SERVIT 423CC1UFNCF User manual

NON-INSULATED HEATING HOLDING

AND PROOFING CABINETS

SERVIT HEATED CABINETS ARE FOR HOT FOOD HOLDING APPLICATIONS ONLY.

THIS MANUAL COVERS CABINETS WITH ELECTRICAL RATINGS OF: 120V 60HZ 2000W

04/2021

www.servitproducts.com

Models: 423CC1UFNCF, 423CC2UFNCF, 423CH1UFNCF, 423CH2UFNCF

NON-INSULATED HEATED HOLDING & PROOFING CABINETS - INSTRUCTIONS FOR USE

Safety Information & Symbols .................................................3

Identifying your Cabinet.............................................................3

Installation and Setup .................................................................4

Holding & Proofing Cabinets Operating Instructions.............5

Care and Maintenance ...............................................................5

Basic Troubleshooting ................................................................6

Holding Cabinets Operating Instructions ..............................7

Care and Maintenance ..............................................................7

Basic Troubleshooting ...............................................................8

Reversing the Door ....................................................................9

Holding & Proofing Cabinets

Service and Replacement Parts ....................................10

Service and Replacement Parts (Circuits) ...................11

Wiring Diagram Parts ........................................................12

Holding Cabinets

Service and Replacement Parts ....................................13

Service and Replacement Parts (Circuits) ...................14

Wiring Diagram Parts ........................................................15

SERVIT NON-INSULATED HEATED

HOLDING & PROOFING CABINETS

TABLE OF CON TENTS

Servit Cabinets are designed to keep foods at optimum serving temperatures without affecting quality. They are built for

tough kitchen duty with rugged metal construction, heavy-duty hardware, fully adjustable universal slides and

easy-to-use controls. Combination module cabinets have additional functionality to proof breads, pastries and more,

giving you dual flexibility all in a single unit.

Holding and Proofing Cabinets are intended to hold food pans or trays of hot, already cooked food at proper serving

temperature or to proof products. This unit is not designed or intended to cook raw food or reheat prepared food.

Use of this unit other than intended use will void warranty.

This manual provides the installation, safety and operating instructions for Holding and Proofing Cabinets. ServIt

recommends all installation, operating, and safety instructions appearing in this manual be read prior to installation or

operation of the unit.

DESCRIPTION

This manual covers cabinets with electrical ratings of: 120V 60HZ 2000W

2

www.servitproducts.com

L01-672

REV 04/21

NON-INSULATED HEATED HOLDING & PROOFING CABINETS - INSTRUCTIONS FOR USE

3

www.servitproducts.com

L01-672

REV 04/21

SAFETY INFORMATION

WARNING: Follow all food safety guidelines. Pre-heat the cabinet to the desired temperature before placing

cooked, hot food into the cabinet. This is not a re-thermalizing cabinet. Food must be at the appropriate

temperature before being placed into this cabinet. Use a food probe to check internal food

temperature — the cabinet temperature is not necessarily the internal food temperature.

WARNING: Only factory-approved service agents should attempt to service, repair or replace electrical components,

wiring or power cord.

WARNING: Unplug the cabinet before cleaning or servicing. Do not wash the cabinet with a water jet or high pressure

water.

WARNING: This cabinet is for hot food holding applications only.

CAUTION: Stainless steel water pan must be installed over moisture element inside cabinet during operation.

Plastic drip pan can not be used inside cabinet and shall be installed outside the cabinet below the drip

trough.

CAUTION: Do not spray or pour water into the module. To clean the cabinet, wipe with a damp cloth and dry with a

towel. Use only cleaning agents approved for Aluminum.

CAUTION: Water dripping onto the floor from open doors can be a slip hazard.

For future reference, note the serial and model number found on the data plate of the cabinet here:

Serial number ________________________________

IDENTIFYING YOUR CABINET

* Save this document for future application, load rating and/or safety reference.

NON-INSULATED HEATED HOLDING & PROOFING CABINETS - INSTRUCTIONS FOR USE

4

www.servitproducts.com

L01-672

REV 04/21

Figure 2: Wall receptacles

NEMA 5-20P

20 Amp Outlet For 120V Cabinet

INSTALLATION AND SETUP

1. Check the packaging and cabinet for shipping damage after unloading the unit, and after removing all the packaging.

2. The receiver of this product is responsible for filing freight damage claims. This equipment must be opened

immediately for inspection. All visible damage must be reported to the freight company within 48 hours and must be

noted on freight bill at the time of delivery.

3. Concealed damage is your responsibility — you must advise the carrier of any loss or damage within 15 days after

receipt of the cabinet. If there is damage, retain the original packaging for inspectors.

4. Any protective covers (plastic or paper sheet) must also be removed before turning the cabinet on.

5. In case of Heated Holding & Proofing Cabinets, Make sure the stainless steel water pan is installed inside the cabinet in

the floor opening on top of the proofing element.

6. In case of Heated Holding & Proofing Cabinets, Install the plastic drip pan under the drip trough at the base of the

cabinet.

7. Install the universal slides into the notches that are built into the walls as shown. The notches are spaced at 1.5”

intervals, each cabinet is supplied with 12 sets of slides, if additional slides are desired please order part number

423PCUSLDPR (which is 1 additional set of slides).

8. Refer to the data plate located near the power cord for the electrical specifications of the cabinet as shown on Page 3.

• With the POWER switch OFF, plug the cord into the appropriate rated, grounded receptacle.

• Cabinets rated at 120 V must be plugged into a 20 amp 125 VAC receptacle.

Metal Pan

Plastic Pan

WARNING: Do not allow combustible materials to be stored or accumulate on, under or next to the cabinet. Do not

block any ventilation louvers or slots.

NON-INSULATED HEATED HOLDING & PROOFING CABINETS - INSTRUCTIONS FOR USE

5

www.servitproducts.com

L01-672

REV 04/21

OPERATING INSTRUCTIONS (HEATED HOLDING & PROOFING CABINETS)

C05-1286 C

Miljoco Industries

F

140

120

50

60 70 80

90

100

105

160

150 170

180

190

200

210

220

100

80

60

30

10

HOLDING & PROOFING CABINET

HOLD

PROOF

OFF

Power / Selector Switch Thermostat Thermometer

1. Fill the stainless pan with water if proofing, or if you desire a small amount of passive humidity while in heated holding

mode.

2. Your cabinet has a 3 way power / selector switch that powers the cabinet on and off and also allows dual

functionality. For heated holding mode set the switch to “hold” (up); for proofing mode set it to “proof” (down); to

power the unit down set to “off” (middle).

3. Heated holding mode (selector switch set to “hold”)

• Set thermostat at desired setting, number 7 is approximately 150°F (66°C), 10 is approximately 190°F (88°C).

• Monitor temperature read-out on thermometer and adjust thermostat to fine tune as necessary.

4. Proofing mode (selector switch set to “proof”)

• Set thermostat at desired setting, approximate temperature yields are below, each yields a pre-determined

humidity level.

-Number 1 is approximately 85°F (30°C)

-Number 2 is approximately 95°F (35°C)

-Number 3 is approximately 105°F (41°C)

• Monitor temperature read-out on thermometer and adjust thermostat to fine tune as necessary.

Note: When the switch is set to hold or proof, the fan is always energized. In order to power off the fan and the unit, set

the switch to “off” (middle).

CARE AND MAINTENANCE

Before proceeding with any maintenance activity strictly follow “Safety Information” on

page 3 of this manual.

Cleaning The Cabinet

WARNING: Unplug the cabinet before cleaning or servicing. Do not wash the cabinet with a water jet or high pressure

water.

CAUTION: Do not spray or pour water into the control enclosure. To clean the cabinet, wipe with a damp cloth and dry

with a towel. Use only cleaning agents approved for Aluminum.

CAUTION: Do not use cleaners with chlorides or phosphates as they may cause damage to Stainless Steel & Aluminum.

1. Make certain that the cabinet has cooled down before cleaning. Use cleaners in proper concentrations. Follow the

manufacturer’s directions for the cleaning product used. After using any cleaning products, thoroughly rinse all

surfaces to remove residue.

2. Use a damp cloth or sponge. Mild soap suitable for Aluminum is acceptable. Dry with a clean towel. Wipe up spills as

soon as possible and regularly clean the cabinet to avoid staining and difficult to clean conditions.

NON-INSULATED HEATED HOLDING & PROOFING CABINETS - INSTRUCTIONS FOR USE

6

www.servitproducts.com

L01-672

REV 04/21

Cabinet Maintenance — All Models

Regularly inspect the casters. Tighten loose fasteners and replace worn or damaged

parts with new SERVIT approved parts. Replace worn or damaged casters immediately.

Additionally, periodic tightening of door latch and hinge screws may be required.

BASIC TROUBLESHOOTING

WARNING: Only factory approved service agents must attempt to service, repair or replace electrical components,

wiring or power cord.

1. Controls do not work (no heat being generated or fan does not run):

• Check that the cabinet is plugged-in.

• Check that the outlet has power.

• Check that the power switch is in the “On” position.

• Check the cabinet wiring from the power cord to the power switch and to the thermostat.

• For holding, make sure in HOLD mode. For proofing, make sure in PROOF mode.

2. Temperature too hot:

a. During initial pre-heat, cabinet may overshoot set point.

b. If displayed temperature exceeds 220°F (104°C):

• Blower wiring is faulty or disconnected. Blower needs replacing.

• The thermostat may have failed and the thermal cut-out device is controlling the temperature.

• Thermal cut-out device may have failed.

3. Temperature too low:

a. The cabinet may still be in pre-heat or recovering from the door being opened.

b. Door is not closed or sealing properly.

c. Worn out door gasket. Replace gasket.

d. Blower is not circulating air:

• Blower wiring is faulty or disconnected.

4. No heat generated

When power is on and in HOLD mode, amp draw for 120V units should be approximately 16 amps and In PROOF

mode, 120V amp draw should be approximately 6.0 amps.

• Air heater element may be faulty.

• The wiring to the air heater element may be faulty or disconnected.

• Thermostat may be faulty.

• The thermal cut out may be open or have a disconnected wire coming to it or going from it to the element.

NON-INSULATED HEATED HOLDING & PROOFING CABINETS - INSTRUCTIONS FOR USE

7

www.servitproducts.com

L01-672

REV 04/21

OPERATING INSTRUCTIONS (HEATED HOLDING CABINETS)

ON

OFF

C05-1287 C

Miljoco Industries

F

140

120

50

60 70 80

90

100

105

160

150 170

180

190

200

210

220

100

80

60

30

10

HEATED HOLDING CABINET

Power Switch Thermostat Thermometer

1. Your cabinet has a power switch that powers the cabinet on and off. For heated holding mode set the switch to “ON”

(up)

2. Heated holding mode (selector switch set to “ON”)

• Set thermostat at desired setting, number 7 is approximately 150°F (66°C), 10 is approximately 190°F (88°C).

• Monitor temperature read-out on thermometer and adjust thermostat to fine tune as necessary.

Note: When the switch is set to ON the fan is always energized. In order to power off the fan and the unit, set the switch

to “off” (down).

CARE AND MAINTENANCE

Before proceeding with any maintenance activity strictly follow “Safety Information” on

page 3 of this manual.

Cleaning The Cabinet

WARNING: Unplug the cabinet before cleaning or servicing. Do not wash the cabinet with a water jet or high pressure

water.

CAUTION: Do not spray or pour water into the control enclosure. To clean the cabinet, wipe with a damp cloth and dry

with a towel. Use only cleaning agents approved for Aluminum.

CAUTION: Do not use cleaners with chlorides or phosphates as they may cause damage to Stainless Steel & Aluminum.

1. Make certain that the cabinet has cooled down before cleaning. Use cleaners in proper concentrations. Follow the

manufacturer’s directions for the cleaning product used. After using any cleaning products, thoroughly rinse all

surfaces to remove residue.

2. Use a damp cloth or sponge. Mild soap suitable for Aluminum is acceptable. Dry with a clean towel. Wipe up spills as

soon as possible and regularly clean the cabinet to avoid staining and difficult to clean conditions.

Cabinet Maintenance — All Models

Keeping the casters free of dirt build-up will go a long way in prolonging their life. Additionally, periodic tightening of door

latch and hinge screws may be required.

Regularly inspect the casters. Tighten loose fasteners and replace worn or damaged

parts with new SERVIT approved parts. Replace worn or damaged casters immediately.

Additionally, periodic tightening of door latch and hinge screws may be required.

NON-INSULATED HEATED HOLDING & PROOFING CABINETS - INSTRUCTIONS FOR USE

8

www.servitproducts.com

L01-672

REV 04/21

BASIC TROUBLESHOOTING

WARNING: Only factory approved service agents must attempt to service, repair or replace electrical components,

wiring or power cord.

1. Controls do not work (no heat being generated or fan does not run):

1. Check that the cabinet is plugged-in.

2. Check that the outlet has power.

3. Check that the power switch is in the “On” position.

4. Check the cabinet wiring from the power cord to the power switch and to the thermostat.

5. For holding, make sure in ON mode.

2. Temperature too hot:

a. During initial pre-heat, cabinet may overshoot set point.

b. If displayed temperature exceeds 220°F (104°C):

3. Blower wiring is faulty or disconnected. Blower needs replacing.

4. The thermostat may have failed and the thermal cut-out device is controlling the temperature.

5. Thermal cut-out device may have failed.

3. Temperature too low:

a. The cabinet may still be in pre-heat or recovering from the door being opened.

b. Door is not closed or sealing properly.

c. Worn out door gasket. Replace gasket.

d. Blower is not circulating air:

5. Blower wiring is faulty or disconnected.

4. No heat generated

When power is on i.e. in HOLD mode, amp draw for 120V units should be approximately 16 amps.

• Air heater element may be faulty.

• The wiring to the air heater element may be faulty or disconnected.

• Thermostat may be faulty.

• The thermal cut out may be open or have a disconnected wire coming to it or going from it to the element.

NON-INSULATED HEATED HOLDING & PROOFING CABINETS - INSTRUCTIONS FOR USE

9

www.servitproducts.com

L01-672

REV 04/21

REVERSING THE DOOR

The door on your cabinet can be reversed to accommodate a right- or left-hand opening. The cabinet has been shipped

with the hinges mounted on the right-hand side. To reverse, follow the instructions listed below:

1. With the door in the closed position, remove the hinge pin by driving it out using a hammer and a drive pin or small

diameter screwdriver.

2. Once the pins are removed grasp the door firmly and pull the latch lever, this will release the door. Set the door aside

being careful not to damage the gasket.

3. Remove the screws from the left side of the cabinet and set aside. Then remove the cabinet mounted part of the hinge

and remount to the left side of the cabinet. Put the screws removed from the left side of the cabinet into the remaining

holes on the right side of the cabinet. Tighten all screws before proceeding.

4. Relocate the latch plate(s) from the left side to the right by removing the two mounting screws. Tighten all screws

before proceeding.

5. Rotate the door 180 degrees and align the door mounted hinge part with the cabinet mounted hinge part and tap the

hinge pin into place so the top of the pin is flush with top of the cabinet mounted hinge part. Invert the door latch by

removing the black plastic screw covers and remove the screws holding the latch in place.

Cabinet

Mounted

Hinge

Door

Mounted

Hinge

Door Handle

Cabinet

Mounted

Hinge

Door

Mounted

Hinge

Clear / Solid Door

Door Handle

Rotate the

door 180° about

horizontal axis

and note the

position

of fasteners.

NON-INSULATED HEATED HOLDING & PROOFING CABINETS - INSTRUCTIONS FOR USE

10

www.servitproducts.com

L01-672

REV 04/21

HEATED HOLDING & PROOFING CABINETS REPLACEMENT

PARTS DIAGRAM

21

12

5

7

2

9

6

8

10

14 13

4

3

1

16

11

22

23

20

19

25

26

24

27

18

28

17

15

Heat Module (under side)

Heat Module (top side)

NON-INSULATED HEATED HOLDING & PROOFING CABINETS - INSTRUCTIONS FOR USE

11

www.servitproducts.com

L01-672

REV 04/21

SERVICE AND REPLACEMENT PARTS OF HEATED HOLDING &

PROOFING CABINET

WARNING: Only factory approved service agents must attempt to service, repair or replace electrical components,

wiring or power cord.

Module CABINET BODY

Item# Replacement Part No. Description Item# Replacement Part No. Description

1 423PC131338 Power - Selector switch 16 423PC120PC Power cord (120V)

2423PC13721 Thermostat 17 423PCGRMT Rubber grommet

3423PC06913 Thermostat Knob 18 423PCSTRNRLF Strain Relief

4423PC13218 Thermometer 19 423PCUSLDPR Universal wire slides (1 pair)

5423PC13096 Terminal Block 20 423PCDRIPPAN Plastic Drip Pan

6 423PC202103 Fan 120V 21 423PCDRIPTRH Drip Trough (includes screws)

7 423PC13365 1950Watt Heating Element 120V 22 423PCSCNB 5" swivel Caster

8 423PC13367 675 Watt Heating Element 120V 23 423PCSCWD 5" Brake Caster

9 423PC11191 Fan intake Collar 24 423PC14119 Door Hinge (qty 1)

10 423PC11185 Stainless Steel Water Pan 25 423PC14118 Door Handle

11 423PCSCLP Sensor and bulb Clamp Kit

26

423PCCFDR Clear Full Height Door (does not include hardware or

gasket)

12 423PC13198 Thermal Cut-out 423PCCDDR Clear Dutch Door (does not include hardware or gasket)

13 423PCINTCVR Air Intake Cover 423PCSDDR Solid Dutch Door (does not include hardware or gasket)

14 423PCEXHCVR Air Exhaust cover 423PCSFDR Solid Full Height Door (does not include hardware or

gasket)

15 423PCCMA Combination Module 27 423PCSHELF Accessory shelf

28

423PCCFDRGKT Door Gasket Full Height

423PCCDDRGKT Door Gasket - Clear Dutch Door

423PCSDDRGKT Door Gasket - Solid Dutch Door

423PCSFDRGKT Door Gasket - Solid Full Height

NON-INSULATED HEATED HOLDING & PROOFING CABINETS - INSTRUCTIONS FOR USE

12

www.servitproducts.com

L01-672

REV 04/21

HEATED HOLDING & PROOFING CABINETS WIRING

DIAGRAM 120V

3

3

1

1

13

13

3

3

8

8

10

10

11

11

13

13

18

18

1

1

1

1

13

13

3

3

18 AWG GREEN/YELLOW 30" SPADE END

18 AWG GREEN/YELLOW 30" SPADE END

3

3

1

1

3

3

19

19

NON-INSULATED HEATED HOLDING & PROOFING CABINETS - INSTRUCTIONS FOR USE

13

www.servitproducts.com

L01-672

REV 04/21

HEATED HOLDING CABINETS REPLACEMENT PARTS DIAGRAM

10

52

8

6

7

12 11

4

3

1

14

9

18

19

21

22 20

23

16

24

15

17

13

Heat Module (under side)

Heat Module (top side)

NON-INSULATED HEATED HOLDING & PROOFING CABINETS - INSTRUCTIONS FOR USE

14

www.servitproducts.com

L01-672

REV 04/21

SERVICE AND REPLACEMENT PARTS OF HEATED

HOLDING CABINETS

WARNING: Only factory approved service agents must attempt to service, repair or replace electrical components,

wiring or power cord.

Module CABINET BODY

Item# Replacement Part No. Description Item# Replacement Part No. Description

1 423PC1313381 Power - Selector switch (Holding Module) 14 423PC120PC Power cord (120V)

2 423PC13721 Thermostat 15 423PCGRMT Rubber grommet

3 423PC06913 Thermostat Knob 16 423PCSTRNRLF Strain Relief

4 423PC13218 Thermometer 17 423PCUSLDPR Universal wire slides (1 pair)

5 423PC13096 Terminal Block 18 423PCSCNB 5" swivel Caster

6 423PC202103 Fan 120V 19 423PCSCWD 5" Brake Caster

7 423PC13365 1950Watt Heating Element 120V 20 423PC14119 Door Hinge (qty 1)

8 423PC11191 Fan intake Collar 21 423PC14118 Door Handle

9 423PCSCLP Sensor and bulb Clamp Kit

22

423PCCFDR Clear Full Height Door (does not include hardware or

gasket)

10 423PC13198 Thermal Cut-out 423PCCDDR Clear Dutch Door (does not include hardware or gasket)

11 423PCINTCVR Air Intake Cover 423PCSDDR Solid Dutch Door (does not include hardware or gasket)

12 423PCEXHCVR Air Exhaust cover 423PCSFDR Solid Full Height Door (does not include hardware or

gasket)

13 423PCHMA Holding Module 23 423PCSHELF Accessory shelf

24

423PCCFDRGKT Door Gasket Full Height

423PCCDDRGKT Door Gasket - Clear Dutch Door

423PCSDDRGKT Door Gasket - Solid Dutch Door

423PCSFDRGKT Door Gasket - Solid Full Height

NON-INSULATED HEATED HOLDING & PROOFING CABINETS - INSTRUCTIONS FOR USE

15

www.servitproducts.com

L01-672

REV 04/21

HEATED HOLDING CABINETS WIRING DIAGRAM 120V

3

3

1

1

13

13

3

3

8

8

10

10

11

11

13

13

18

18

1

1

1

1

13

13

3

3

18 AWG GREEN/YELLOW 30" SPADE END

18 AWG GREEN/YELLOW 30" SPADE END

1

1

3

3

ON

ON

19

19

EQUIPMENT LIMITED WARRANTY

ServIt warrants its equipment to be free from defects in material and workmanship for a period of 1 year when purchased

from an authorized dealer. This is the sole and exclusive warranty made by ServIt covering your ServIt brand equipment.

A claim under this warranty must be made within 1 year from the date of delivery of the equipment.

Only the equipment’s original purchaser may make a claim under this warranty. ServIt reserves the right to approve or

deny the repair or replacement of any part or repair request. The warranty is not transferable.

Covered Models:

This warranty covers these ServIt Steam Table models only:

423CC1UFNCF, 423CC2UFNCF, 423CH1UFNCF & 423CH2UFNCF

To Make a Warranty Claim:

This warranty is only valid on equipment purchased from an authorized dealer. To make a claim, please contact Ready

Kitchen Warranty.

This Limited Warranty does not cover:

• Equipment sold or used outside the Continental United States.

• Use of unfiltered water (if applicable)

• ServIt has the sole discretion on wearable parts not covered under warranty.

• Equipment not purchased directly from an authorized dealer.

• Equipment used for residential or other non-commercial purposes.

• Equipment that has been altered, modified, or repaired by anyone other than an authorized service agency.

• Equipment where the serial number plate has been removed or altered.

• Damage or failure due to improper installation, improper utility connection or supply, and issues resulting from

improper ventilation or airflow

• Defects and damage due to improper maintenance, wear and tear, misuse, abuse, vandalism, or Act of God.

• Use of sealed well unit without water or maintaining proper water level.

• Use of open well unit in wet operation without spillage pan.

Any action for breach of this warranty must be commenced within 1 year of the date on which the breach occurred.

No modification of this warranty, or waiver of its terms, shall be effective unless approved in a writing signed by the

parties. The law of the Commonwealth of Pennsylvania shall govern this warranty and the parties’ rights and duties under

it. ServIt shall not under any circumstances be liable for incidental or consequential damages of any kind, including but

not limited to loss of profits.

Residential, Food Truck, and Non-Commercial Warranty

Valid only in the Contiguous United States ServIt warrants new equipment sold to residential, food truck, and other

non-commercial customers to be operational upon delivery and proper installation, not to exceed a period of 30 days

from the date of delivery. Contact your authorized place of purchase for assistance.

© 2021 ServIt, Lancaster, PA 17602

L01-672 REV 04/21

• Phone: 717-381-4844

Please include your name, model number, serial number, proof of purchase, proof of installation ready before

calling.

• Email: Help@ReadyKitchenWarranty.com

Please include your name, model number, serial number, proof of purchase, proof of installation, and a brief

description of the issue in your email. Including clear pictures of the issue will help expedite the process. Failure to

include one or more of these things will extend processing time.

Other manuals for 423CC1UFNCF

1

This manual suits for next models

3

Table of contents

Other SERVIT Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Gastrodomus

Gastrodomus CL Instructions for use and maintenance

Falcon

Falcon E350/32 Installation and servicing instructions

Amitek

Amitek AX215RG Installation, operating and service instructions

JAC

JAC HF Translation of original user instructions

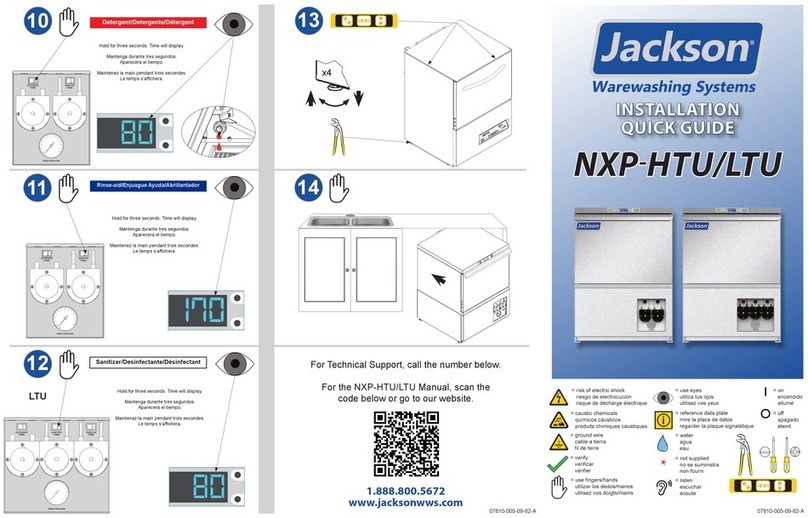

Jackson

Jackson NXP-HTU Installation quick guide

Electrolux

Electrolux SkyLine ChillS 202 user manual