1www.danvex.

SAVE THIS MANUAL FOR FUTURE REFERENCE

CONTENT

Introduction ............................................................................................................................................................3

Purpose .............................................................................................................................................................3

Content .............................................................................................................................................................3

Copyright .........................................................................................................................................................3

1.

SAFETY AND APPLICATION .........................................................................................................................4

1.1 Safety of use ............................................................................................................................................4

1.2 Applications .............................................................................................................................................5

2 DEVICE INFORMATION ..................................................................................................................................6

2.1 Standards ..................................................................................................................................................6

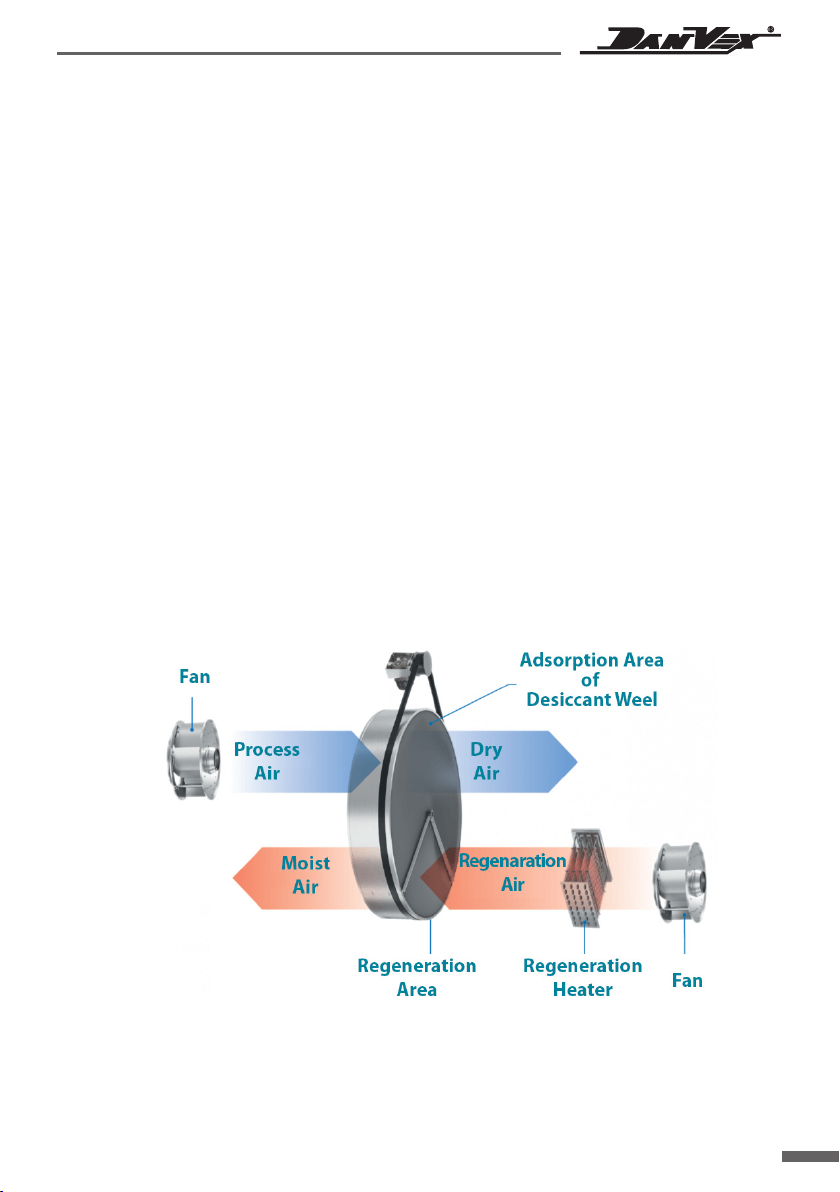

2.2 How it works ............................................................................................................................................6

2.3 Construction ............................................................................................................................................7

2.3.1 Enclosure ................................................................................................................................................7

2.3.2 Conveying air circuit ..........................................................................................................................7

2.3.3 Regeneration air circuit .....................................................................................................................7

2.3.4 Rotor ........................................................................................................................................................7

2.3.5 Rotor drive .............................................................................................................................................7

2.3.6 Safety devices .......................................................................................................................................7

3 INSTALLATION .................................................................................................................................................8

3.1 Introduction ..............................................................................................................................................8

3.2 Transport and storage ...........................................................................................................................8

3.3 Checking before installation ...............................................................................................................8

3.4 Moving ........................................................................................................................................................8

3.5 Place of installation and its arrangement ......................................................................................8

3.6 Support/ Foundation .............................................................................................................................8

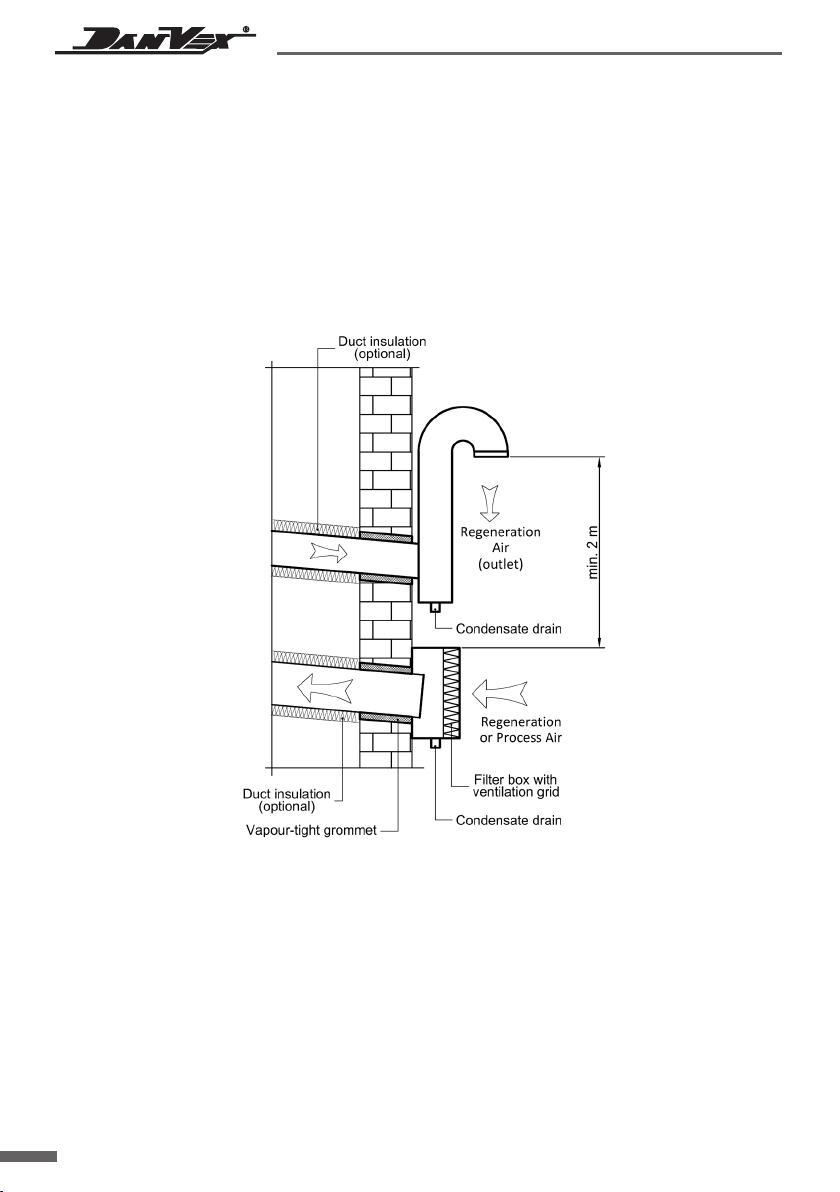

3.7 Connecting to air ducts .........................................................................................................................8

3.8 Electrical connection .............................................................................................................................12

3.9 Connecting external humidity sensors ...........................................................................................12

3.10 Checking before starting ...................................................................................................................13