Seresco NE Series User manual

1

Seresco: (pronounced Sir-ES-co) meaning “to become dry”

Installation and Operation Manual

NE Series Dehumidifiers

For NE-004-016 Models:

PV, NV, PH and NH Configuration Natatorium Dehumidifiers

NC Series Outdoor Air-cooled Condensers

2

1-888- SERESCO (737-3726)

Additional copies of this manual can be downloaded from:

www.seresco.net

Seresco Technologies Incorporated

1283 Algoma Road, Unit 1

Kanata, Ontario,

K1B 3W7

CAUTION

ONLY TRAINED, QUALIFIED PERSONNEL SHOULD INSTALL AND/OR SERVICE SERESCO

EQUIPMENT. SERIOUS INJURY AND PROPERTY DAMAGE CAN RESULT FROM

IMPROPER INSTALLATION/SERVICE OF THIS EQUIPMENT. HIGH VOLTAGE ELECTRICAL

COMPONENTS AND REFRIGERANT UNDER PRESSURE ARE PRESENT

3

TABLE OF CONTENTS

1. Introduction ...................................................................………………...................…… 4

1.1 Packaged Mechanical Refrigeration Systems............................................….........…… 5

1.2 NE Series Dehumidifier features……..............................................….........…………… 6

2. Installation .................................................................................………….…………….. 7

2.1 Uncrating and Inspecting..................................................................................….…… 7

2.2 Mounting and Service Clearance………………………….........................................…… 7

2.3. High Voltage Electrical Connections ...................................................................…….. 8

2.3.1 Wire and Fuse Sizing.............................................................................…… 8

2.3.2 Line Voltage Connections.................................................................….…… 8

2.4. Control Wiring......……………………...................................................................……… 8

2.5. Controller and Programming....................……........................................................…… 9

2.5.1 Normal Mode and Programming……………........................................…….. 10

2.5.3 Logs…………….....................................……………………………………….. 11

2.5.5 Sensors and locations………….....................................…………………….. 12

2.6. System Design Overview….................................................................…………....……. 13

2.6.1 System duct design and air pattern ………...................................….......….. 13

2.6.2 Evaporation rate and latent loads…………...................................….......….. 14

2.6.3 Required Access Space……………………...................................….......…… 14

2.6.4 Exhaust Air……….........…………………………….........................…......…… 15

2.6.5 Supply Air flow…………………………….…...................................…......…… 15

2.6.6 Cooling and Heating loads…………………....................................…......……15

2.6.7 Outdoor Air……………………………………...................................…......…... 15

2.7. Condensate Drain ….........................................................………............................……16

2.8. Pool Water Heating (PH AND PV Models Only)…..................................……………….. 16

2.8.1 Water Flow Schedule …………................................................................…...16

2.8.1 Pool Water Piping Diagram ………...............................................……………17

2.9. Outdoor Air-cooled Condenser Installation......................…………...........................….. 18

2.9.1 Refrigerant Piping to Remote Condensers....……................................….. 18

2.9.2 Charging of Remote Condensers…......................………………………....…..19

3. Pool Water Chemistry ….................……………………..…...............……….............… 20

4. Start-up Procedures …...........................…………….....................………….........…….. 21

4.1. Pre Start-up …........................................................…………….................................…..21

4.2. Start-up Procedure ….............................................………........................................….. 21

4.3. System Operation Modes…..................................................................................……... 22

4.3.1 Power On………………………….….........................................................…...22

4.3.2 Dehumidification Mode…......................……………...................................…. 22

4.3.3 Air Conditioning Mode …....................................................……………….…..22

4.3.4 Pool Water Heating Mode (PH AND PV Models Only)…...........…………….. 22

4.3.5 Blower Operation….................................................………........................…. 22

4.3.6 Compressor Start Sequence…..........................................................….....….23

4.3.7 Air Heat Demand ….........................................................................….......….23

5. Service and Maintenance…................................................………………….……....... 23

5.1. Routine Maintenance….........................................................................………….......….23

5.2. Compressor Replacement…..................................................................................……. 23

6. Service References …………………………………………………………………………. 24

6.1. Nameplate …....................................................…………………................................…. 24

6.2. Mechanical System Trouble shooting….....................................................................…. 25

6.3. Microprocessor Trouble shooting…...........................................................................…. 27

6.4. Blower Adjustment Procedure…...................................................…………..............…. 28

6.5. Basic Unit Operation …...........................................................……………….……....…. 28

6.6. Factory Start-up Supervision…..…..........………….................................................…… 29

6.7. Warranty…………………….…..................................................…............................……30

6.8. Refrigeration Diagrams……………………….…....…..............….………………………… 32

6.9. Field Wiring Diagram…………………….…....…................….………………………… 33

6.10. Typical Electrical Panel Layout………..……………………..…......…..............…… 33

6.11. Warranty Registration and Start-up Report……………………..…......…..............…… 34

4

1. Natatorium: a facility that

contains an indoor pool,

whirlpool or spa ranging in size

from a small residential

installation to a large commercial

indoor waterpark.

Seresco’s Natatorium Dehumidifiers were

developed by a team of industry experts with a

lifetime of experience developed while working

with many thousands of indoor pools. A

natatorium has many critical design issues that

must be fully understood and properly addressed

to ensure years of comfortable and trouble free

operation of the facility.

This booklet contains valuable design guidelines

based on Seresco's extensive knowledge and

experience in solving humidity control problems

in many thousands of indoor pool installations.

Seresco Technologies Inc., manufacturer of the

NE Series of natatorium air quality control

systems is dedicated to providing state-of-the-art

features and design, quality engineering and the

most reliable products in the market.

The environment in a natatorium should be the

same as in any other room in a building:

comfortable and healthy for the occupants and

their activity, and provide good air quality. The

space conditions in a natatorium need to be

precisely maintained in order to maximize human

comfort and health as well as preserve building

integrity. Relative humidity, air temperature,

water temperature and air quality are all key

environmental aspects to control. High relative

humidity levels are not only a problem to bather

comfort and health, but can seriously damage the

building structure possibly leading to building

component failures. Revenues can also be

affected in commercial facilities. Several hotel

chains offer a full money-back guarantee should

the hotel guest have any complaint regarding

their stay.

A properly designed and maintained natatorium

delivers years of pleasure. The first step is to

become familiar with the design challenges and

to understand how to address them. A

Natatorium’s overall performance is inversely

proportional to the amount of compromises and

shortcuts taken in the design and construction of

the natatorium.

A Successful Facility. A natatorium is

one of the most notoriously difficult facilities to

design because there are so many critical

considerations that if overlooked develop into

problems with the building structure or complaints

from the occupants. The designer must take a

complete system approach, from basic

engineering issues to the more subtle details in

the air distribution. Experience and a complete

understanding of the design issues help the

designer satisfy:

Comfort and Health

Humidity Control

Indoor Air Quality

Condensation Control

Comfort and Health: Human comfort

levels are very sensitive to temperature and

relative humidity. It is essential that both are

controlled and stable. While temperature control

is generally well understood and mastered by

designers, it is important to recognize what

temperature levels natatorium patrons want. The

space temperatures in a natatorium are unique to

each project and assumptions must never be

made. Fluctuation of relative humidity levels can

be an even greater concern because it has a

direct effect on human comfort and health.

Figure 1 shows that relative humidity levels

outside the 40%- 60% range can result in

increased human susceptibility to disease from

bacteria, viruses, fungi and other contaminants

that reduce air quality and potentially lead to

respiratory problems.

Figure 1- Relative Humidity Effect on Health

Factors.

5

The type of facility being designed dictates the

space temperature. Table 1 helps target some

typical conditions. It is critical to understand who

will be using the facility in order to deliver the

conditions most likely to satisfy them.

Pool Type Air

Temperature, °F Water

Temperature, °F

Competition 78 to 85 76 to 82

Diving 80 to 85 84 to 88

Elderly Swimmers 84 to 85 85 to 90

Hotel 82 to 85 82 to 86

Physical Therapy 80 to 85 90 to 95

Recreational 82 to 85 80 to 85

Whirlpool/spa 80 to 85 102 to 104

Table 1 – Typical Natatorium Operating

Conditions

Indoor pools are normally maintained between 50

and 60% RH for two reasons:

Swimmers leaving the water feel chilly at lower

relative humidity levels due to evaporation off the

body and:

It is considerably more expensive (and

unnecessary) to maintain 40% RH instead of

50% RH.

General Notes:

Facilities with warmer water temperatures tend to

have warmer space temperatures.

Physical Therapy facilities will cater to therapist

comfort rather than the patient because they are

generally not in the space for more than an hour,

whereas the therapist is there all day. The

designer should consult local codes. Some

States require a full purge of the room air with

100% outdoor air for every hour of occupancy.

Elderly swimmers tend to prefer much warmer air

and water temperatures.

Humidity Control: High relative humidity

levels inside a building are well known for their

destructive effects on building structure and can

pose serious health concerns. Buildings with high

humidity levels are prone to condensation problems

that can destroy the building structure. They also

facilitate the growth of mold and mildew, which in

addition to being unsightly, can adversely impact

the air quality. Controlling humidity requires that a

total moisture load be accurately calculated. This

amount of moisture must be removed from the

space at the same rate it is generated to maintain

stable space conditions.

1.1 Packaged mechanical refrigeration

system. By far the most common and popular

method of removing moisture from the space, these

are packaged refrigeration units like those built by

Seresco. The units are designed and developed

specifically for dehumidifying indoor pools.

A major benefit of this approach is that both the

sensible and latent heat is combined with the heat

generated by the compressor’s power consumption

and can be directed to wherever heat may be

required in the natatorium. This process is unique in

the HVAC industry as is uses both the cooling and

heat rejection sides of the refrigeration cycle. The

system can be simultaneously dehumidifying

(cooling) the air and then reheating it (and/or the

pool water) to deliver dehumidified and reheated air

to the space, and warm water to the pool.

How it works. Figure 2 illustrates schematically

how warm humid air passes through the

dehumidifying coil and is cooled to below its dew

point. As a result moisture condenses out of the air.

Depending on the space temperature requirements

the hot gas from the compressor can be used to

reheat the air or reject its heat to an outdoor

condenser. Compressor hot gas can also be used

to heat the pool water.

Figure 2 Mechanical Refrigeration System.

Typical Operating Conditions:

Air On Evaporator: 84°F, 50% RH

Air Off Evaporator: 50°F

Suction Pressure: 65 PSIG

High Pressure: 220 PSIG

Superheat: 12-15 °F

Pool Water Heat: in 84°F- out 92°F

6

1.2 NE Series Dehumidifier

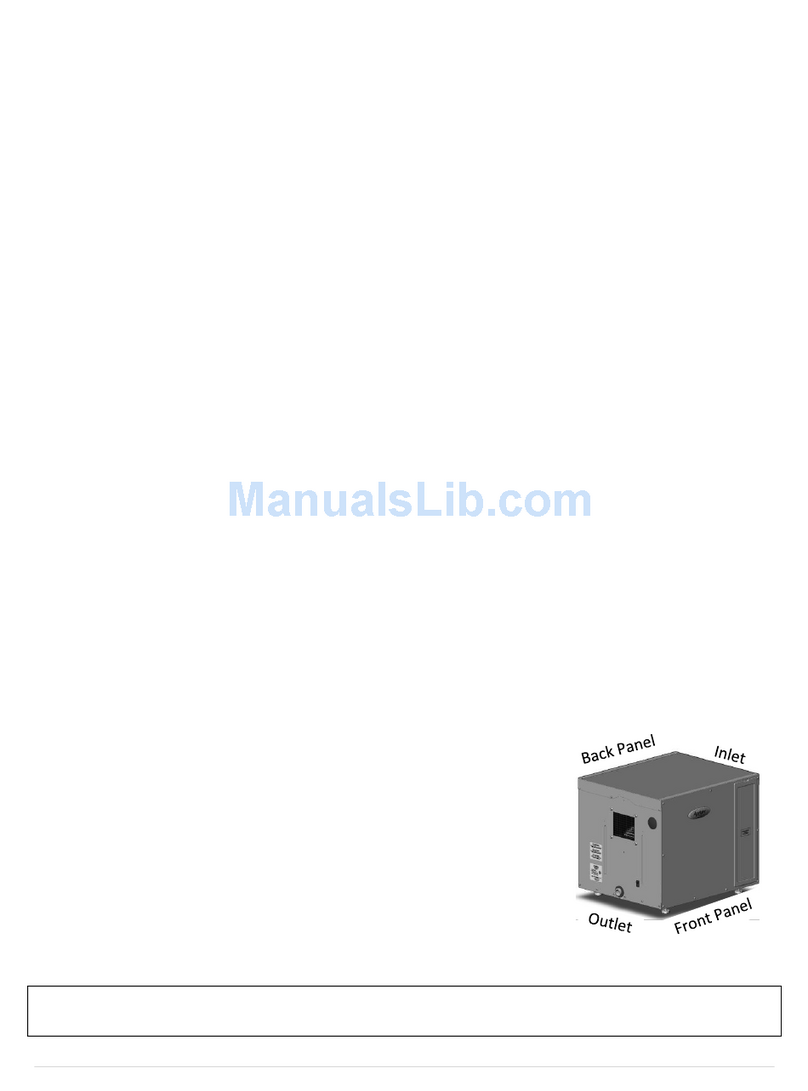

Features. Figure 3 identifies where several

major components are located within the NE Series

unit.

Figure 3 – NE Series Dehumidifier Major

Components

1 - Air Filters. The standard filter is a 2” pleated

30% efficient filter. 4” 95% filters are available on

certain models. Access to the filters is through a

service access door.

2 - Evaporator. The coil is corrosion protected to

ensure a long lifespan and designed to ensure

premium dehumidification performance. It is also

recessed into the cabinet allowing these units to

perform even if the duct connection is less than

perfect.

3 - Drain Pan. The drain pan has compound slopes

to ensure zero water retention.

4 - Reheat Coil. This corrosion protected

condenser coil is capable of rejecting 100% of

compressor heat to the air steam.

5 - Blower. Plug fans are standard on all units. The

backward inclined airfoil blower wheel provides high

static pressure with low motor power. This feature

helps ensure the NE unit will perform to

specifications even if the duct connections to the

unit or if the overall duct installation are less than

ideal.

6 - Compressors: The NE Series is equipped with

robust high-efficiency scroll compressors.

7 - Direct driven blowers: No belts to adjust or

maintain! The motor is even out of the air stream.

The NE Series uses Inverter Spike Resistant direct

driven blower motors. This blower drive design

simplifies unit maintenance and delivers the air

more efficiently.

8 - Electrical Panel. All electrical components and

connections are inside this panel.

9 - Receiver. The receivers have two sight glasses.

This facilitates the system charging process

10 - Pool Water Heater. This coaxial heat

exchanger is provided with the PH and PV models.

The water circuit is corrosion resistant cupro-nickel

pipe.

11 - Command Center. The Keypad and Display

panel has a backlit graphic Liquid Crystal Display

(LCD) and 7 system status LEDs.

12 - Evaporator Bypass Damper. The motorized

bypass damper is controlled by the Command

Center and it is used to ensure the evaporator is

always operating at optimum pressures.

13 - Outside Air Opening. Manual air balancing

dampers are provided and two-inch air filters.

14 - Cabinet: Seresco has taken all possible

commercially feasible precautions to protect the NE

Series units against the corrosion. The sheet metal

is galvanized automotive grade G-90 with both

sides painted.

15 - Refrigerant Pressure transducers. These

allow the user or serviceman to access the vital

information of refrigerant pressures through the

operator panel of the microprocessor rather than

having to connect a set of refrigerant manifold

gauges. This is the most important operation and

diagnostic data for any refrigeration system.

7

2. Installation

2.1 Uncrating and Inspecting

Seresco inspects and fully tests each

dehumidifier in all operating modes before it

ships from the factory. The unit can suffer

damage in transit. Check the equipment

thoroughly for both visible and concealed

damage before you sign the receiving papers.

Document any damage in writing on the

carrier’s bill of lading to ensure that damage

claims are handled promptly. If the unit has

been damaged, obtain a claim form from the

carrier. Promptly fill out and return the form,

and notify Seresco of any damage.

Damage claims or missing parts must

be filed with the freight carrier.

2.2. Mounting and Service Clearance

The NE Series dehumidifier continuously

removes a significant amount of moisture from

the room air. Some models have a pool water

heating option. Condensate lines and pool

water circuits can leak.

Do not install the unit in a location

where a water leak will cause damage.

The mechanical room where the unit is

installed should have a floor drain.

If there is no floor drain, a secondary pan

with a drain or condensate pump should be

installed under the entire unit. (as is done

with a residential washing machine)

Do not store pool chemicals in the same

room as the dehumidifier.

Install the unit on an appropriate mounting

base or a platform. Install industry standard

components that prevent vibration and sound

transmission. Never install the dehumidifier on

a wooden platform that can resonate. Do not

install the unit near occupied rooms such as

bedrooms. Never suspend from the floor joists

of an occupied room above the mechanical

room. Never locate the unit above a swimming

pool or a spa water surface.

Figures 5 & 6 illustrate typical unit mounting

configurations.

Ensure the support structure will not

interfere with the operation of or access to

unit.

No Access = no service or maintenance.

All NE series units have been designed to

require only two sides access.

Looking into the return duct connection allow a

minimum of 36 inches of clearance on the

right side (with the logo on it) and opposite

end of the NE series dehumidifier for piping,

duct connections, and service access.

Figure 5 – Typical Floor

Installation

Figure 6 – Typical Suspended Installation

DO NOT install a standard indoor

dehumidifier in an unconditioned space or

where ambient temperatures can fall below

45°F or climb above 90°F. If such a space is

being considered, Seresco offers outdoor-

rated dehumidifiers with weatherproofing and

thicker insulation.

8

2.3. High Voltage Electrical

Connections

The installing contractor must ensure

that all electrical wiring satisfies all

National, State and Local codes.

2.3.1 Wire and Fuse Sizing

The field-installed power supply wires and

over current devices must be sized to

handle the minimum ampacity of the

dehumidifier without exceeding the

maximum fuse size rating. Both the MCA

and MOP are indicated on the unit

nameplate.

Improper wiring to the dehumidifier

could create the possibility of

shock and may lead to system

failure.

2.3.2 Line Voltage Connections

Figure 7 shows typical power wiring

connections. Single-phase units power

supply must have 3 wires (2 power, 1

ground). On three phase units the power

supply must have 4 wires (3 power, 1

ground). Connect the power supply wires

to the main power block located inside the

electrical panel.

Always check the nameplate voltage before

connecting to the unit.

Figure 7 – Power Wire Connection

2.4. Control Wiring

The NE Series dehumidifiers have all necessary

sensors unit mounted and set points pre-

programmed at the factory. Remote duct heaters,

outdoor air-cooled condensers, auxiliary pool water

heaters and remote exhaust fans all require

interfacing with the dehumidifier. Their connection

terminals are identified on page 33

The microprocessor has been programmed to

control their operation. Figure 8 illustrates how an

Ethernet connection to the Internet allows all

functions to be monitored by trained professionals

with Seresco’s Websentry. It is the final step to

ensure the facility operates trouble free.

Figure 8 – Control Wiring

9

2.5 Controller, Programming and

Sensors

The NE Series Command Center (Figure 9) is

the brains behind the NE Series

Dehumidification System. The Command

Center is composed of a microcontroller

system, an LCD display and keypad, an

Ethernet interface, and WebSentry – a web

browser based remote interface tool for

monitoring and controlling NE Series systems

from anywhere in the world via the internet

Figure 9 – Command Center

The keyboard/display panel is shown in Figure

9 and is located on the NE Series unit at the

mechanical compartment access. The LCD

display has a built-in backlight for easy

reading in low light conditions.

The keys have the following functions:

1, 2, 3 Correspond to numbered selections

4, 5, 6 (menu items and parameters) on the

screen (eg. 1-Menu, press 1for the

main menu)

Back Allows you to return to the previous

menu or cancel a parameter change.

Used for viewing additional

menus, alarms or operating

data and for changing

parameters on the screen such as

setpoints.

Enter Press to save changes to

parameters and (optionally) press

again to return to the main sensor

screen.

There are 7 LEDs as shown and their function

is as follows:

Alarm Solid Red indicates an active alarm

(that has not yet been cleared). A

Flashing Red indicates an alarm that

has not been acknowledged yet.

Dehum Solid Green indicates system is in

dehumidification mode. Compressor

will run when anti-short cycle timer is

satisfied.

A/C Solid Green indicates system is

in air-conditioning mode. Compressor

will run when anti-short cycle timer is

satisfied.

Pool Solid Green indicates that pool

heating is on. If Dehum or A/C is also

on, then heating is by the NE Series

unit. If Dehum and A/C are off,

auxiliary heating is energized.

Heat Solid Green indicates that the

auxiliary air heating system is on.

Filter Solid Yellow indicates that the air

filters are dirty and need changing

(optional only).

Service Solid Yellow indicates that the NE

Series unit is in Service Mode.

Flashing Yellow indicates that the

blower or compressor have been

manually disabled (when not in

Service Mode).

There are two main modes of operation for the

NE Series Units: “Normal Mode” and “Service

Mode”. In normal mode, the user can view

sensor information, view unit operating status,

change setpoints (password protected), adjust

the occupied/unoccupied schedule (password

protected), and view alarms and warnings.

The system operates automatically.

In Service Mode, the trained technician has

access to special features to aid in system

commissioning and troubleshooting, including

Ethernet network access test utilities.

The system operates under manual control.

10

2.5.1 Normal Mode:

Menus and selections are accessed using the “1-6” numbered keys – each menu item and

parameter is preceded by a number from 1 to 6. When the scroll keys can be used to access

additional menu items they will appear on the screen (and ). The same scroll keys are used to

change values after a parameter has been selected.

A User Password is required to view/change setpoints and schedules. Passwords are 3 digits

long, and entry is done using the scroll keys (and ) to change the 1st digit to the correct

password value – then press Enter to accept that digit and move on to the 2nd digit, repeat for the

3rd digit. The User password is supplied to the customer under separate cover.

From the main screen, which shows sensor readings, press 1 (-Menu) to open the main menu

structure below. From any menu level, the Back button will return to the previous menu

level without making any changes. Note that some menu items are only visible if the unit

has been configured with that option:

Setpoint

Temperature Room temperature setpoint

Humidity Room relative humidity setpoint

Pool Temp Pool water temperature setpoint

Economizer Outdoor air temperature below which economizer not used

Freezestat Supply air temperature below which Freezestat alarm trips

Purge Supply air temperature below which Purge will stop

Heat Recovery Outdoor air temperature below which heat recovery starts

Schedule Sets occupied/unoccupied state for ventilation control

Time Slot 1-6 There are 6 available time slots that can be established

Weekday None/All/Weekday/Weekend/Monday to Sunday selection

On Time at which occupied status and ventilation begins

Off Time at which unoccupied status begins, ventilation stops

System

Blower/Compressor Enabling/disabling blower and compressor operation

Purge Starts/stops purge 100% ventilation operation

System Restart Manual reset

Alarm Log View Alarms

System Status See Section 2.5.4

System Summary Summary of system configurations

User Settings

Display

Backlight Turn backlight on or off

Reset Display Idle time before display reverts to the main sensor screen

Short Message Time for which short information messages remain visible

Long Message Time for which long information messages remain visible

System Clock

Date Set the date

Time Set the time

Zone Set the time zone

Daylight Set daylight savings on or off manually

Date Format Format the date on the screen

Time Format Format the time on the screen

Synch Synchronize with internet time server (when connected)

User Password

Enabled Enable/disable user password control

Password Change user password

Retention Set time for which password entry remains valid

Factory Settings

Service Mode

Figure 10 Command Center Quick Menu

11

2.5.2 Service Mode

From the Startup Menu there is a Service

Mode available for factory trained service

technicians. Please contact factory for

additional information.

2.5.3 Logs

The CommandCenter logs alarm messages

which can be accessed from the

LCD/Keypad.

Alarm messages are as follows:

HP# -NN High pressure trip (# indicates

compressor, NN can be SW

or TD indicating switch or

transducer alarm)

LP# -NN Low pressure trip (# indicates

compressor, NN can be SW

or TD indicating switch or

transducer alarm)

Blower OL Blower overload trip

No Air Airflow alarm, air pressure

switch (optional) reading too

low air pressure differential

Fire Firestat signal active

Waterflow Low water flow, controls have

detected pool water out

temperature is too high

Filter Dirty filter, filter switch

(optional) reading a high

pressure differential

Pumpdown Compressor pumpdown timed

out (no LP switch detected)

Freeze Freezestat

Purge Supply air too cold during

purge, purge shut down

Volt Mon Voltage monitor

Oil # Oil failure (# indicates

compressor)

No Config System not configured at

startup (only needs to be

done once)

Restart Manual Reset required to start

normal operation

SW Error System has detected an

internal error – contact factory

CompPower Indicates that compressor has

been manually disabled

through an external switch for

an extended period of time

SensorNNN Indicates sensor fault where

NNN identifies the sensor

2.5.4 System Status

The CommandCenter has a feature which

will provide more detailed information about

the internal operation of the system, which

can assist an owner or service technician in

understanding his NE Series unit is doing at

any given moment.

This feature is accessed through the menu

system at /Main Menu/System/System

Status.

The various system elements are broken

into three main groups:

Environment Related to air relative

humidity and temperature

control, pool heating control

Compressor Related to the operation of

the compressors

Other Related to miscellaneous

system operations

Selecting the Compressor elements takes

you to a screen showing the compressor

status, and also which solenoid valves and

contactors are energized. The solenoid

valves and contactors are coded as follows:

PW Compressor contactor

PD Pumpdown valve

DH Dehumidification (reheat) valve

AC Air conditioning valve

PH Pool water heating valve

PB Pool water heating bypass valve

12

2.5.5 Sensors and location.

Figures 11 & 12 identify where the sensors are

located in the NE Series units. Each sensor is

accessible through the Command Center or Web

Sentry. Sensor history is stored and can be

reviewed in tabular form.

All Sensors can be calibrated in service mode.

Figure 11 – Sensor location in a Vertical unit

Sensors:

Room air temperature

Room air humidity

Pool water entering temperature

Pool water leaving temperature

Outside air temperature

Air temperature leaving the evaporator

Supply air temperature

Compressor hot gas discharge temperature

Compressor suction gas temperature

Refrigerant Pressure Transducers:

Refrigerant High pressure

Refrigerant Suction pressure

These allow the user or serviceman to access the

vital refrigerant pressures through the operator

panel of the microprocessor rather than having to

connect a set of refrigerant manifold gauges.

Figure 12 – Sensor location in a Horizontal unit

13

2.6. System Design Checklist. Ensuring

that all critical system design aspects have been

addressed is paramount to obtaining a safe and

healthy pool environment. Seresco’s name is a

useful checklist.

System duct design and air

pattern

Evaporation rate and latent

loads

Required Access Space

Exhaust Air

Supply Air flow

Cooling and Heating loads

Outdoor Air

2.6.1 System Duct Design and Air

Pattern

The overall duct design will determine whether or

not the space will be comfortable and

condensation free. Special care must be taken to

ensure the entire room sees the required air

changes per hour and that all

exterior windows have air delivered to them.

Stagnant areas, especially where occupants can

access (the deck area for example) will suffer

from poor air quality and lead to complaints.

Traditional problems in indoor pools are easily

predictable and can be avoided by following to

models provided here. Figures 13 & 14 illustrate

good air distribution practices and layouts.

All air distribution systems should:

Supply 4-6 volumetric air changes per hour.

Blanket exterior windows, exterior surfaces

prone and other areas prone to

condensation with supply air. A good rule of

thumb is 3 - 5 CFM per ft² of exterior glass.

Locate the return grille to enhance the

overall air pattern within the room.

Prevent air short-circuiting. Avoid installing

the return air grille too close to a supply

grille.

Select grilles, registers and diffusers that

deliver the required throw distance, and the

specified CFM rating.

Introduced outdoor air per local codes and/or

ASHRAE Standards

Maintain a negative pressure in the space

with an exhaust fan.

Figure 13 – Perimeter Duct Layout

14

Figure 14 – Perimeter Below Grade Duct Layout

General Recommendations:

Galvanized sheet metal ducts are

acceptable in most installations. A

below-grade duct system should use

PVC or plastic-coated galvanized spiral

pipe to avoid deterioration.

Ductwork that passes through an

unconditioned area should be insulated

on the exterior.

When applicable, locate exhaust fan

air intakes as close to the whirlpool as

possible.

To prevent excessive vibration noise,

install neoprene flex connectors when

attaching ductwork to the

dehumidifier.

Skylights require significant airflow to

avoid condensation on their surfaces.

2.6.2 Evaporation and Latent Loads

Every building’s moisture (latent) load is

calculated in the same way. There are

generally three sources of moisture that are

considered:

Internal load; evaporation rate

Occupants

Outdoor air load

It is important to be aware of the design criteria

used to calculate the total load and reconcile a

unit selection. Seresco’s Natatorium Design

Manual has more information on this subject.

2.6.3 Required Access Space

Access Space

No Access = no service or maintenance.

All NE series dehumidifiers have been

designed to require only two sides access.

Allow a minimum of 36 inches of clearance

on the sides indicated in Figure 15 for piping

and service access. Mirror access units are

also available.

Figure 15 – Recommended Access Space

15

2.6.4 Exhaust Air. ASHRAE recommends

the room be maintained at 0.05-0.15” WC

negative pressure relative to surrounding spaces.

Ten percent more exhaust air than

outdoor air is a good

rule of thumb.

Figure 16 illustrates how the location of the

exhaust fan can also significantly improve the air

quality in the space. A spa or whirlpool should

have the exhaust air intake grille located directly

above it. This extracts the highest concentration

of pollutants before it can diffuse into the space

and negatively impact the room air quality.

Figure 16 – Exhaust Air Intake recommendation

2.6.5 Supply Air. ASHRAE

recommendations for proper volumetric air

changes per hour are important to ensuring that

an entire room will see air movement. Stagnant

areas must be avoided, as they will be prone to

condensation and air quality problems.

Short-circuiting between supply and return air

must also be avoided as it significantly reduces

the actual air changes within the space.

ASHRAE recommends:

4-6 volumetric air changes per hour in a

regular natatorium.

6-8 volumetric air changes per hour in

facilities with spectators

A quick calculation will determine the supply air

requirement. Nominal air flows from NE series

units are summarized in Table 3.

Supply air required (CFM) = [room volume (ft³) x

desired air changes] / 60

Model 1.0” ESP

004 2000

005 2500

006 3000

007 3400

008 3800

010 4600

012 5600

014 6400

Table 3. Nominal Air Flow Rates (CFM)

2.6.6 Cooling and Heating Loads. All

buildings should have cooling and heating load

calculations done to determine their specific

requirements. The room air temperature of an

indoor pool facility is generally 10-15 ºF warmer

than a typical occupied space. Therefore, the

heating requirement is larger than a traditional

room and the cooling needs are less.

Rules of thumb do not apply. This is a

unique space that requires accurate load

calculations.

Outdoor air must be included in load

calculations as it often represents up to 50%

of the heating load.

Space cooling is a free byproduct from packaged

dehumidifiers. These systems dehumidify by

cooling the air below its dew point. The

compressor heat can be used to heat the pool

water during this time or merely sent outdoors to

a condenser as is done with traditional air

conditioning systems. If the cooling load exceeds

the standard output of a dehumidification unit, a

larger unit with compressor staging is often

specified.

2.6.7 Outdoor Air. The introduction of

outdoor air is essential to maintaining good air

quality in any facility. The impact of outdoor air

ventilation on a natatorium changes with the

weather. Introducing outdoor air during the

summer adds moisture to the space and in the

winter removes moisture from the space. For

maximum dehumidification load calculation the

Summer Design conditions are considered.

Ventilation codes generally require that outdoor

air be introduced into a commercial building

during occupied hours. ASHRAE Standard 62-

1999 recommends the introduction of outdoor air

into a natatorium at the following rates:

0.5 CFM/ft² of pool and (wet) deck area

15 CFM per spectator.

Most designers use the larger of

the two values.

Seresco suggests that only the wet deck (a 5-6’

perimeter) be considered in this calculation, as

the purpose of this outdoor air is to help dilute

chemicals off-gassed from water. A predictably

16

dry portion of the deck will not factor into the IAQ

issues.

The NE Series units have an outdoor air opening

with a filter and manual balancing damper.

Optional unit mounted motorized dampers and

time clocks are available. Figure 17 illustrates a

typical connection configuration.

Figure 17 – Outdoor Air Duct Detail

Outdoor air requires considerable heating in

the winter and can add significant moisture

in the summer. Exceeding code

requirements is not recommended as it will

increase the operating expenses and may

increase the size of the dehumidifier.

Locate the outdoor air intake away from any

sources of airborne contamination such as

exhaust fans or plumbing vents.

If more than 20% of the total airflow is

outdoor air or if the winter design

temperature is below 10ºF: The outdoor air

must be preheated to 65ºF.

If outdoor air is introduced into the return

duct: it must be preheated to the space

temperature.

2.7. Condensate Drain. The dehumidifier is

a draw through configuration as a result the

Figure 18 – P Trap

entire cabinet is under negative pressure.

Without a trap, condensate will not drain and the

unit will overflow into your mechanical room.

Per Figure 18 pitch the condensate drain line

a minimum of 1/8” per linear foot, and

support the pipe with code-approved

hangers at least every 5 feet.

If the drain line passes through an

unconditioned space, heat tracing is required

to prevent the condensate in the drain from

freezing.

When gravity disposal is not possible, a

condensate pump can be used. Follow the

pump manufacturer’s installation

instructions.

2.8. Pool Water Heating (PH and PV

Models Only). The energy a pool loses

through evaporation represents approximately

90% of its annual water-heating requirement. The

Seresco unit captures 100% of this heat as a by-

product of the dehumidification process and can

return this energy back to the pool, thereby

greatly reducing pool water heating costs. During

the cooling season the dehumidifier is capable of

providing 100% of the pool’s water-heating

requirement. Refer to Figure 18 for proper pool

water piping connections to the NE Series unit.

2.8.1 Water Piping Connections. The NE

unit requires only a fraction of the total water

being circulated by the main filter system. Refer

to Table 4 or the unit nameplate for nominal

water flow rates.

The water circuit should tap off the main pool

water line downstream of the main filter and

upstream of the auxiliary pool water heater

and chemical feeder.

Install an auxiliary water pump to deliver the

unit’s required water flow. It is an open

system and the pool’s main circulating pump

can rarely accommodate additional system

pressure.

All systems require auxiliary pool water

heaters. The Seresco unit will control

their operation when it is not able to

provide water heating.

Max Water Flow Rates (GPM) &

Pressure Drop (PSI)

Model GPM PSI

004 6 6

005 8 4

006 12 5

007 12 6

008 16 4

010 18 6

012 22 6

014 25 6

Table 4. Unit GPM Schedule

17

Figure 19 – Proper Pool Water Piping Installation

18

2.9. Outdoor Air Cooled Condenser

Installation.

This condenser is used in air conditioning mode

where it rejects unneeded heat from the space to

outdoors. Proper installation is essential to

ensure it can function as intended. Proper airflow

and refrigerant piping are paramount.

Ensure an appropriate maximum ambient air

temperature has been specified.

Ensure the unit has proper airflow per Figure

20. A perimeter of free area equal to its width

must be provided.

Use line sizes as specified by Seresco.

To avoid potential seasonal system charge

problems, ensure the installed line lengths

are never longer than indicated on the plans

and specifications.

If the condenser is installed above the

dehumidifier, ensure the hot gas line has

proper oil traps.

Contact Seresco if the condenser is installed

more than eight (8) feet below the

dehumidifier.

The installer must endeavor to ensure that

all industry standards for refrigeration

component installation are met. This

includes but is not limited to; proper line

sizing, materials, nitrogen purging, brazing

with Silfos 5 or better (NO SOFT SOLDER),

evacuation, cleanliness, traps, long radius

elbows and system charging.

Install the remote condenser on a level, hard

surface.

2.9.1 Refrigerant Piping of Remote

Condensers

1.NE series dehumidifiers are equipped

with isolation valves and access valves

located in the blower compartment. Do

not open the isolation valves until all

exterior piping is leak checked and

evacuated. The last outdoor condenser

vacuum can be broken with liquid R-22.

Monitor the exact amount of R-22

added, as the total system charge must

be per the unit nameplate.

2.NE series dehumidifiers have refrigerant

pipe stubs for the line set connection

inside the cabinet.

3.Use standard commercial refrigeration

piping practices when installing the

refrigeration piping between the

dehumidifier and the remote air-cooled

condenser.

oHot Gas and Liquid line sizes should

be per unit nameplate. The stubs

inside the NE unit will be the correct

sizes for line lengths up to 50’.

Figure 20 – Typical Outdoor Condenser

Installation

oDo not exceed 50’ total line length or

install the condenser more than 8’

below the NE unit.

oPer figure 21, install an oil trap at the

start of and at every 15 feet of vertical

lift in the hot gas discharge line as

shown in Figure 18. Pitch horizontal

lines a minimum of 1/2” every 5 feet in

the direction of flow. All piping must be

clean and de-burred. Keep copper

chips and foreign materials out of the

tubing. A nitrogen purge while brazing

is paramount to reduce the chances of

oxidation in the pipes.

oKeep the Hot Gas and Liquid lines a

minimum of 2” apart to prevent heat

transfer. Insulate the hot gas line in all

areas where a person may come in

contact with the line and be in danger

of a burn.

oWhen all piping work is complete,

check for leaks by pressurizing the

remote condenser and line set with

dry nitrogen. If no leaks are detected,

the circuit is ready to be evacuated.

Evacuate the condenser and piping to

a minimum 250 microns. Isolate the

piping for ONE HOUR to verify that

the system is free from leaks,

moisture, and non-condensables.

Consult Seresco before installing the

outdoor air-cooled condenser

more then 8 feet below or more than

50 feet away from the dehumidifier.

19

Figure 21 – Typical Outdoor Condenser Installation

NE

Model

Factory

Charge

(Lbs)

50’ line

contractor

charge

(Lbs)

Factory

Oil

Charge

(Oz)

004 25 17 9

005 27 28 12

006 27 29 12

007 28 32 14

008 44 32 15

010 48 48 20

012 51 62 29

014 61 77 35

Table 5 - R-22 and Oil Charges

2.9.2 Charging of Remote Condensers

Once a proper evacuation has been

accomplished the system is ready for

charging. The outdoor air-cooled condenser

requires a field charge by the installing

contractor. The field charge required

depends on the size of the condenser and

the length of the piping. The unit nameplate

will show the exact field charge required.

Refer to Table 5 to determine the necessary

charge for your application.

1. The last vacuum can be broken with

liquid R-22. Monitor the exact amount of

R-22 added, as the total system charge

must be per the unit nameplate.

2. Connect the control wiring to the

terminals provided inside the electrical

compartment of the dehumidifier and

outdoor condenser. Refer to the low

voltage wiring schematic for details. The

condenser fan(s) will not operate until

this is complete.

3. Once you have charged and checked

the condenser and line set for leaks,

open the service valves located in the

compressor compartment of the

dehumidifier.

20

4. There is an access valve in the liquid

line after the pump down valve. The

pump down valve can be manually

closed during start-up mode via the

controller. Add only as much refrigerant

as is needed to get to the total charge

indicated on the nameplate.Never

charge liquid into the suction line

access valve!

5. The receiver has 2 sight glasses with

float balls to help ensure the maximum

and minimum refrigerant levels are

easily met.

3.0 Pool Water Chemistry. Pool water

quality directly affects space air quality, lifespan

and performance of the mechanical equipment.

Poor water chemistry is the single

biggest cause of indoor air quality

(IAQ) and corrosion problems in a

Natatorium.

Table 6 shows the National Spa and Pool

Institute recommended levels for water quality.

3.1 Chlorine smell in the pool area. The

chlorine smell that is often associated with indoor

pools is not actually the smell of excess chlorine

in the water but of that of off-gassed Combined

Chlorines. Combined Chlorines are a product of

insufficient free chlorine and can result in high

levels of bacteria and algae in the pool water.

Maintaining proper free chlorine levels will help

eliminate the foul odors.

The proper amount of outdoor air and exhaust air

to and from the space is also crucial to ensuring

chemical concentration levels are maintained

within acceptable levels.

The powerful chlorine smell that is

often associated with indoor

pools is NOT the result of too

much free chlorine in the water; it

is TOO LITTLE free chlorine that is

the culprit!

3.2 Filtration. Elevated concentrations of

biological waste and dissolved solids in water

have been shown to directly contribute to high

combined chlorine (chloramine) levels. It is

important to provide adequate water exchange

rates as well as proper treatment and filtration to

prevent any build up of these undesirable

components.

3.3 pH Level. High pH allows for scale formation,

which reduces pool water heater efficiency. Low

pH levels (acidic) are corrosive and may damage

the metal parts in pumps, water heaters and

piping. Maintaining pH levels between 7.2 and

7.6 are vital for the longest possible life for the

pool equipment.

Table 6 lists the NSPI recommended levels of

each.

Pools

Desirable Range

pH 7.4 – 7.6

Alkalinity 80 – 100 PPM

Free

Chlorine 2.0 – 3.0 PPM

Combined

Chlorine 0 PPM

Dissolved

Solids 100 – 300 PPM

Total

Hardness 225 – 250 PPM

Table 6 - National Spa and Pool Institute

Recommended Levels for Water Quality

3.4 Corrosion. The deterioration of the pool

building and equipment can result from poor

water chemistry. A well balanced pool with proper

water treatment and sufficient outdoor air/exhaust

air dilution offers an environment that will not

affect the health of the users or cause damage to

mechanical equipment or the structure.

Local codes generally require a separate,

ventilated space MUST be provided to store

pool chemicals.

DO NOT STORE POOL CHEMICALS IN THE

MECHANICAL EQUIPMENT ROOM!

Seresco has taken all possible commercially

feasible precautions to protect the NE Series

units against the corrosion caused by

accidentally high chemical levels. The equipment,

materials and paints are all resistant to airborne

chemicals for a short period of time.

Other manuals for NE Series

2

Table of contents

Other Seresco Dehumidifier manuals

Popular Dehumidifier manuals by other brands

Fortress Technologies

Fortress Technologies FDH1214 user manual

DEVOLA

DEVOLA DVM550ML instruction manual

SMC Networks

SMC Networks IDF22E-20-A Operation manual

Aprilaire

Aprilaire 1710A troubleshooting manual

Cooper & Hunter

Cooper & Hunter CH-D008WD5 owner's manual

Pro Breeze

Pro Breeze PB-08 instruction manual