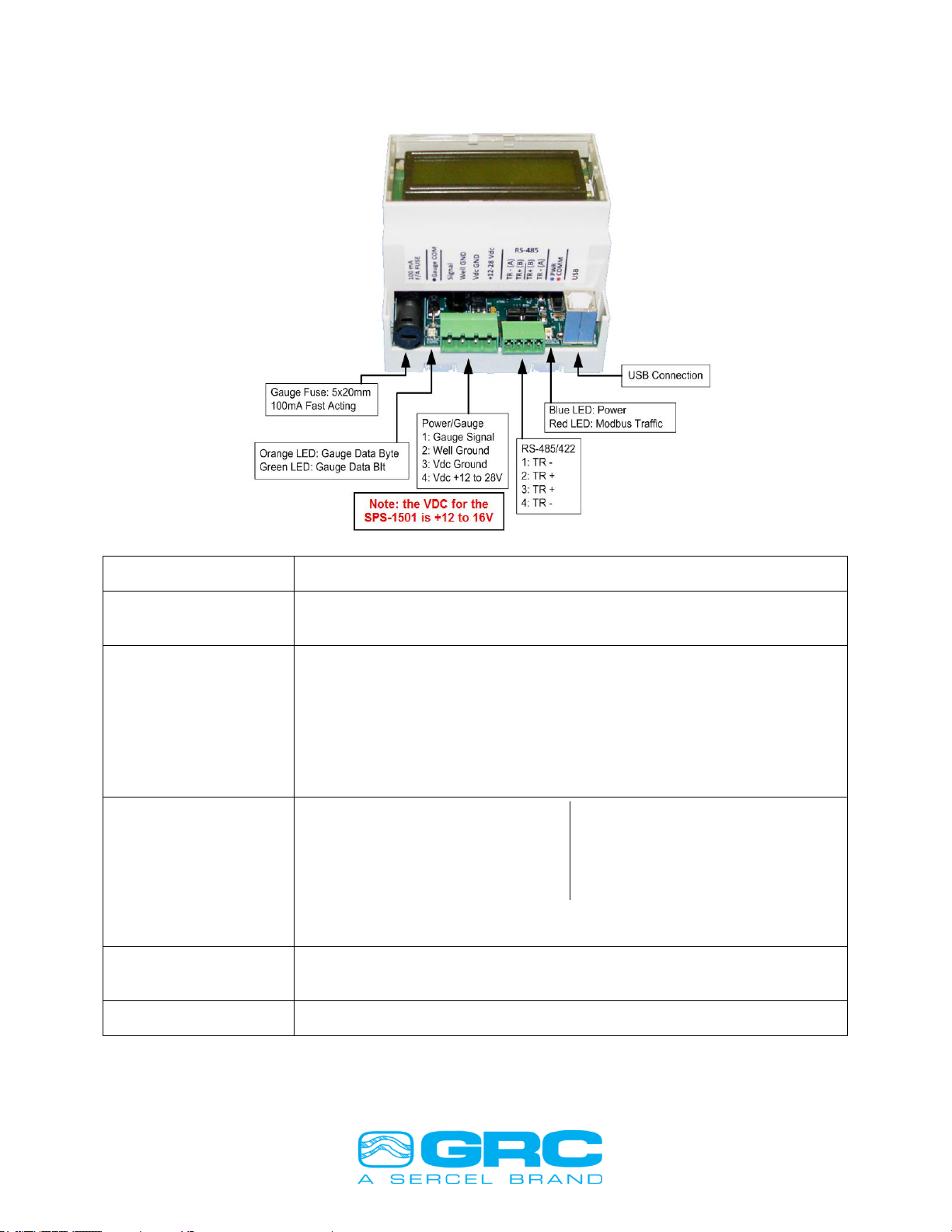

2.0 SPS-1500/SPS-1501 Connections

Gauge Fuse

Gauge signal fuse, 100mA 5x20mm, GRC P/N 043-0047-00

Gauge Comm.

Bi-Color LED

Flashes green for every gauge data bit received

Flashes orange for every gauge data byte received

Power/Gauge

Connections

Gauge Signal

Gauge Signal Return/Wellhead Ground

Vdc Ground

Vdc Power +12v to 28v DC for the SPS-1500 and +12 to 16V for the

SPS-1501

NOTE: Apply torque of 5 inch-pound to secure the wires firmly.

RS-485 / RS-422

Modbus Slave

RS-485: Install (2) Jumpers

1. TR -

2. TR +

3. TR +

4. TR -

RS-422: Remove (2) Jumpers

1. T -

2. T +

3. R +

4. R –

NOTE: Apply torque of 2 inch-pound to secure the wires firmly.

Power/Modbus

Bi-Color LED

Solid blue when power is connected

Blinks red when a Modbus request is received

USB PC Connection

Modbus and firmware updating via USB Virtual COM Port

Figure 1. SPS-1500/SPS-1501 Connections

Doc. No. 006-0202-00 Rev AH 6

3.0 SPS-1500/SPS-1501 LCD

On power-up the SPS-1500/SPS-1501 displays these screens in sequence:

1. Firmware Version/Date Screen

2. Modbus Information

Then the screen cycles through the analyzing steps to acquire the tool, which takes 2-4

minutes. Once the tool is acquired the LCD automatically scrolls through both gauge

readings and diagnostic screens. The display is updated once per second, and the

screen advances every 3 seconds by default.

The displayed data includes the gauge serial number, the latest sensor reading and

Modbus register addresses where that data can be polled from. All enabled parameters

on the tool will be displayed. The screens operate in a loop displaying tool parameters,

then diagnostic screens, and back to tool parameters.

3.1 Status & Diagnostic Screens

There are 8 diagnostic screens that display the status and other useful information

about the SPS-1500/SPS-1501. They are fully customizable with Sercel-GRC’s

DataWorks application or other Modbus editing software –you may enable or disable

screens and also control the scrolling time of the screens. Section 4.5 of this manual

shows how to change the LCD settings.

Firmware Version/Date

Displays the firmware revision and date.

By default this screen is only shown on power up.

Tool Information

Top line: Gauge serial number and gauge type.

Bottom line: Tool baud rate

Modbus Information

Displays the device Modbus baud-rate and slave

address/id

GRC SPS-1500

4.2 9-SEPT-18

1234567 ESP+

ToolBaud: 5.000

Baudrate: 9600

Slave ID: 1

1234567 R40135

Pi: 102.3 PSI

Gauge Serial

Number

Latest Reading

Modbus Register

Address for displayed

value

Doc. No. 006-0202-00 Rev AH 7

Tool Communication Settings

Displays the tool communication settings, described

below:AAn: Auto Analyze ON/OFF

AVlt: Auto Volt ON/OFF

ABd: Auto Baud ON/OFF

BdL: Tool baud low-high limits

Signal Levels

Displays the minimum (Min), average (Now), and

maximum (Max) line current in mA.

Line Voltage

Displays the minimum (MinV), existing (NowV), and

maximum (MaxV) line voltage measured at the surface.

Packet Count and Run Time

Displays the data packet number and elapsed time

since the last power on (displayed as elapsed days,

hours, minutes).

3.2 Status & Error Message

On power up, the SPS-1500/SPS-1501 will go through 16

analyzing steps to find the optimum tool communication

settings. Once the analyze steps are complete, the tool will

send its headers and then begin sending tool readings.

Should an error occur, the error will take precedence over

the scrolling data and be displayed on the screen. If the

error is critical, the board might restart the analyzing steps to

reacquire the tool.

See Appendix 4 SPS-1500 Synchronization and Startup to view the complete startup

sequence.

AAn:ON AVlt:ON

ABd:ON BdL:3-6

Min Now Max

18.2 28.3 28.5

MinV NowV MaxV

55.2 55.7 55.9

RcvDat 435

RunTm:001d18h25m

Stat: Analyze 6

Okay

*** ERROR ***

ESP Framing

m

A

m

A

m

A

Doc. No. 006-0202-00 Rev AH 8

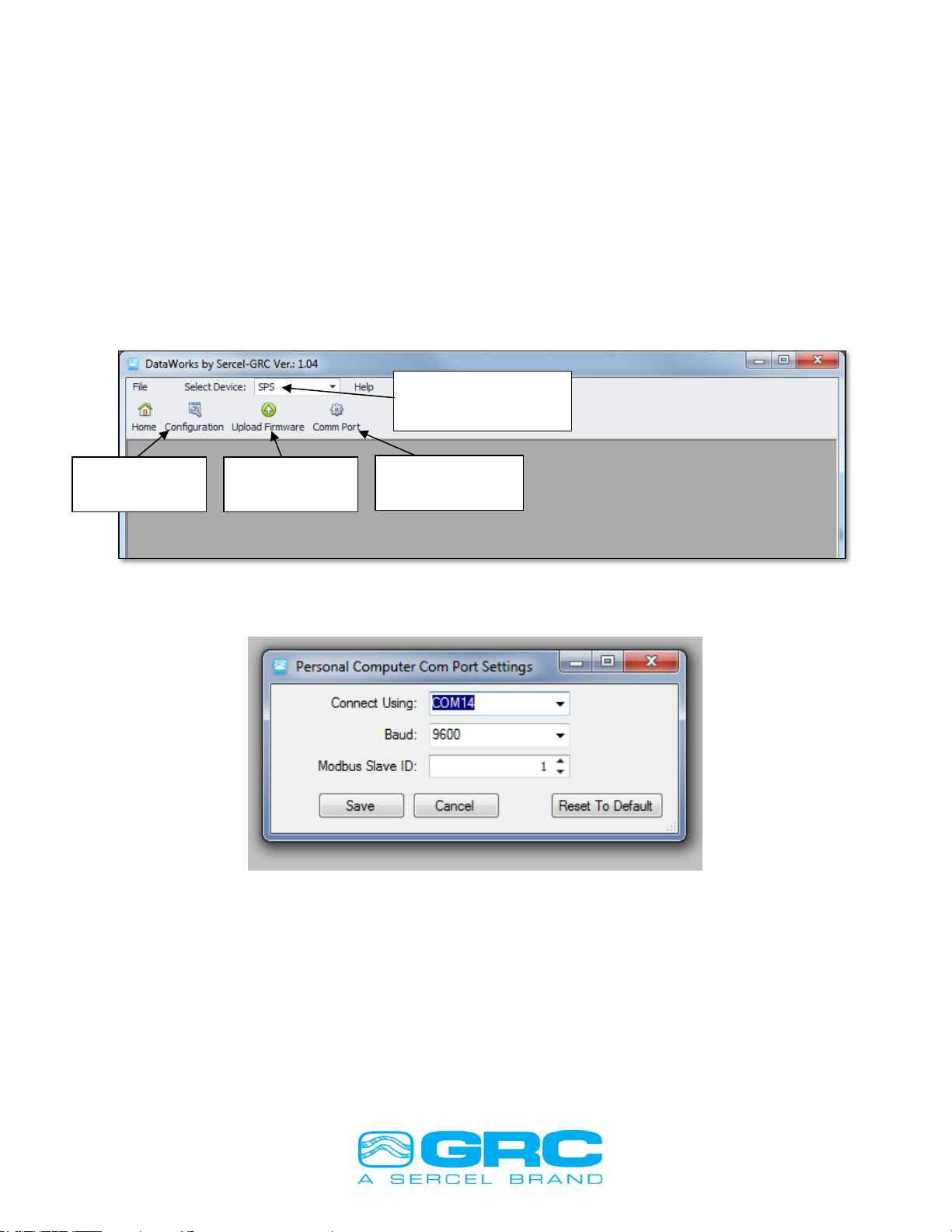

4.0 SPS-1500/SPS-1501 DataWorks Software Configuration

DataWorks by Sercel-GRC is a PC software package for configuration, monitoring, and

troubleshooting the SPS-1500/SPS-1501. Install the software using the installation

program available from Sercel-GRC’s Customer Service. Once the software is installed

connect the SPS-1500/SPS-1501 to the PC using the USB port on the SPS-1500/

SPS-1501. Run the DataWorks program and set up the serial communication port from

the ‘Comm Port’ button as shown in Figure 2. This button will open the ‘Personal

Computer Com Port Settings’ menu. Select the correct Comm Port and Modbus Slave

ID for the SPS-1500/SPS-1501. The default values are shown in Figure 3.

Figure 2. Navigating DataWorks Menu

Figure 3. Communication Port Settings Menu

4.1 DataWorks 1.04 Configuration Menu

Once the SPS-1500/SPS-1501 is configured to communicate with the PC, click on

‘Configuration’ to access different features (as shown in Figure 4).

Comm Port

Settings Button

Configuration

Button

Firmware

Update Button

Select SPS from

Dropdown Box

Doc. No. 006-0202-00 Rev AH 9

Figure 4. DataWorks 1.04 Configuration Menu

The connected gauge serial number is displayed on the ‘Real-Time’ tab. Click on ‘Real-

Time’ to enter the graphing window shown in Figure 5.

The Real-Time graph has the following options:

a) Start/Stop Save for Gauge Data. The gauge data can be saved to a computer in the

form of ASCII format (*.csv file).

b) Graph any parameter on Primary Y-axis.

c) Edit maximum and minimum limits for Primary/Secondary Y-axis.

d) Graph any parameter on Secondary Y-axis.

e) Select between ‘Elapsed Time’ and ‘Real-Time’ on X-axis.

f) Update/Reset. Enter the values in ‘Max:’ and ‘Min:’ fields and click on ‘Update’. The

values can be reset to previously Auto Scaled limits by clicking on ‘Reset’ button.

g) Chart Controls - Enable/Disable Auto Scale. Disabling Auto Scale will allow the user to

change the maximum and lower limits for Y-axis. Enabling Auto Scale will gray out the

maximum and lower limit field.

h) Clear All. This option allows clearing the graph and the data grid as well as stops the

saving of data.

i) Grid Controls - Enable/Disable Auto Scale. With Auto Scale enabled, the cursor will

always point to the latest gauge reading; which appear in the last row of the data grid.

With Auto Scale disabled, the cursor does not point to the current gauge reading; the

user has to scroll through the data grid.

j) Edit Sample Rate (Data Refresh Rate). The Sample Rate controls the data display rate

on the data grid.

k) The chart to plot gauges parameters. All the enabled channels appear in the pull-down

menu of Primary/Secondary Y-axis which can be plotted.

l) Gauge data grid. The gauge enable-channels and High-speed-enable-channels appear

in a grid with a time stamp.

Doc. No. 006-0202-00 Rev AH 10

Figure 5. Real-Time Graphing

Gauge data can be saved to the computer in ASCII format (*.csv). Click on ‘Start Save’

and select the folder location for the gauge data file. The saved file is automatically

named using the naming convention of ‘Gauge Serial Number Time Stamp’. The gauge

data is being written to the file as long as ‘Stop Save’ button is not clicked. Once the

‘Stop Save’ is pressed, the data recording stops. The saved ‘GaugeSN_timestamp.csv’

file can be opened in DataWorks ‘Real-Time’ window with the following options (see

Figure 6):

a) Save Plot –The active plot on the graphing window with the currently selected

parameter can be saved in *.png format.

b) Print Plot –This feature prints the graph.

c) Export To CSV –The data file can be saved back after data manipulation.

d) Y axis option –Different parameters can be selected across the ‘Primary Y’ and

‘Secondary Y’axis.

e) Max. and Min. Limits –The upper and lower limit for Primary Y-axis and Secondary Y-

axis are adjustable.

f) X Axis –This option allows switching between ‘Real-Time’ and ‘Elapsed Time’. Real-

Time is the time with date and timestamp, and Elapsed-Time corresponds to the total

number of hours through the operation.

b

c

d

e

f

g

h

i

j

k

l

a

Doc. No. 006-0202-00 Rev AH 11

g) Update –Click on ‘Update’ to reflect the newly entered upper and lower limits on the

graph.

h) Reset –This feature resets the previously set upper and lower y-axis limits.

Figure 6. Data Manipulation features from saved gauge data file

4.2 Modbus Communication Map Settings

The Communication Map configures the Gauge Modbus data output from the SPS-

1500/SPS-1501. Figure 7 shows the configuration tables for the communication setting

menu. Most installations will use the default data table. The Communication Map can

change the data type or size for installations located in different regions or with special

requirements. The settings allow the user to customize the Modbus map to meet the

installation requirements.

The Modbus data registers can be shifted anywhere between holding registers 40001-

49999. Changing the Modbus map begins with moving the SPS Holding Register base

g

a

c

b

d

e

f

h

Doc. No. 006-0202-00 Rev AH 12

address. The SPS Holding Register base address value must be 128 registers from the

OEM Holding Register base address.

The default setting for the gauge data parameter range is 40129-40146. To change the

gauge parameter address within this range set the ‘Order’ to the corresponding

address. The software will not allow multiple selections to be set to the same value.

Setting the ‘Order’ to ‘0’ will remove the parameter from the Modbus map and also from

the SPS-1500/SPS-1501 display.

The ‘OEM Map’ has the following configurable options:

a) Order –The ‘OEM Register Parameter’ is mapped to any ‘Reg Map’ Modbus registers

by changing the ‘Order’ via clicking the up and down arrows.

b) Dec Pts –The decimal places on any gauge parameter are changed by clicking the up

and down arrows; adjustable up to 3 decimal places.

c) Unit –The units for the gauge parameter are selectable via a pull-down menu.

d) Length –The bit length for each available ‘OEM Register Parameter’ is selectable

between 16 and 32 via the up and down arrows. If Serial Number is selected for 16-bit,

then the Real-Time will show ‘65536-Real-Time’ instead of ‘Gauge Serial-Number Real-

Time’.

Figure 7. Modbus Communication Map Menu

To set the gauge data parameter range to another range, determine the OEM Holding

Register Base address. This will be the lowest register value of the custom Modbus

map. Once this value is determined use the scroll boxes for the OEM Holding Register

to set this value, then set the SPS Holding Register Base address value to at least 128

registers higher or lower than the OEM Holding Register value. The software will not

write Base address values inside the 128 register limit to the SPS-1500/SPS-1501. After

c

a

b

d

Doc. No. 006-0202-00 Rev AH 13

the value is selected click the Parameter in the left column to retain the setting. Once all

the values are set, click the ‘Send to Unit’ button to write the configuration to the SPS-

1500/SPS-1501. Contact Sercel-GRC Customer Service for additional information on

map configuration.

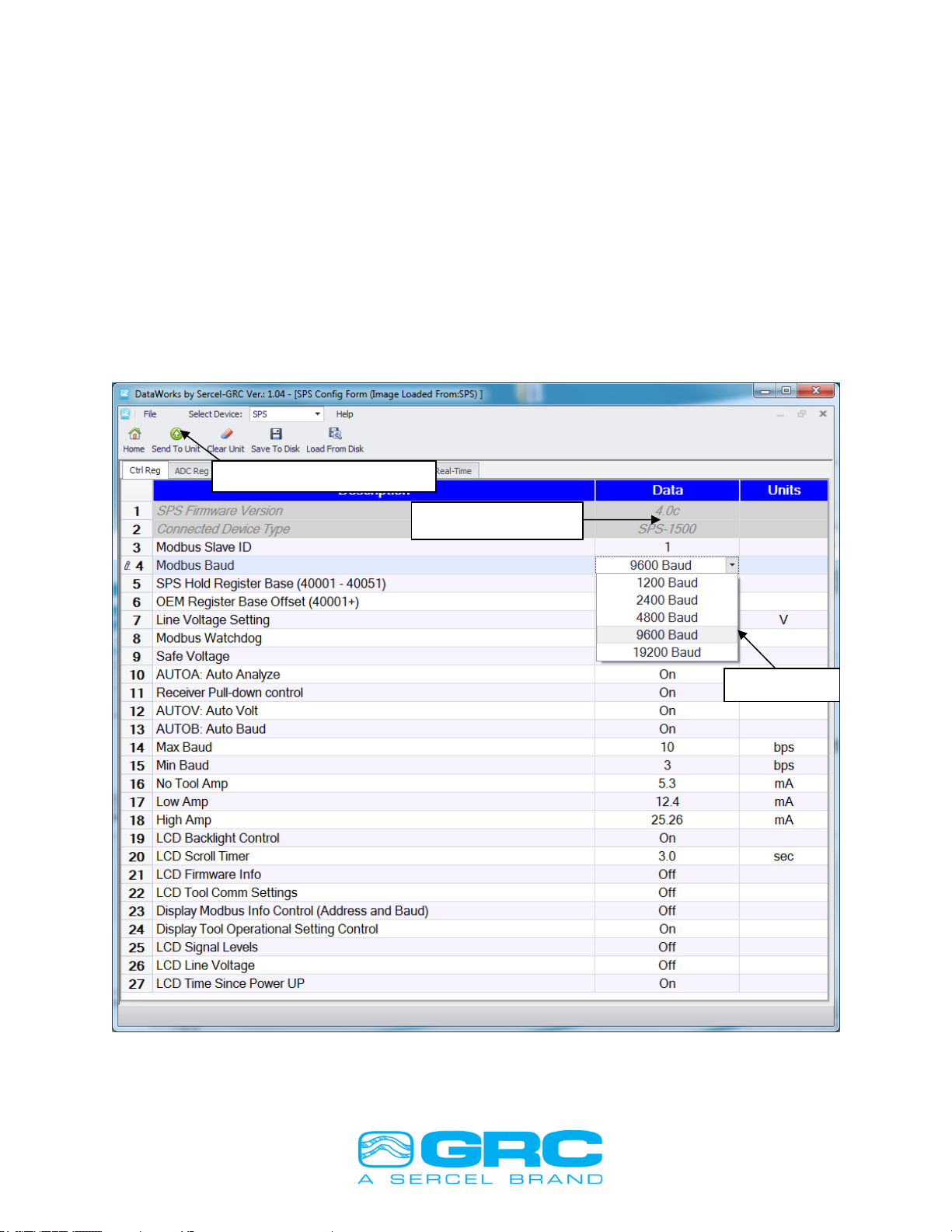

4.3 Modbus Slave ID & Baud Rate Settings

The ‘Ctrl Reg’ tab has several adjustable configuration settings that can be executed in

the SPS- 1500/SPS-1501. The Modbus Slave ID is selectable in the range 1 thru 254.

The Modbus Baud Rate is selectable from the pull-down menu. Once the desired

Modbus slave ID and baud rate have been selected, click on ‘Send to Unit’ to write the

configuration to the SPS- 1500/SPS-1501 (see Figure 8). These settings are saved on

the EEPROM of SPS- 1500/SPS-1501, so the settings are retained in the next power

up.

Figure 8. SPS Control Register Settings

Send to Unit Button

Baud Rate

Modbus Slave ID

Doc. No. 006-0202-00 Rev AH 14

4.4 SPS Configuration Settings

The SPS-1500/SPS-1501 controller board is configured from the factory to

automatically detect the optimum signal and voltage settings for gauge communication.

Some instances may require adjusting the communication settings due to noisy

environments, longer wire lengths or other issues that can cause communication

problems. DataWorks will automatically detect the SPS configuration and display the

current settings. To make changes to the SPS configuration select the parameter to

change and make the change using the scroll box. Once all the changes are made click

the ‘Send to Unit’ button.

Cycle SPS-1500/SPS-1501 power to complete SPS configuration changes.

The function ‘Save to Disk’ saves the SPS-1500/SPS-1501 control register’s

configurations. Once all the desired settings are done, click on ‘Save to Disk’ and the

window opens up to input a configuration file name. The saved configuration file can be

retrieved and loaded back into DataWorks using the function ‘Load From Disk’.

4.5 SPS Manual Operation

The SPS-1500/SPS-1501 is designed to automatically detect and operate at optimum

levels of communication. The device also has built-in features to protect the electronics

from damage. To change the operating modes of the SPS-1500/SPS-1501 select the

Configuration register and use the scroll box for the parameter to change the value. The

Scroll box will limit the value to the range for the specific register. The LCD configuration

can be set using the SPS configuration screen (see Figure 9 for LCD options).

To enable the Manual mode switch the Auto Volt and Auto Analyze off. This will set the

line voltage to the Power On Voltage value. To increase the line voltage change the

data value to the set voltage required (Min 40V - Max 80V).

Auto Baud sets the tool communication rate to the maximum rate the line conditions will

allow. Setting the Min and Max Baud to open the range can eliminate Baud rate errors

from the tool. It is common to see ‘Baud Fast’ or ‘Baud Slow’ errors during the line

analysis. The setting should only change as described in the troubleshooting section of

this manual.

The Modbus Watchdog feature monitors the SPS-1500/SPS-1501 Modbus port for

communication packets. When the SPS-1500/SPS-1501 receives a valid Modbus

packet a timer starts and if the unit does not receive another valid Modbus packet within

5 minutes the unit will reset. If the SPS-1500/SPS-1501 never receives a Modbus

packet the unit runs without starting the timer.

Safe Voltage will prevent the SPS-1500/1501 from running if a high line imbalance is

detected on the gauge input line. This protects the electronics from overloading the

signal when trying to operate over the imbalance (does not apply to the SPS-1501).

Doc. No. 006-0202-00 Rev AH 15

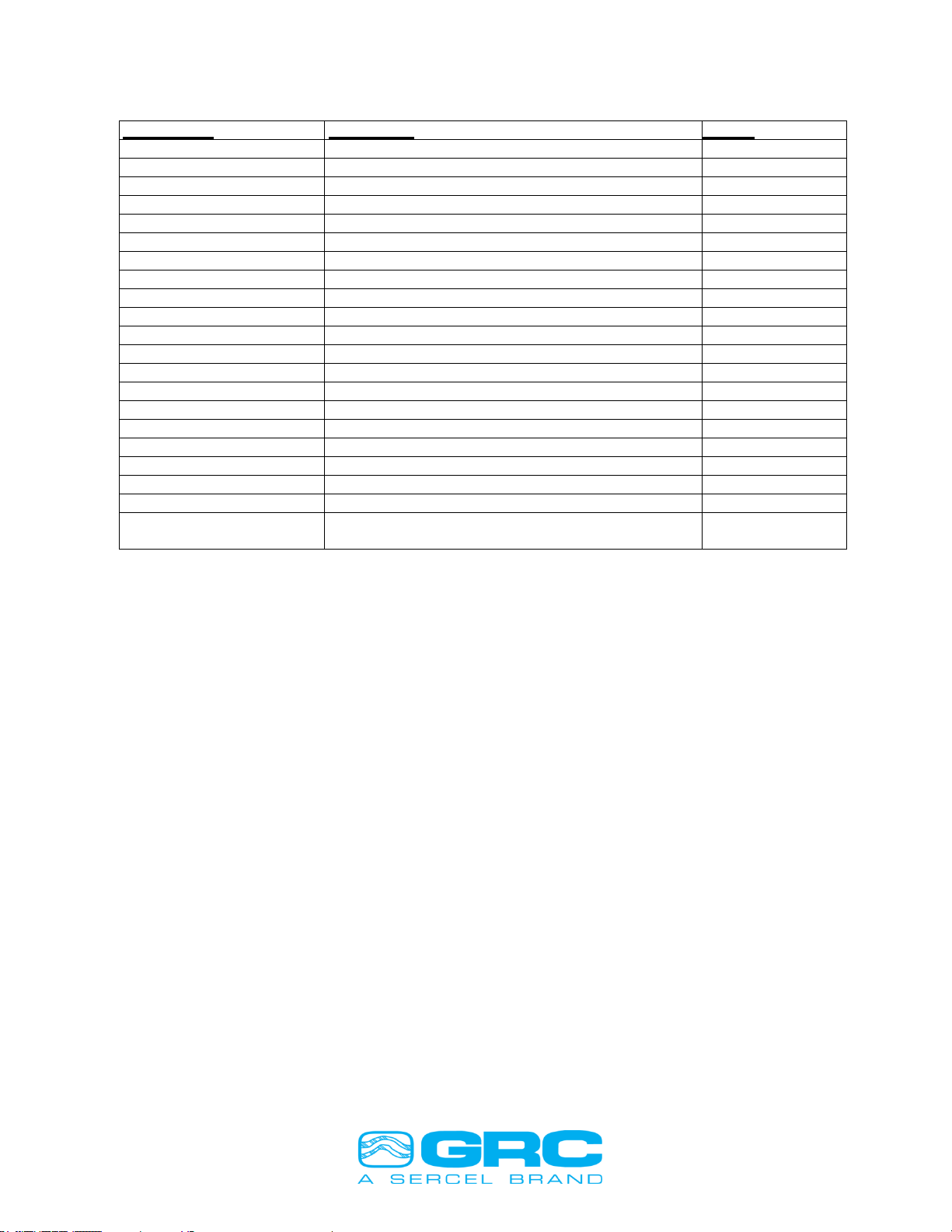

SPS Control

Description

Default

Power On Voltage Setting

Sets initial Line Voltage at startup

40.00

MBWD:Modbus Watchdog

Enables 5 Min Modbus packet timer

on

SAFEV:Safe Voltage

Measures Signal Levels before gauge power on

on

Auto Volt

Sets optimum line voltage

on

Auto Analyze

Analyzes for optimum line communication

on

Auto Baud

Toggle Auto Baud

on

Minimum Baud Rate

Edit Minimum tool baud rate

3

Maximum Baud Rate

Edit Maximum tool baud rate

6

Line Voltage Tolerance

Edit Line Voltage Tolerance

4

Low Current

Edit low current threshold

13-14

High Current

Edit high current threshold

24-25

LCD Backlight

Toggle LCD backlight

on

LCD Time

Adjust time between data screens

3

LCD Firmware Information

Toggle Display: Firmware Version

off

LCD Tool Information

Toggle Display: Tool Information

on

LCD Modbus Information

Toggle Display: Modbus Information

on

LCD Wye Imbalance

Toggle Display: Wye Voltage Imbalance

on

LCD Comm Settings

Toggle Display: SPS Communication Settings

on

LCD Signal Levels

Toggle Display: SPS-Tool Signal Levels

on

LCD Line Voltage

Toggle Display: Current Line Voltage

on

LCD Run Time

Toggle Display: SPS-1500/SPS-1501 Power On

Time

on

Figure 9. SPS Configuration Control Settings

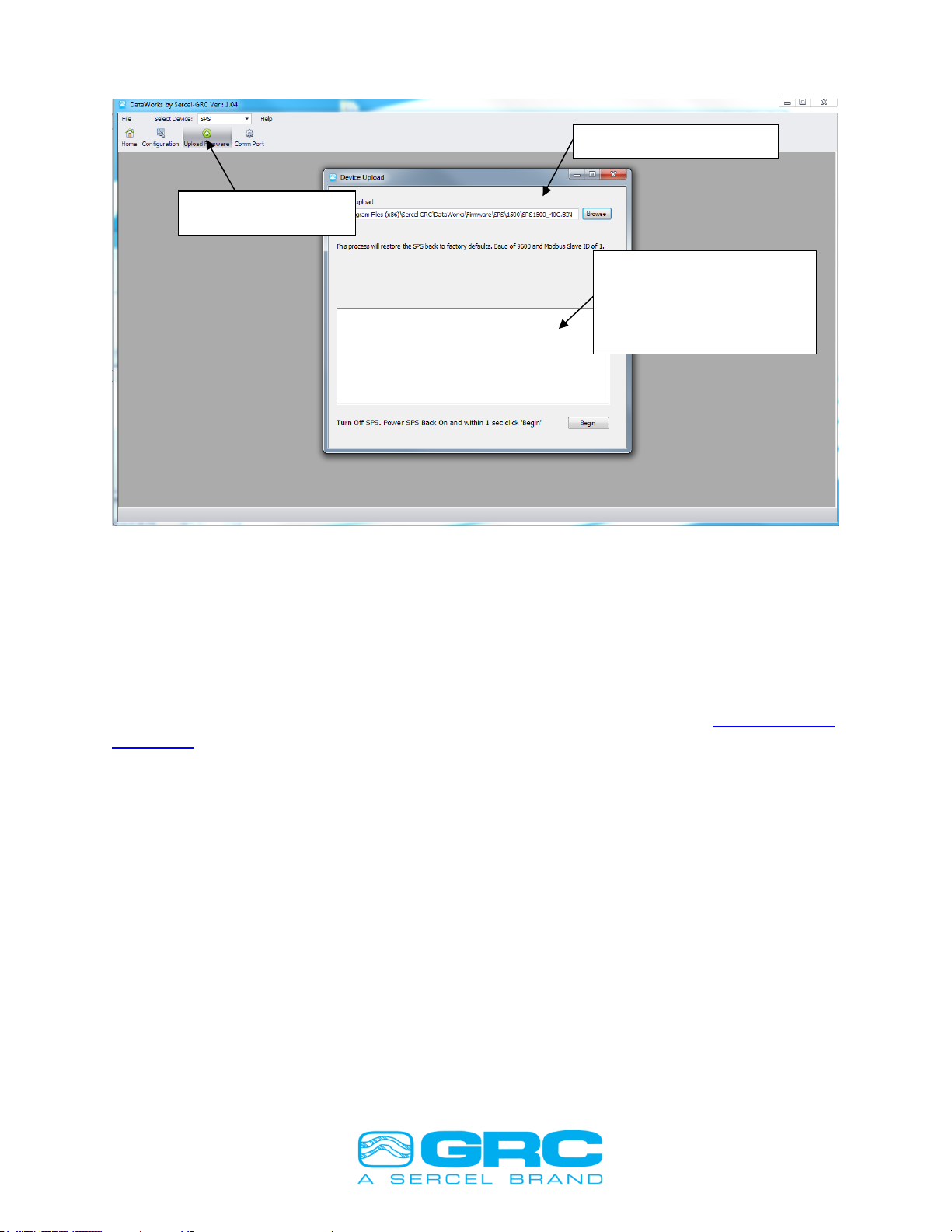

4.6 Firmware Update

To update the SPS-1500/SPS-1501 firmware version, connect the device to a PC as

described in section 4.0. Click the ‘Upload Firmware’ button on the DataWorks Home

Screen menu as shown in Figure 10. Verify the Comm Port by clicking ‘OK’ on the SPS

Connect window and the Upload Firmware screen will open.

Click the ‘Browse’ button to select the location of the firmware file. When the file is

selected begin the update process by cycling the power to the SPS-1500/SPS-1501

immediately after clicking the ‘Begin’ button. The power must cycle within 1 second of

sending the ‘Begin’ command. This time period allows the Bootloader to detect the file

transfer. Once the firmware upload is completed the SPS-1500/SPS-1501 will return to

normal operation.

Note: The SPS-1501 will not communicate with the C-4001T if SPS-1500 firmware

is uploaded. Use only firmware designed for the SPS-1501. The same is true for

the SPS-1500. Only use firmware designed for the SPS-1500 or it will not

communicate with the ESP gauge line.

Doc. No. 006-0202-00 Rev AH 16

Figure 10. Uploading Firmware in DataWorks

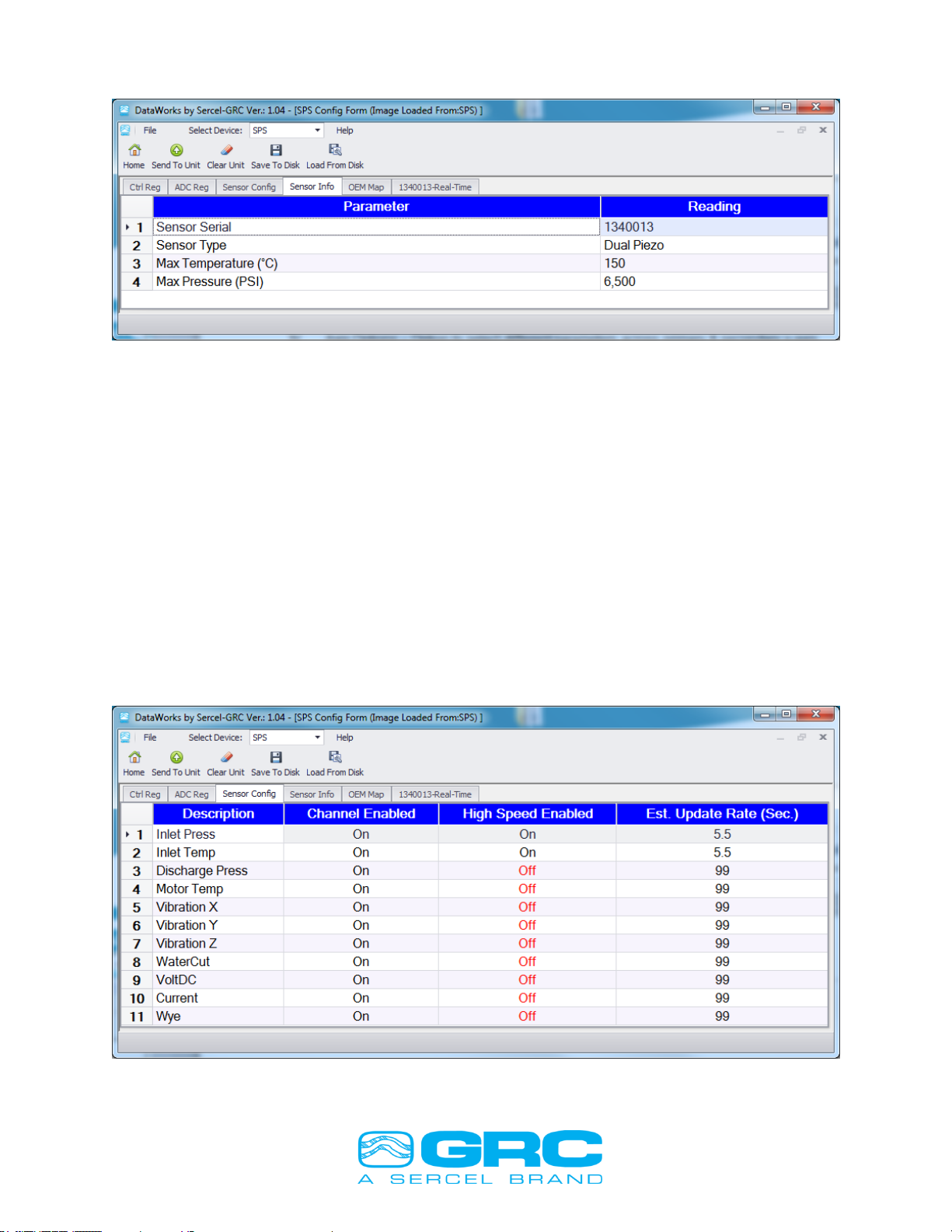

5.0 ESP ‘E’ Series Sensor Configuration

Sercel-GRC ESP-2500 and ESP-3500 Models are available in an ‘E’ series. The ‘E’

series will include a Two-Way Configuration feature. This option allows the user to

Enable or Disable ESP Sensor parameters and to configure the Downhole Sensor to

communicate at a higher speed data rate using the SPS-1500/1501 and DataWorks

Software. Contact Sercel-GRC Sales for ‘E’ Series Gauge information at sales@Sercel-

GRC.com

To utilize the features available on the ‘E’ Series gauge, allow the SPS-1500/1501 to

established data communication with the ‘E’ Series Downhole Sensor. Once

communication is established, DataWorks software will display two additional tabs when

the user is on the ‘Configuration’ page. The additional tabs are labeled ‘Sensor Config’

and ‘Sensor Info’, as shown in Figure 11.

Firmware Update

Select Firmware File

Turn off power to SPS.

Re-Apply Power and

immediately press

‘Begin’

Doc. No. 006-0202-00 Rev AH 17

Figure 11. Sensor Information Window

To configure any parameter to transmit data at the high-speed data rate, or to enable or

disable any available sensor parameter, click on the Sensor Config tab. Unavailable

parameters will be shaded in gray and text will be in italics.

To enable/disable sensor parameters, click on the desired parameter under ‘Channel

Enabled’ and select ‘Off’ or ‘On’ from the drop-down box as shown in Figure 12.

‘Off’ will disable the selected channel and the downhole sensor will no longer send data

for the selected parameter to the surface unit. When all desired changes have been

made, click the ‘Send to Unit’ button to send the configuration to the downhole sensor.

To set sensor parameters to transmit at the high speed’ data rate, click on the desired

parameter under ‘High-Speed Enabled’ and select ‘Off’ or ‘On’ from the drop-down box.

When all desired changes have been made, click the ‘Send to Unit’ button to send the

configuration to the downhole sensor.

Figure 12. Sensor Configuration Window

Doc. No. 006-0202-00 Rev AH 18

After clicking on the ‘Send to Unit’ button, the software will give the message: ‘Do you

wish to send the Sensor Configuration?’. Click yes to send the configuration to the

downhole sensor, shown in Figure 13.

The SPS-1500/SPS-1501 will restart and give the following display messages:

Power Off

Sync Phase 3

Sync Phase 4

Sync Phase 5

Checking Tool

Programming Tool

Tool Response

Tool Configured!

Rcv Hdr 0

Rcv Hdr 1

Rcv Dat1

Figure 13. Send Sensor Configuration Message

Selecting ‘No’ to this message will only send changes made to the ‘Config Coils’ tab and

the ‘Ctrl Reg’ tab, but will not send any sensor configuration to the downhole sensor.

Selecting ‘Cancel’ to this message will not send any changes to the SPS-1500/SPS-

1501.

The Parameter Enable/Disable channel and High-Speed Enable/Disable configurations

that are sent to the downhole sensor will be saved in the SPS-1500/1501 and resent to

the sensor in the event of a power loss. To return the sensor to the factory default

configuration, click the ‘Clear Unit’ button. This will re-enable all default sensor

parameters and reset all high speed channels to standard mode.

Doc. No. 006-0202-00 Rev AH 19

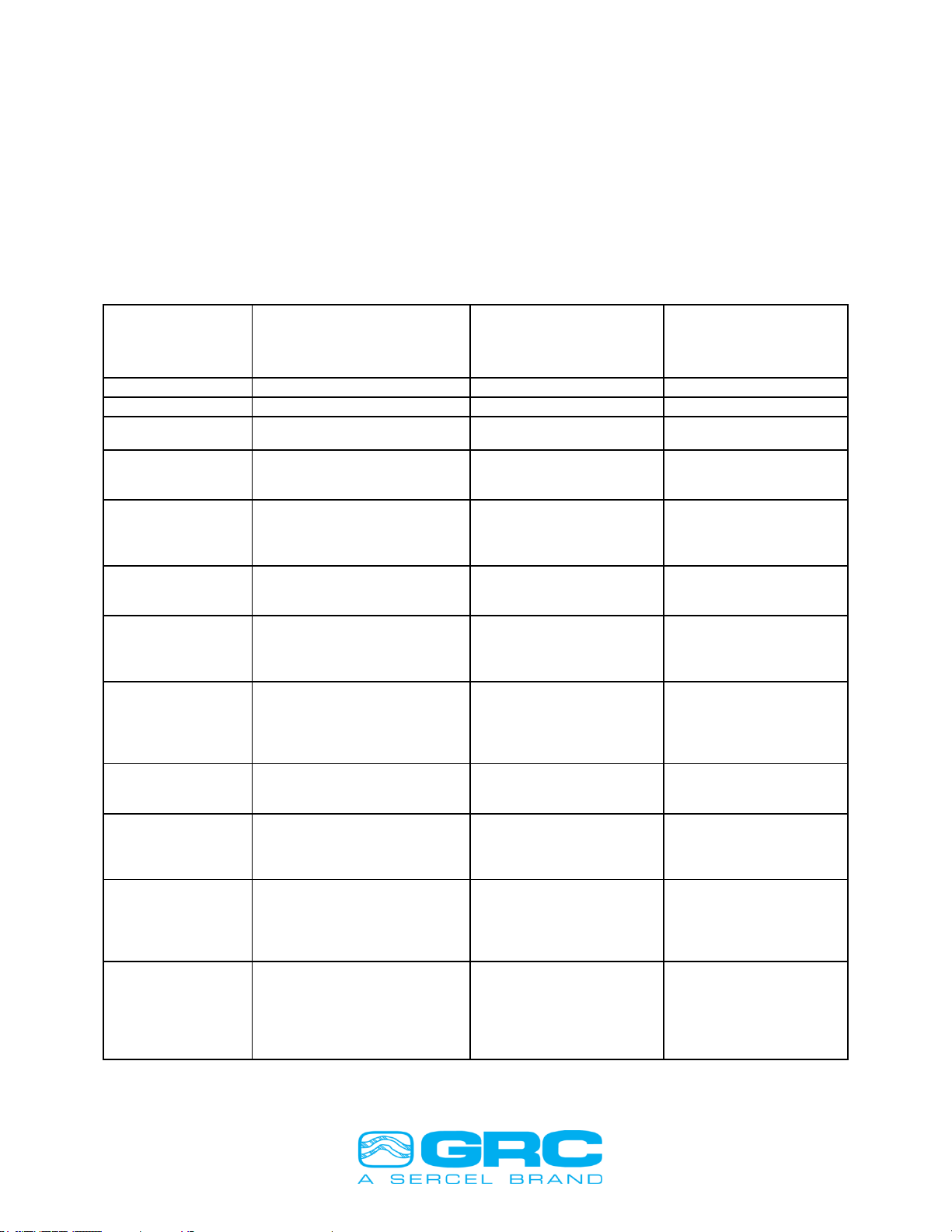

6.0 High Speed Operation

High Speed operation can be configured on any available sensor channel. The

channel(s) that are set to ‘High Speed’ will update at a higher sample rate than the

standard mode. Update Rates for various sensor configurations are shown in Figure 14.

High Speed enabled channels will display ‘HS’ beside the Modbus register on the SPS-

1500/SPS-1501 LCD. While running ‘Real Time’ via DataWorks software, a High Speed

channel will be displayed +HS on the enabled channels column heading (see Figures

15 and 16).

ESP Gauge

High Speed Mode

Configuration (High Speed

Parameters Enabled)

*High Speed Update

Rate for Selected

Parameters (Seconds

to next update value)

**Full Rate for

remaining parameters

(Seconds to next

update value)

ESP-2500

Standard

None

30

ESP-3500

Standard

None

35

ESP-2500/3500

Intake Pressure

ONLY

2.5

none

ESP-2500/3500

Intake Pressure

Intake Temperature

ONLY

4.5

none

ESP-2500/3500

Intake Pressure

Intake Temperature

Motor Temp

ONLY

6.5

none

ESP-2500

Intake Pressure

(All other parameters at Full

Rate)

4

60

ESP-2500

Intake Pressure

Intake Temperature

(All other parameters at Full

Rate)

6

72

ESP-2500

Intake Pressure

Intake Temperature

Motor Temp

(All other parameters at Full

Rate)

8

80

ESP-3500

Intake Pressure

(All other parameters at Full

Rate)

4

76

ESP-3500

Intake Pressure

Discharge Pressure

(All other parameters at Full

Rate)

6

126

ESP-3500

Intake Pressure

Discharge Pressure

Intake Temperature

(All other parameters at Full

Rate)

8

144

ESP-3500

Intake Pressure

Discharge Pressure

Intake Temperature

Motor Temperature

(All other parameters at Full

Rate)

10

150

Figure 14. ‘High Speed’ Data Rates

Doc. No. 006-0202-00 Rev AH 20

Figure 15. ‘High Speed’ Enabled Channel Display

Figure 16. ‘High Speed’ DataWorks Display

High-Speed Enabled

Channel shows ‘+HS’ in its

Column Header

This manual suits for next models

1

Table of contents

Other Sercel Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Vemer

Vemer ENERGY-400 D90 user manual

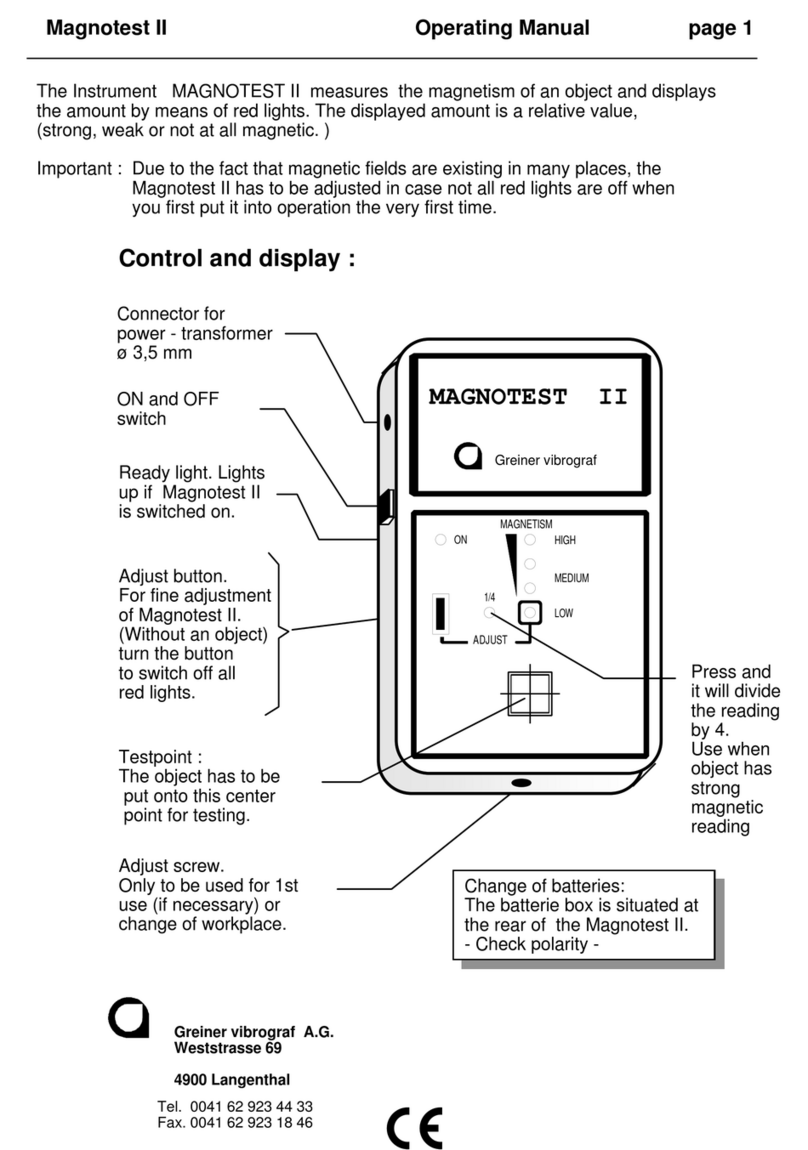

Greiner Vibrograf

Greiner Vibrograf Magnotest II operating manual

Agilent Technologies

Agilent Technologies U2722A user guide

Master Meter

Master Meter Allegro installation guide

ACS contsys

ACS contsys DAL-311x3x0S operating instructions

Hilti

Hilti pd-e Operating instruction