serva Blue Series User manual

BlueLine

Instruments for Electrophoresis

INSTRUCTION MANUAL

___________________________________________________________________

HPE™ BlueHorizon

Flatbed Electrophoresis System

(Cat. No.: HPE-BH)

SERVA Electrophoresis GmbH Carl-Benz-Str. 7 D-69115 Heidelberg

Phone +49-6221-138400, Fax +49-6221-1384010

e-mail: info@serva.de http://www.serva.de

DOMINIQUE DUTSCHER SAS

1

DOMINIQUE DUTSCHER SAS

2

Content

1 Safety ................................................................................................................... 3

2 Introduction .......................................................................................................... 4

3 Installation ............................................................................................................ 5

4 Operation ............................................................................................................. 6

4.1 Adjust the electrodes ..................................................................................... 6

4.2 Apply a gel ..................................................................................................... 6

4.3 Prepare Electrode Wicks ............................................................................... 7

4.3.1 SDS Gel Kit, CleanGel, HPE Gel ............................................................ 7

4.3.2 PreCotes, PreNets, CleanGel IEF ........................................................... 8

4.3.3 FocusGel................................................................................................. 8

4.4 Sample preparation and loading .................................................................... 8

4.4.1 SDS Gel Kit ............................................................................................. 8

4.4.2 CleanGel ................................................................................................. 8

4.4.3 HPE Gel .................................................................................................. 8

4.4.4 PreCotes, PreNets ................................................................................ 10

4.4.5 CleanGel IEF ........................................................................................ 10

4.4.6 FocusGel............................................................................................... 10

4.5 Start the run ................................................................................................. 11

4.6 After the run ................................................................................................. 12

5 Maintenance ...................................................................................................... 13

5.1 Cleaning ...................................................................................................... 13

6 Technical data .................................................................................................... 14

7 Explanations ...................................................................................................... 14

8 Trouble Shooting ................................................................................................ 15

9 Addendum: Example Applications ..................................................................... 19

10 Pack List and Order Information ........................................................................ 20

Vers. 01/14

DOMINIQUE DUTSCHER SAS

3

1 Safety

The SERVA HPETM BlueHorizon comply with the standards and directives mentioned

in the applicable CE declaration.

Please take note of the following safety measures:

Warning: Operation of this instrument requires high voltage.

Disconnect the high voltage external power supply before opening

any drawer.

Turn off and disconnect any high voltage power supply before

opening the safety lid.

Disconnect the high voltage external power supply and the AC

main supply before cleaning or servicing.

Do not spill or store liquids on top of the unit.

If liquid is spilled into the HPETM BlueHorizon, disconnect the high

voltage power supply and the AC main power immediately before

opening the safety enclosure lid.

Do not operate or connect power sources to the equipment if

there is any mechanical damage.

The supplied DC cables are rated for 5,000V. Only use cables

and adaptors supplied with the HPETM BlueHorizon or ensure that

these have a suitable DC insulation compliance for the used

voltages.

DOMINIQUE DUTSCHER SAS

4

2 Introduction

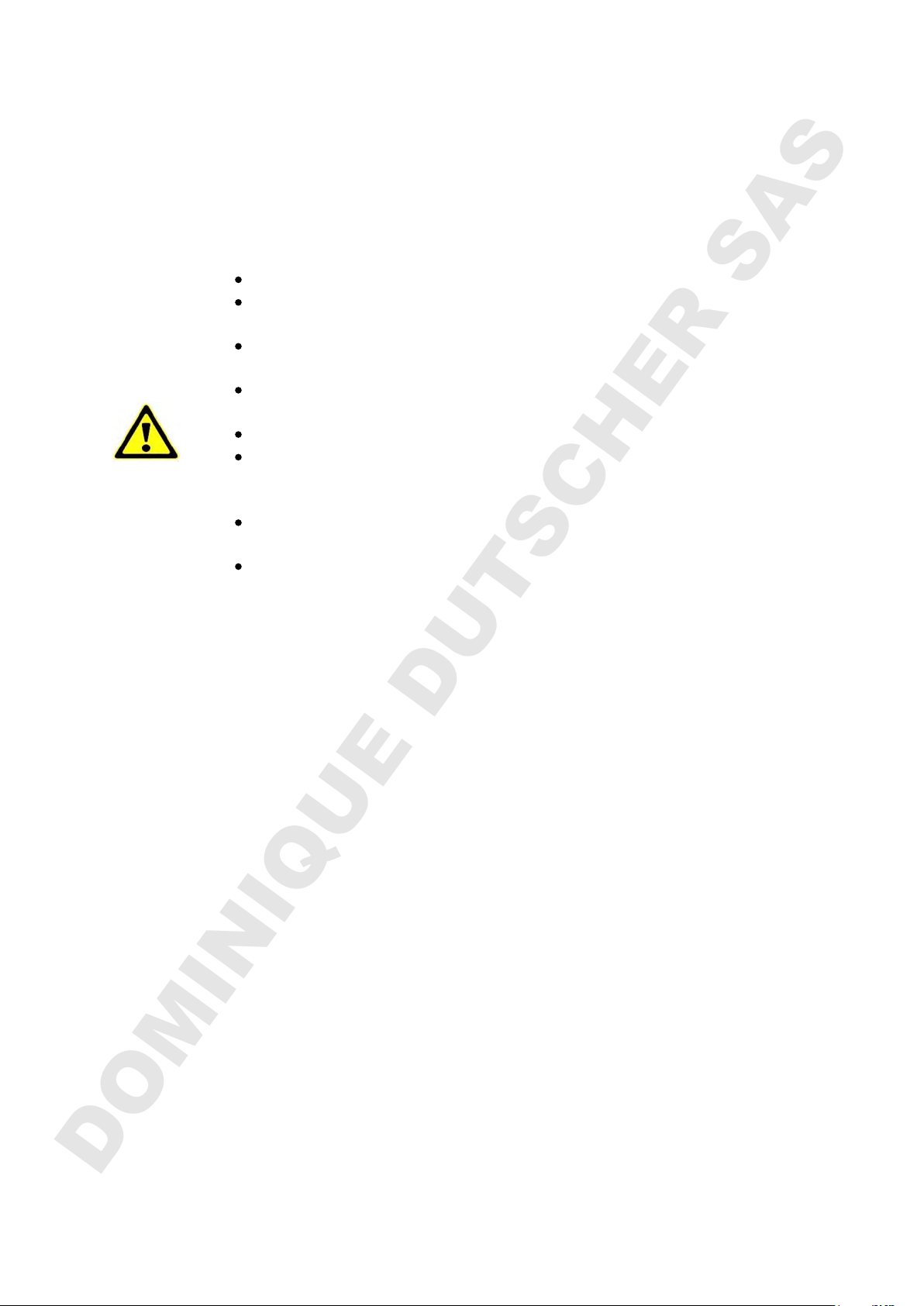

The HPETM BlueHorizon is a flatbed system for horizontal electrophoresis. Main

applications are isoelectric focusing (IEF), 2D PAGE, SDS PAGE and the separation

of nucleic acids in polyacrylamide gels.

The stable and easy-to-clean metal housing allows a space-saving positioning of the

power supply on top. The system is cost-saving, because it works without buffer

chambers. Instead, fabric wicks are soaked with concentrated electrophoresis

buffers.

The integrated drawer holds the cooling plate that is connected to the SERVA HPE™

Cooling Unit (cat. no. HPE-CU1). The cooling plate is made from a special ceramic

material (maximum gel size 260 x 205 mm) for efficient heat conductance down to 4

°C resulting in rapid and straight migration and therefore highly focused spots and

bands.

The electrode lid comes with one pair of platinum electrodes. They can be installed to

three electrode positions serving a wide variety of different gel sizes. A lid with triple

electrodes for bi-directional electrophoresis is available optional.

With the drawer / lid arrangement, the plastic-backed gels are protected from dust

and light during the run to avoid photo-bleaching of fluorescent labels.

DOMINIQUE DUTSCHER SAS

5

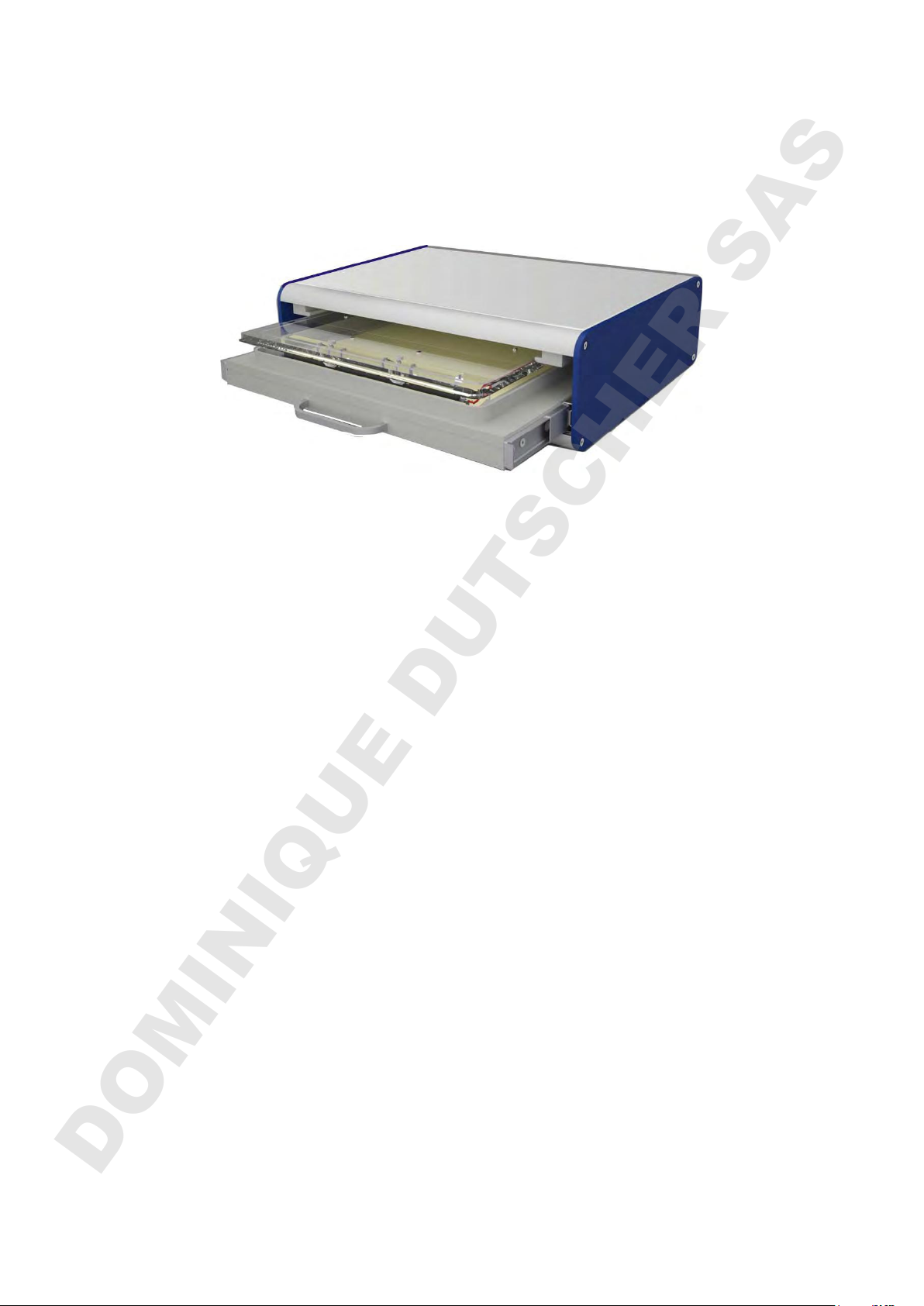

3 Installation

HPETM BlueHorizon (left: side/front view, right: back view)

The base-unit

Place the base unit on the bench. Unevenness of the lab bench can be corrected by

using a spirit level and adjusting the levelling feet.

Connecting the SERVA HPE™ Cooling Unit (Chiller)

Important note: Warm air should not be exhausted towards the BlueHorizon!

Connect the BlueHorizon to the chiller using the provided tubing and fix them with the

hose clamps. It is important to tighten these clamps sufficiently to obtain an air-tight

seal. The chiller ”Outlet“ must be connected to the BlueHorizon “Inlet” and the chiller

“Inlet” to the BlueHorizon “Outlet”. If the flow-direction is wrong, the cooling will work

incorrectly. In order to protect the cooling plate from corrosion, the cooling liquid must

contain an anti-corrosive additive (Cat. no. 43392)

Air Removal

For efficient cooling, it is vital to remove any air from within the cooling plate. Switch

on and leave the chiller running until all of the air in the connecting pipes is removed,

this may take several minutes. Then refill the chiller reservoir with cooling liquid (3

parts of water and 1 part anti-corrosive additive) as the BlueHorizon takes up about 1

litre.

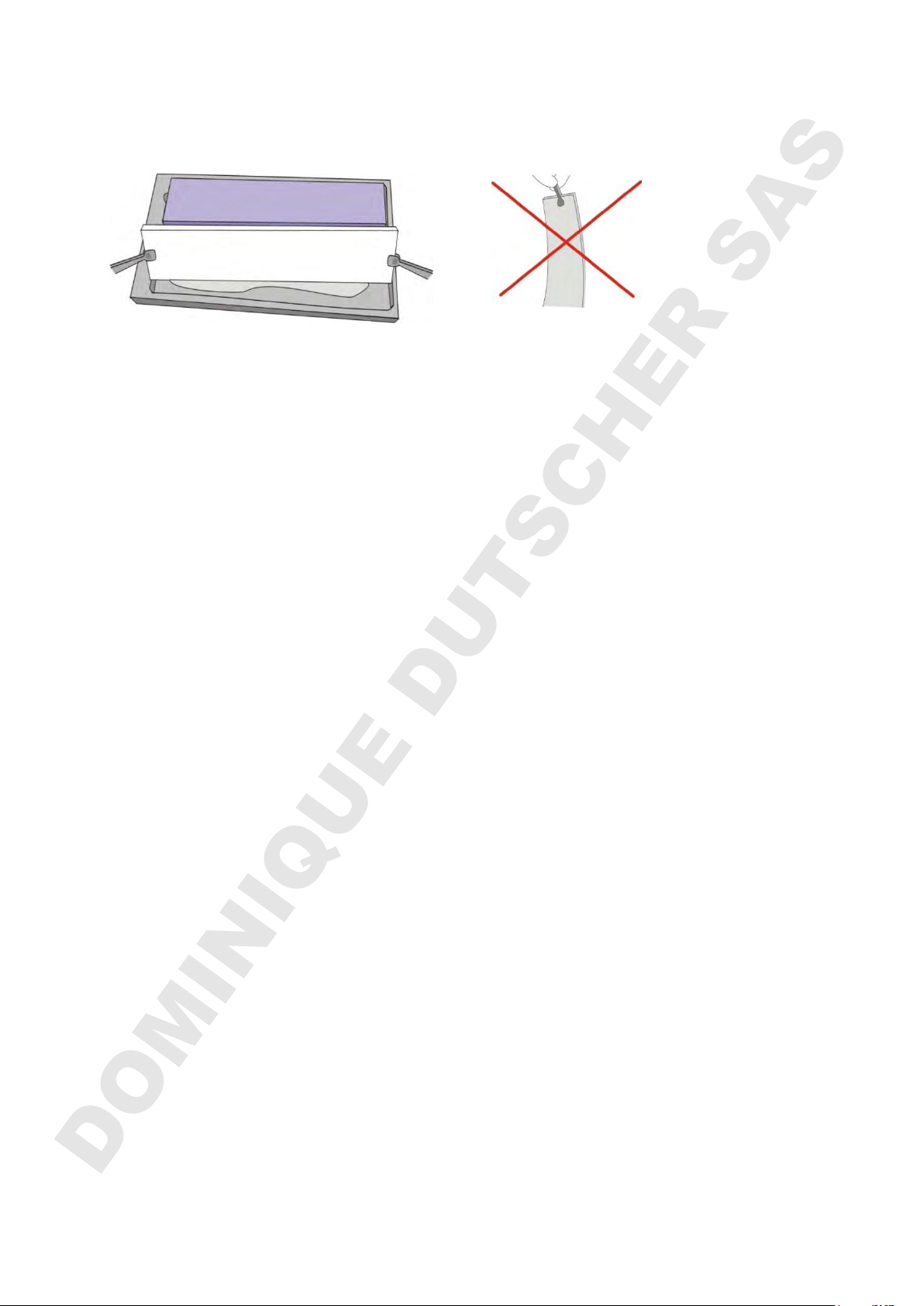

Electrode Lid Storage

Remove the protection film and paper. Insert the lid into its “park” position” above the

drawer with the connecting plugs of the lid towards the backside of the BlueHorizon.

The electrodes are carefully constructed from platinum coated titanium rods and

could be damaged if not handled correctly. When not in use, always insert the lid into

its “park” position. Never place the lid on the bench with electrode side down to avoid

damage.

Connecting the Power Supply

Connect the power supply (black / red cables). Place it on top to save bench space.

DOMINIQUE DUTSCHER SAS

6

4 Operation

In this section, general instructions for loading and running gels on the HPETM

BlueHorizon are described. Running conditions for specific gel types, videos, and

other useful information are provided on the enclosed DVD and on www.serva.de.

Important Information: Always wear powder free disposable gloves when handling

gels or stripes. Do not open a drawer during an active electrophoresis run without

switching off or pause the power supply. Opening a drawer during running power

causes your power supply to detect a “ground leakage”. That may cause a

disturbance of the running programme or in the worst case damages the power

supply.

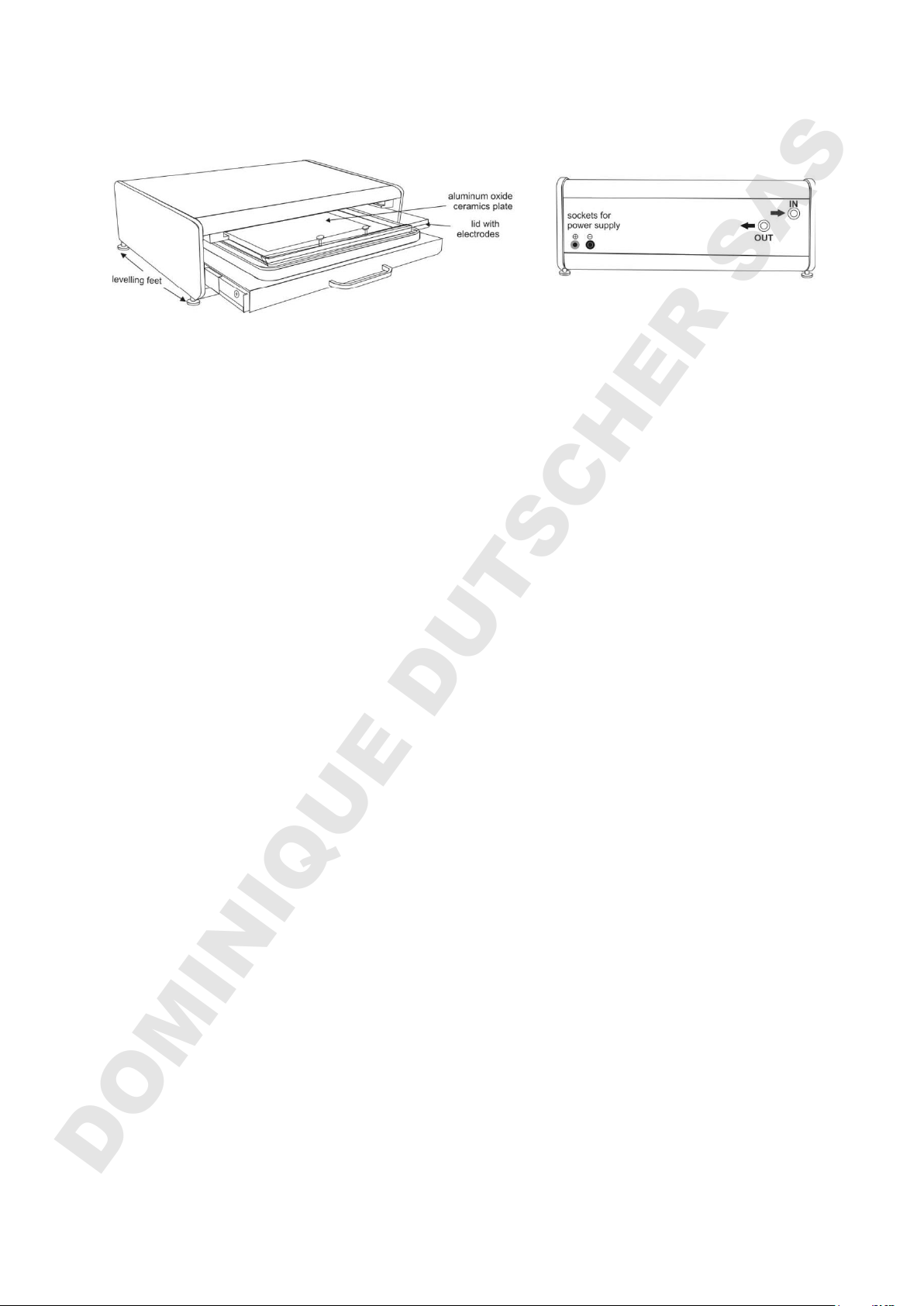

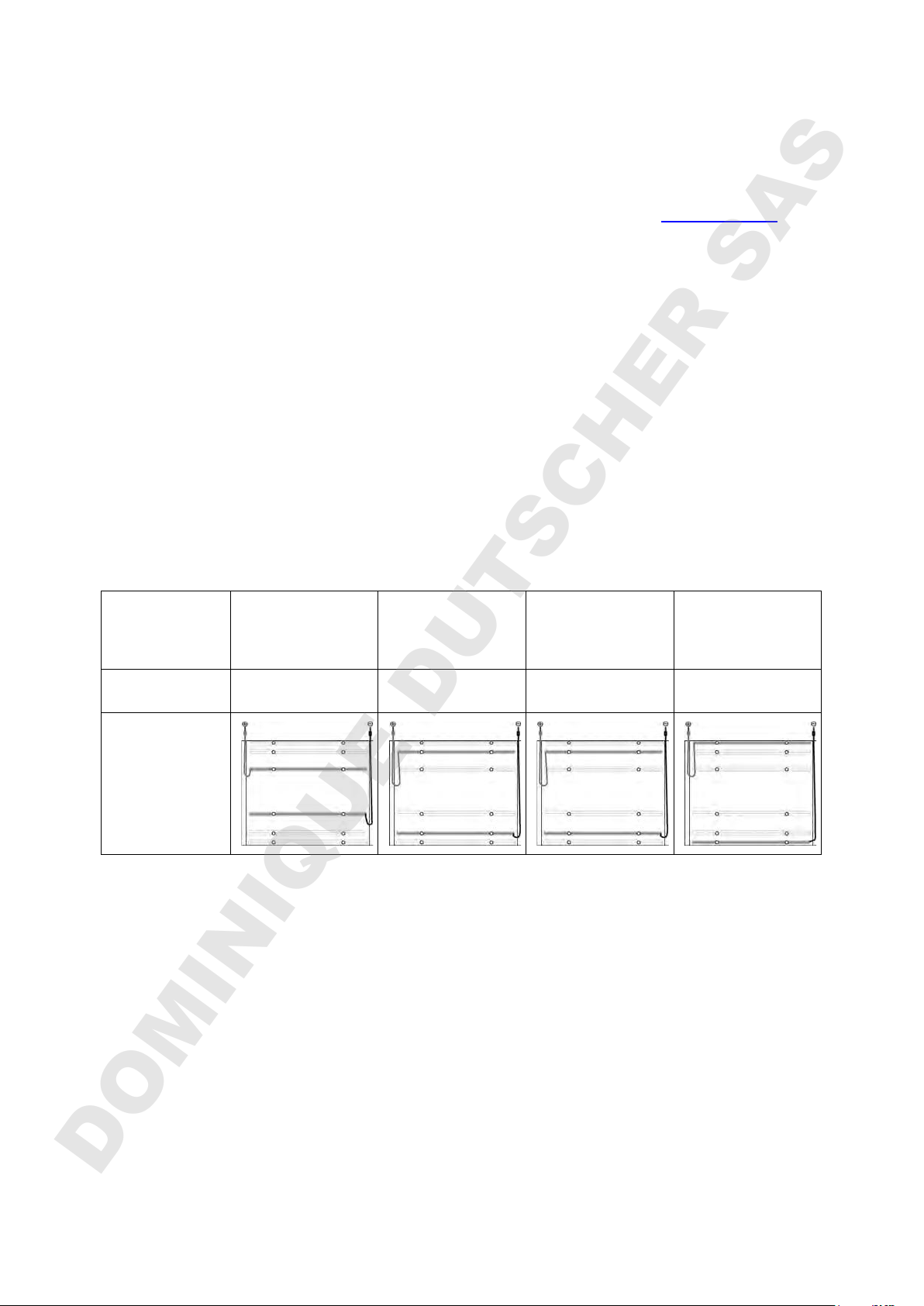

4.1 Adjust the electrodes

In the electrode lid, the electrode positions can be adjusted to different gels sizes.

When changing the electrode positions, place the electrode lid half way in the park

position and loosen the screws of the first electrode. Be careful to catch the nut on

the underside of the lid into which the screw fits. Then turn the lid and change the

second electrode as described above. Please note: The position for PreCotes is not

fixed but adjustable. Before each run with PreCotes or CleanGels IEF, superpose the

electrodes and the wicks on the gel.

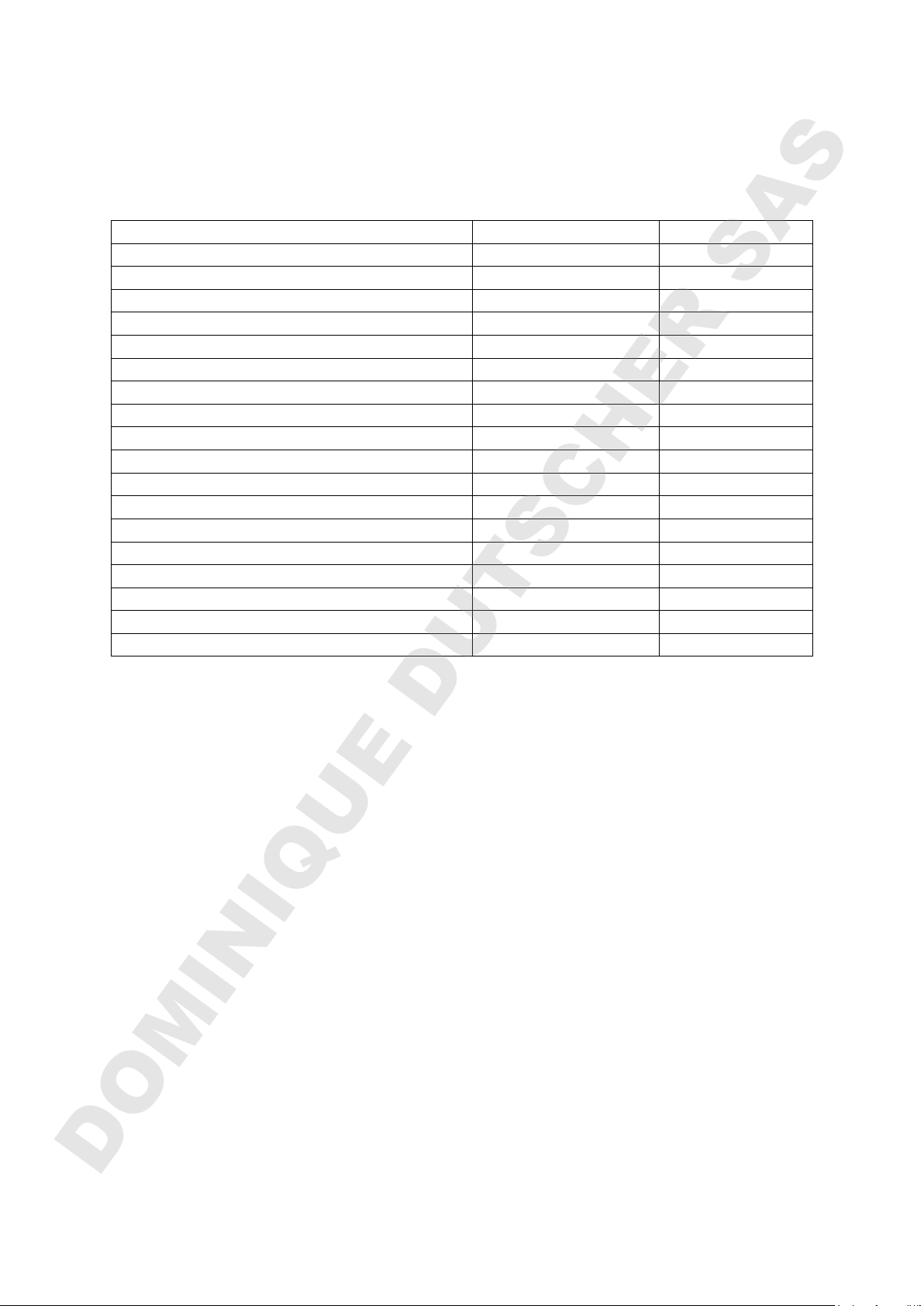

Gels

PreCotes

CleanGel IEF

FocusGel

SDS Gel

CleanGel

2D HPE Triple /

Double Gels

2D HPE Large

Gel

Application IEF 1D PAGE 2D PAGE HiRes

2D PAGE

Electrode

position

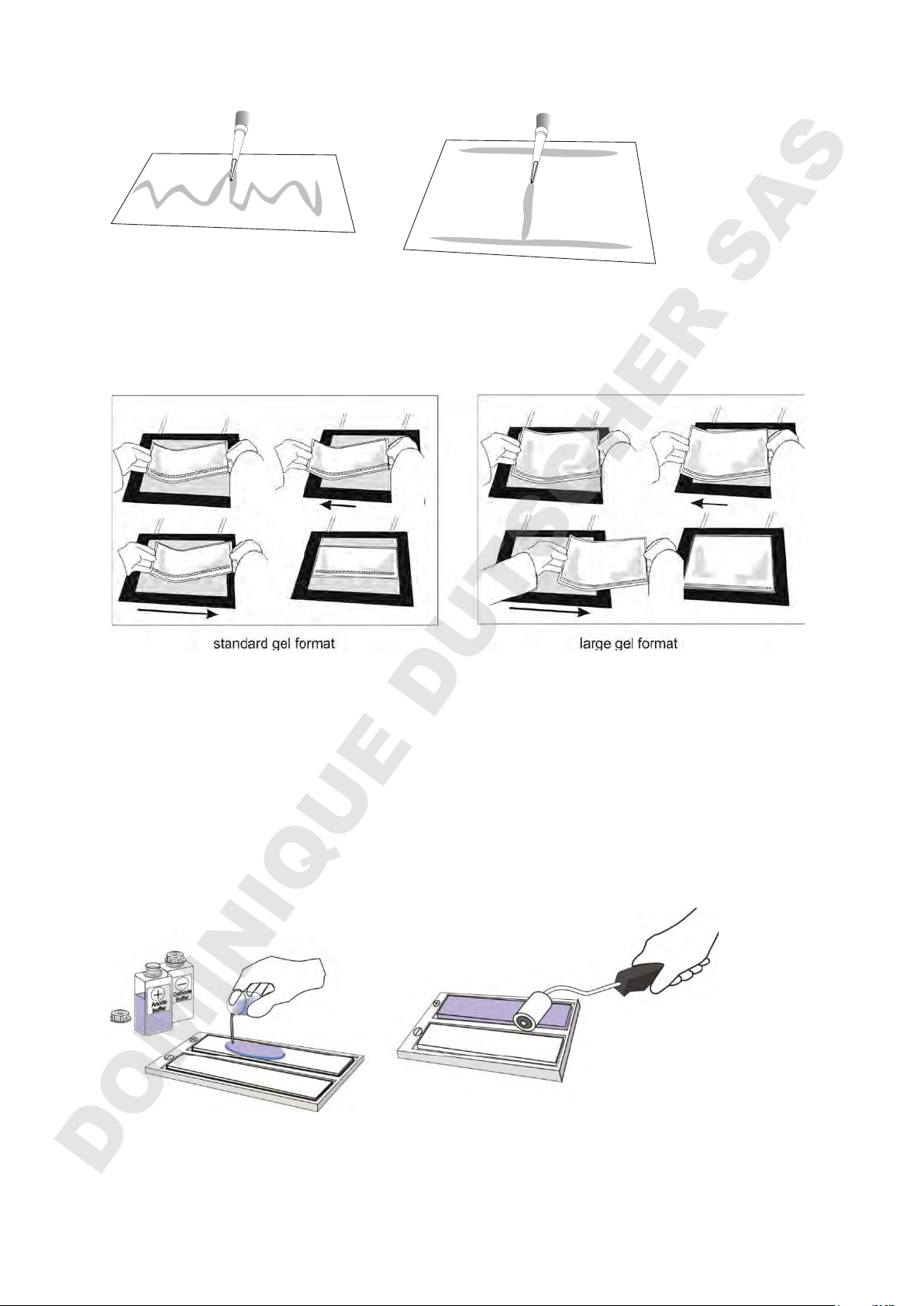

4.2 Apply a gel

Important Information: To avoid water condensation on the gel surface, do not yet

switch on the chiller.

A specially formulated cooling fluid is added between the surface of the cooling plate

and the gel to ensure good contact, even temperature control and efficient heat

dissipation. For a standard format gel spread 3 ml cooling contact fluid onto the

centre of the cooling plate. For a large format gel spread 6 ml cooling contact fluid

onto the cooling plate in the shape of an “H”:

DOMINIQUE DUTSCHER SAS

7

standard gel format large gel format

To disperse, slide a gel bent into a U-shape from side to side. The sides of the gel

are then gently lowered. Avoid air bubbles between the cooling plate and gel. Excess

cooling fluid from around the gel is removed using a lint-free tissue.

4.3 Prepare Electrode Wicks

4.3.1 SDS Gel Kit, CleanGel, HPE Gel

All buffers needed are provided in the SERVA Gel and Buffer Kits. We do not

recommend different or self-made components.

Electrode wicks, soaked in an appropriate buffer, provide a convenient alternative to

buffer tanks. The wicks should be fully soaked with 45 ml buffer for at least 10

minutes. The wicks should be rolled to remove air bubbles and to distribute the buffer

evenly using the supplied roller:

Electrode wicks are applied with the cathode (white) at the front, anode (blue) at the

back. Remove excess electrode buffer from the wicks by tilting the electrode wicks

along one long edge and dab it on the paper pool bottom. When moving the wicks

DOMINIQUE DUTSCHER SAS

8

always hold them horizontal, as holding them at a vertical angle can result in unequal

buffer concentration.

The electrode wicks should overlap the gel by at least 2 mm. It is important that

buffer is not dropped onto the gel surface and therefore avoid moving the buffer

soaked wicks over the gel.

4.3.2 PreCotes, PreNets, CleanGel IEF

Place two electrode wicks (5 mm) soaked with anode and cathode buffer. Apply them

on the corresponding gel edges: acidic solution on the Anode (+) side, basic solution

on the cathode (-) side. Wicks must not extend beyond edge of gel but be aligned

parallel to each other and corresponding to where the electrodes will be placed.

4.3.3 FocusGel

On FocusGels, the electrodes are directly placed onto the gel without the need of

buffer soaked wicks.

4.4 Sample preparation and loading

4.4.1 SDS Gel Kit

1) Add one volume sample to one volume sample buffer (2x) and dilute the sample

to loading concentration with the sample diluter (depends on the sensitivity of

staining method). Reduce and alkylate your sample.

2) Pipette samples into the sample wells.

4.4.2 CleanGel

Prepare samples according to the related gel instruction manual or specific

application procedure.

4.4.3 HPE Gel

1) Equilibrate the IPG strip

SERVA IPG strip equilibrator (Cat. no. HPE-A04) provides a convenient way to

equilibrate IPG strips. After equilibration, the strip can be easily transferred from

the slots holding the first equilibration solution (e.g. DTT) to the slots holding the

second solution (e.g. IAA).

DOMINIQUE DUTSCHER SAS

9

Prepare the two equilibration solutions from the SERVA IPG Strip equilibration

buffer:

DTT solution: Weigh urea and Dithiothreitol (DTT), add the equilibration buffer

and dissolve completely.

IAA solution: Weigh urea and Iodoacetamide (IAA), add the equilibration buffer

and dissolve completely.

Sufficient amount for 1 x 18cm, 1 x 24 cm, 2 x 11cm, 3 x 7cm

Urea [g] DTT [mg] IAA [mg] Eq. Buffer [ml] Total [ml]

DTT solution

1.8

50

-

5

6

IAA solution 1.8 - 125 5 6

Equilibrate each strip in 6 ml (18 or 24 cm strips), 3 ml (11 cm strips) or 2 ml (7

cm strips) solution in an equilibrator on an orbital shaker with 30 –50 /min in DTT

for 15 min and in IAA solution for 15 min.

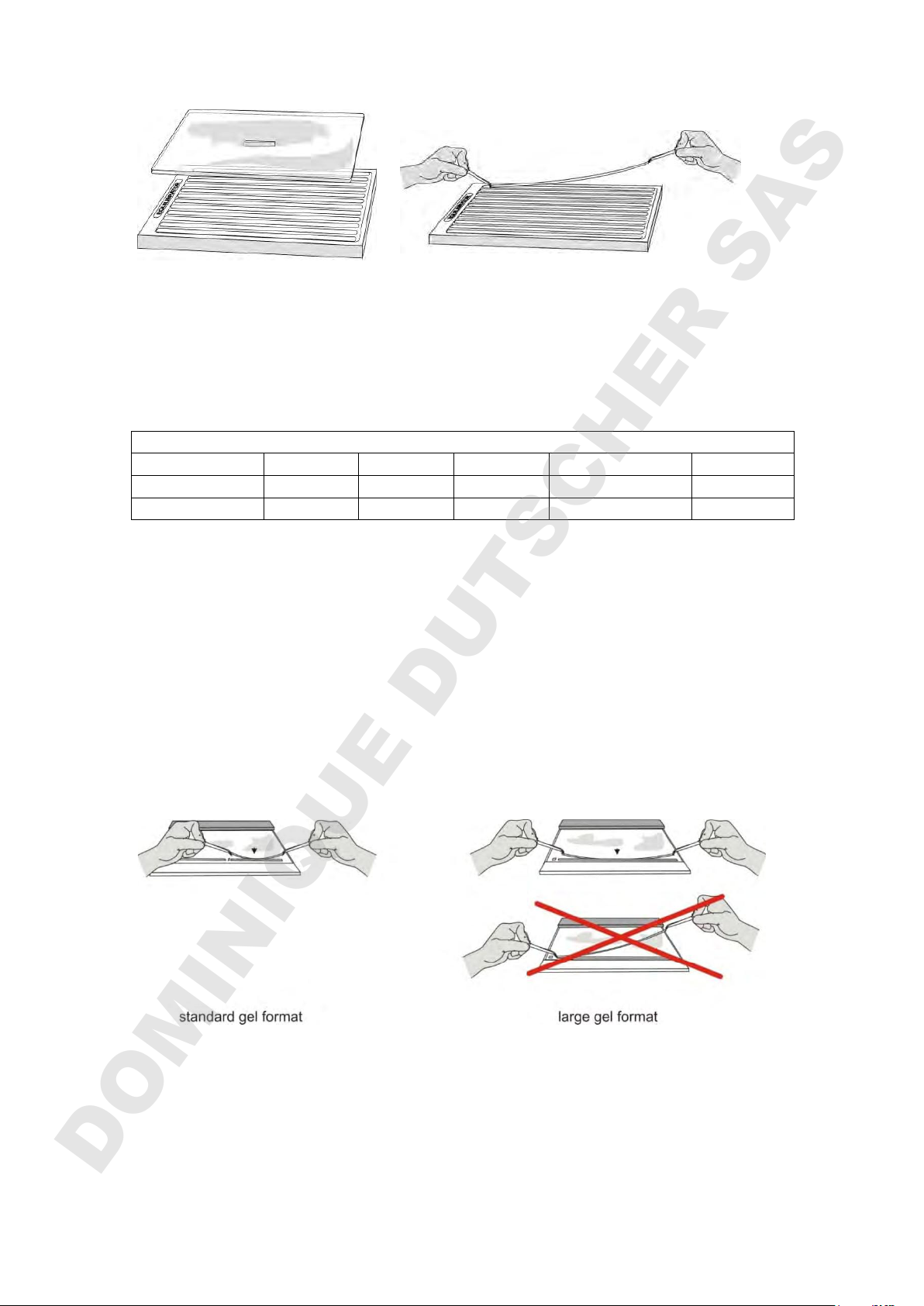

2) Applying the IPG-strip

IPG strips should still contain equilibration buffer on their surfaces. Do not blot

IPG strips dry, this can cause vertical streaking in the second dimension due to

insufficient protein transfer. Some IPG strips have rather long protruding support

film on the ends: In this case the plastic film support on both sides of the IPG-strip

must be trimmed just beyond the gel.

The strip should be carried horizontally and applied to the slot center first.

The strip should be placed in the IPG slot, gel side down, with the anodal side to

the right. To ensure good contact in the slot the back of the forceps is slid gently

along the back of the IPG strip.

DOMINIQUE DUTSCHER SAS

10

4.4.4 PreCotes, PreNets

1) Unpack the gels and remove the protective cover-film from the gel surface. Keep

the cover film as it can serve as a protective sheet later.

2) Adjust sample concentration to about 1 - 10 mg protein/ml and desalt by dialysis;

by dilution with dest. water or by lyophilization and resuspension in dest. water.

3) Centrifuge the samples for 5 minutes at approx. 12,000 g; use only the

supernatant. By omitting this step the separation pattern might become fuzzy and,

eventually, precipitates may form within the applicator strip slots.

4) Position the applicator strip on the gel and slightly pressing it with the back of a

forceps. Apply the required sample volume using a pipette. Do not leave empty

slots between samples. Depending on sample type, it is possible to apply the

samples with or without pre-focusing.

4.4.5 CleanGel IEF

1) Unpack and rehydrate the dry gel according to the gel instruction manual.

2) Prepare and apply samples on the gel according to the related gel instruction

manual or specific application procedure.

4.4.6 FocusGel

1) Unpack the gels and remove the protective cover-film from the gel surface. If

necessary, remove excessive moisture from the gel surface with the edge of a

drying cardboard. Keep the cover film as it will serve as a protective sheet later.

The gel is ready to use.

FocusGel 24S and 40S: For some sample types, e.g. serum and CSF the position

of the pre-formed wells is optimized for anodal application in a pH gradient 6-11.

This well position might also be suitable for other sample types. Nonetheless, the

gels can be turned around for cathodal application if needed.

2) Apply the required sample volume using a pipette. Do not leave empty slots

between samples. Depending on sample type, it is possible to apply the samples

with or without pre-focusing.

3) Take care that the electrodes are placed directly on the FocusGel surface at the

gel edges and not on the support film!

DOMINIQUE DUTSCHER SAS

11

4.5 Start the run

1) Close the lid while lowering the electrodes on the wicks. Plug in the leads.

2) Switch the thermostatic circulator on, set to

HPE Gels: 15 °C

SDS Gels: 15 °C

Clean Gels: dependent on the application (see gel manual)

PreCotes, PreNets: 10°C

CleanGel IEF: 10°C

Focus Gel: dependent on the application (see gel manual)

Note: During Electrophoresis the electric resistance of the gel is slowly increasing.

Therefore, the heat production during the starting phase is rather low. It does not

cause overheating when the chiller begins cooling at the same time the

electrophoresis is started.

3) Start the run according to the settings described in the gel manual.

DOMINIQUE DUTSCHER SAS

12

4.6 After the run

After electrophoresis, clean the device as described and follow with staining and

detection. We recommend:

Staining

Application

Cat. No.

SERVA HPE™ Silver Staining Kit (MS compatible) 2D 43395

SERVA CSF Silver Staining Kit CSF IEF 43398

SERVA Silver Staining Kit Native PAGE Native PAGE 35077

SERVA Silver Staining Kit SDS PAGE SDS PAGE 35076

SERVA HPE™ Coomassie® Staining Kit PAGE, 2D 43396

SERVA Blue G PAGE 35050, 17524

SERVA Blue R PAGE 35051, 17525

SERVA Blue R Staining Kit PAGE 42531

SERVA DensiStain Blue G Staining Solution PAGE 35078

Quick Coomassie™ Stain IEF, PAGE GEN-QC-STAIN-1L

SERVA Blue W IEF 35053

SERVA Violet 17 Staining Kit IEF, native PAGE 35074

SERVA Violet 17 IEF, native PAGE 35072

SERVASnow Staining Kit PAGE background stain 35080

SERVA ProteinStain Fluo-R (MS compatible) IEF, PAGE, 2D 35091

SERVA Purple (MS compatible) PAGE, 2D 43386

SERVA Lightning Red for 1D SDS PAGE (label) PAGE 43401

SERVA HPE™ Lightning Red (label) 2D 43400

DOMINIQUE DUTSCHER SAS

13

5 Maintenance

5.1 Cleaning

Regularly clean the housing of the SERVA HPETM BlueHorizon.

Precautions for avoiding electric shock

Electronic devices can cause electric shocks in case of an operating

error. Never try to repair electric parts. Never open the housing.

Switch off the instrument and disconnect it from the power supply

before starting with cleaning or disinfection works.

Never let get liquids inside the housing.

Do not perform spray disinfection.

Do only connect the instrument with the power supply if it is

completely dry.

The repair service may only be performed by authorized staff trained by

the manufacturer. A modification of the instrument is not permitted.

Caution when handling aggressive chemical

s

Do not use aggressive chemicals e.g. strong and weak bases, strong

acids, formaldehyde, acetone, halogenated hydrocarbons, phenol and

other organic solvents for cleaning the instrument and its accessories.

In case of contamination with aggressive chemicals, clean the

instrument with a neutral detergent immediately.

Use neither corrosive detergents nor aggressive solvents or

abrasive polishing agents.

Cleaning

When running the BlueHorizon for the first time, or if the cooling plates became

soiled, clean them using a 0.1% SDS solution, followed by isopropyl alcohol and

finally distilled water. Disconnect the instrument from the power supply before you

start cleaning to obtain the best results it is recommended to clean the cooling plates

and electrodes before and immediately after use with distilled water. The cooling

plate can be gently rubbed and dried using a lint-free tissue. Abrasive cleaners and

other solvents must not be used. Cleaning of the platinum electrodes after each run

is particularly important to prevent crystallization of buffer salts, which can result in

uneven contact. Electrodes should be cleaned with distilled water-moistened lint-free

tissue.

DOMINIQUE DUTSCHER SAS

14

Disinfection

1. Disconnect the instrument from the power supply before you start disinfecting.

2. Let the instrument cool down.

3. Clean the instrument as described above.

4. Select a disinfection method compliant to the applicable local legal regulations

and directives.

5. Wipe off all outer parts of the instrument with the disinfectant and a lint-free

cloth.

Decontamination before shipment

If you need to send the instrument back to us, decontaminate all parts. Document this

in our Decontamination Certificate (Download on www.serva.de) and include it within

the shipment.

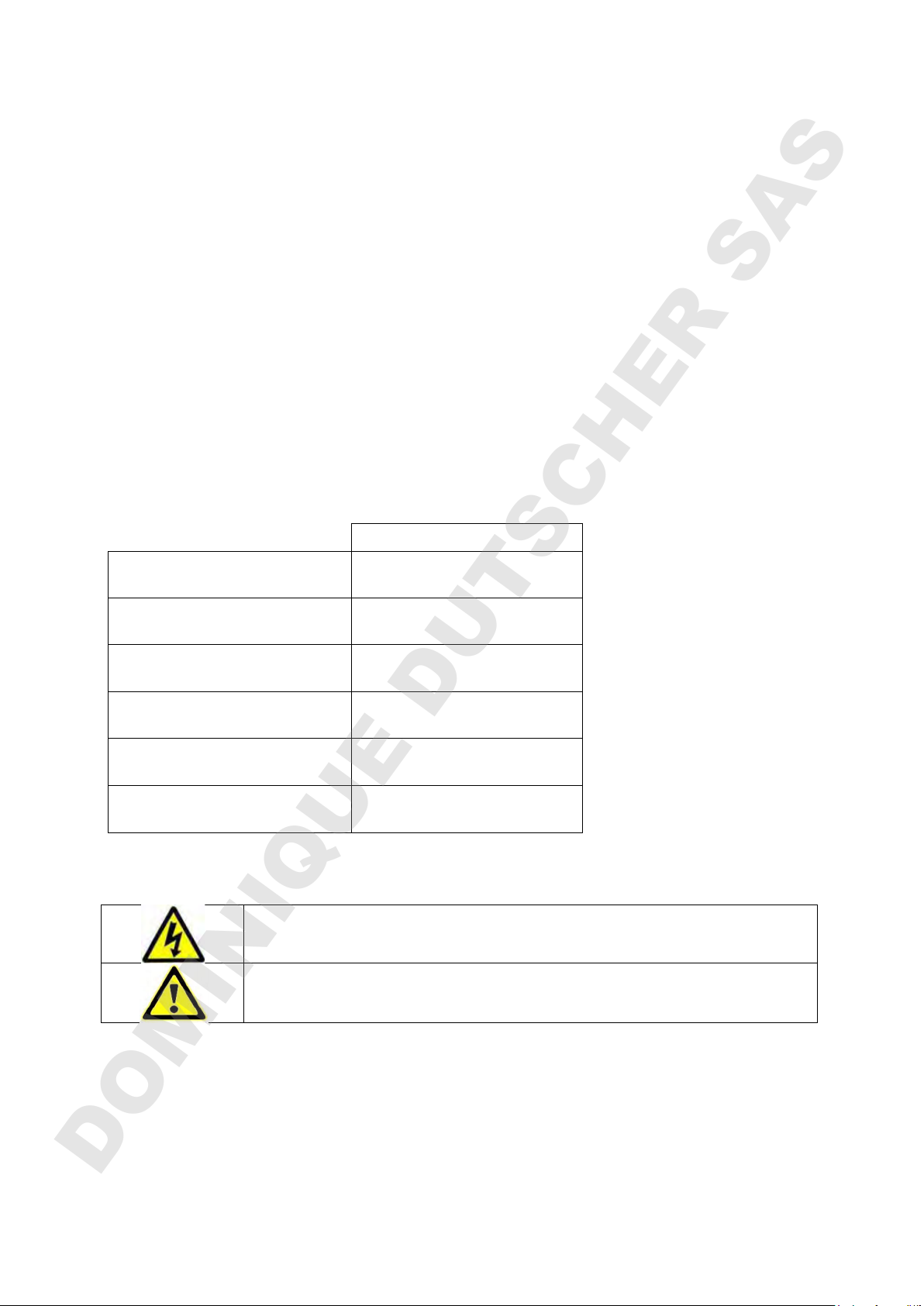

6 Technical data

SERVA Blue

Horizon

Max. Spannung, Strom / 3000V, 25mA

Max Voltage, Current

Max. Gelgröße / 260 x 205 mm

Max gel size

Temperatur-Arbeitsbereich / +4°C to +30°C

Temperature-working range

Elektrodenabstand / 270, 195, 115 mm

Electrode distance

Abmessungen (B x T x H) / 450 x 500 x 120 mm

Dimensions (W x D x H)

Gewicht (ohne Block) / 6 kg

Weight (without block)

7 Explanations

Attention! Electric shock!

Attention!

DOMINIQUE DUTSCHER SAS

15

8 Trouble Shooting

Symptom Cause Remedy

7.1 Effects during electrophoresis

No water flow after

chiller is switched

on.

Wrongly connected

tubing or kinked tube.

Straighten tubing. Check tubing:

Chiller-“Out“ connected to chamber-

“In“.

Air bubbles

between film-

backing and cooling

plate.

Insufficient volume of

cool contact fluid

Lift up gel on one side and apply a

higher volume

Excess cooling fluid

around the film

support.

Too much cooling fluid

applied on the cooling

plate.

Remove excess fluid with lint-free

tissue paper.

Water droplets on

gel surface.

Gel was pre-cooled

without lid at high

humidity conditions

leading to water

condensation.

Do not switch on chiller during gel

application and sample loading.

No electric current,

drawer control

lamps do not

illuminate after

starting the power

supply.

Electronic control

detects wrong

orientation of electric

field.

Plug power supply cables in correctly:

black cable to cathode, red cable to

anode.

Electronic control

detects that one or

more draws do not

contain a gel.

When less than four gels are run,

unplug the non-used electrode lids

and place them into the parking

position.

Lids not properly

positioned or not

plugged-in.

Re-position lids and check

connections between lids and

drawers.

Condensation

inside of electrode

lid.

The gel gets hot

during electrophoresis

because of insufficient

heat dissipation.

Do not forget to switch chiller on!

Check chiller temperature and ensure

no other apparatus is connected to

the same chiller.

DOMINIQUE DUTSCHER SAS

16

Front is curved

instead of straight.

The gel gets hot

during electrophoresis

because of insufficient

heat dissipation.

See above

BlueHorizon is subject

to hot exhaust from

chiller or other

apparatus.

Relocate chiller or other apparatus.

The gel gets hot

during electrophoresis

because too much

power is applied per

gel.

If you run less than four gels at

a time,

reduce the mA and W settings in the

power supply accordingly. Follow

strictly the manual.

Migration of front is

very slow and will

not reach the anode

in time.

The electric field is too

low. Adjust the mA and W settings

according to the number of gels run.

Front is slanted, not

straight.

Uneven buffer

concentration within

the electrode wicks.

Always hold electrode wicks

horizontal when carrying them to the

gel.

Condensation water

develops inside

electrode lid near

to IPG strip(s).

Local heat production

at IPG strip(s)

because of

electroendosmotic

effect.

Remove IPG strip(s) from gel after the

first 70 minutes and then continue the

run. Follow strictly the manual.

Minor

disturbance(s) in

the front.

Buffer drop(s) fell on

the gel surface. Avoid passing wicks over gel surface.

Air bubbles inside the

wicks.

Gently roll wicks in PaperPool to

remove air.

2D Gels: Irregular

bulging of the front

on one side.

Equilibration buffer

unequally distributed

within the IPG strip(s).

Hold the IPG strip(s) horizontal, start

in the middle when placing the strip

into the slot.

DOMINIQUE DUTSCHER SAS

17

2D Gels: Run stops,

front does not

continue to migrate,

sparking at the IPG

strip(s).

Strong

electroendosmosis

effect at the IPG

strip(s), because it

has not been removed

after the first 70

minutes.

Remove IPG strip(s) from gel after the

first 70 minutes and then continue the

run. Follow strictly the manual.

7.2 Effects during scanning

Gel edges curl up

during scanning.

Gel edges start to dry

out.

Apply Scan-Frame on the edges of

the gel during scanning.

12.4 Effects seen in the result

2D Gels: Horizontal

streaking

The first dimension

IEF separation in the

IPG strip did not work

well because of

inappropriate sample

preparation IEF

separation problems.

Check the trouble shooting guides

supplied by the providers of the IPG

strips and web forums.

2D Gels: Vertical

streaking

Insufficient

equilibration of the

IPG strip.

Use the equilibration buffer supplied

with the HPE gels, weigh-out the

correct amounts of DTT and IAA

(should be of highest reagent quality),

follow the manual.

IPG strip has become

too dry.

Ensure that there is still a thin layer of

buffer on the surface.

Local disturbances

in the pattern

Air bubble in the

cooling contact fluid

layer

Use sufficient cooling contact fluid on

the cooling plate (3 for standard size

gels, or 6 ml for large gels), distribute

is evenly by sliding the gel with the

film-backing several times left and

right.

Air bubble in a buffer

wick

Distribute the buffer solutions evenly

in the wicks by thoroughly rolling

DOMINIQUE DUTSCHER SAS

18

SERVAPurple

staining:

Unsufficient

sensitivity of

staining

Wrong protocol (for

non-backed gels) has

been applied, or the

solution volumes were

too small

Follow the protocol of this HPE

Horizon manual which has been

optimized for the HPE Flatbed gels.

DOMINIQUE DUTSCHER SAS

19

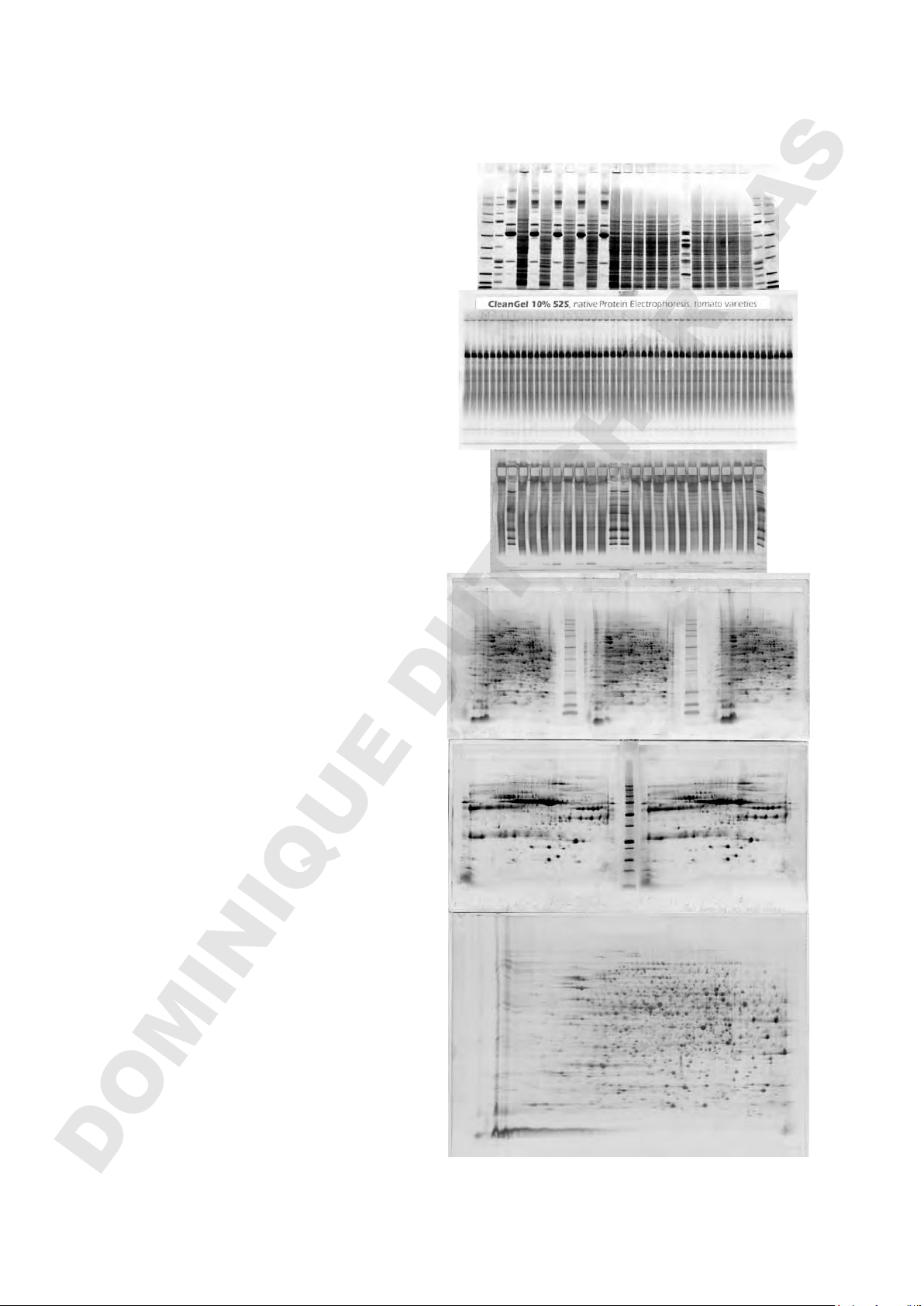

9 Addendum: Example Applications

1D SDS PAGE 25 slots

SDS Gel Kit 10% 25S; Cat. No. 43359

Marker, muscle, E. coli extracts

Coomassie® staining

SERVA Blue R Staining Kit; Cat No. 42531

1D native PAGE 52 slots

CleanGel 10% 52S; Cat. No. 43340

Native Buffer; Cat. No. 43352

Tomato seeds

Coomassie® staining

SERVA Blue R Staining Kit; Cat No. 42531

Precast Horizontal Gel for Isoelectric Focusing

FocusGel 6-11 24 slots; Cat. No. 43329

Cerebrospinal fluids and serum

Ammoniacalic silver staining with SERVA CSF

Silver Staining Kit; Cat. No. 43398

2D Electrophoresis

2D HPE™ Triple-Gel NF 12.5 % Kit; Cat. No.

43300

E. coli extracts

ServaPurple™ staining; Cat. No. 43386

2D Electrophoresis

2D HPE™ Double Gel NF 12.5 % Kit, Cat. No.

43302

Human serum proteins

ServaPurple™ staining; Cat. No. 43386

2D Electrophoresis

2D HPE™ Large Gel 12.5 % Kit,Cat. No. 43310.

E.coli proteins

ServaPurple™ staining; Cat. No. 43386

DOMINIQUE DUTSCHER SAS

This manual suits for next models

2

Table of contents

Other serva Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual